1980Mooney

Verified Member-

Posts

3,628 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 1980Mooney

-

AOG Shelbyville TN, KSYI--Solved and Home!

1980Mooney replied to Hank's topic in Vintage Mooneys (pre-J models)

I agree that it is usually the field wire on the alternator that vibrates/fatigues loose. That happened to me over desolate West Texas/Eastern New Mexico about 25 years ago. But something doesn't make sense. If that happened or alternator failure of any kind happened - then first, the Ammeter would start pegging to the left with a constant drain on the battery. Then the Low Volts light would come on as the battery voltage dropped with the power draw. Those indications on the panel normally gives the pilot time to shut down unnecessary Nav/Comms, lights, etc. and conserve battery power. But you say the Ammeter was centered which means no draw on the battery. And that your Nav/Comms reset/restarted a couple times which meant they experienced complete loss of power (not just low volts). Could it be related to the Main power solenoid - either the solenoid or the main power switch on the panel or the wiring to it? -

Rocket in landing incident at KHND.

1980Mooney replied to NickG's topic in Mooney Safety & Accident Discussion

Cassity still appears as the owner in the FAA Registry. He has not been on MS since June of last year. About that time the Registry shows that he also purchased N693BS, a 2021 SUPER PETREL LS (amphibious). ADSB-Exchange shows that it showed up at Henderson on September 19, 2024. It appears to fly fairly regularly from Henderson to Lake Mead. Per ADSB-Exchange the Rocket didn't fly much - last flight in 2024 was November 29 around Henderson, then on February 15-16, 2025 to Buckeye, AZ and back, and then on June 28, 2025 a few short flights around Las Vegas. On July 2 it flew to Provo. This happened the next day on the return. Per FlightAware and ADSB-Exchange it looks like he landed at a high rate of descent, pushed it into the runway about 1/4-1/3 down the 5,000 ft, runway and porpoised extremely hard. As noted above look at how the tail section rear of the steel fuselage frame is buckled downward. That took a high downward force while on the main landing gear. It is hard to tell from the pic but the spinner looks like it is crushed in and one blade is completely bent under the lower cowling. It looks like all the landing gear are sheared off/collapsed In addition to @LANCECASPER comment about the fuselage frame, this Rocket has an STC bespoke engine mount that may also be damaged adding to the cost. Per ADSB-Exchange, he came in way too high. At about 1.5 nm from the threshold, he was about 1,000 ft AGL and descending at -2,000 fpm. That is about a 6 degree glide slope. His rate of descent reduced to about -450 fpm as he crossed the airport fence but increased to about -770 fpm as he crossed the runway threshold which makes it look like he forced it into the runway. (Note - ADSB shows he was about 150 AGL when crossing the threshold. Also 35R is a shorter runway and set back from taxiway A - the threshold is at taxiway C) https://globe.adsbexchange.com/?icao=a8b2af&lat=35.968&lon=-115.124&zoom=15.1&showTrace=2025-07-03&trackLabels×tamp=1751562032 N66JG Flight Tracking and History 03-Jul-2025 (KPVU-KHND) - FlightAware N693BS Flight Tracking and History 06-Jun-2025 (KHND-KVGT) - FlightAware -

The Acclaim POH states that Preflight Inspection includes : Nose and Main Landing Gear - Gear, Shock Discs, Tires and Gear Doors ……INSPECT So the answer is “yes” you are supposed to if you adhere to the POH. And if you are checking tire pressure you have to crawl under regardless.

-

The low this morning in Idaho where the OP resides was 44 degrees F this morning........

