-

Posts

11,903 -

Joined

-

Last visited

-

Days Won

163

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Shadrach

-

Flying with a 250hr CFI is a weird dynamic. I’m guessing it’s much like a seasoned NCO having to answer to a green officer fresh out of OCS. I’ve flown with some really good, low time instructors, they know they are there to observe that I am meeting standards. Beyond that, they are eager to learn.

-

We are flying the same power plant so I will give an exact SOP. All knobs forward for take off. Positive rate, gear up Flaps up ~85MIAS. Pitch for desired climb speed. I use ~120MIAS for cruise climb. Less if I’m light. If noise is a concern reduce RPM to 2500 as soon as practicable Reference leanest Cylinder and maintain EGT ~1250 +/-30° depending on hottest CHT. Cowl flaps closed 25’ below target altitude. Level and set desired RPM and mixture

-

You’re reading it wrong. It 3.4lbs for the C model and 15lbs for F’s and Js.

-

2024: Thoughts on the sweet spot in the M20 model range?

Shadrach replied to BlueSky247's topic in General Mooney Talk

I don’t see any movement. In addition to having an efficient intake, the J must have a super efficient air filter. No restriction. Truly impressive. -

I’ve known many old and bold pilots. I’m not advocating bold behavior. I’m just saying this old axiom does not always fit. The poll needs a 5th option “Not old and no longer bold”

-

It reads to me like if you upload engine monitor data to the savvy website, you should expect that the data may be shared with Savvy clients.

-

2024: Thoughts on the sweet spot in the M20 model range?

Shadrach replied to BlueSky247's topic in General Mooney Talk

It does not offer a lot at high DAs in the F model either. Where it is useful is at lower DAs in a way that Mooney never intended and it suits my unconventional power plant management perfectly. Opening the Ram Air at DAs below 5000’ is good for a 20° to 35° egt drop on the lean side of peak depending on the DA. -

We will have to disagree that all information should be held to the same standard as HIPAA, or that that is even a reasonable analogy. There are two issues at stake here: 1) What is Savvy’s policy and are they adhering to it. 2) What are the implications of having information on hand that in extreme cases might prevent loss of property and life and what is ethical way to handle that information. I value my privacy a great deal. However, I’m not going to get worked up about protecting aircraft engine data that I knowingly put in the database of a third party. Life is too short.

-

So you’re saying that if Savvy is conducting a prebuy service and they have data that is germane to the condition of the engine (or lack there off), they have no responsibility to inform the buyer? Say they have data that shows a CHT that exceeded redline…and they don’t disclose. Where does that leave them if their client is flying home and a cylinder head separates from the barrel and causes an accident?

-

You can’t really separate those tasks which is why Lawyers check for conflicts before taking on a client. If savvy has historical data on an aircraft that a buyer they are assisting in a potential is considering, how do they not disclose that that they have that information? A compromise would be to ensure that Savvy requests the seller’s permission to disclose. If the seller says no, Savvy can then inform the buyer that the seller refuses to release the data. Seller gets to keep their data private, buyer may decide to walk away. Everybody wins or everybody loses…

