-

Posts

9,949 -

Joined

-

Last visited

-

Days Won

222

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by PT20J

-

That nose gear part is actually called a leg. The truss is the part the pivot bolt goes through. Usually, steering play is in the steering horn and various rod ends in the steering system. The leg in the picture appears unairworthy. There are dents in the tubes that appear to exceed the 1/32” max allowable.

-

The fact that the gear waring sonalert operates when the gear is up and the throttle is closed indicates that you have power from the Gear Warning breaker to the Gear Down Limit Switch NC contact all the way to the throttle switch. The floorboard lamp is connected directly to the NO contact on this switch and should be relatively easy to access. I would check that this light is getting power when the gear is down and that it is not burned out. The Gear Unsafe light gets power from the C contact on the Gear Up Limit Switch. This switch has contacts that are easier to access than the Down Limit Switch and I would check that there is power to the C contact when the gear is neither completely up or down. Also, check that the lamp lights when the Test button is pressed on the annunciator panel. The Gear Down lamp dims when the Nav lights are on, so you could cycle the nav lights and see if that makes any difference. Since two of the non-functioning lights are in the annunciator panel, there might be a fault here. There is no lamp test for the Gear Down lamp, so the only way to eliminate a burned out lamp is to replace it or swap it with a known good lamp. You can also remove the connector from the back of the annunciator panel and check voltage on the pins for the lamps to see if the problem might be within the panel. The circuits for these gear lights is pretty simple, but there are series diodes that could have failed.

-

I just stuff mine in the side pocket beneath the wemac on the pilot's side.

-

Based on the G100UL fuel leak thread what's your position?

PT20J replied to gabez's topic in General Mooney Talk

The Lycoming IO-360-A series (200 hp) has a compression ratio of 8.7:1. The Lycoming IO-390-A series (210 hp) has a compression ratio of 8.9:1. The Lycoming 0-360-A series (180 hp) has a compression ratio of 8.5:1. -

I don’t have a picture of my throttle switch, but I’m pretty sure it is a Honeywell V3-1. Does the gear horn sound under the following conditions? 1. Gear up, throttle closed. 2. Gear down, no airspeed, gear switch up (bypass red button should also illuminate) Are you still not getting any Gear Down, Gear Unsafe, floor gear position lights inder any condition of gear up or down?

-

Based on the G100UL fuel leak thread what's your position?

PT20J replied to gabez's topic in General Mooney Talk

According to my paint guy, it’s the clear coat that gives extra UV protection and is resistant to Skydrol. I’m going to spring for an extra $3500 to get the new paint job clear coated. If it’s resistant to Skydrol, maybe it’s more resistant to G100UL staining and/or easier to polish out. He thinks it is also helps with corrosion. He paints the airplanes for a local flight school at Paine Field WA. They were having corrosion issues from deicing with isopropyl alcohol until he started clear coating them and there have been no issues since. -

Or, they are milking the installed base because new sales are nil.

-

At least on the 100 series, the #8 screws on the top of the wing are threaded into tapped holes in the aluminum frame that only catch a couple of threads. For something that the manufacturer believes should be removed annually, rivnuts would have been a better choice. Some of mine have been drilled and tapped for #10 screws.

-

That's the problem with greases: They are an oil mixed with a thickener and the oil and thickener separate over time if left to sit.

-

Based on the G100UL fuel leak thread what's your position?

PT20J replied to gabez's topic in General Mooney Talk

The RSA fuel servos originally used Buna-N rubber parts and a cure date decal was affixed to the servo. Back in 1980, Bendix switched to flourosilicone parts and issued a service bulletin. RS-76-Rev1.pdf -

Based on the G100UL fuel leak thread what's your position?

PT20J replied to gabez's topic in General Mooney Talk

Can we pleeease stop discussing Skydrol. Everyone agrees on two things: 1) it's nasty stuff, and 2) it's not used in Mooneys. I would still like to figure out how to resolve the discrepancy between the two tests with one showing no affect on paint and the other showing severe paint damage. The discussion about o-rings got me wondering how long nitrile o-rings last in service. As near as I can find out, no one knows because there are too many variables. SAE AS5316 sets the shelf life for aerospace applications at 15 years. But I found a paper that suggests 7 would be more appropriate. https://www.sciencedirect.com/science/article/abs/pii/S0141391022003779 So, let's say 35 years ago the factory installed an o-ring that had been stored for 5 years. That means that the o-ring is 40 years old. Now suppose the fuel is switched to G100UL and sometime later the o-ring starts to leak. How can we know that that old/tired o-ring would not have leaked if it had remained on 100LL? I'm not arguing one way or the other, but merely pointing out that nitrile o-rings are life limited parts and perhaps they don't get replaced as often as they should. -

When I was testing the Garmin Smart Glide, I noticed that I had to pull the prop back in my M20J or the rpm fell in the yellow arc at idle throttle and best glide speed.

