Fix

Verified Member-

Posts

139 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Sweden

-

Reg #

D-xxxx

-

Model

M20K 252/Encore

-

Base

ESML

Recent Profile Visitors

1,763 profile views

Fix's Achievements

-

Updated my Gami Injectors and did a quick flight today. Now I have a Gami spread of 0.3 - 0.4g/h instead of 0.6-0.7g/h. Will do a proper test flight soon as the weather is favorable here again.

-

I've timed my mags several times with flower pot and digital meter and piston pin. Maybe I messed up, I've double checked it. At least both mags are even, maybe could try to adjust both mags 1 degree. At 29" 2300 RPM at 10.1g/h LOP I my TIT show just above 1550f on the analog gauge, most likley 1510-1560f range. Maybe it's higher than "normal", but on the other side it's still well below 1650f and also if the reading is "higher" even if the real TIT should be lower I have a margin to ~1600-1610f were my personal limit is. If I had a very low TIT with a functional TIT probe, then I might get above 1650f with out knowing it? On the Garmin G500, do you calibrate the TIT against the analog gauge or how does it work? I can also see that your EGT is lower than mine, what would be normal EGT temp? Is there any difference between JPI probes and Garmin Probes and the original Probes with read out?

-

Had another trip last friday at FL100. This flight my engine behaved as it should :-) FL100 29.5" 2300rpm @ 9.9-10.0g/h TAS: ~163KT TIT: ~1575F Will install my replacement Gami Injectors next week for Cyl 1 + 3 and it will be interesting to see how engine behaves then and if I get below 0.5g.

-

Can you Swap the Mags from Left to Right and vice versa? If the problems moves you know it's the mag...

-

Let's buy Mooney - Crowdsourced Version - Straw dog.

Fix replied to Yetti's topic in General Mooney Talk

I would have no problems to donate/subscribe yearly $1000-2000 if it was directly to Mooney. Now I'm financing a another company that would make profit from our donations/subscriptions. -

Lasar Aviation Mooney Assurance Program - Really?

Fix replied to PeteMc's topic in General Mooney Talk

I would be more happy to pay directly to Mooney as an supporter than to Lasar. Now I feel the money get into the wrong pockets. As I wrote before Lasar did markup a part with 60% just to drop ship it directly to me. Would be 100times better if Mooney took 40% of that money, and then Lasar had a normal cut like 20% instead. Will see what happens, but for $200 each month and only 10% discount on parts not worth it. Let's say I will need a part in 2 years that cost $5000, then I get 10% ($500 off) and then pay $4800 in "subscription fees" = $4500+4800 = $9300... Guess it's better to pay full price instead. Why not add an "supporter" subscription for $10-$30 instead to help out in general. -

Would be interesting to gather some more information here... I assume regarding EGT is where the probes are mounted/drilled in the exhaust. Or are they "factory drilled" at exactly the same position? Also with TIT Probe, is that location always the same on all -MB / -SB

-

I replaced my Stock TIT prove around 60h ago, so I expect it should be OK. I've noticed that if I calibrate my JPI TIT after the stock TIT, they will differ depending on what altitude I fly on. If I calibrate it for at 4000ft at some power setting, JPI TIT will under read if I then fly higher, and vice versa. Right now I think it's calibrated so it's not showing "too low" values on the JPI, where I think it's better to be safe than sorry. Used flower pot, digital meter and spark plug pin. If I didn't mess up, my mags should be timed within 0.5degress. At FL 160 where the turbo have to work harder I have: 25" 2500 12.6g/h (65% ROP) EGT: Highest 1418f - Lowest 1353f - TIT: 1499f CHT: 359f - 330f - - 29.5" 2300 10.1 (65% LOP) EGT: Highest 1493f - Lowest 1406f - TIT: 1599f CHT: 353f - 316f My Cyl 6 EGT is lowest by ~40f from the others. *** I've checked some other flights at FL140. There my TIT was ~1500F at 25" 2500 12.6g/h

