squeaky.stow

Basic Member-

Posts

320 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by squeaky.stow

-

Is that an autopilot for an Aercoupe?

-

Hi Jim, So when you drilled out the rivets, were you able to just pop the eyeball vent out of the housing? In my case I drilled out the rivets but found that the vent was firmly glued into the black plastic housing. I couldn’t understand why Mooney would go to the trouble of gluing AND riveting them in place. My headliner had been removed and recovered in the past, so maybe someone did some work then, but there was no evidence of the vents having been cut out before. Cheers, Mark

-

I bought my Mooney with a very specific mission in mind. Non-stop 600 mile commute to our summer place on my precious few days off and the ability to reliably be back in the office on Monday morning. The 252 excelled at that mission better than I had ever hoped. TKS, turbo and XM weather make for awesome dispatch reliability. Now that I am retired it is harder to justify, but I find that putting on a sad pouty face and welling tears keeps the wife from pressing the issue too hard. For now.... Besides, you can never really “justify” owning an airplane. We do it because we love airplanes and would rather waste our money on them than on (insert your vice of choice here). If I ever have to move on, I am sad to say that my next Mooney won’t be a Mooney. More likely a Cub or Champ or a homebuilt. Something cheap to own and just for sunny evenings when the air is like glass.

-

The engine driven pump can’t pump until the engine is running. Priming is pretty much the only way we ever run the boost pump but it serves a useful secondary purpose to confirm that the electric pump still works. I went for several months with a failed low boost switch because I never turned it on, so I didn’t realize that the regulator had failed.

-

Good question. Maybe one of the engine experts will jump in here. Maybe TCM put a really robust engine driven fuel pump in the TSIO360 and they think failure is unlikely? It certainly puts out all the pressure you need for normal ops. If you turn on the boost pump in our airplanes when it isn’t needed it will run too rich and cause it to stumble.

-

Aircraft that require a fuel pressure gauge generally also require that the electric pump be turned on for certain phases of flight. On the J it must be on for takeoff and landing, thus the requirement for an operational pump for both VFR and IFR, and there is a POH requirement to check the pressure when you turn it off after takeoff, thus the requirement for an operating fuel pressure gauge. On the 252 we are never required to turn it on during normal operations so we have no fuel pressure gauge. It is interesting that we also have no list of required equipment of any sort in the POH even though Mooney did provide one in some older models. Even though we don’t require the pump for normal operations, it is required for emergency procedures. This is where @jlunseth ‘s point comes in. If you know your boost pump is not working and you don’t fix it because it’s not in any required equipment list, it might raise some embarrassing questions during an accident investigation if you lost power due to say, being late to switch tanks, and then were unable to restart a serviceable engine. I would fly VFR without my second alternator because I have an out (land), but having no vacuum system for a backup, I would not fly IFR. If I had a vacuum driven backup ADI, different story.

-

Is that you? You just won the cool contest! I mean you’re a 252 owner, so already cool. Soon to be an Encore, even cooler! But hang gliding a 10000 feet? You win. I resign.

-

I should add the @carusoam caveat that I am not an AME / A&P or avionics technician, so take my comments as worthless until confirmed by one of those. There are several really good ones on this forum so expect to hear from one soon. The Carusoam Caveat. Did I just coin a new phrase?

-

I have a K with KFC200 and the altitude hold keeps the selected altitude within 50 feet or better. From what you describe, I suspect you have a problem with your trim system. The jack screws are known to get stiff with age if not serviced, and eventually the electric trim motor will not be able to cut it. You should not hear the trim warning sonalert in flight unless the trim has failed, and with the electric trim off, you should be able to manually trim with very little effort on the trim wheel, so something is definitely wrong. I would start with the maintenance log and see when it was last serviced.

-

Thanks Paul. Sounds like I have a new project for my next annual. Living in San Diego, I am guessing you don’t see -20C that often, but did you notice a difference in the retraction when you replaced the spring? After 35 years, mine must be a little fatigued.

