-

Posts

664 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by shawnd

-

What is this hose for in the fuel injection system?

shawnd replied to shawnd's topic in Modern Mooney Discussion

Thanks @GEE-BEE Cowl Savers are now .085 inches. Will PM you. -

What is this hose for in the fuel injection system?

shawnd replied to shawnd's topic in Modern Mooney Discussion

Haha - re: fuel, One of the things I had done while the cowl flap motor was out was take the belly off for a closer look and found the fuel selector valve leaking. So went ahead and had the fuel selector valve o-rings replaced. Once that was done, I wanted to replace the worn out adel clamps around the cowling and I noticed deep nicks in the ignition harness so swapped that out and, why not, replaced the spark plugs as well. Took the opportunity to get the cylinders boroscoped and compression tested. Glad I got the opportunity to learn a ton while the plane was grounded. Best yet - looks I still have a lot more to learn! -

What is this hose for in the fuel injection system?

shawnd replied to shawnd's topic in Modern Mooney Discussion

I am planning on taking the plane down to a MSC soon for a few other things. Will have them take care of this as well. Thanks for the pointer. -

What is this hose for in the fuel injection system?

shawnd replied to shawnd's topic in Modern Mooney Discussion

Hmm yeah could be - will do tonight. Thanks! -

What is this hose for in the fuel injection system?

shawnd replied to shawnd's topic in Modern Mooney Discussion

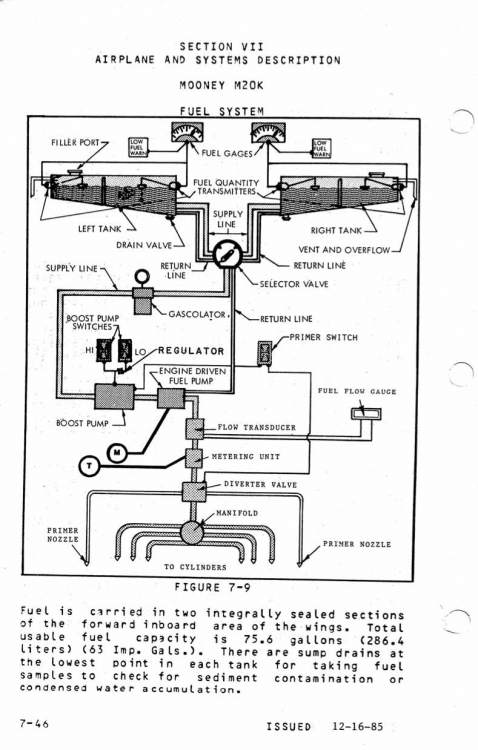

@carusoam the baffle seal looks bad in this picture but isn't that bad. Still flexible and engine gets plenty of cooling based on CHT/EGT temps on JPI. However, I do plan on replacing them with McFarlane CowlSavers. @N231BN You are right that the 252 has a flow transducer, see pic. "Fuel flow is represented digitally and indicates volume of fuel being used in GPH". Having said that, its not part of the manifold based on the image, but maybe the image is just supposed to give a high level idea. Would be great to know if there is a part # for this hose. @M20Doc is it possible to replace it with a slightly longer one to route it better? -

What is this hose for in the fuel injection system?

shawnd replied to shawnd's topic in Modern Mooney Discussion

It has the Hoskins FT-101 fuel flow gauge. It’s scary that it’s carrying fuel straight into the cabin! Yeah Aircraft is a M20K 252. No fuel pressure gauge. -

What is this hose for in the fuel injection system?

shawnd replied to shawnd's topic in Modern Mooney Discussion

Thanks and hmm, I have no idea. I guess I am missing some other areas of knowledge around this area. For ex, when I lean my engine out during runup, once I push the throttle in, the fuel flow also increases. How does this happen when the mixture control is untouched? If it is the manifold pressure line - is it safe to unplug it and replace it with a longer line. Anyone have a part # or specifics what it can replaced with? -

Trying to understand what this second line from the fuel manifold for. Of course the one covered in firesleeve is the fuel line but this second one connects on the port side of the manifold, snakes underneath the port side intake manifold and connects to the firewall on the passenger side. TCM IPC shows only one connection - the fuel line. Any ideas? I am trying to see if I can get a longer hose to cleanup how its routed around through the wall behind the engine. Engine TSIO360MB-6B PS. been away - stories to tell, will update in post once the plane is all fixed up.

