outermarker

Supporter-

Posts

251 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by outermarker

-

I think I need a breaker/switch...

outermarker replied to Nukemzzz's topic in Vintage Mooneys (pre-J models)

I have noticed a lot of play in my breaker switches so it's time to replace them. I do have one switch unlike the other on/off type switches. The switch that selects position light/off/strobes. I have sticker shock as to the cost of these Klixon breaker switches. Since Tyco was mentioned in this thread has anyone followed through to see if Tyco can be used as a replacement? albert -

Cabin comfort 1965 M20E

outermarker replied to Chris Strube's topic in Vintage Mooneys (pre-J models)

I too have a 65' E. There are ducts going to the baggage compartment and to the back seat area. Pull the belly pans and be prepared to scratch your head and say, "how'd they do that?!" I felt so overwhelmed when I saw it that I just left it in place. It was the original ducts and I knew that it was a can of worms I didn't want to mess with if I had any intentions of flying this past summer. Good Luck and take lots of photos to educate us all. Oh Yeah, make sure you can get the proper type/size before beginning or the lead times will leave you wanting to kick a dog on the way home! -

Ohh Noooo!!! Be prepared to pay for some guys kid to go to college! I sure wish that part could be made AND SOLD for 1/10 of the price currently being touted. I bet that there are a lot of owners waiting for such a thing to happen. The same is true for the landing gear disks. Good luck!

-

Mid 60's Mooney or Mid 50's Vtail...

outermarker replied to C.Marshall's topic in Vintage Mooneys (pre-J models)

I have owned both. The J model (58') Bonanza is the first year with heavy spar and fuel injection. That would be the earliest model I would consider. Once a Bonanza is in good shape it's not too bad on maintenance. It's on par with any heavy single. However, getting one into that condition can be hazardous on your wallet. The engine TBO is less than a vintage Mooney. It is roomy, easy to fly and land. I currently have a short body E. It's fast and a little less maintenance. I don't have a dash to place anything on. I have to slide the seat all the way forward to reach the rudder pedals and thereby I have the yoke and panel in my chest. This makes it difficult to have charts on my lap or a portable GPS somewhere that doesn't block out other instruments. Finding a mechanic that wants to work on a Mooney can be a challenge also. For just a few pennies more I would buy an older twin Commanche. Two 160hp fuel injected, 2000hr TBO engines. Pushing the throttles to the stops will give you +1200fpm climb. If you fly at 65% (21 square) power you will burn 14gph@200 mph. Get one with tip tanks and you have 120 gallons, those are long legs or a lot of non-stop cross-country flights. Lastly, call an insurance company to see what the rates are between what you are looking for. Fixed costs are fixed costs and that does play into the decision over a decade of aircraft ownership. With all airplanes, if you find one that has been properly maintaned you will pay a primium for it. But you get to enjoy it sooner and a lot longer before the big-ticket items are due or need to be replaced. I have owned all three for at least 10 years...so I know. -

Looking for Bendix ignition switch repair kit

outermarker replied to AFpilot22's topic in Vintage Mooneys (pre-J models)

If anyone has a Bendix rebuild kit(10-357515), or a gently used switch(10-357210-1), I’d be interested. I had my first “experience” last week when my switch sorta, kinda worked after stopping for an hour. In time the switch worked well enough to get the engine started, but left me confused since I never experienced a partial switch failure once the engine was hot. -

I think I need a breaker/switch...

outermarker replied to Nukemzzz's topic in Vintage Mooneys (pre-J models)

thanks very much for the heads up! -

Hi Raymond, Why did you make a cutout instead of a slit like the other fuel lines? When I removed the shroud, I saw evidence that the shroud frame had been wearing into the fuel pump housing. Did you build up that area with high temperature RTV? Did you secure the shroud so that it won't settle on top of the fuel pump with time and age? Oh yeah, the drawings are GREAT! I am going to try High Temperature Silicon rubber (1/8"). I'll do a final fit this weekend. The rivet size is 3/32" or 2mm. After the final fit I'll seal up the cuts that were made to fit over the hoses with high temp rtv. albert

-

+20 year old donuts (1966 M20E)

outermarker replied to Matt Ward's topic in Vintage Mooneys (pre-J models)

Thanks Robert. I know mine are old and long in tooth. I'm simply curious at this point. The discs will be replaced this year. -

+20 year old donuts (1966 M20E)

outermarker replied to Matt Ward's topic in Vintage Mooneys (pre-J models)

Thanks Hank....I now have a project for this weekend! -

+20 year old donuts (1966 M20E)

outermarker replied to Matt Ward's topic in Vintage Mooneys (pre-J models)

Where can I find the manufactured date on the disc? I see the part number. I'm curious as to just how old my discs are. This has been a very good thread! -

+20 year old donuts (1966 M20E)

outermarker replied to Matt Ward's topic in Vintage Mooneys (pre-J models)

@ Turbo...I hope you loaned them to someone based at your airport. Thanks for the offer too. -

If anyone has a main gear disc replacement tool for sale, I would like to talk with you as I am sure others would also. All experience in the process is also appreciated. Can discs be purchased direct from LORD?

