-

Posts

128 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by dcastor

-

I have a Makergear M2, using 1.75mm ABS filament. Keep experimenting and reading there are lots of settings that can mess up a print, I've done a lot of trial and error.

-

I only have white and black in ABS and Red and Blue in PLA. I will send a couple in red and blue so you can experiment with those and maybe pick up some black and white if I have another need for it and your results are good. I've been more impressed with the printing results from ABS, it just seems to flow better, but I'm excited to see what you can do. Dave

-

It's an interesting idea... I'm willing to send a couple your way to experiment with. PM me your mailing address please. The layers under the text is mostly solid plastic, but there are some voids the way I printed. Will that matter for your process?

-

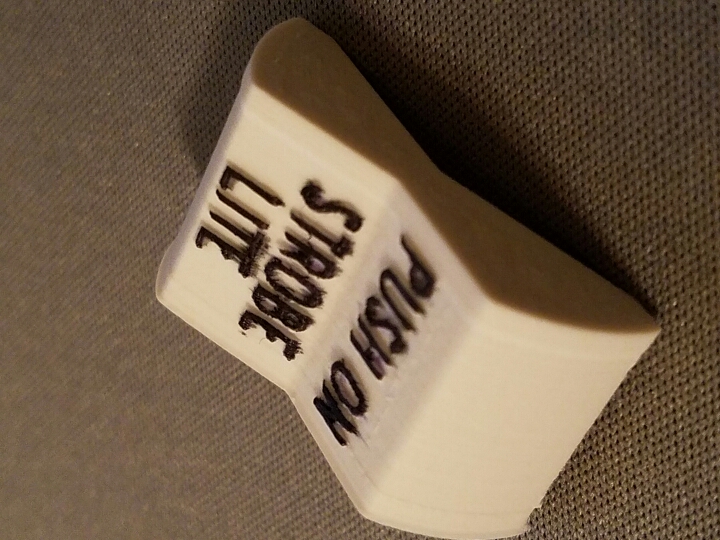

I thought you all would like to see my latest revision. The text looks a bit streaky because it's just a magic marker (its a prototype), but the text is actually raised. I may try to do recessed letters and fill with paint (similar to the originals). This may be motivation to upgrade my 3d printer to two extruders so I can print in two colors. Please don't buy the ones for from this NDesign company... I can do better than their prints now and while I can't promise they would come out quickly, I would be glad to provide them for half what they are charging. Dave

-

inside cabin fresh air vent cut off

dcastor replied to TheTurtle's topic in Vintage Mooneys (pre-J models)

I had a piece of acrylic laser cut for the window that covers my trim and flaps indicator. Really simple process with Ponoko.com...you download a PDF with their templates then use a graphic editing program to define where the cuts go. Upload your file and for a couple of bucks you'll have a perfectly piece of acrylic. They also do a variety of other materials as well, so you could experiment with aluminum. Good luck! -

I will just add that the third plub I don't think that's exactly why the relay and third pin is there, although you are right it would prevent reverse polarity too. The third pin is shorter, so it doesn't trigger the relay until the other two pins (+ and -) are already making contact. So, I think the main reason for this is to prevent arcing. The reason I think this is if that's the main goal, it would be far simpler to use plugs that only go in one way, which is accomplished by this 3-pin plug. I'll admit that I've seen versions of this plug with jumper cables connected to it, which would be really easy to screw up...so it could be the engineer was looking for a fool-proof solution. Dave

-

Matt, I'm not sure that proseal on the top of the case would help, the oil did seem to be coming out of the bolt holes themselves, not between the halves. The mechanic checked the crank seal pretty thoroughly, after cleaning the engine with mineral spirits. No leaks found in that area. In fact both mechanics at the shop did a pretty thorough look over the case and didn't find any cracks. I think you are noticing the pooling of oil above #2...it was dry after cleaning and the engine run. I think in the photo posted the oil was just pooling there because it's a flat spot. Dave

-

On a recent flight I found a small amount of oil on the back side of my prop and a smudge on the engine cowling (see photos). I was afraid it was coming from the prop hub, but after removing the engine cowl we found more oil on the engine. After cleaning the engine well and an engine run, it seems to be coming from 3 bolts along the top of the case that hold the halves together. Mechanic checked the bolts and they seemed tight, though he didn't use a torque wrench. He wants to run fix action by the head mechanic, but he's leaning toward removing the bolts and applying thread sealant to stop the leak. Sorry I didn't get a photo after cleaning and engine run. Sound reasonable? Dave C

-

Layer separation may be solved by using a higher extrusion temperature, or bed temperature. I haven't seen that issue with my prints, it's likely we are using different settings.

-

I don't want to steal Steve's thunder, but I built a 3d model so Steve could share with his Oshkosh contact. I was trying to help save the design fee. In the meantime, and set up a 3d printer...one of my first prints was my 3d design for these switch covers. This print is in PLA, I have yet to print in ABS which I think will give a better quality, but please let me know what you think. Also ABS can be chemicaly smoothed with Acetone so that will improve the surface finish. I may also experiment with some printed text inserts so the text can be "built-in" in effect molded in a different color. Dave C

-

I've already got a good 3d model if it avoids some of the design costs, I'd be willing to share. I tested it with Shapeways and the fit is perfect...but I wasn't happy with the finish. If he can do better I'm in.

-

Interesting...these molded earplugs are the norm in USAF fighters. I was leaning towards a clarity aloft system for a couple of frequent passengers because they are always complaining about headset squeeze. I flew with a guy once who swore by the Clarity Aloft headset and said "don't waste your money on ANR". I thought molded plugs would be a good upgrade for the clarity aloft. Your review gives me pause.

