-

Posts

699 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by wombat

-

I got my pitch trim motor back from Autopilots Central. They said that what they did (replace a couple of resistors and remove some capacitors) shouldn't have made a difference. But I plugged it in, powered on, and the electric trim worked and the autopilot passed the self-test. Super exciting. So I flipped the power off and back on, and... It failed again. Can't get it to work again. I've heard that the autopilot disconnect switch will sometimes test good with a multimeter, but fail to actually carry load, so I used short jumper wires (14 gauge) to connect both of the the connections that go through the autopilot disconnect. There was no change, unfortunately. I'm taking the plane to an avionics shop on Tuesday and they said that if I get it there in the morning they can test out all of the autopilot wiring during the day while I wait. Since there was the single success, this makes me suspect something in the autopilot itself. So I expect I'll be sending that off in the near future.

-

Got the cash, but prefer to finance, where?

wombat replied to SilentT's topic in General Mooney Talk

<Joke mode on> Maybe he just knows how to invest better than you and can achieve investment returns that beat current rates easily? -

I'm really glad you found a cause for your #5 temp being crazy. Is all of the rest of the stuff fixed? Lighting, ASI, autopilot, etc? I'm still fixing my Rocket after my most recent annual. The pitch trim servo is on its way to an autopilot shop for IRAN.

