-

Posts

190 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 65MooneyPilot

-

I am sure you can have it field approved. It is just an aluminum channel screwed into the instrument panel.

-

I have https://www.radiorax.com/ they work well and when you change radios you just slide the mount nut to match the can. Not cheap but it is a one time deal.

-

Ok, great explanation! The test being a simple voltage says a lot. Getting into the nuts and bolts of how it works is always interesting. The installer should have noticed the indicator error when it was initially checked but nothing surprises me these days. I have caught several wiring errors since I have been installing all my new equipment.

-

I checked mine and the OBS and DTK is the same in the test 150 degrees. When I turn the OBS knob the OBS in the test does not change. It stays 150 degrees. In the OP’s picture it has 003 degrees and DTK 150 degrees. So the needle going to the right is correct. If the OBS knob in the OP’s changed the degrees in the test then if you turned it to 150 degrees it would be on the left.

-

On my E, I wired the LHS into the green down light. If you put the gear down on downwind or before you put any flaps out the LHS will not say anything. At 200 feet and below, if the LHS is not sensing the gear down it will repeatedly tell you to check the gear. The landing height system is another tool in the toolbox that is quite useful. I have been using them in the Boeings I have flown for years. It will not stop you from an approach speed that is to high and proceeding to bounce on the runway so be vigilant for that. Getting a lot of landing practice is the best. In my 757 I new exactly where the tires were by the sight picture. Having the callouts were a great backup after a long day of 12 hours of flying and close to an 18 hour duty day. You can have a long day in any plane and the LHS is nice to have.

-

Sorry, I am not much help in the Autopilot department but there are people here that are. I would have to see the wiring diagram to properly trouble shoot the problem. To answer your original question now days with G5’s, they use a GAD29 to talk to the AP and the G275’s I think talk directly to the autopilot.

-

I don’t have a high tech autopilot, I still have my wing leveler. Does the autopilot get its information from the HSI indicator? If the indicator works fine then I would start looking at where the AP gets its info.

-

Is it stuck on Nav or GPS? The GTN 625 Manual says it is compatible with the KI 525A. I have a KI 209A which has the switching relay built in. If it is not switching than your relay in your IRU 525 may be bad.

-

The 406 ELT RCPI has a test button in the reset button to test the ELT. If you didn’t, you also need to install the beeper module which also has a battery. When you test the ELT it will sound the beeper with one beep if all is good and multiple beeps if something is wrong.

-

ForeFlight on airline HACK!

65MooneyPilot replied to 201Steve's topic in Miscellaneous Aviation Talk

In the thousands of hours I spent in the back of an airplane positioning to go to work I found out a few things in regards to the iPad and iPhone. They both like the internet better than the network. So, to find your position while flying in the back you need to turn off the internet that is logged on the aircrafts onboard internet. Hold it up to the window and it will find your position. When you land if you have the aircrafts internet on again you need to turn it off to call on the network or it will fight you from making a call. My iPad does not have the GPS chips in it, I always used an external GPS receiver for it. Your discovery is great and if it keeps working use it. -

I converted my ADF tray to mount the GAD29 and GAD13. It works well. Then installed it where it was back in the rack. The GAD29 fits right in any old tray you are not using anymore.

-

More maintinance frustrations....

65MooneyPilot replied to Austintatious's topic in General Mooney Talk

My last two pitot static checks have gone horribly wrong. The first time they just damaged the A/S indicator, it read 40 mph after they got done. I sent it in and had it fixed. Two years later I tried a different shop and they damaged the ASI and the VSI. The ASI was damaged beyond repair and had to be replaced. The VSI They we’re able to repair. They tried to blame it on the age of the indicators and told me that they were not responsible. I took them to small claims court and the day before the court date the owner wrote me a check to settle out of court. I was able to get a pre-flown ASI from a generous mster and it works great. This year it is due so here we go again. I am thinking of taking a video of everything working on the flight over before they start working. I am also thinking about having them verify and signing that the indicators are indicating properly before they start. Don’t know if they will do it but I am over the shops telling me it’s not there fault when you know it is. -

That is it. The GTRIG represents the flight ID. You can put up to 8 characters for the flight ID according to the manual.

-

Ok, just read the Trig manual and it appears easier to change the flight ID than I thought. I will have to try it next time I go to the hangar. I learn or re-learn something every day.

-

I have a Trig TT-31 Transponder and none of my Garmin’s talk to it that I am aware of. No worries thought because right now I don’t have a need to change the the ID.

-

I don’t have a G1000 so it is a pain for me. I would have to go into the maintenance setup every time. Sounds like the G1000 can be setup like transport category airplanes. If you do change the setup, which looks easy, you just have to add checking it every time during your preflight. It should retain the last flight ID until you change it so when you complete the Angel flight you just put the “N” number back in. In the US, I have never been questioned about having the wrong flight ID entered in, but in Europe they will tell you it’s wrong right after departure.

-

I don’t know about Angel flights but changing your ADSB flight ID is a pain. Why do you need to change it? If it is just for a call sign, you can put it in the remarks section of the flight plan and all the controllers will see it. In the airline world when you initialize the FMS you put in the flight number and in some of the 737, 757’s I flew the flight number went into the transponder.

