-

Posts

1,248 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Marc_B

-

I had a two week slot, but missed it by a month with the Mooney in the shop. Took right around 2.5 wks; due to weather/schedule I picked it up 3 weeks after drop off.

-

Glare shield repair and covering, yokes, seats, carpet, ultraleather cover the plastics and side panels, headliners, placards, compass post, rudder boots...pretty much any of the interior besides the panel. They can also repair seats, arm rests, lumbar supports, etc. They replaced one of the plastic knobs on my pilot seat that had broken.

-

Picked up the Mooney from San Antonio and Hector and crew do amazing work! Due to other work my drop off was delayed and fortunately Aero Comfort worked with me and still got me in. Hector was easy to work with and made the process straightforward and helped with choices where I was waffling. I have pilot O2 connections on headliner so he suggested O2D2 pocket in copilot seat back and this is a great place for it! Easy to access, allows clean tube mgmt, and has easy to pull out and adjust from pilot seat. If you’re looking for price, reach out to Hector for latest pricing sheet. All aspects of work is priced as package or individually so very transparent pricing and no surprises. He can do it all or just what you need. Thanks Hector and crew for saving me from maroon madness! Seats are just as comfortable as they are beautiful!

- 13 replies

-

- 13

-

-

I've been using an XL moving blanket from Harbor Freight. Inexpensive and works well. Not quite as much loft as a sleeping bag, but much larger size wise and I can fold it to fit and add layers. But I'm in a hangar and don't have to worry about wind blowing the blanket off or flapping back and forth underneath straps. If I were outside in the elements I'd probably opt for a custom cover like Bruce's. https://www.harborfreight.com/80-in-x-144-in-extra-large-double-sided-moving-blanket-58062.html

-

When I did the PROTE at BJC there was an attendant on oxygen inside the enclosure with us, 5 pilots going though the chamber, a person on a microphone outside asking questions and running the equipment and about 3 people standing around watching. We weren't locked inside, we had demand oxygen masks in our laps, and we were monitoring our pulse ox the entire time. Instruction was at 5 minutes everyone put on masks OR sooner if you were at 60% or lower, had more then 3 symptoms of hypoxia, or if one of the instructors told you to put on mask. @kortopates They said the idea behind brief time and not below 60% was to avoid hypoxia amnesia where you don't remember your experience. The instructor outside asked everyone a question at some point (i.e. what are the forces of flight, what is a typical glide slope angle, etc.) and then instructed you to write a 3 and circle it. Then on the debrief they asked what number you had circled and do you remember what that represents? One guy was clueless and honestly couldn't remember being asked a question. We had a sheet with crossword puzzle, math problems, and a maze to do "in your free time" but everyone had to write down their symptoms every min on the min (1/2/3/4/5). they had write ins as well as typical symptoms (color saturation, nausea, headache, tingling, air hunger, tired/fatigue, etc.) Never once did I feel the process was dangerous or unsafe. On the contrary, my experience was very well run. At 5 minutes I was at 70%, felt a little overtired (just finished a night shift) type feeling/dull, felt a slight need to take deeper breaths, and some slight tingling. So if I feel dull and overtired that's my cue to consider oxygen and check my pulse ox. Highly recommend all pilots do this, even the normally aspirated guys can get high enough to have problems! Plus it's good to know your hypoxia symptoms in case there may be something else at play (i.e. CO). CO may show normal pulse ox reading...so if it doesn't add up, maybe head down.

