-

Posts

1,214 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by dkkim73

-

How to discourage walkers on the runway?

dkkim73 replied to wombat's topic in Miscellaneous Aviation Talk

I'm with Shadrach; there is a PR aspect to be managed. People have a lot of misconceptions about private airplanes, and having a positive interaction might be the thing they remember whenever the local anti-airport forces get going. May be also truly ignorant of procedures and the risk level. What someone said about "you may be hard to see" is probably a good point to make. -

Another thing you can do is run the PDF scans through an OCR program. I received the majority of my logs in PDF form as well buying the plane, and did this. Makes keyword search very easy. Have shared Dropbox links with AP/IAs and other helpful folks, makes it quick for them to look for specific info. Over time I hope to abstract more of the important data into a spreadsheet as you have done, also.

-

Struggling to get complex hours before ownership

dkkim73 replied to SilentT's topic in General Mooney Talk

I'm pretty sure they can take the heat. -

There is a great write up on this mod elsewhere on mooneyspace including detailed scanned docs. Highly recommended, and I saw better numbers on the very first flight.

-

Mine (installed when I bought it) has been flawless and very useful... If the audio fix was not decisive perhaps there is a bad ground or similar issue? Perhaps microkit can look at logs and see if there's any erratic data that would shed light on the dirty window hypothesis. BTW Mooney did the install, they were very thorough on the installation and the documentation of the installation.

-

Wow; glad it worked out so well! Good eyes on his part. Out of curiosity, how did the problem present inflight and how did you diagnose it? I am very impressed by the GFC700 but also increasingly aware of how important it is to be mindful of the autopilot to avoid getting bitten. I realize I never posted the resolution. We ended up using some lightly-used units that had come off an engineering plane at Mooney; they were kind enough to warranty them, and it saved some money (for the seller but a good thing still) and more importantly time. And on the plus side, both the avionics guy and I viewed the light use as a positive, that they had been ops-checked. The other option would have been the flat-rate Garmin rebuild or exchange service.

-

Mechanic/shop recommendations; minimalist or Savvy-friendly?

dkkim73 replied to dkkim73's topic in General Mooney Talk

The engine is a TSIO-550G(3). I'm a bit fuzzy on whether "N" cylinders go with "N" engines and G with G, etc. -

Mechanic/shop recommendations; minimalist or Savvy-friendly?

dkkim73 replied to dkkim73's topic in General Mooney Talk

It was definitely cleaned up and waxed when I visited to look at it. That said, the paint is original and in great shape! The leading edge might be accentuated by the TKS strips. Indeed, the engine arrangement, baffles, plumbing, etc, is very elegant. It's a lot of power and design packed into a small place. Kind of reminds me of the funny Lightning McQueen quote from cars, "I'm a precision instrument of speed and aerodynamics" which is later misquoted by his rusty old truck friend. -

Mechanic/shop recommendations; minimalist or Savvy-friendly?