-

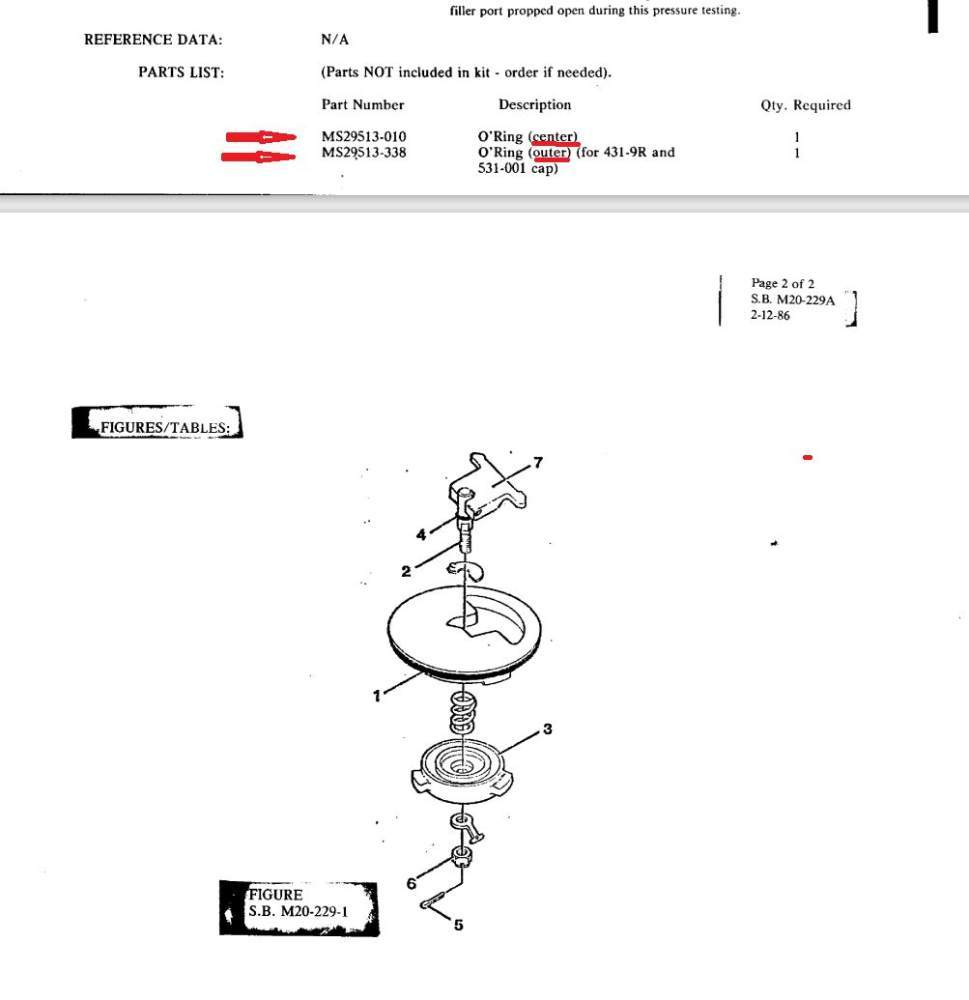

Just curious - did you replace both o-rings on each cap? The big outer one and the small one around the shaft? I know you are new to ownership and things may appear simple. You removed the cotter pin and nut, then decompressed the spring in order to disassemble? And you reassembled, didn't lose that half moon clip and adjusted with proper spring tension so that is stays closed but does not bind? Great job if you did both. It's a learning experience.... From SB (Service Bulletin) M20-229A,

-

Just be careful if you are attempting to buy a used one online rather than local and in-person. And even local and in person there are pitfalls. Due to the price and lack of availability, these are favorites for online scammers. The Inogen G5 and identical OxyGo Next were introduced in 2019. I searched OfferUp, Mercari, Craigslist and eBay (they sold them at the time) back in 2021. There were a considerable number of what appeared to be legitimate lightly used units for sale at the time. I spoke to a couple individual sellers in New Mexico and Colorado (natural markets due to the high altitude) that advertised on Craigslist that seemed honest and legit. I ultimately found a lightly used (about 120 hours) OxyGo Next locally in Houston on Craigslist for about $400. I have searched again recently looking for a second one. I added Facebook Marketplace to the sites. The market is different now eBay will no longer sell full portable units. It is because what @Marc_B said above - the FDA classifies this as needing a prescription. If you post a unit on eBay, it will be taken down by the moderators. Yes they sell parts and accessories. There are "bait and switch" scammers online. On OfferUp I called a seller and they said the "portable in the ad has been sold but I have a stationary 120 volt unit I can sell you". The condition could be crap. Get visual confirmation of Total Hours Used. I found a local G5 recently with 15,000 hours on it. On Marketplace, I contacted a seller in Texas. They sent video of the unit and seemed legit. But then things got weird and ultimately they could not provide evidence of shipping. PayPal reversed and refunded my payment. If you find one locally being sold by relatives of someone who no longer needs it, be cautious if it has been sitting for a long time (like years). If the relatives left the battery installed in the unit sitting for months/years, it will likely be fully discharged. The Inogen/OxyGo batteries are LI-ION. Fully discharging a lithium-ion battery is harmful and can cause irreversible damage. They may be shot. (There are a lot of shot "used" batteries for sale on these sites). The batteries used to be ridiculously expensive but prices have come down. Some places wanted $680 for a 16 cell (double capacity) battery in 2022-23. They are about half that now, but since they are made in China are probably going up. Buyer beware.....

-

@M20GforMe - as a new owner you are "drinking from a firehose" right now. I can tell from your quote for the Annual that you are using Coletti Aviation at KLOT. Mooney M20 Annual Inspection | COLETTI AVIATION There aren't any PIREP's on Coletti on either Mooneyspace or Beechtalk so it is hard to say anything about their experience, but their pricing seems to be pretty transparent. Maintenance | COLETTI AVIATION Looking at your list, there are some things that another A&P (actually it is the IA) "might" let you "kick the can down the road", but it can be "pay me now or pay me a lot more later". For instance, it appears there is corrosion on the steel tubular fuselage cage - 4.5 shop hours to address it. You definitely want to do it. Then there is the corrosion on the Push/Pull control tubes. I had the same issue when I changed A&P - the old one signed off on the surface corrosion, but the new one would not. In the end it was better to stop the corrosion sooner rather than later. You might be able to spread some of this out over future Annuals but spending more money to put your plane back together, fly to another A&P, pay them to undo your plane again - and then perhaps write up the same list of discrepancies becomes a real money loser. Read this article by Mike Bush - others have referenced Mike Bush who is "Savvy Aviation" EAA_2011-05_is-it-safe-is-it-airworthy.pdf