-

Old thread I know, but I'd like to add a data point. I have a davtron OAT guage connected to a sensor in the right wing (factory location). Recently an avionics shop installed an EDM-730 for me and I expected they would remove the DAVTRON and put the sensor for OAT in the same spot...no, they drilled a hole in the co-pilot scoop. On sunny days, the OAT guage reads about 4 deg C warmer than the one under the wing. So, to those reading this thread, I highly recommend mounting under wing to get a reliable temperature...it could be the difference between icing and no icing. Dave C

-

I've had an M20J with the A3B6D engine for a little over 3 years. So far I've had no significant problems. I did have the dual magnetos fail on me, which required overhaul. Since an overhaul involves both magnetos and I think overhaul shops that deal with the dual magnetos is on the decline it has made the cost of overhaul increase. The other drawback is that the IO-360 is not recommended for MOGAS by Lycoming so while I don't know if an STC exists or is possible for Mooney's equipped with an O-360, it's certainly not going to happen with the IO-360. Other than these two minor issues, it's been a great engine.

-

The skin edging on my M20J empennage has cracked and large chunks are missing. Anyone know of a good replacement? See photo attached

-

And yes, the ailerons are actuated by rods.

-

Lasar is probably the best source for Mooney parts that I know of, short of going to the factory. White industries might also be able to help, bough they don't specialize in Mooneys. Are you in Australia? I might be interested in the damaged aileron if he doesn't want to keep it. Dave

-

I just renewed my policy for $1061. I'm just over 300 hrs tt and about 150 hrs in type ($65k hull value). My insurance has been pretty close to this for the last few years. Falcon Insurance (a broker from Kerrville TX) does all the shopping around for you. This year they suggested I jump to a new company since the rates are a bit lower than US Specialty who it seems are raising their rates for everyone with RG aircraft.

-

Went to the hangar today to do an oil change. Saw a spot on the cowling that looks like a rough white film. I think it looks like exhaust byproducts. In the same area in the exhaust I saw a bronze discoloration. Is this signs of an exhaust leak? Please see attached photos.

-

I think I've got the ring probes that go under the spark plugs...ill see what I can do to confirm. That's surprising because it would mean my CHTs seem below normal range that I've heard from others. How did you confirm that the factory probes were accurate?

-

The analog CHT gauge in my M20J is reading well below (about 75 deg) what I see on my JPI engine monitor. Anyone know of a way to calibrate this instrument? The lead to the probe was shortened a little bit when the terminal at the end corroded, but it was probably a half inch, I can't imagine that would cause such an inaccurate reading. thanks in advance, Dave C

-

I've had my M20J for almost 3 years now and have on occasion kicked myself for not bringing simple to the airplane that might have avoided a return to the house unnecessary. Anything you all can think of that has saved a flight or two? I am thinking there might be other things that I should add I haven't thought of, so thought I'd throw it out here for discussion. Some things I've to get started: 1. screwdriver (Phillips and Regular, or better a driver with interchangeable tips) 2. AA batteries (for ANR headset, portable radio, etc) 3. GE 330 bulbs 4. Spare quart of oil, and funnel. Dave

-

I haven't been logging oil consumption but .1/10 hrs is very close to what I've seen with my A3B6D once total quantity is down to about 6.5 quarts. Before that it's probably burning through at 3-4 times that rate. I am told this is normal by 2 A&Ps. Dave

-

I bought a used PMA 8000b from Pacific Coast last October... my avionics shop kept delaying install until about March. The holidays and other airplanes kept getting priority. I even contacted a second shop to try to get it installed. When the audio panel was finally installed, it worked fine for about 90 mins, then all the lights went dark. Turns out a ribbon cable inside the audio panel had shorted out, my avionics shop said it was improperly routed, chaffed on a heatsink inside the audio panel and shorted. Pacific Coast Avionics has a 90 day warranty policy on yellow tag items, which expired while the audio panel sat in the box they shipped it in awaiting install. And, they seem unwilling to consider that they should take responsibility for shipping a defective part. I had no way to know about the issue until it was installed, but perhaps that's one I'll have to suck up... What's been really frustrating is dealing with PCA since identifying the issue. I spoke with their VP who said they needed to see the device and they would consider covering the cost of repairs. The box was marked for his attention. It went to PCA and sat for 3 days while the avionics tech "got around to it". They shipped it off to PS Engineering for repair, then PS engineering shipped it back to PCA (vs. to me direct). Then today, the customer service dept tells me I owe them for the repairs, and it seems the VP was never consulted on the issue. I never heard anything from PCA except for when I called them. Oh and next week everybody, but the shipping department is going to be at Sun and Fun, and the VP is already on the road, so chances are this audio panel (and my plane) are going to be sitting for another week. PCA: Hope you all enjoy Sun and Fun...you won't be getting any future business from me.

-

I wonder if someone with a later model J can take a good photo of the vents used in their airplane and answer how does air get into the duct up there? In the 1977 J, there is a scoop on the top of the cabin that opens when a dial in the headliner is turned. I'm thinking about replacing my headliner and I wonder if the newer style headliner will work, because it looks like Mooney just used parts left over from the M20F/G and made it fit (poorly) in the M20J airframe...until they got around to a redesign. Also it seems the vent louvers on the original 77 J are not available from plane plastics. The headliner I'd like to use was on serial numbers 24-0084; 24-0378 THRU 24-0900 (and probably later). Thanks! Dave