-

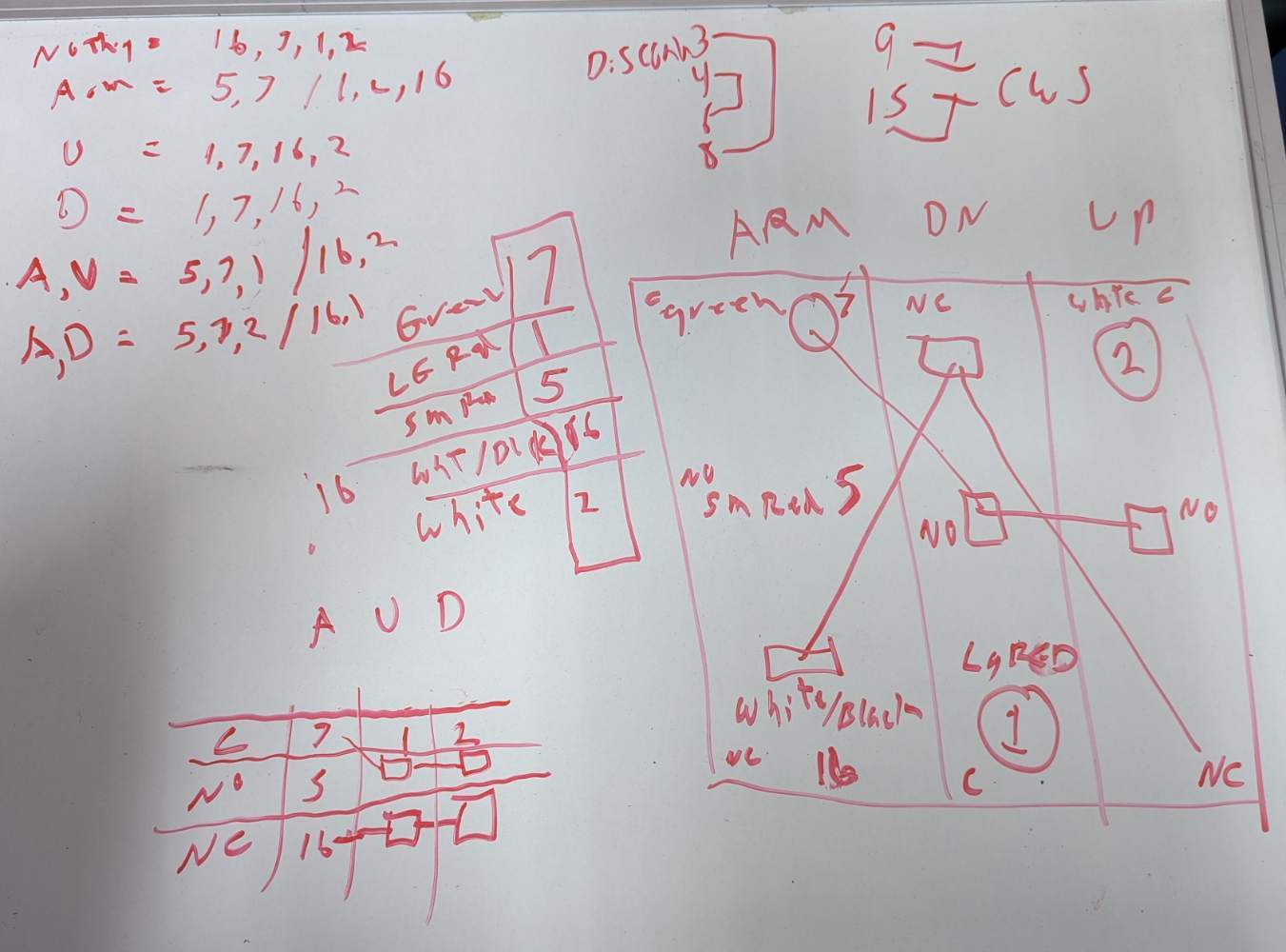

Well, after going back and double-checking things, I think everything in the yoke is good. My actual wiring is almost exactly like @0TreeLemur's is. I think the next thing is to see if I can find somewhere to bench test the KC192, since that's the easiest to remove. (One static air source and one small hex from the front panel then it slides right out.) Or maybe there is a way to get more diagnostic info than "Beeping forever because something isn't right" My notes from in the cockpit as I was looking and testing today, and the barrel connector the wires go to, with the numbers for the pin on them. Kind of a hassle, but if I had just looked at the wire colors and this *first* I would have saved myself 8 to 16 hours of frustration.

-

I took a much closer look at the wiring diagrams and the wiring on the switches. It does seem to be wired correctly, which is not shocking because it worked this way when I bought it. All of the switches operate normally(*) when measured with an ohm meter back at the disconnect point behind the panel. I've checked the CWS (Normally open, closes when I press it) Autopilot disconnect (two connections that are normally closed, and open when pressed) and the autopilot arm is normally open between 8&9, closes when I press it. Up and Down are normally open to 8 but connect it when pressed. (*) Upon further thought, I neglected to check both poles of all switches, I just checked one of each when compared to the common (Green, line 8). So there is still a chance this is something I can fix on my own! The CWS and Autopilot Disconnect are fully correct though. But the three micro-switches for up, down, and arm might still be experiencing a failure. Thinking about it, the way I described it, (up and down normally open to 8) would indicate a faulty 'arm' switch state.... They should be normally closed to 8 unless 'arm' is pressed, at which point the should be open to 8 unless Arm is pressed, in which case they should be closed to 8 AND 9. Hmmmm... This might be the problem. @0TreeLemurThat's what I thought at first, but if you look at the codes NC (Normally Closed) and C (Common) on the diagram, they have two switches one way and one of the ends the other way around. Mine is physically set up so that both ends are the same and the middle one is reversed. It ends up doing the same thing and you can install them in any setup as long as the two on the "up" and "down" switch are not the same. While I'm not actually happy with the wiring that's been done here, it was obviously working fine for a while. If there is a problem, it lies within one of the honewell switches. I've never done the autopilot test without the engine running, so I am not aware of any noises it makes. Bad on me.

-

So... The soonest anyone local can look at the plane is the end of March. So I've been doing a bit more troubleshooting, and the switches I've checked in the yoke are all good, by matching wire colors and looking at the diagram, I was able to test the CWS, autopilot disconnect (closed on both pairs of wires), pressing the switch opens them, and the autopilot arm and the trim up and trim down switches. I think maybe the next thing is either check at the servo, or try to bench test the autopilot.