-

No worries -- none of us knows everything and we are here to help each other.

-

Is the slop in the steering or the pivot? And how much slop is there? Slop in the steering can be checked by jacking the airplane and grabbing the nosewheel and twisting it from side to side and noting where the lost motion is in all the visible components. Slop in the pivot will be noted when moving the nosewheel front to back. Mooneys typically have some play in the steering that gets worse with wear. The wear points are the steering horn and the rod ends, not the truss. You can shim the horn until it gets bad enough that it needs to be rebushed. Rod ends are easily replaced. If your mechanic thinks the truss pivot is worn, then perhaps the LASAR bushing mod is a good option. However, you might first try checking the torque on the pivot bolt.

-

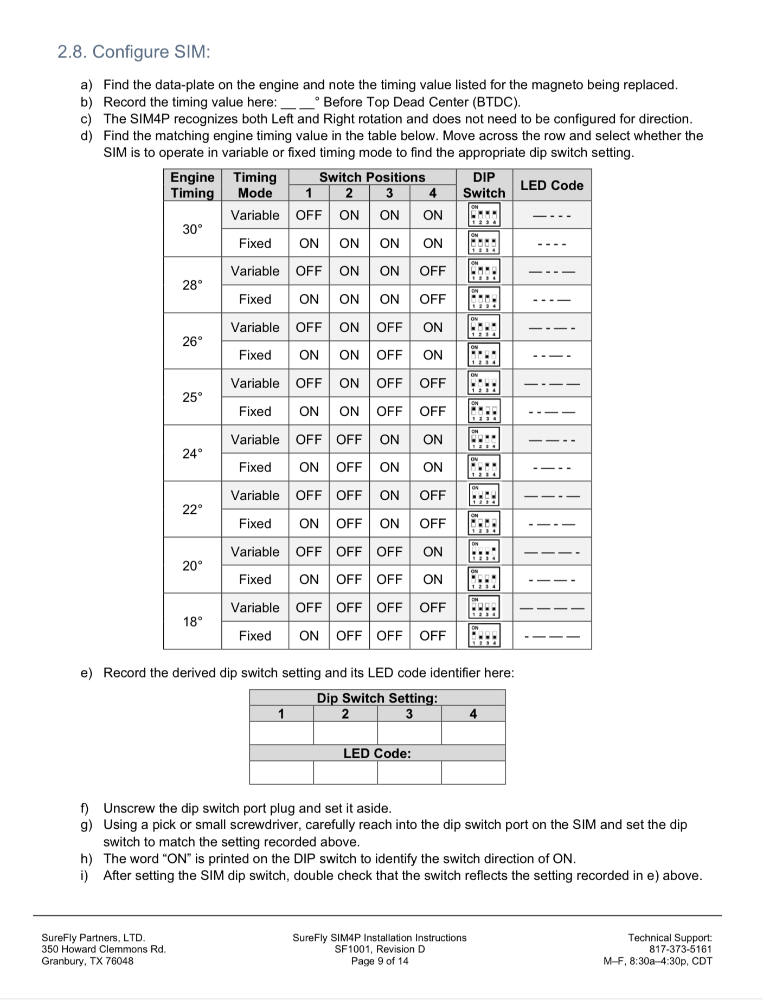

@Marc_B is correct. The advance (20 or 25 deg) is set by dip switches when you install it. So, you can set it for 25 and if you don't like it you can change it to 20. (You will have to remark the engine data plate if you change the timing and make the appropriate logbook entry). The only choices you get when ordering are whether you are replacing an impulse coupling mag or a non impulse coupling mag.