-

Perhaps you did not see that the shop found corrosion on the engine mount and prescribed Corrective Action of "Strip down, clean and paint to prevent reoccurrence". If you are having the engine pulled (for issues you highlight) and if they are removing the engine mount frame, then it would be really cheap/"penny wise" to not replace the Lord or Barry mounts at the time. @M20GforMe - corrosion allowance is only 10%. I don't know your mount tubular dimensions, but it might only be 0.035- 0.065 inch thick. That means that corrosion of only 0.004 - 0.006 inches renders it unairworthy. That could be one thick hairs width. Then you get into welding it. It would be best to address it while the engine is out. Otherwise the cost becomes huge if you have to do it in the future.

-

GAMI spread too high ... what to do?

1980Mooney replied to NicoN's topic in Modern Mooney Discussion

You didn’t mention if there were any events prior to finding this: - How long/flight hours ago did you or partner last record tighter/normal spreads? - Was any work done on the engine recently or recent Annual prior to discovering the high spread? -

The dive shops I go to in the Houston area have pure oxygen.

-

Absolutely correct. @highflyer77 there was a recent topic about Monroy tanks and @Pinecone commented: "If you fill main with aux empty, fuel starts moving into aux. So when you stop filling main and put on the cap, the level in the main is still going down. So you fill the aux, but the main is not full, so the level in the aux goes down and leaves you short of full. Filling aux first means fuel is moving from aux to main. Then you fill the main, which reduces flow from aux to main. So you then top the aux after doing the same to the other side and you are much closer to full." The shop that did the W&B had no way to accurately know how much fuel that you had in the tanks to start with - and they had no way of knowing if they actually filled the Monroy and Mains all the way to "Full Fuel".

-

"hot summer months"....I see that you are near Boise, Idaho. "hot"?....seriously?? I noticed that your 9 day forecast shows that the Low will be 49 F and the High with be 71 F. And I see that your current Relative Humidity is 18% right now with a High that might touch 86. Here near the Gulf Coast the High is in the 90's and the Low generally is about 75 F. Earlier this week the Low was 81 F. Relative Humidity was 99-100% this morning. Even in the 90's F, the relative humidity never gets below 65%. It gets really "fun" when the Tower tells you to hold for release, or if there is a lot of landing traffic. We would KILL for your "hot summer" flying weather.

-

Go to a dive shop. Easy and cheap.

-

I’m not sure if I follow your point. Swift also requires that you pay for an STC to use their fuel. And the economic reality is that, because AVGAS consumption is so low, virtually all but the busiest airports have only one supplier of AVGAS. - Daily deliveries of all grades of AVGAS average slightly over 400,000 gallon per day NATIONWIDE. - There are about 5,000 public airports and 14,000 private airstrips. - Just considering the public airports, that is ONLY 80 gallons per day per airport on average. Gas/connivence store sell more beer than that per day. Grocery stores sell more milk than that per day. You may want market competition but the market reality does not support it. The Govt doesn’t have anything to do with it.

-

What conversion? A bit more information would be helpful for anyone to answer.

-

Talking about a specific location is meaningless. Look at the big picture. Globally, 1,500 SEP were built/sold in all of 2024 and only 317 in Q1 of 2025. Yes there are some homebuilts but they do not meaningfully replace certified aircraft - either in mission or life of use. But the number of GA that are crashed or just rot away every year exceeds the number coming into the market. The cost of purchasing and owning/maintaining a GA SEP is rising faster than inflation. Look at the price increases at Lycoming - or anything that Hartzell/Arcline Capital owns...or any other aviation supplier scooped up by Private Equity - up 50% over the last couple years. You have to practically be a millionaire to acquire a new Cirrus. Mooney went out of new aircraft business 6 years ago because they were "only" charging $700,000 and $800,000 for their 2 base models and could not make a go of it. This will not drive growth. At best GA piston may flatline.

-

Also it depends upon your model and location. Are you in the US or outside? There are comments that "the factory is making parts". Definitely not all parts and not full support for all models. And then some parts are sourced by Mooney Corp from third parties through exclusivity contracts. Things as simple at the mechanical wing fuel level gauge dials can only be purchased by Mooney and not owners directly from the manufacturer. The problem is that Mooney doesn't have enough money to order third party parts in quantity for inventory or for MSC's. Here is a critical intake boot on an E that has a 35 week lead time after 10 orders have been received....

-

Yes I understand that - I am using the word figuratively but the aft of the plane has to be removed. It is a major event - all the wiring going to the tail which includes power and any remote avionics like autopilot has to be pulled, control rods, etc in addition to drilling out all the rivets. Then it all has to be reassembled - and that sum total work is in addition to actually repairing the plane. What a PITA.

-

I think that you are talking about Pippen-York Avionics. But I don't think that they will be much help in pulling the TIO-540 to send it out for the prop strike AD/Inspection or replacing the prop in order to get it into shape to ferry it somewhere. The alternative would be to cut the fuselage behind the back seats and put it on a truck/trailer.