-

Some clarifications/corrections: You *can* take pictures of people's license plates and keep them in a database as long as you want. You are even free to sell access to it if you want. There are some restrictions on what government entities can do in this regard, but those restrictions are for the government and not for you as a citizen or resident. A raspberry Pi is a single board computer, or SBC. It's just a small computer. The most common version is a little smaller than the palm of your hand. Not very fast or capable compared to modern PCs but perfectly capable of quite a lot of interesting things. You can plug cameras into them, or software defined radio receivers. Or both. There is pre-built software to use these radios to listen to ADS-B transmissions and forward that data on to sites like flightaware or flightradar24 or others. They make it quite easy to set up. You can also get other software for the computer and radios that will forward that data to ForeFlight in your cockpit. It's called stratux and it is just an easy and cheap ADS-B in system. The name is a play on "stratus" and it works basically just like a stratus device. I've assembled about a dozen of these devices, of which 5 are running with cameras, 3 are running with software defined radios listening to ADS-B and forwarding to FlightAware, 3 are in airplanes forwarding to ForeFlight (Well, two of them I've given away so I don't know if they are still in those planes), and one is also running my small alfalfa field's sprinkler system with some add-on hardware called OpenSprinkler. I'm happy to talk anyone through exactly what to buy and how to assemble it and configure it so they can run a FlightAware station too. It does give you access to the paid tier of FlightAware so you can see more history and stuff, which is nice. Regarding Van Eck phreaking... Yeah, that's true... But also, you can do something similar to LCDs. If things are lined up.. Just have it facing an open window, and set up a telescope 2 miles away. When you put it like that, it doesn't sound so crazy, but it's an example "receive the emissions from the CRT and reconstruct the image on the screen". And it doesn't even have to be a CRT. You can also do it with LCDs not using visible light. Also, if listen really close, the sound of each key on the keyboard is different, and you can just set up a microphone and tell what people are typing. All sorts of interesting stuff! Regarding Blue Force Tracker (BFT). Yes, it's technically possible some person or organization that is hostile to US Forces could get access to that data, but..... The level of difficulty in getting access to that data at all is above what any organization in the world (including China and Russia) can do and even if they had access, getting it to a person or group that could take action based on that data in a timely way is also beyond what any organization could do. Heck, the US Military could barely make use of it, and it's ours and integrated into our systems! I'll admit that the last time I used that was about 10 years ago, but it was barely useful just because of the delays and frequency of system malfunctions and stuff just dropping out of the network. But watching trains of smurf turds marching across Iraq was fun. It would be WAY easier and cheaper and more effective for any hostile force to station a bunch of people to watch along where they expected US Military to go and report in on some in-house made iPad app. Until we completely stop broadcasting our location by producing sound and being visible, BFT isn't going to be the way someone finds our locations. Edit: Adding some links to the things I mentioned: https://opensprinkler.com/product/opensprinkler-pi/ https://www.flightaware.com/adsb/piaware/ https://stratux.me/ https://www.raspberrypi.com/ https://www.raspberrypi.com/products/raspberry-pi-high-quality-camera/ https://www.amazon.com/RTL-SDR-Blog-RTL2832U-Software-Defined/dp/B0BMKZCKTF

-

Well, I'm giving up. Time to call for help. My inability to get more slack in the wires was a total killer. I suspect if I took the yoke off the push-pull tube I'd be able to get slack, but..... I've thought "If only I take this one more thing apart" for every step of the way. If I can't get anyone to look at it in the next week or two, I'll probably go through each wire on the yoke harness, identify what it's connected to, so I can determine the expected state (open/closed) from every other wire and then I can test at the harness disconnect. But this is also totally assuming the problem is in the yoke. Well, there is at least one problem in the yoke NOW though. Everything is back together nearly as good as when I started looking, except one of the wires on the electric trim switch is now disconnected. I still have three new micro switches on order.

-

I would love to, but do you know where might I find the disconnect relay? Are you talking about the autopilot disconnect switch on the yoke? I'm super frustrated with all of this, might just take it to a shop and pay my AMUs to get it working. The plane's been down since November.