dkkim73 replied to dkkim73's topic in General Mooney Talk

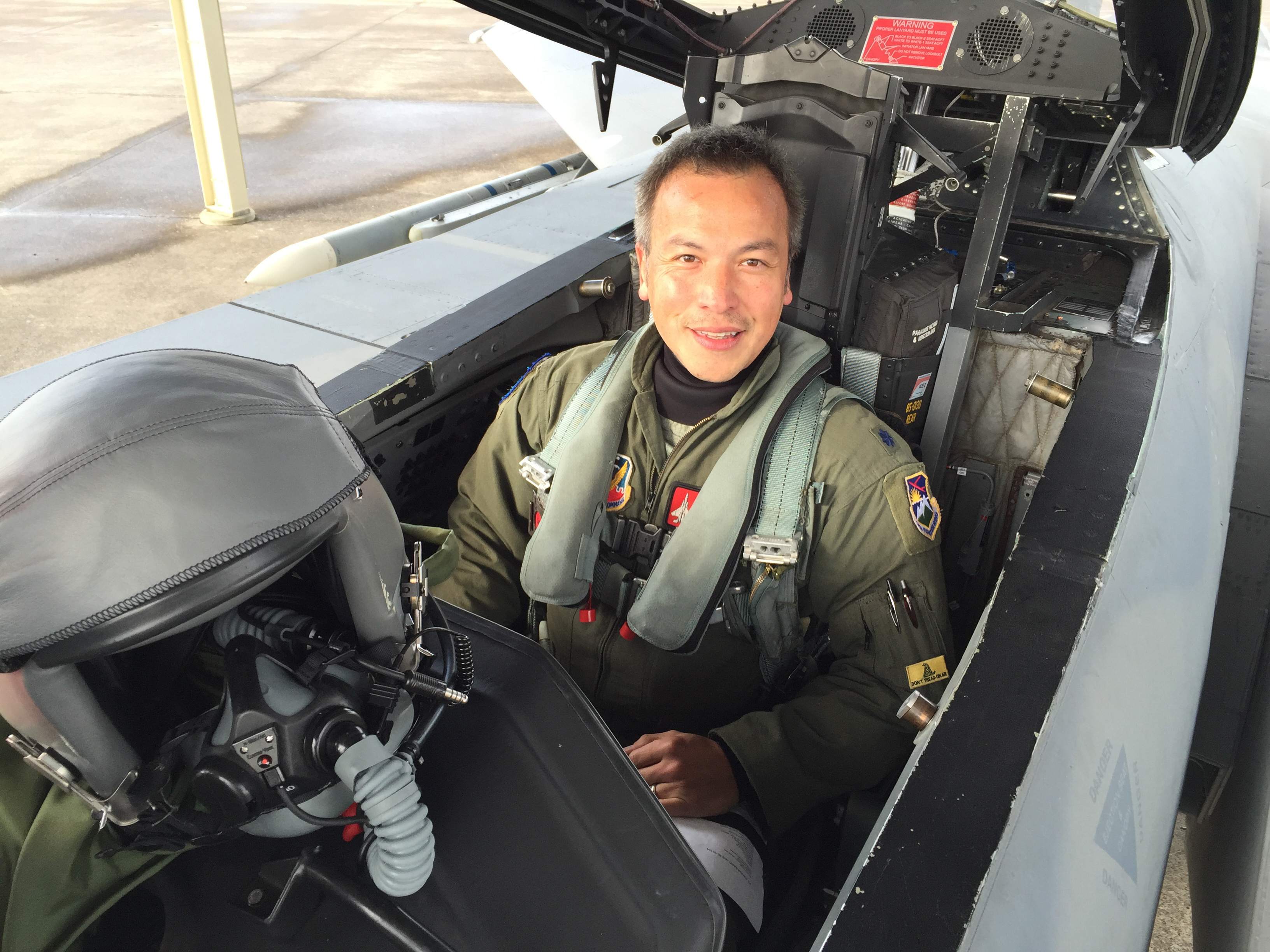

That's actually a great description. Is this what you mean by alternating? See Left forward cylinder. This was from the demo flight. -

Bringing the plane for maintenance and practicing my new commute yesterday. Nearing the Crazy Mountains, between Livingston and Harlowton, in south-central Montana, 13K.

-

Mechanic/shop recommendations; minimalist or Savvy-friendly?

dkkim73 replied to dkkim73's topic in General Mooney Talk

Thanks for all the thoughts and info, Andrew! I am not sure what kind of cylinders are in there. The logbook mentions replacing a prior cylinder with part # "658178A3"; a search on the web doesn't make clear what type of cylinder it was (G or N). CHTs have been, for me, pretty easy to manage in cruise (knock on my wooden head). I think it's the Acclaim cowl and baffle design and the lack of a cowl flap control for me to mis-set. E.g. from a winter flight yesterday: 334F was highest during full power/full rich climb to 12K. Then 25/2500/lean gave temps 250-280 (almost seems too low). Summer at high altitudes might be different. Not sure what this means about the history, but hopefully it was not hard to control for the prior owner. I don't have any digital logs predating my ownership. No idea if he went max power high altitude or was more conservative. I guess work on 4 cylinders could be due to anything, including the breather tube problem (serviced recently). The flight was to a different shop nearby with experience lapping valves in place. I'll let you know what I hear next week! D -

Mechanic/shop recommendations; minimalist or Savvy-friendly?

dkkim73 replied to dkkim73's topic in General Mooney Talk

Looking at their "built" engine options is like being a starving orphan outside a candy store in a Dickens novel. ETA: I did have a nice conversation with one of their folks last week. Very interesting and he was kind and helpful. I'm waiting to hear back on an inventory on refurb'ed cylinders (in case I end up needing at least 1 or 2, hopefully not). -