-

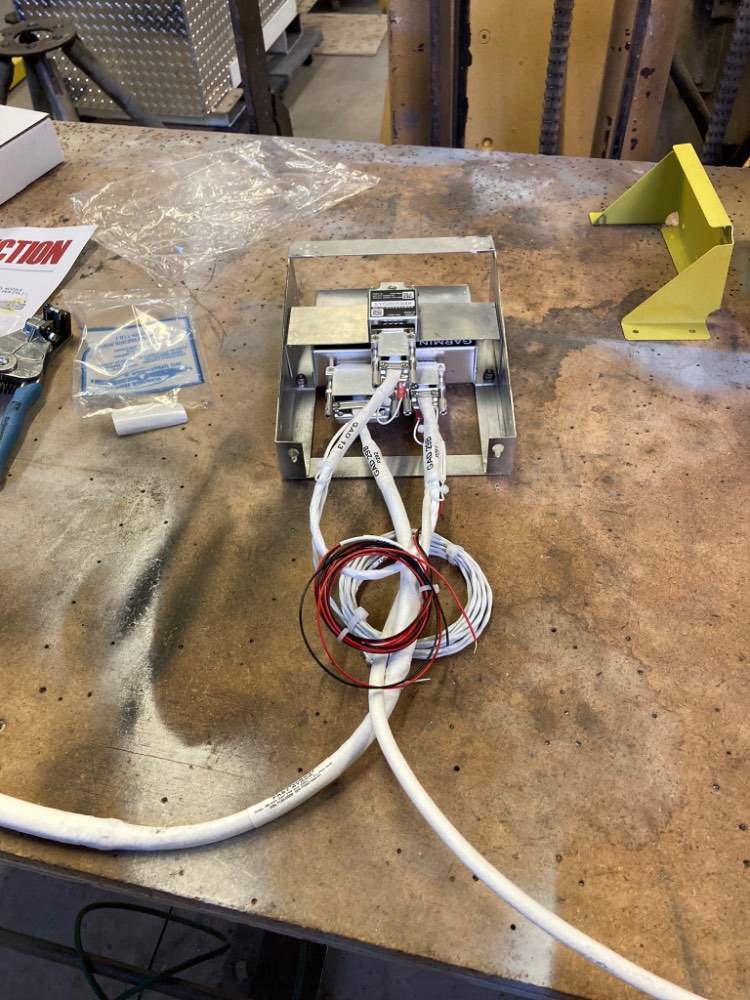

There is a lot to think about on these upgrades. We have all put a lot of thought into our panels. There is all kinds of options. My question is would your A&P be interested in installing your panel and if you are mechanically inclined you could help? Here is why, G5’s, GPS175 and most radios can be installed by A&P/IA’s. Find a 6 pack panel for the pilot side, install the G5’s, GPS 175, GAD29D, GAD13, GMU 11, temp prob, NAV COM with Glide slope receiver(Trig for instance) Get an Approach Systems Hub and order all the wiring harness from them . All A&P capable installs. It’s a lot of work but it may save some money and you will be autopilot ready if you want to make that step. Actually all the avionics can be purchased from Approach Systems. This would be a lot less if your A&P had a reasonable rate and you were able to help. Hammdo’s panel the left side would definitely work for you. Your instruments are currently all over the place in your panel and I highly recommend before instrument training you rearrange the instruments. I am not sure how the VOR Indicator made it over to the right side of the panel. Good luck, any questions you can pm me. This is my latest second G5 upgrade. I went in small increments to get this far.

-

SBM20-208B Fuselage Tube Inspection

65MooneyPilot replied to 65MooneyPilot's topic in Vintage Mooneys (pre-J models)

I removed the bolt on the right side and found out it was in fact a -17A bolt with two light washers installed. I used a bore scope to look up inside and it still has most of the zinc chromate primer in it. I ordered the -17A bolts and they should be here this week. -

SBM20-208B Fuselage Tube Inspection

65MooneyPilot replied to 65MooneyPilot's topic in Vintage Mooneys (pre-J models)

Thank you for answering my question. I knew it was technical and only a fellow mechanic that has done the inspection could answer it. I am still waiting for the bolts to be delivered before I start. -

I have a question about step 14 where it says to remove AN7H-17A and run a magnet inside the tube. The parts manual in figure 2 index 2 says that bolt is an AN7H-16A. Somehow it has turned into a -17A bolt. Also is the nut/ thread for that bolt inside the tube? If so, is it possible the thread is corroded and has this been a problem during this inspection? Thanks

-

Aileron Control Link Reinforcing Gussets

65MooneyPilot replied to RampMan's topic in Vintage Mooneys (pre-J models)

Back in the day LASAR used to add them. Getting a preflown part is probably easier. -

Troubleshoot GI275/GMU11 calibration failure

65MooneyPilot replied to NicoN's topic in Avionics/Panel Discussion

Here are a few pictures in the previous post, two of them I saved from the Mooney space pages and the other two are my plane during install. In my limited experience if it passes the interference test it should calibrate. -

Troubleshoot GI275/GMU11 calibration failure

65MooneyPilot replied to NicoN's topic in Avionics/Panel Discussion

I have some basic questions since I just installed one in my plane. What was the magnetometer interference test score? I am thinking it must have passed. Is the Gmu11 at or close to the wing sheet metal splice but not passed the aileron control tube and not close to the gear. Is the ramp where they are trying to calibrate it is clean underneath, no rebar in concrete. Also no water or fuel lines either. We have had this discussion before on what is underneath the ramp. Thanks, let us know