-

I think I will be holding off on updating my expired database update until I hear more. Fortunately I don't have to go anywhere. FWIW I have found that Garmin is pretty responsive with their customer service line for DB issues. At least twice I have accidentally bumped my laptop and lost the USB connection during the upload to my card, resulting in an error message that I had already downloaded the update and could not do it again. In both cases I was able to reach a real person at Garmin very quickly and they reset my download permission. If it is trashing the card, that's a much bigger problem. Please keep us posted on any resolutions.

-

I would be interested to know if anyone on this forum with vacuum brakes has tried changing the retraction spring and if so: 1) Did it make a difference? 2) Where did you source the part?

-

Yes. Unfortunately the vacuum operated speedbrakes do this all the time when they get cold soaked. Up here in the frozen north I try to avoid using them in the winter. It has nothing to do with icing. They are extended by the vacuum servo but retracted by just a spring. I think that the rubber bellows on the servo gets stiff in the cold and it impedes the retraction. In my experience they usually go down about half way, and then depending on how cold it is, they may (or may not) slowly creep down the rest of the way over a period of several minutes. I plan to try changing the spring at some point as it may have become weaker with age. Binding in the cables that run from the servo to the brakes has also been suggested as a possible culprit, but unless they both start binding by the same amount, that would cause them to retract asymmetrically. In my case the cables were fine. The good news is that if you do have to land with them partially deployed, you won’t notice a significant handling difference. The first time I used them in very cold weather (-20C) they stayed half deployed. A tiny bit more power was required on approach, but no change in landing attitude and the landing “feel” was unchanged. (Disclaimer: I am not advocating this as a technique, but I had no choice but to be a test pilot when they would not retract.)

-

If your company is not authorized (crew training is a requirement among other things) you are not supposed to log on and use it, but that doesn’t necessarily mean the system won’t let you log on if you have the equipment and it is operational. When CPDLC was still very new, my company got a couple of new 767s with satcom, ADS-C and CPDLC. We were not authorized to use it because we had not been trained and very few fins were equipped at that time, but one day over the Atlantic a bright young FO who had flown for another carrier overseas says “Watch this” and logged on to Gander Oceanic. We were immediately accepted. He logged off again pretty quick.

-

Shout-out to @Jim F He did it first and showed me how the Wemac vents actually work. That gave me the courage to try the DIY repair while the headliner was out. Once you make the first cut it’s too late to turn back!

-

Try logging on to KUSA next time you are flying one of the equipped fins. If it is not active you will get a rejection message.

-

I don’t know much about the Ovation. Is it possible that you can remove the vent assembly from the center of the headliner without taking out the headliner itself? If so that labor estimate would make sense. For my plane you had to remove the entire headliner, which was a lot more than 2 hours. Once I had it out, the vents were pretty easy to fix and even if I had bought new ones, I would still have had to cut the old ones out and glue the new ones in. It struck me as a poor design that there was no way to remove and service them without cutting things apart. Maybe they improved on that with newer models?