-

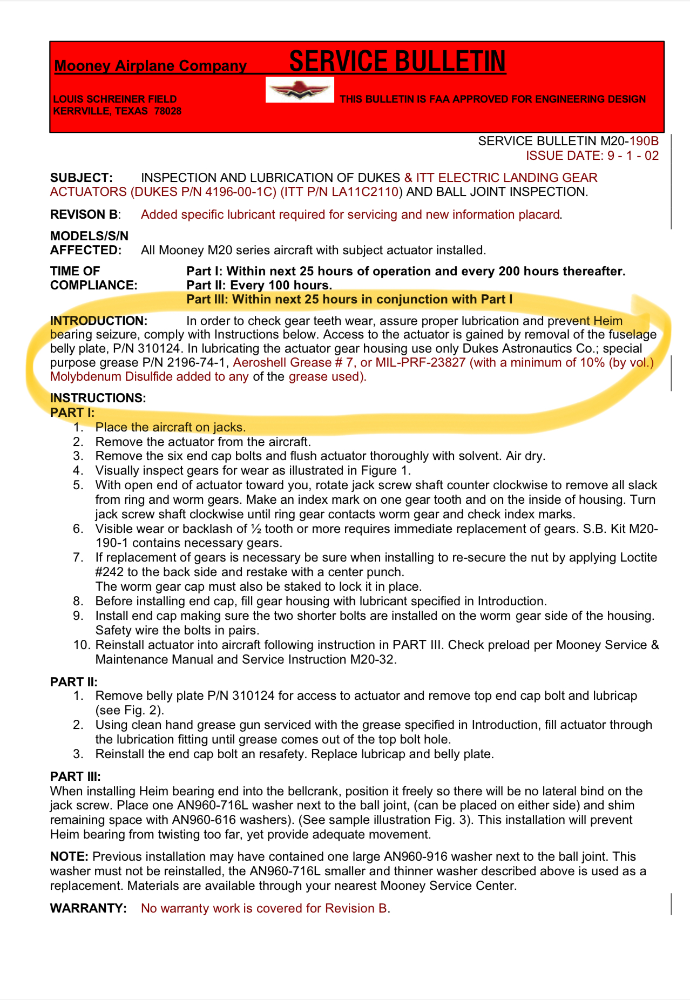

But the service bulletin says MIL-PRF-23827 mixed with 10% (by vol.) Molybdenum Disulfide. So, wouldn't you still have to mix in 5% moly with AS 33 to meet the spec called out in the AD?

-

Doesn’t the AD reference SB M20-190 which requires 10% moly by volume? I don’t believe there is such a commercial product available. LASAR used to mix it and sell it in small containers - perhaps they still do.

-

According to the M20J Service Manual, the proper lubricant for the hold open arm is MIL-L-3545 grease which is Aeroshell 5.

-

Based on the G100UL fuel leak thread what's your position?

PT20J replied to gabez's topic in General Mooney Talk

Let's see: GAMI has over ten years of research, development and testing. Some testing was witnessed by FAA personnel and the results were approved by the FAA resulting in an STC. Much of this is described on the G100UL.com website. The Youtuber was not vetted by anyone. His test was not observed by anyone. We don't know his motivations. Maybe he was paid by Swift. Maybe he dosed the 100LL with paint stripper. Probably not, but the point is that WE DO NOT KNOW. Yet some seem to give high regard to the Youtuber while denouncing every argument George puts forth to explain the G100UL testing and certification process as tainted by self interest. George has offered to share the contents of the certification file with anyone interested in visiting Ada to view it. That's pretty unusual. I know of no STC I can purchase that comes with certification and test data to support the FAA's decision to approve it. If anyone has a beef with the approval process for G100UL, I respectfully suggest that you should take it up with the FAA. I continue to support continued independent testing. But the results of the Youtuber need to be repeated and confirmed by others before they are taken seriously. Anyone remember cold fusion? It looked promising until it proved unrepeatable by peers. -

Based on the G100UL fuel leak thread what's your position?

PT20J replied to gabez's topic in General Mooney Talk

George @George Braly, forgive me if I misunderstood the test. The G100UL.com website FAQ states in pertinent part, "Those three Beechcraft painted louvre panels were immersed in:" Upon review, I see that the text is somewhat ambiguous. I took "Beechcraft painted" to mean "painted by Beechcraft." From your response, I believe you intended it to mean "painted panels removed from a Beechcraft." -

Lube the baggage hold open arm also!

-

I would think a dry film lube would be best on the starter. Evidently DuPont used to make Teflon lubricants, but as @A64Pilot said, its current products utilize boron nitride. A friend showed me a spray can of boron nitride he got years ago in Japan, so it’s been around a while (I don’t know who made it: all the writing was in Japanese). It sprays out as a white powder (so it’s a little messy) and is very slippery.

-

Based on the G100UL fuel leak thread what's your position?

PT20J replied to gabez's topic in General Mooney Talk

I agree. Something happened to the painted parts in the video. The test should be repeated by others with sample parts from various aircraft with different paint systems. The GAMI tests were all with Beechcraft panels. Beech is known for quality. Who knows about the paint systems used by Cessna, Piper, Mooney, etc.