-

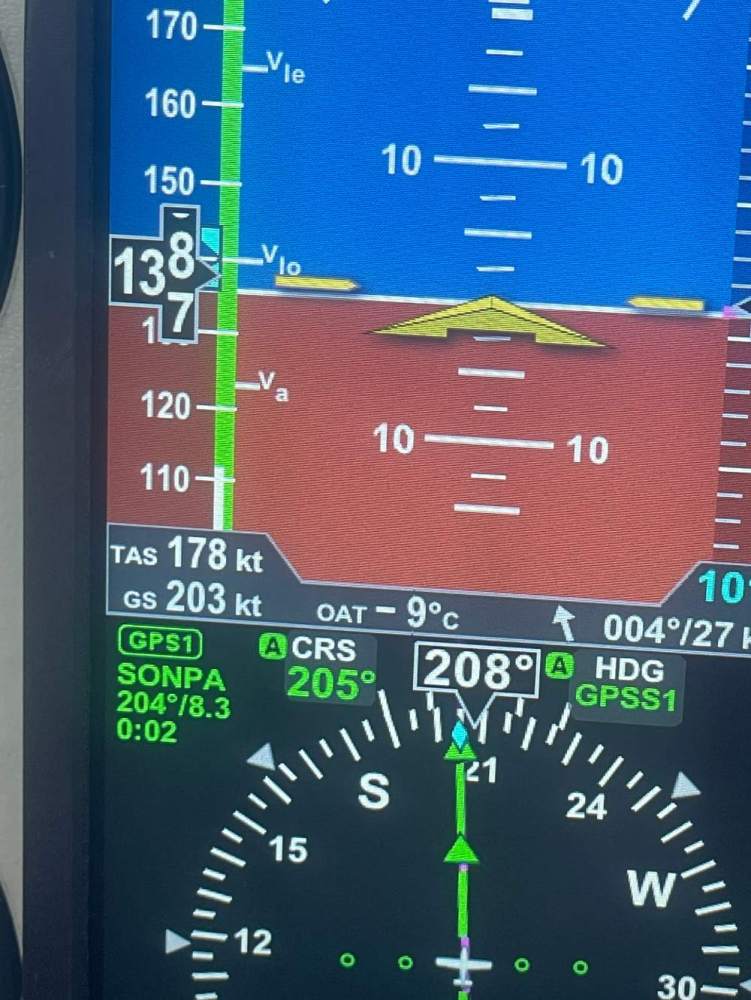

Update: New Maggie Harness, Gami Injectors and new Tempest Fine wire Spark plugs... Engine runs runs smoother, more even RPM drop at Engine run up. Also idle is stable after a flight when taxi, before I had some issues were I needed to add some rpm to have it running and not quit. Guess the harness fixed that. Did some Gami spread test and most likely in average I have 0.7 with Gami. Cyl 1 & 3 is to lean. Hopefully Gami will send replacement, they are not the fastest to respond. LOP, is not perfect but now I can at least fly LOP 29.5" 2300 10.1 (LOP 5-15 degree). After some fiddling I can get engine to run OK, but I expect improvement when I get replacement injectors. On my from ESSB to ESML I got a new speed record at FL160. 29" 2300rpm 10.1g/h, Cowl flap closed, All CHT under 369f, TIT ~1590-1600f Tail winds are nice :-)

-

30% increase is maybe reasonable if we can get the parts we need. But, when I ordered a part from Lasar and Mooney sent it directly to me the forgot to remove the invoice to Lasar. Sadly Lasar added 60% on top of the Mooney price just to order that part. Sure, Price and Demand... But 60% markup is ridiculous... and now an additional 30% on that. I would be much more happy to give that 60% markup directly to Mooney instead of Lasar.

-

If you can consider an M20K 252 Encore or 252 with Encore upgrade you can load it pretty good.

-

My road to getting my -SB engine to run smoothly at LOP continues... I now got my Maggie Harness (Thanks Paul for assisting) and also my Gami Injectors arrived. I've suspected lots of things, but made the decision to change ignition harness to be 100% that there wasn't any issues. They looked fine when we looked at it, but since left mag even when I changed it and also did an 500h inspection didn't solve rough LOP I decided to buy one anyway. What can you say, I'm glad that I did order a new harness, since there was damage to the old one on several wires. One of the wires were actually really bad, and was in direct contact with metal. This was 5B on Left Mag... rest of chaffed wires were on bottom plugs too. This was only on ~550h since new! All damage was in clamp. (You needed to remove wire to see it) Wire with most chaffing was forced against an rivet due to wrong installation and wrong clamp. Also impossible to see without removing wire. Even if this don't solve my LOP issues, I now have a fresh and correctly installed ignition harness. Started to install new harness yesterday. Gami injectors will be next up. Cylinder 5B. Severe chaffing, through outer rubber and braid shield... Some more chaffing, due to JPI probe wire in same clamp. Some more chaffing, due to JPI probe wire in same clamp. When the installed new engine, they used old/wrong clamps that put lots of force on wires. On several wires when clamped together. After some hours of careful wire planning it slowly looks much better. Now all Ignition wires will be in own clamps, and all JPI probe wires in separate clamps.

-

Will check it next time.

-

There are actually more one more supplier of TEL in Asia according to Shell. (Can be found in their application in EU) Shell is also buying from that supplier. (If I didn't read it wrong)

-

Put back my newly inspected 500h Slick Mag. Engine runs more smoothly in general, but didn't solve my LOP issue. I can get it running 29" 2300 10.1 but it's not 100% smooth as I would like. Good news is that my GAMI Injectors will be sent out this week. Another good news is I had an little oil leak that been hard to find over the last 12 months. If my detective work is correct, then it was leaking from the Oil Stick rubber hose. Fitted 2x new clamps and a new rubber hose and made sure that the metal tubes got connected as they should. Last flight over an hour it appear that it stopped leaking... It was not leaking much, but it flying around everywhere making a mess.