-

LED Replacement for Whelen Model #70303 Light

Marc_B replied to StevenL757's topic in Avionics / Parts Classifieds

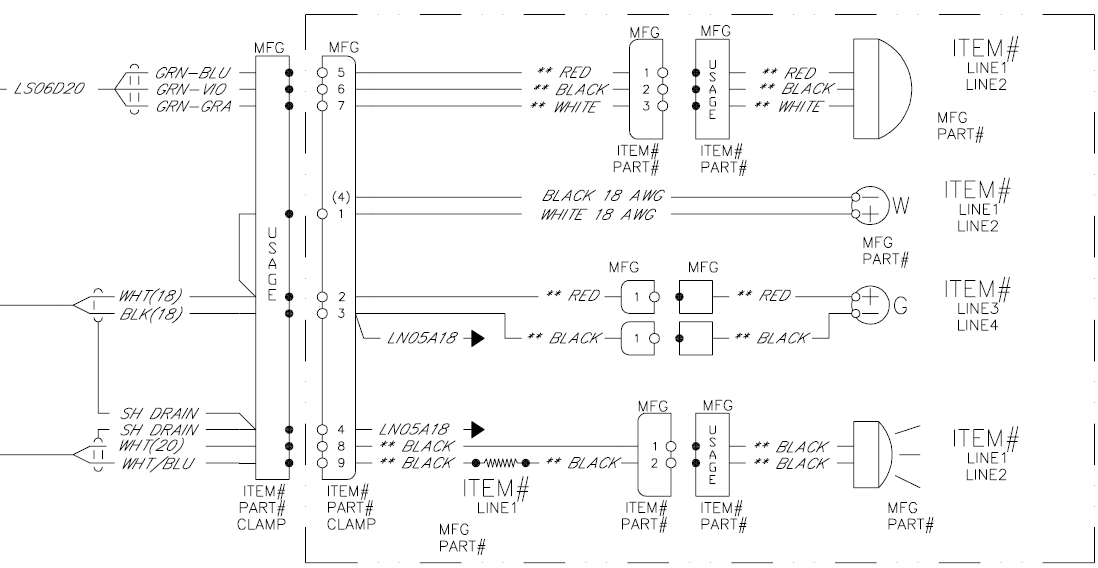

Interesting. I'll have to check my voltage as I'm not sure...M20K Encore, MSM schematic (25-2001 thru 25-2012) looks like it has a resistor but not marked regarding specs. 28V system; but not sure the voltage on the recogs. Where is the resistor located? at the wing tip vs. accessible from inspection panel? I have a set on pre-order from @OSUAV8TER. -

@Marauder ya it's a great unit and worked well. I would have kept it but the GFC500 said "homie don't play dat" ha ha. So G5 in, ESI500 out. I think that pricing on the G5/GI275 vs pricing of a new ESI500 are off enough that I may have to just price it as a used G5 to sell it...or keep it for now. Great standby and pretty easy to use when I'd play partial panel.

-

I did a PROTE event last year that was hosted at one of the flight schools down at Metro (KBJC). It was free, took about 20 min start to finish and was just a 5 min trip in the portable chamber with 27,000ft simulated oxygen. It was basically to expose you to hypoxia and see what type of symptoms and pulse ox at 1/2/3/4/5 minute marks. I found out about this through the Colorado Pilot’s Association, not the FAA. So they’re still up and running. Perhaps it just takes a site to request and host it?? Maybe send an email to CPA and see if they know who to contact. I would love to take the FAA aeromedical physiology class in OKC. It sounds move involved and covers more information than just a hypoxia chamber. So if you find out more, post up! It’s on my aviation bucket list.

-

Refurbish seats and other interior components

Marc_B replied to AeroEng's topic in Modern Mooney Discussion

To minimize downtime, couple this with other maintenance. How about taking out and sending off interior you want updated while aircraft is down for annual? But even with drop-off for a turnkey complete interior this may only take 2-3 weeks. Hardest part is that the best shops may be scheduling 6 months+ in advance. -

price dropped on ESI.

-

@hais work in process. hoping to have it squared away in the near future.

