-

Posts

135 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 29-0363

-

Awesome stuff. This is one of the times where a pilot really earn his/her salary.

-

Tips for scratch free removal of lower cowl

29-0363 replied to VetRepp's topic in Modern Mooney Discussion

It only takes one careless removal of the bottom cowl to do the damage. Whenever my M20R needs engine bay access I insist that strips of duct tape are placed where it is vulnerable. I also make the point that if they do scratch the paint, the repair cost will be their problem. -

And here's another Mooney on a great adventure (possibly meeting up with N887PS?) https://flightaware.com/live/flight/N432BG

-

I ask the ebay seller whether there was any damage history, and this was the reply. "Has had belly and wing repair.. both done correctly and fully documented. welcome to have it inspected . I will fix any thing inspection finds wrong jerry"

-

After having done everything on the list, what do you do if the vendor decides not to sell? It happened to me in 2006 after depositing 90K in escrow, a signed agreement and spent 2K on a pre-buy. I could have taken the legal option but it would be messy and costly, or as it happened I walked away and got the escrow transferred to the airplane I eventually bought. The vendor promised to reimburse me for the out of pocket expenses - I'm still waiting.

-

-

Inside the cockpit - Behind the panel directly underneath the entry door. IIRC there is an elbow fitting that is replaced with a tee fitting. I've seen a few different ways of tanking for ferry flights - purpose built aluminium or stainless steel, steel drums, and a neoprene bladder tank. in all instances the ferry tank MUST be securely anchored. There was a fatal crash of an Ovation a few years ago, where investigators found the bladder tank had not been secured at all and believed it shifted in flight altering the CG aft. It had only just departed from Hollister CA on a ferry to Australia. There is an earlier thread on the subject.

-

Welcome Chris. Where do we send the bill for the advertising you thought was free?

-

Speedbrakes are another tool in the toolbox of energy management. Extremely useful when operating in Control zones and you've been left high until the last minute, and they are an aid to engine management on descent (avoidance of shock cooling).. Their effect is far greater at cruise and descent speeds when the centre of lift is further back, and have some but not a lot of effect if left extended for a go-around or missed approach at lower speeds.

-

$$$ M20J Landing Gear Clutch Spring $$$

29-0363 replied to mulro767's topic in Modern Mooney Discussion

I agree, the price is way over what it would cost to make. I believe the SB was issued after a just one spring failed in the late 90's and the airplane landed gear up. The weak point in the spring is where they bend the 90 degree tangs on each end to retain it in place. You'll only need to replace the spring if it breaks, but here's a catch. When it does break, the undercarriage stops at whatever point in the extend/retract cycle the spring has failed, and one more sobering point I'll add, the manual extension needs an intact unbroken spring to operate - broken spring = manual extension disabled. Good luck! -

I've had a Super Tow 2 for about 5 years and really only use it when I'm on my own, but it has a traction problem. I couldn't recommend it to anybody because the towing cradle won't drive itself under the nosewheel as it is supposed to, because there is not enough traction. The main wheels will slip on any dry level surface be it cement or hardtop. The one good feature is the lazy suzan under the nosewheel that give great manouverability in tight spaces (you can spin 180 degrees on a dime) but you need to be very very alert.

-

Question for our math professor: Turning point over water?

29-0363 replied to yvesg's topic in Miscellaneous Aviation Talk

One also needs to consider that a decision to turn back will take time and corresponding loss of altitude during a 180 degree turn, for no distance benefit. while difficult to establish exactly where that point would be, I would keep heading outbound if the engine became silent about one minute before the PNR. -

Question for our math professor: Turning point over water?

29-0363 replied to yvesg's topic in Miscellaneous Aviation Talk

I regularly cross water in my M20R (Spencer Gulf in South Australia) where the distance between land is around 55NM. I plan at FL110 or FL120 and I reckon there's only a very short time where an engine failure would give me wet feet. Spencer Gulf water may not be quite as cold as Lake Michigan but it's renowned for its population of Great White sharks. Something the PNR formula doesn't take into consideration is the distance travelled as the airplane slows from 175K to best glide speed of around 85K while maintaining level flight. Only when you've washed of the all that excess speed and stopped the prop from windmilling would you begin descent. You would hope that extra distance would be the difference between landing in the shallows and landing on the beach. -