-

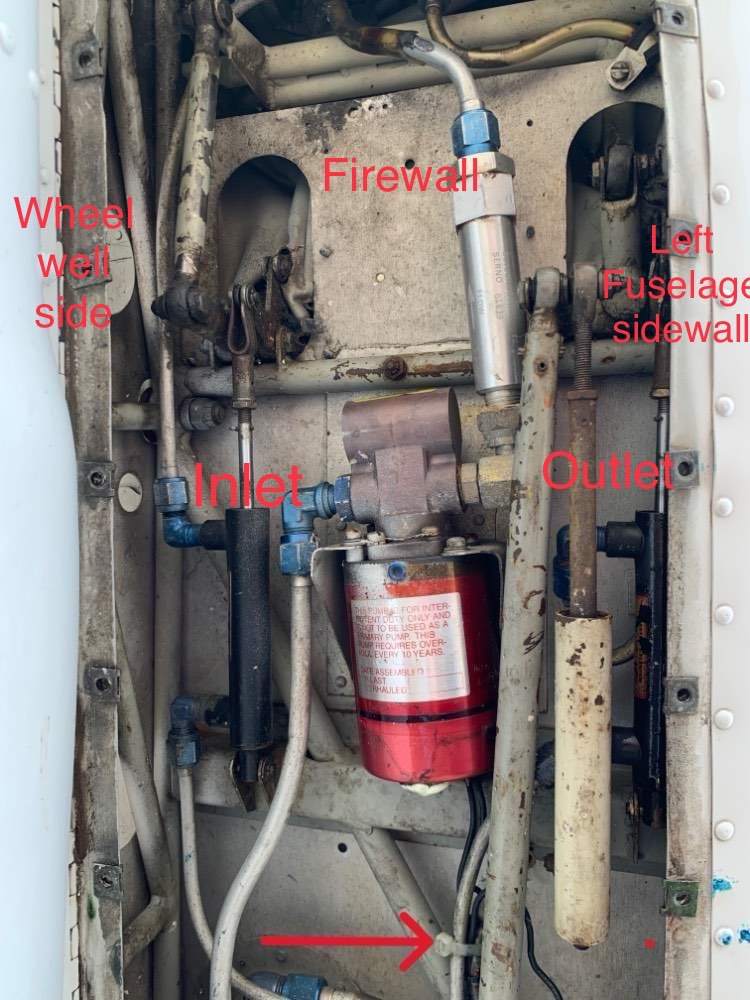

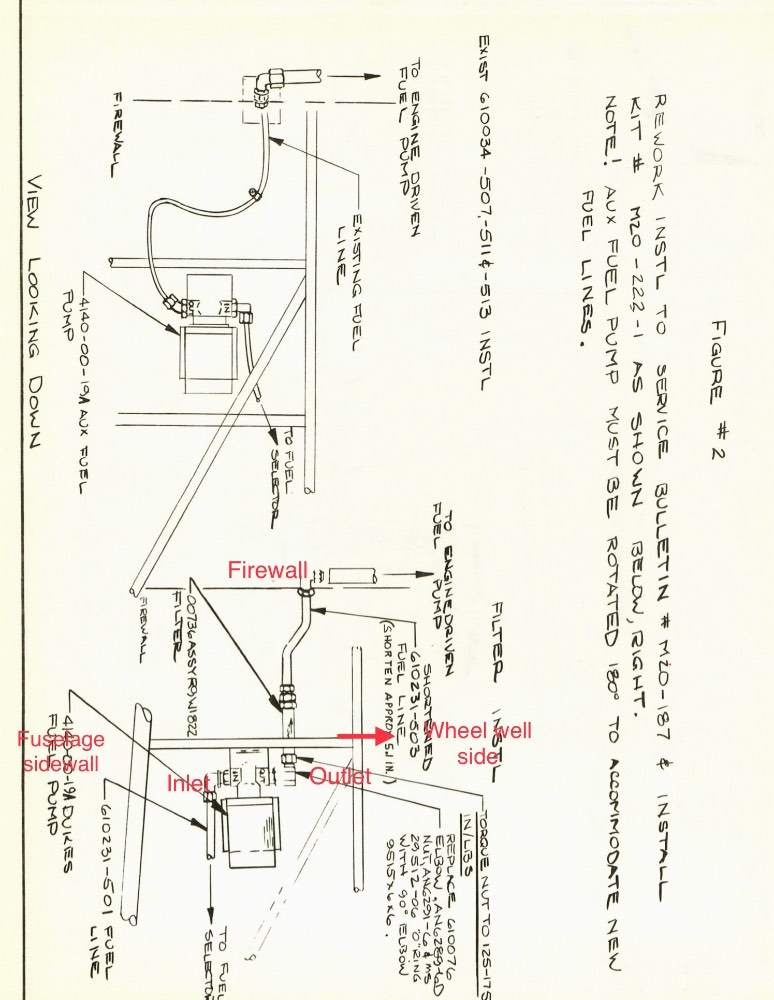

If one is looking up and the other is looking down, how can the filter be on the same side in each image? Look at the labeled images very carefully and then reconsider.

-

Does your Owners Manual have an AFM supplement? I would think it would be covered there.

-

I see the concern. However, at least with an aircraft, you have the option of whether to share data with a third party or not. Modern cars are storing more and more data history and there is nothing any of us can do about it. Porsche ECUs have been logging redline overruns for more than 20 years. Anyone with a reasonably sophisticated scanner can see how many excursions past redline and what category for the totality of the car's life. Dealer service history is public, as are emissions test results. So, while I understand the concern, there is little to stop the collection of data. It does not mean we have to like it. I expect that in the not so distant future, GA engine monitors will capture and permanently store any engine data that is outside of the limitations section of the TCDS. If a buyer has contracted Savvy to help with a purchase and they have data from an airplane that is on the potential buy list, it is completely normal for that buyer to want to know what that data reflects whether in raw data or analysis. Savvy is acting as the buyer's agent and should be expected to represent their interests. Similar issues come up with oil analysis. I fully understand the desire to keep that information private. If you don't want your data tied to you or your plane, you should probably use a bogus N number.

-

2024: Thoughts on the sweet spot in the M20 model range?

Shadrach replied to BlueSky247's topic in General Mooney Talk

I read this a lot of this…yet oddly, I manage to pull field level manifold pressure on take off and see well over ambient pressure with the ram air open. As much as 1.5” at low altitudes. I’m sure it was the inefficient intake that caused Mooney to install the ram air…and to keep it on the original J before deleting it on later models…I mean, we’ve all seen the data….right? It’s out there, right? Surely someone has recorded the minuscule delta between ram air open and closed in a J? I am also sure that no manufacturer has ever implemented a cost savings strategy that eliminated a feature and then marketed as something else…you can take their word for it…never happens…ever. -

Nothing about this installation makes sense looking at the image. It looks to me like that pump was installed upside down. The outlet to the firewall should be on the right side of the pump when looking down (see diagram) looking up from the bottom it should be on the left. Whomever performed the SB did not review the instructions carefully. The drain can be fitted to either side. In this case the drain does not appear to be installed. No bueno.