-

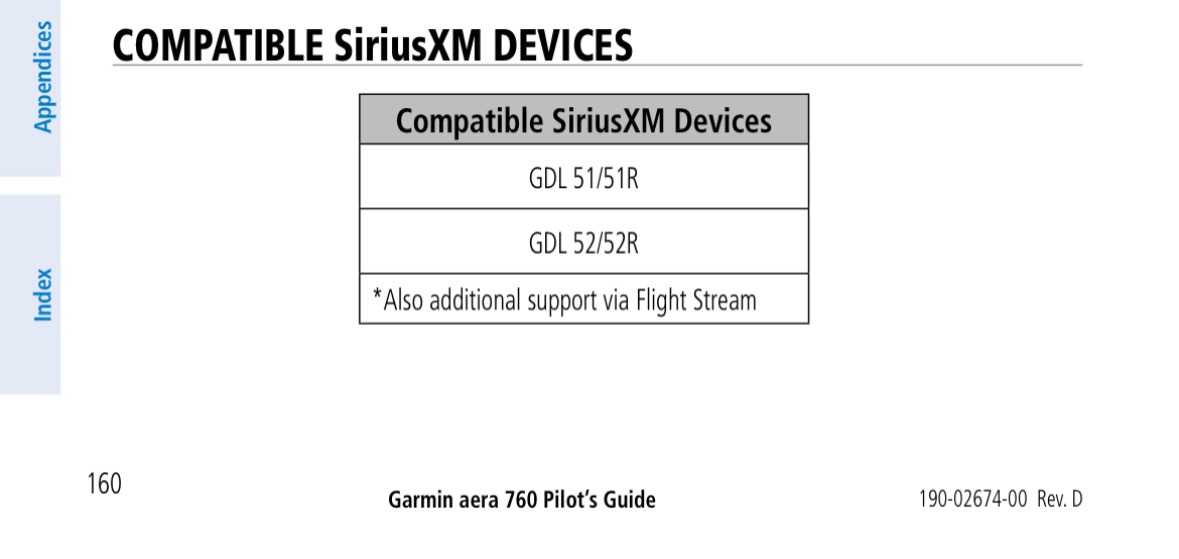

It depends on where you’re receiving XM feed. I have a 760 and receive XM from gdl69a sxm via FS510 card in the GTN750. But you’ll need XM weather antenna to supply the feed in some form or fashion. Either from built in or dash. ^this is from pilot guide.

-

Is one a landing light and the other is really the taxi light?

-

There has been a list on aviation consumer and scheme designers of top rated shops. Not sure if this needs an update or re-validation? But for someone who is planning repaint in the next year…what tips do you have to insure a great result? It seems like even some of the shops on the top list have an occasional questionable experience. Is that something the owner could have curtailed or any recent bad experience should mean pick a new place? Is that something the owner should be explicit and communicate more clearly? what’s the best way to stack the deck in favor of a good experience for both you and the shop? what shops of the “top list” have people had excellent experience with and which have had substandard experience with?

-

@A64Pilot That's kinda what I was trying to figure out...if it's slow progression and I can just wait til repaint (planning on within next 1-2 years depending on schedule), then I'd rather wait and have it fixed right.

-

See if this has what you need... wingtip_IPC_M20K.pdf

-

Anyone out there with recent Hawk experience in the past 12-18 months can you PM me about your experience? Thanks! Marc.

-

I have some small areas around a few access panels with some corrosion and some paint chips around some rivets/leading edge. I'm planning a full repaint which would completely address these areas. But I'm trying to figure out when it makes the most sense to address. Is this something that can wait a year or two, something that should be temporized now, or something that I should address as soon as practical? My Mooney spent a period of time on both coasts with previous owners; it's now in northern Colorado and lives in a hangar. Inside wings look great and have had CorrosionX applied, so no corrosion concerns other than 2-3 access panels with what you see. Thanks, Marc.

-

Insurance provider recommendations

Marc_B replied to Balckbird's topic in Vintage Mooneys (pre-J models)

I'll be the contrarian and say that if you're a low time pilot that AVEMCO may be your best bet. When I was purchasing my M20K, AVEMCO was half ($4700/yr...yes, the policies I was quoted from everyone else were 10-11AMU/yr). I would love to work with Parker due to the recommendations here, but I haven't quite hit the magic spot where rates "normalize." @Parker_Woodruff where is the break point (hrs/ratings/etc.) where AVEMCO isn't a significant amount cheaper? Of course I do understand the differences in policies and provisions. I was actually surprised the last time I reached out now that I have 300+ hrs, IR and close to 200 hrs in type...of course this could be just the current climate and market?? -

Price drop.