-

Good points! The whole exhaust and turbo system was inspected during purchase and was given the green light. Though probably going to keep an eye on it every annual given the age. The turbo transition, where the different exhausts combine and where the TIT probe sits, is likely the most critical of the whole system. It can thin out and swell from chatting with Frank @ Chandler Aviation. Thanks again @M20Doc and @carusoam for the help.

-

Purchased new thimbles and washers for the EGT probe and its secured to the exhaust. Not sure how it got to the state it was in prior but glad its fixed!

-

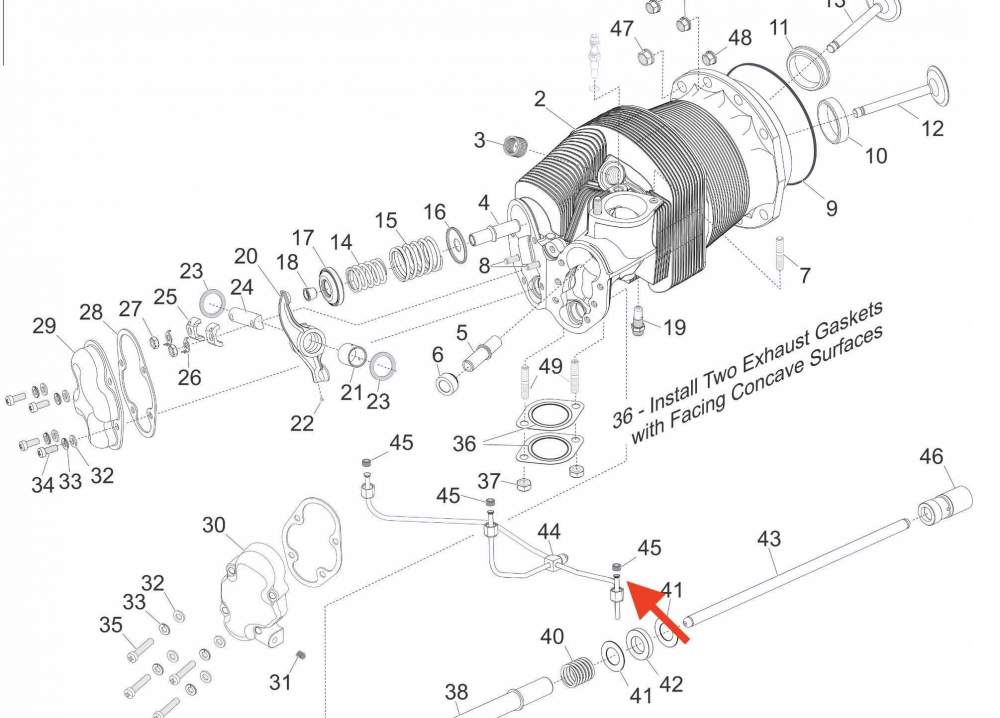

Thank you folks! It was exactly as you described @M20Doc. The seal sits below the flair and you push the flair end up into the head with the seal behind it. Tighten the nut up and everything stays firmly in place. @carusoam got all 6 replaced and nuts torqued to spec. While mucking with the cyl #1 drain, discovered my EGT1 clamp was loose and looks like I am missing the stainless steel clamp thimble piece; so a call to JPI is next. From their picture, you can see the washer and thimble (?) so should be easy to acquire. My A&P reviewed all of this btw.

-

Not hangared doesn't just mean dropping the purchase price by 5-10K. I am sure others will chime in here, but you need a really thorough pre-buy inspection. Corrosion can result in repair bills far higher than 10K. Sometimes, there no option but to junk the airplane. For hard landings, there's gear rigging, parts etc. But there's also the issue of stress those landings cause on the rest of the frame. Were the tanks sealed recently? If so, who did it? Are they reputable? Did the plane encounter prop strike b/c a student though they could force the plane down? If so, who did the repair work and what they did they replace? People / insurance companies can take the cheaper way out in these cases. Have you done a logbook inspection? Was the plane serviced by a reputable shop or a Mooney Service Center? Which one and how often? To save money, they have taken the cheaper road. These may sound discouraging but now is the time to be vigilant. Better to have walked away from the plane now than having a $70-$80K stone sitting in your hangar. Getting a "really" good deal has more or less always proven to be a bad deal in the long run.