-

So to summarize the above post: A maintenance professional may feel uncomfortable installing a part that an owner has previously removed. Before an owner removes a part, it’s good practice to consult with their maintenance professional to ensure the maintenance professional is comfortable reinstalling the removed part. Seems like common sense to me…And I said as much in my first reply to the comment about my “liberal interpretation of the preventative maintenance”.

-

Looks to me like whoever performed SB-20-222 installed spacers to angle the fuel filter away from the rudder control rod.

-

I have not assumed any of the things you say that I’ve assumed. There is no need for assumptions in this case. Removing parts and or components is not preventative maintenance, nor is it maintenance. It is disassembly. Nothing more, nothing less. Disassembling an airplane without credentials does not violate any FARs. One can legally remove any part they wish from their airplane. It goes without saying that a credentialed mechanic with the appropriate ratings must return the aircraft service by either replacing/installing the removed parts or supervising their replacement/installation. You’re needlessly muddying the water with “assumptions” when the regs are quite clear about defining maintenance and preventative maintenance. Disassembly is not included in either definition. I’ve had this conversation with an FAA PMI and it was not a controversial opinion. If I remove the prop from my engine and send out for overhaul, what reg have I violated?

-

It’s always a good idea to coordinate with your maintenance professional and communicate your plans. That being said, I think your interpretation is the one that is liberal and I’ll explain why. 1) Removing parts is not preventive maintenance. Preventative Maintenance is a specific category of maintenance that a non credentialed owner can perform and return the aircraft to service with a log book entry. 2) Maintenance means (per FAR) inspection, overhaul, repair, preservation, and the replacement of parts, but excludes preventive maintenance. Notice that “removal” of parts is not included? By FAR definition, the “Removal” of parts does not fit the definition of Maintenance nor the definition of Preventive Maintenance. It is simply the removal of parts and there is nothing illegal about it. Anyone can make an aircraft unairworthy…only an IA or A&P can perform the Maintenance needed to return the aircraft to service. However, they are under no obligation to work on machine they don’t wish to work on. There may be good reason for an A&P I/A to avoid an aircraft from which an owner has removed parts, but that’s a personal choice that has nothing to do with FARs. Hell, we have a credentialed IA on my field with a reputation that makes other credentialed pros loath to touch airplanes with his signature in the logs…

-

You can test power to the pump with a multimeter. The leads are likely handshake connectors wrapped in plastic or heat shrink. They appear to be zip tied to the left brake line (see red arrow). Once you have verified the pump is the problem. Turn the fuel selector to the off position. Put a catch can under the gascolator and drain it using the pull ring on the selector in the cockpit. When loosening the pump plumbing, you will get some some leakage, but it should only be a few ounces. Nevertheless, have a catch can ready.

-

^^^^^This! Also, there is no legal requirement for a credentialed A&P to remove the pump. You can pull it and send out for OH now, and then have a freshly overhauled pump ready for your A&P to install in a week or so.

-

What is interesting is that N606M has never been assigned to any Mooney aircraft.

-

Yup! I edited it to reflect what it says rather than what I read. At quick glance I misread the 15lbs for the mid bodies as being for the short bodies.

-

It seems you are looking for useable and unusable. The TCDS gives useable fuel in volume and unusable in mass... It may seem odd but it's practical as useable fuel is measured in gallons at the pump, but unusable fuel is used for W&B data, so giving it in weight is more practical. The answer to your question(s) by volume and using round numbers is 26gals useable and .28 gals unusable per side.

-

I do a 180°, max performance turn in between hangar rows every time I put my plane away. Lots of tight turns and full power brake releases at short fields. My brake cylinder shafts have been subjected to whatever hundreds of pounds of pedal pressure delivers to the shaft without bowing. I just rebuilt both cylinders and the parking brake valve for the first time this year after 57 years in service. Everything was straight and in good shape save for the o-rings which hardened enough to weep fluid. I suspect that yours was likely bent during a maintenance event. It would take a tremendous amount of force to bow one of the shafts from compression alone. I have straightened vintage motorcycle push rods by drilling a hole in a 2x4 slightly larger than the rod. Then affixing the rod in the drill chuck to run it through the hole in the 2x4 with of a slight side load. Takes a few passes, but is an effective way of straightening a slightly bent rod or shaft I must say that I am disappointed that you did not take the opportunity to correct the unapproved fluid situation during this maintenance event. It may function fine but the industry specified 5606 for a reason. The approved synthetic replacement for this application is MIL-PRF-83282D and is equal to or superior to 5606 and ATF in every way. Much higher flash point. Superior operating temp range. Resistance to oxidation and gelling. It is less hygrscopic and more resistant to breakdown while being kind to seals and o-rings. I understand the frustration with regulatory inertia and how it can sometimes prevent the use of more modern and superior products. However, in this case, there is a reasonably priced, modern, approved product that is by all accounts superior to the unapproved product you’re using. A complete system fill with Royco 782 (MIL-PRF-83282D) costs less than $20 USD. Seems like a silly hill on which to plant a flag…