-

+20 year old donuts (1966 M20E)

outermarker replied to Matt Ward's topic in Vintage Mooneys (pre-J models)

Does anyone have the disc removal tool for the main gear that they would want to sell? Sometime this year I plan to change out the discs. -

I too, have a beat up old fiber type fuel pump shroud that needs a major overhaul or replacement if I could find one. Mine doesn't have any attachment points which I find odd. It seems like it just sits there relying on the scat tube to hold it in place and not rattle around too much. The one Spruce sells looks like it uses the fuel pump bolts as the attachment points. I don't like the idea of having to remove the fuel pump bolts to remove the shroud so I can inspect the pump. Could the fiber material be baffling material? I also asked Lycoming about it and they said it was a Mooney part. However, as mentioned above the Mooney Parts Manual is no roadmap to success. Any thoughts on using high temp silicone? I can buy an 1/8" thick sheet and cut it to fit. Silicone Sheet, 70A Durometer, Smooth Finish, No Backing, 0.125" Thickness, 12" Width, 12" Length, Red Temp rating is 500F

-

High fuel pressure with new fuel pump

outermarker replied to MooneyBob's topic in General Mooney Talk

I'm going to replace my mechanical fuel pump this year. This thread mentions for a IO360-A1A , a Lycoming pump LW-15473. A Tempest pump 41234 is also mention to be for this engine. It seems that both pumps are being supplied by Tempest. They are both an overhauled pump. What am I missing besides about $150 if I choose the Tempest version of the Lycoming LW-15473? TEMPEST O/H FUEL PUMP 15473 $307.00/Each 41234 TEMPEST O/H FUEL PUMP $464.00/Each -

My 65' E has post lights which are Whelen, and are flat on top. I have also noted on other Mooney's Glar-Ban post lights which have a bump on top. Both types use the same bulb, GE 330. And although the bases are similar, the Glar-Ban won't work in my aircraft. I am not planning on converting to LED's soon so if anyone has Whelen post light heads or the entire assembly, in any color, I'd sure like to have a few spares on the shelf. Another item to change in the near future are the toggle circuit breakers. Since I use the fuel pump toggle the most it displays some wear (sloppiness). The fuel pump circuit breaker is p/n 7072-05-10 and as mentioned in another post, I won't even mention the price unless you are sitting down first. Of course, the price has quadrupled on the excuse of Covid. There have also been complaints of wrong labeling, so I would rather seek a serviceable part if anyone has one to sell. albert

-

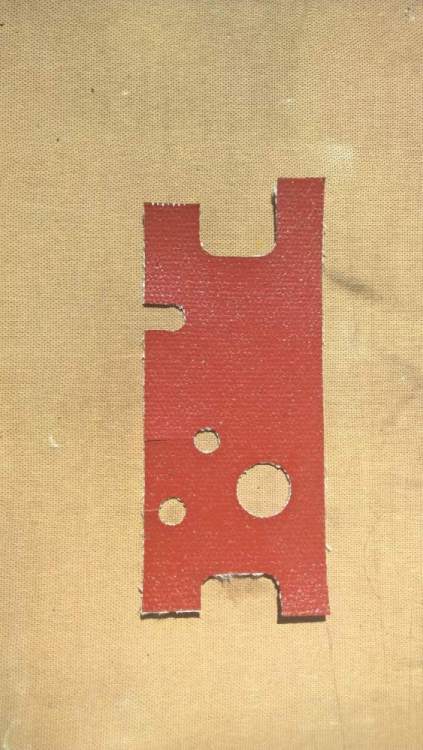

The part’s circled is what I’m after. Thanks for the parts breakdown.

-

Where can I buy a "Tow Limit Kit"? If none are around, are there drawings available? thanks, albert

-

Over the past year I have had some post lights loosen when turning the hood to adjust the illumination direction. Boy, these are a pain in the butt to get to! Is there a tool which doubles to install the nylon(?) nut which has the power lead attached? I suppose I could cut a slot in a long thin wall socket wide enough for the wire to pass through, but was hoping some cleaver person already knows where I could buy the correct tool and not reinvent the wheel so to speak. Also, if anyone has some working old post lights laying about, I’d be interested in having some spares. thanks! albert