-

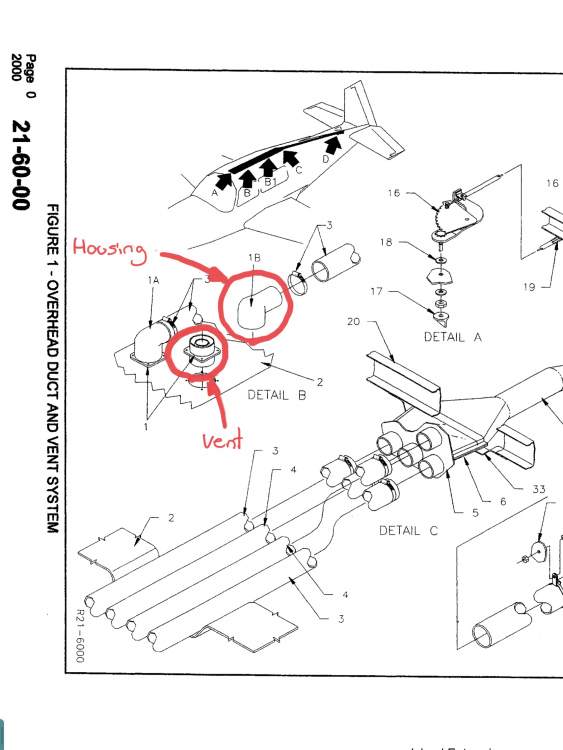

Hi Freddy, Are these the overhead air vents you are talking about? If so, I went through this recently with my 252. Older but similar. Repairing them is fairly easy, but getting access to them is a huge PITA. Let’s talk about the easy part first. The butterfly valve is opened and closed by turning the outer ring of the nozzle which turns a ring clip that has a u-shaped tab with a slot in it. A little rod attached to the butterfly valve sits in this slot in the tab and as the ring clip turns in the housing, the changing geometry opens or closes the butterfly valve. See first picture. There are actually two parts to the ring clip that both fit in a circular slot around the inside circumference of the housing. There is a spring clip that looks like a bent bicycle rim that keeps tension on the assembly, then the ring clip with the u shaped tab. Both sandwich into the little circular slot, but if the ring clip falls out then all the pieces just rattle around inside the vent. Once you get the vent out of the plastic housing it is very easy to reassemble and put a drop of Loctite on the ring clip to keep it secure. Now for the hard part. The vent assemblies are attached to the back side of your headliner and the metal Wemac valve is inside a black plastic housing. In my case I had the headliner out for an avionics upgrade so that was my opportunity. For the first one I cut the entire housing out of the headliner, only to discover that the metal valve is actually glued into the black housing so I still couldn’t get it out, and the offending ring clip is on the back side of the vent, inside that black housing. I actually had to cut the housing in half to get access to the back of the vent, but it was easy to glue it back on with plumbers ABS cement. For vents 2, 3 and 4 I left them in the headliner and just cut the black housing. There was no point in cutting them out of the headliner. In picture 3 you can see the vent with the housing cut open and the loose ring and spring clips. In the last picture the housing is glued back on. You can see the cut line. Your part numbers are different from the 252 so your valves and housings won’t be identical but they look very similar from the pictures in the IPC so I think your job should be similar. Regards, Mark

-

FWIW, I don’t see CPDLC coming to GA anytime soon in North America. Outside of Europe, CPDLC operates exclusively on the FANS (Future Air Navigation System) network which communicates via satellite. Since it is by definition, two way communication, and because the satellites are geostationary, you need expensive gear and a pretty big dish to be able to play. In Europe they can also provide CPDLC through the ground based ATN network which is VHF, so the cost of the equipment could theoretically be made affordable for GA. To my knowledge there are no plans to bring ATN to North America. WRT the PDC discussion, there are multiple different ways to deliver a PDC. CPDLC is just the newest way.

-

Cobra is printing Klixon covers. They won’t fit on an ETA switch.

-

It’s kind of ironic that the country that invented most of this technology is the last to adopt it. Frequency hand-offs via CPDLC are pretty standard in much of the world now for those with the equipment to use it, but if you fly from Toronto to London, you will get kicked off CPDLC as you enter Boston Center and have to log back on when you enter Moncton airspace. Other services like altitude and speed changes are also becoming more common in many parts of the world and are pretty much the standard in oceanic airspace. On the other hand, PDC clearances on the ground via CPDLC are so far the exclusive domain of the USA, so you are ahead on that front. PDC in all other countries is delivered via ACARS datalink and is just a text print-out of your clearance. The CPDLC version has the advantage that changes to your clearance ( a different SID for example) can be pushed directly to your FMC and all you have to do is accept or reject.