Mechanic/shop recommendations; minimalist or Savvy-friendly?

dkkim73 replied to dkkim73's topic in General Mooney Talk

This makes a lot of sense, and I've heard similar things intimated before. It's like an older used car, but at a higher level. I'm thankful that the bones seem solid. I am a struck at the range of approaches to things, e.g. cylinders. Minimalist vs. maximalist. It's kind of an art out there. Not entirely dissimilar from medicine. And probably some other complex domains. -

Mechanic/shop recommendations; minimalist or Savvy-friendly?

dkkim73 replied to dkkim73's topic in General Mooney Talk

Thank you all for the info and PM's. I'll watch for the seminar. I had seen that Savvy article before, very helpful. Update: after some bush-beating and a number of calls, working with Savvy, etc, I found a shop in the region that is experienced in lapping valves in place, amenable to step-wise approaches, and Savvy-friendly. Currently planning to get them the plane for a couple days in the first week of April. Local maintenance did reveal a too *lean* mixture with other fuel set-up in parameters (low metered/unmetered, high metered/unmetered fuel flows, MP's) all nominal. So hopefully that explains the original problem (stumbling/taxi cuts/lack of power on go-around). I just got back home and have yet to flight-test. @Danb TY re: the paint job! Isn't it? It's a beautiful plane, and really engineering-wise a thing of beauty. Still a bit surreal to be able to fly it. I was a bit surprised when I got oriented to the AC that all the trim control is linked through the AP. And man is that a lot of trim turns for a Cessna/Piper pilot if you go the muscle route... I will pray for your electric trim. We need a patron saint of aviation maintenance. David -

I appreciate the desire to keep things stock and "use the right tool for the right job", but maybe you should just retrofit the original setup with an oscillation overthruster? Simpler approach, arguably. And no need to keep checking inverse reactive current every 25 hrs. *PP thoughts only...

-

Are the Bonanza and Baron on the same path as the M20?

dkkim73 replied to Rick Junkin's topic in Miscellaneous Aviation Talk

Being new to ownership I've had that exact thought. Eg Cuban cars and fridges in the embargo days. You can buy new Smart phones but a lot of stuff that requires real expertise or depth shows short supply lines. Gives a person pause. -

Mechanic/shop recommendations; minimalist or Savvy-friendly?

dkkim73 replied to dkkim73's topic in General Mooney Talk

I appreciate the thoughts. I read a lot of Mr. Busch's writings in the early AvWeb, and catching up on all his work since I became an owner, I have to say he does make a lot of sense. The Savvy people (I subscribed to Mx) seem very knowledgeable and helpful. They have a very empirical approach, review data logs, etc. I think the challenging thing is the sheer heterogeneity of viewpoints among A&Ps. I'm not philosophically opposed to a top and running it over nominal TBO with inspections to "get the value out of it", I just wish I had a better sense of probabilities. My own motivation to do more prophylactically is driven primarily by wanting to have use of the airplane (e.g. bigger hit now vs. multiple potential downtimes for maintenance). As for the TSIO-550(G3)... one does read a lot of stories. I am given to understand it is a very thermodynamically efficient engine, and some aspects of it seem very elegant to me. Certainly a lot of power, and I would hope the derated application (280hp in the M20TN) would improve reliability. The cylinders do sound like a perennial weak point, though. What is the collective wisdom on choosing replacement cylinders? I read things about new-in-box Continental cylinders sometimes not being right, etc. Some rebuilders will re-do the cylinders. Or is that costly overoptimization of a part that is simply more likely to need work or replacement regardless? D -

Mechanic/shop recommendations; minimalist or Savvy-friendly?

dkkim73 replied to dkkim73's topic in General Mooney Talk

Well, clearly I come across better in print. I'd had that exact same thought about knowing where to look, and managing it expectantly. -

Mechanic/shop recommendations; minimalist or Savvy-friendly?