-

Schools typically leave their planes outside - so question for the trainer a/c would be what kind of weather did have to sit in, if it was sitting outside.

-

My 6 new compression seals are coming in tomorrow. @M20Doc Thanks for clarifying. I think what you are saying makes sense now. With "Slip the new seal onto the tube", the flair end of the tube is pushed/pressed into the seal which is then locked in place when the nut is tightened to the male connector and compresses the seal. It's the seal's width that prevents the tube from falling through the nut. I have never seen something like this and thought it was like the rest of the flair style pipe fittings. With the new seal in hand, I am hoping it will make more sense.

-

Welcome aboard @Pierre07! Nice looking and shiny new bird!

-

Finally got to the hangar and took the nut off. I didn't find any aluminum sheared inside between the nut lip and the compression seal. However, the nut slides around the flair which doesn't seem like was the intended design. I imagine the flair at the tip of the aluminum drain tube should prevent the nut from sliding off the drain tube assembly - correct? Curious if there is a way to get this back into service without redoing the flair at the end of the tube end or replacing the whole drain tube assembly. Got high resolution and well lit pictures this time around.

-

Can you post a picture of the installation from the service manual? For my 252, ran into roller pins that connect the motor shaft to the arm and requires drift punches. So be sure to have the right tools ahead of time. Also, probably a good idea to replace the pins with new ones along with others perhaps on re-assembly.

-

Useful load increase from instrument removal?

shawnd replied to Tx_Aggie's topic in Modern Mooney Discussion

Nice - I will give this a shot to see if I can detect anything. If it needs to be replaced, I will be yanking this and putting in a newer computer that interfaces directly with the GTN-750. of course, later -

I am going to go back tomorrow and disconnect the nut and inspect it to see if the tube sheared and if there's a piece left in there. If so, need to create a new lip. Anyone know what tool I might need? I would need to check with the A&P if he has one, if not, probably have to buy one.

-

Dealing with oil leak, possibly from crankcase seam?

shawnd replied to DXB's topic in General Mooney Talk

Good catch and good luck! That’s scary indeed. I am trying to confirm oil leaks in my plane too. After your post, I am going to focus harder in the area near the mags. -

Congrats Brandon! And welcome to the forums and Seattle! Be sure to get out there and fly as much as possible because the weather right now, clear blue and 70s, doesn’t like to stick around for too long! I don’t know of very many Mooney specific owner/instructors in the area, but schools like Rainier Flight Services (KRNT), Galvin (KBFI), or Regal Air (KPAE) have great instructors who can help. Though Galvin has a Mooney M20J and instructors familiar with it. Dave C was my instructor who was great. Nicole, their chief instructor, is another Mooney fan and instructor who is awesome. Unfortunately haven’t flown with her. Where about are you located? And what do you need instruction with? Great looking plane, welcome again!

-

While my cowling motor is away getting overhauled and the cowling is off, I am taking the opportunity to familiarize myself with the TSIO360MB6B engine. And while browsing, I found the drain tube from cylinder #5 disconnected - not sure how. Is this concerning? Based on the service manual from TCM, an A&P should be able to put in a new compression seal (#45) and tighten and torque the nut to the male connector (#19)? The head of the drain tube looks intact as far as I can see.

-

Instrument Panel Switch Replacement

shawnd replied to Speed Merchant's topic in Modern Mooney Discussion

More coffee needed. Well at least if you need the switch covers - that path works -

Instrument Panel Switch Replacement

shawnd replied to Speed Merchant's topic in Modern Mooney Discussion

It's massively painful to find new replacement ones. This forum can also point to someone who 3D printed them, which is nice. Lasar may have some - giving them a call is best option. I recently had to replace my broken recog light switch. I went the label route and ended up being indistinguishable. Dymo LetraTag label maker + similar color rocker switches and magic. Cheap and easy! -

Useful load increase from instrument removal?

shawnd replied to Tx_Aggie's topic in Modern Mooney Discussion

Is there a way to bench test the strike finder on the ground? I imagine most folks don't run into lightning and thunderstorms and fly near it to see if its working. I have one installed as well and was thinking of pulling it along with ADF and Apollo GPS, but now I am second guessing.