-

When I adjust Baro on the G500TXi it will sync to the G5. But when I adjust barometer setting on G5 it reverse highlights in yellow that it’s different but doesn’t send back to G500TXi. Is there just a lag or are you suggesting this should be instantaneous?

-

Work done: G500 legacy to TXi upgrade GTN 750/650 Xi upgrade; existing FS510 connection GFC500 with YD + G5 / removal of ESI500 & KFC150/S-TEC YD IAI annunciator 2 row to 1 row annunciator GDL 69A SXM + antenna install Complete panel cut, powder coat and etching Garmin Aera 760 upgrade with bare wire Whelen 9080525D LED Beacon install Started having a few kinks with my KFC150 so decided to upgrade to GFC500. Figured that if I was going to upgrade this, then I might as well upgrade some of the other equipment while the price and availability of equipment contributed to an easy pathway for upgrade with trade in of legacy equipment. Worked with AATG up in Greeley. Fortunately they're on my home field, and Steve & George have been a great help in the past. Took a little longer than expected, but on budget and they did an awesome job! Gray panel color was a little darker than I expected but actually makes the placards easier to see and turned out even better than previous I think. All work was done in house with AATG including panel. A couple wrinkles lead to project going over estimated time, but I think we came up with good solutions. Mooney Encores don't have standard rudder trim that "plays nice" with the GFC500, so the S-tec had to either replace the Garmin YD or be removed; we removed in order to take advantage of fully integrated YD. The upper avionics panel in the Encore has a larger tube that cuts down the total radio stack height enough that a 2 row annunciator was too big (for GMC507, GTN750, GTN 650), but IAI made a single row to fit; still working out the kinks on this one. Initial thoughts of the GFC500 and updates is that the update is much more intuitive and faster to use. Having Baro sync and GFC automatically adjusting altitude is awesome. I’ve found that tapping baro on G500TXi and then using knob is the fastest way for me to update barometer enroute. G500TXi knobs in a much better place to access outside the horns. Previously had to reach through the horns to access the PFD buttons/knob on the legacy G500. Between touchscreen and the width of the unit it is better accessible around the yoke. GFC500 at the top of the stack was suggested by AATG and seems faster to access. I’ve also really enjoyed the remote radio feature with the G500TXi/GTNXi. It’s nice to be able to send freqs to both radios from same waypoint page. Interesting quirk is that freq being sent to active first takes the standby position then moves to active; so you have to choose active then standby; otherwise your standby is overwritten. AP: KFC150 would typically overshoot altitude target and I would have to use the up/down rocker to correct…now no need as the target IS the altitude. I haven’t had a chance to really experiment with the VNAV but imagine this will make STARs a breeze. I also find that when I’m in heading mode (90% of the time flying around DEN bravo they just give vectors with seemingly constant changes) it is WAY easier to adjust the heading from the GMC507 than it was using the legacy G500 knob that was right in the way of the yoke horns…so much more straight forward now. I'm still squaring away GPS to ILS auto-switching, but approaches come down on rails. I honestly wonder if you could have the GFC land for you by just controlling throttle it's just right on course! Smart glide is an interesting feature that I hope to never need, but is pretty cool to use. I initially thought that the green “v” vector path to the nearest airport on the flight path would be unnecessary, but I find that it really helps contribute to situational awareness and especially helps with pointing at airports behind you. Adds to the game "if I had to land now, where would I aim?". Overall a great integrated flight deck that works every bit as well as advertised. Previous steam to glass was done by the prior owner so it made this transition sting much less. If you are serious about some avionics work and want an estimate I'd recommend you reach out to AATG. PS. I'm cloning Don Kaye and have leaned on him for help! So I both blame him for this and thank him for this!! ha ha. Looking forward to flying with @donkaye again to get some more tricks of the trade for all the new goodies!

-

@OSUAV8TER I’m sure has the confirmed answer. But I think these can be used for 14v as well as 28v and will just have a different current draw between the two. Is that correct James? I’ve got a pair on order from him and have a 28v system so I hope so!

-

price dropped on the ESI.