dkkim73 replied to dkkim73's topic in General Mooney Talk

Thank you guys for the good info and thoughts. I did speak to Brian Kendrick... On the original issue: he thought the mixture was likely too lean based on the story (assessment of the local guy) where we had all thought maybe too rich previously. Might also explain some marginally-higher TIT's on takeoff. The local guy just did a fuel check on my request, said all he had to adjust was mixture to get rid of stumbling. Flight testing pending. As for the cylinders, he thought lap #3 (hot spot, low compressions recently and intermittently in past) and flush #4 (lowish recent compressions). Anyhow, I did find a shop less than 2 hrs away recommended by a DPE. The guy I talked too was very open to valve lapping, suggested it de novo in fact. Oddly the place I'm looking to commute to soon. So hoping to get them to try that on the 2 low/lowish cylinders. Went to the shop yesterday evening. I can see and hear the compression findings. The cracks in the three cylinders (2,4,5) are not macroscopically visible but show on eddy current. Some say this is too sensitive (the local A&P works on a range of aircraft including turbines and has a lot of gear). He seems totally sincere that he thinks this is a real relevant crack but also says he replaces them right away and has never seen a failure and can't give me any predictive #s on failure rate. So... maybe ECI is too sensitive a test (several say yes), or my CB glasses? He's offered to advance the work, let me pay later, etc, so I think this is just his philosophy (shop is busy so I'm sure I'm not a cash cow, probably more of a sad idealistic foundling with a nice plane). I'm currently planning to fly the plane to the other site and have the less invasive things done first. At least a few knowledgebale, though remote, folks, encourage this and say the AC is flyable. Part of me thinks, hey 1450 hrs SNEW, the two problem cylinders still original... maybe order a few spares? Maybe talk myself into more? Still not yet had an oil analysis or scoping into the camshafts etc so I don't know how long replacing a bunch of cylinders (1-6) would extend things vs a full overhaul, vs going on-condition. If the bottom end is solid, I might be inclined to throw newer jugs on and let it ride (Mike Busch is having indigestion as I think this right now about the first part, probably approves of the second). Any thoughts appreciated, D -

Hello All, I took my Acclaim in for the local A&P to look at. We'd talked about some work including servicing the AMSAFE inflators, and a possible weak cylinder/hot spot on valve. Most specifically, I'd asked for him to look at fuel flow and idle fuel pressure and mixture settings on this visit, due to stumbling on go-arounds I'd been noticing. The gentleman, who is well-regarded locally, also has a reputation for being extremely thorough, has recommended replacement of all cylinders as a "starting point". I won't go into all of the rationale here, but it includes some things like recently-low compressions, possible cracks between the fuel and spark plugs, etc. Note that the hot compressions were all good a couple months ago and the plane was cleared out of annual at the Mooney Factory Service Center (about 30 tach hours ago). They did boroscopy and remote assessment was primarily that there was one hot spot on an exhaust valve to watch. I do subscribe to SavvyMx and have received advice, also from others, that a more conservative step-wise approach would be good. Including lapping valves in place and a ring flush procedure. Rotocoil replacement, etc. And the fuel thing is quite possibly entirely separate. Many (an overwhelming # of, actually) details aside, I am trying to find shops reasonably close for a 2nd opinion. Am currently based at KBIL. Got two good recommendations but they are in Texas. Anyone have detailed experiences with shops in the region who might be more amenable to a step-wise approach and working closely with Savvy? Thank you, David

-

Speedbrake does not fully retract

dkkim73 replied to Fritz Kaiser's topic in Modern Mooney Discussion

Possibly, though might also a different model (they require both brakes and the brain box to be sent). It could also be more because of the lack of the interval service. The quotes came via the A&P so I did not get the nuances. Planning to do them at the beginning of next annual at this point (several knowledgeable folks suggested it was more reasonable to defer, as this all came up right before I was going to get the plane). -

Speedbrake does not fully retract

dkkim73 replied to Fritz Kaiser's topic in Modern Mooney Discussion

I was also quoted $4000, by precise flight via the Mooney factory service center. Apparently they had not had the 1000-hour service with the previous owner and so no repair was offered, only full overall. Maybe that explains the difference? BTW I have the newer electric ones where the box coordinates deployment, sounds like same as the OP's, left intermittently sticks out about 1/2". -

Exactly the issue.

-

Worth finding a good IFR trainer. I had some club archers and warriors that were solid, with 430/530 stacks and classic gear, inexpensive... a while ago. Worth finding a good accessible, rentable reference platform IMHO. Make a generic version of your checklist, then adapt to your new Mooney when the time comes. D