Engine stalls during turns while taxiing

29-0363 replied to David Mazer's topic in General Mooney Talk

This is the reply from Wed Dale of MAC after I contacted him about the engine stalling while turning. These notes are specific to the Continental IO-550-G in the Ovation. Good Morning. Your fuel flow should be set up to the following specs: 1. Warm engine to 160-180 F oil temp. 2. Adjust low unmetered fuel pressure to 8.0 to 10.0 PSI. We find they do best at the high end of the spec. The MaintenanceManual calls for 9.0 PSI, but that setting can leave the engine lean, just as you are experiencing. 3.Set the high pressure to 24.5 to 25.0 Gallons per hour at 2500 rpm and full throttle using the onboard gauges. This adjustment often times affects the low end setting, so it will have to be rechecked as well. 4. Adjust the idle mixture to get a 50 to 75 RPM rise at 750 RPM initial setting. 5.Adjust the idle to 750 RPM. 6. After any adjustment, lightly tap on the component which was adjusted. This helps the adjusted pieces seat into their new position, and a very important step in the process. These engines like to run a little rich at idle, as most Continental engines do. You may want to use Chapter 71-00-51of the M20R manual and TCM SID97-3 Setup Procedures as a guideline, but the specs I have provided work well at our Service Center. -

Engine stalls during turns while taxiing

29-0363 replied to David Mazer's topic in General Mooney Talk

This is the reply from Wed Dale of MAC after I contacted him in Nov 2002 about the engine stalling while turning. Good Morning. Your fuel flow should be set up to the following specs: 1. Warm engine to 160-180 F oil temp. 2. Adjust low unmetered fuel pressure to 8.0 to 10.0 PSI. We find they do best at the high end of the spec. The MaintenanceManual calls for 9.0 PSI, but that setting can leave the engine lean, just as you are experiencing. 3.Set the high pressure to 24.5 to 25.0 Gallons per hour at 2500 rpm and full throttle using the onboard gauges. This adjustment often times affects the low end setting, so it will have to be rechecked as well. 4. Adjust the idle mixture to get a 50 to 75 RPM rise at 750 RPM initial setting. 5.Adjust the idle to 750 RPM. 6. After any adjustment, lightly tap on the component which was adjusted. This helps the adjusted pieces seat into their new position, and a very important step in the process. These engines like to run a little rich at idle, as most Continental engines do. You may want to use Chapter 71-00-51of the M20R manual and TCM SID97-3 Setup Procedures as a guideline, but the specs I have provided work well at our Service Center. -

Engine stalls during turns while taxiing

29-0363 replied to David Mazer's topic in General Mooney Talk

I had an identical problem on my 1998 Ovation with the Continental IO-550G. It began with a drop in RPM in right turns and until I solved it I would add a tiny bit of throttle before turning to keep it running. The final straw was a night landing on YBBN RWY 19 - the engine quit and I had to do a hot start and vacate before the following 737 did a GA. I spoke with the factory and was told to check and adjust the fuel pressures at both idle and high RPM. They also referred me to the engine handbook. The pressures were checked, found to be out of adjustment, and once recalibrated the problem was solved. -

I did my training in the Grumman AA-1B and most of my early flying was in the AA-5A and AA-5B. They are easy to fly, light and responsive on the controls and steering on the ground is a little quirky for some because of the castoring nose wheel and differential braking to steer. For what they are they are a great airplane. In answer to the question of what is the airplane: it's an Avion Robins. My one and only experience doing aerobatics was in one of them just out of Stratford-on-Avon in the UK - also very nice to fly. http://en.wikipedia.org/wiki/Avions_Robin

-

From the album: #29-0363's album

Sharing the airstrip with local cattle in Far North Queensland. They like to rub themselves against control surfaces and break off static wicks. -

Towards the end of a 4.5 hr flight (by myself) in Ovation 29-0156, I made it to FL200. It was back in May 2001 in Queensland Australia. Temp on the ground was about 27C, OAT at altitude was about -15c if I recall. Took a while to get there and there wasn't much climb left. Control forces were very light with IAS about 105K, and it was awfully quiet!

-

Are you referring to an indicator light on your panel, or the indicator on the floor?

-

Ditto for 29-0363. Have you tried applying contact cleaner to the pins on the bayonet connection? It helps but like you say, the erratic readings reappear.

-

I've posted the MFD engine page of 29-0363 in cruise at 8,000 ft. Note #5 CHT is higher than the others - always has been, as well as having the lowest EGT. On leaning #4 will always peak first, then almost simultaneously #2 will peak. Leaning was around 100F ROP, hence the high FF.

-

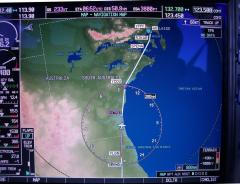

From the album: #29-0363's album

29-0363 G1000 MFD display in cruise @ A080