-

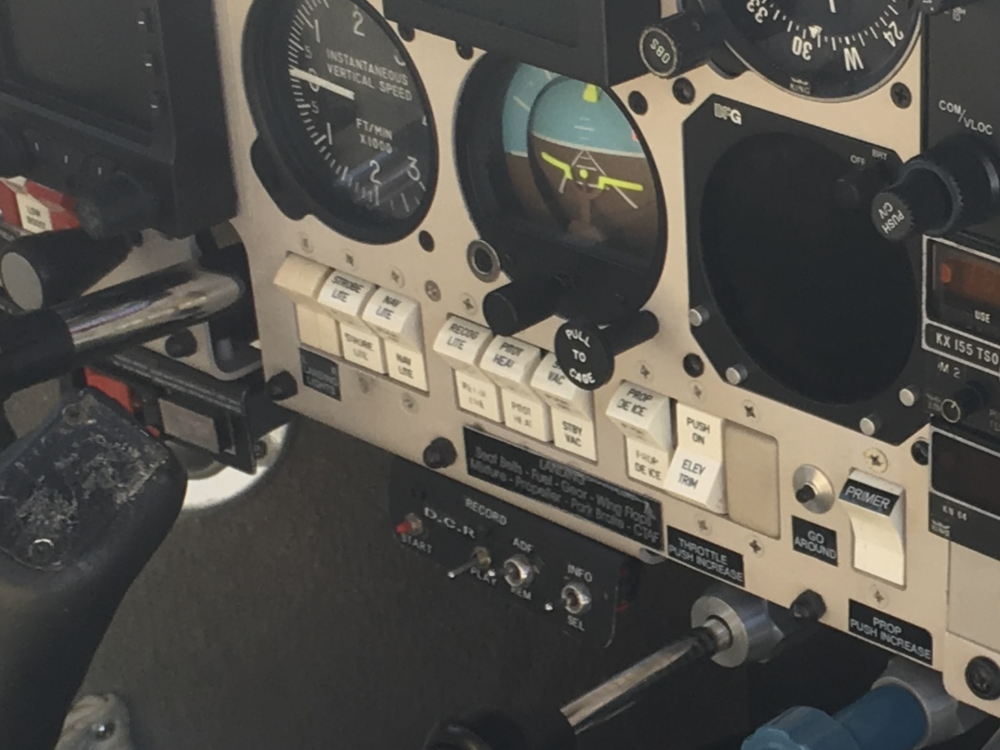

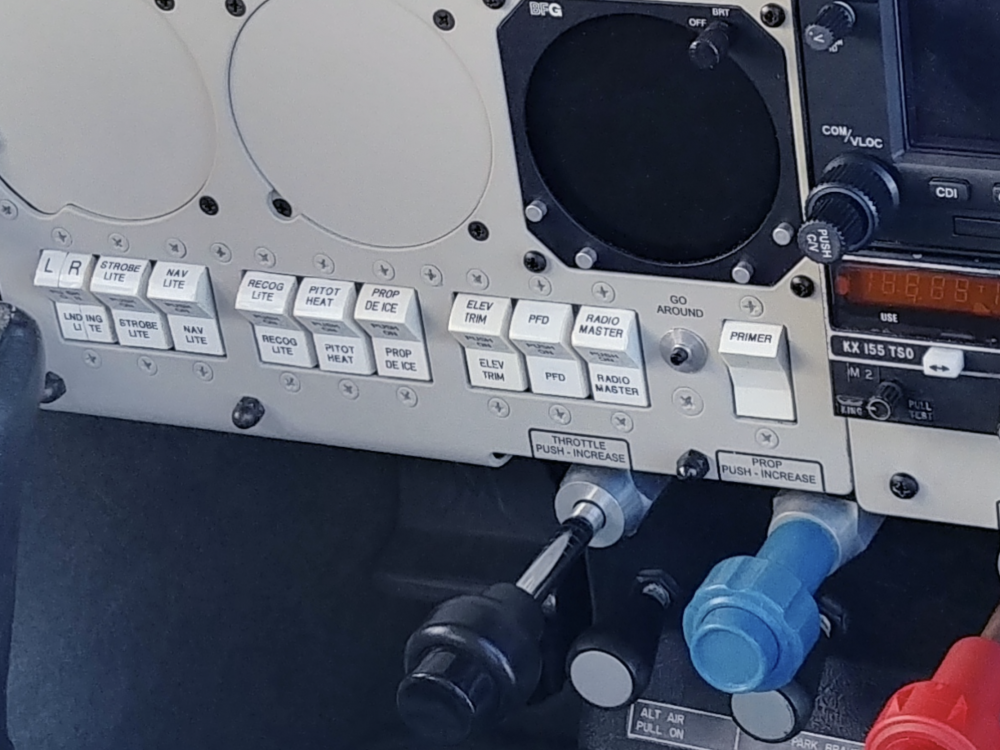

Those are ETA switches. No longer made or supported and really hard to find. The switch cover can be distinguished from the older Klixon switches by the fact that they have lettering on the curved top face of the switch cover - the part which becomes hidden when the switch is turned on. The Klixon covers don’t have that lettering on the curved part and they are a semi-transparent plastic rather than the opaque white. LASAR still has these on their website, but are sold out of all of them. I think I bought the last one they had. (Sorry) There is a vendor offering a 3D printed version here: https://www.shapeways.com/product/YR7FSMMJW/mooney-rocker-switch-cover-quot-eta-quot-type I have not tried them and have seen mixed reviews here on Mooneyspace. They certainly won’t be a perfect match. One option if you can find used covers is that they are easy to re-label with a Dymo label printer. The white tape colour is almost a perfect match and the font can be matched perfectly. I was able to find a used ETA switch of the correct amperage here on Mooneyspace after a long search and I relabelled the cover to suit. See before and after pictures below. As a really expensive last-ditch option, you could buy an entire switch of the right amperage from Lasar and relabel it, but that’s a pretty pricey way to repair a cheap plastic part. Your best bet is the used market and plenty of patience. Good luck.

-

Bump

-

RAM Alternative for iPad Yoke Mount

squeaky.stow replied to PeteMc's topic in Avionics/Panel Discussion

@PeteMc This may be a stupid question so feel free to disregard it but how confident are you in your Ram supplier? The reason I ask is that I have bought Ram EZ Roller cradles in the past that turned out to be the incorrect part number. The AIR 3 and 4 are almost identical in size but with a slightly different corner shape, which makes me wonder if someone sent you the wrong cradle. I had one that I had to force the iPad into and found that it was the wrong part number even though I specified the correct model of iPad. I have an Air 3 and a Mini 4 and have used both with the EZ Roller. After playing with both in the plane I have settled on the Air 3 due to the larger screen. The Mini stays in the flight bag as a backup. I had to use two swivel arms to get the larger Air 3 to sit comfortably between the yoke handles without obscuring any instruments. The picture is the Mini. The Air sits flatter with the assistance of an additional short swivel arm. -

You realize that asking a bunch of Mooney fanatics if you should buy a Mooney is a pretty rhetorical question, right? Of course you should! But seriously, Mooneys excel at going a long way in a short time on relatively little fuel. If that is your priority, it is a great airplane. If you want a big spacious cabin and large payloads you should probably look elsewhere. At the very least, have your wife sit in one before you decide. The more you spend, the greater the weather dispatch reliability. My 252 can climb over most weather and has de-icing and XM weather but it is not “known icing” certified. I once was planning a trip across the UP from Ontario to Minnesota in the winter and had to wait for a week to find a weather window without icing. If you can’t afford to sit and wait out a weather system, you need an expensive Mooney. If you don’t mind waiting it out, any Mooney will suit this mission. One thing you can count on is getting lots of useful information on this forum. Good on you for joining before you purchase. I lurked around here for several years before I bought my 252 and I am sure it saved me from several bad decisions. Good luck with the adventure! Mark