-

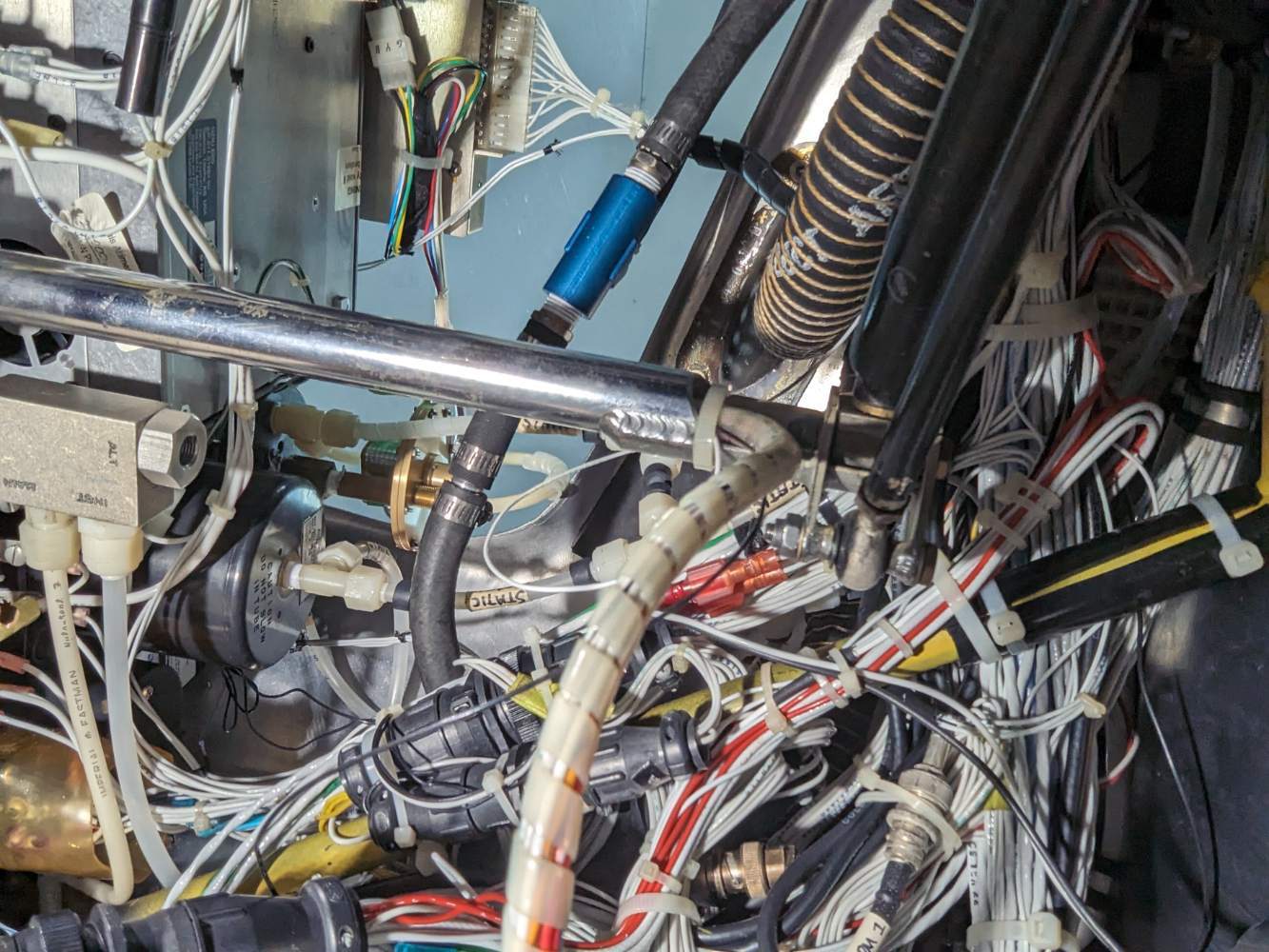

Thanks for all the input. I did find this diagram of the yoke wiring from the KAP 150 install manual. @Fly Boomer Despite the many other wiring problems the plane might have, the wiring coming out of the yoke look really good. The two lone wires not in the wrap are the new ones they hooked up recently. Everything else is tidy and looks great. @MikeOH I don't have a separate trim breaker, just the autopilot breaker. And it's providing power to both the trim switch and the autopilot itself successfully. But maybe somewhere else there is a wire disconnected. Yeah, that red wire is barely hanging on. Everything is covered in silicone, the person that was in there last really gooped it up. If I end up needing to do any soldering, I'm replacing all three switches. They are Honeywell 1sx74-t SPDT switches, and be had for $38 to $48 (Mouser Vs. Digikey) I actually just went ahead and bought three of those switches to replace these three.

-

I have opened up the electric trim switch in the yoke. It's not wired anything like I was expecting. It looks like I've got a whole bunch of stuff wired together there that shouldn't be that way, according to the diagram from this other thread:

-

Thanks for the advice. I had been assuming that if the electric trim actuator switch was disconnected the autopilot self-test would still work, but apparently not. I'll investigate this part more. @Fly Boomer I'm confused about why you say 'since it was on the opposite horn of the yoke, I suspect the wiring from the thumb switch.' Since it's on the opposite horn, I'd tend to NOT suspect the thumb switch, since there was never any need to mess with the wires in that horn. Getting the wires through the yoke to get the thumb switch out is going to be a huge pain. I can't get any of those wires to move at all.

-

Got the plane back from annual, and the electric trim no longer works. The switch for electric trim is getting 14V, and when switched 'on' it has 14V on the downstream side too. (i.e. that switch is working properly) The autopilot self-test fails. The electric trim on the yoke fails to do anything. There is also no additional draw on the electrical system, so I don't suspect it's a problem with the servo. The manual trim wheel works fine. There was some minor work done behind the panel during this annual; adding two wires to the Garmin GPS and routing them to a new button on the yoke, as well as removing and re-installing the engine monitor and a slide-out/slide-in replacement of the GPS. I expect this activity dislodged some wire or connector behind the panel. The wire added to the yoke was on the right hand side, opposite the electric trim and AP disconnect and CWS buttons, so I expect those remained undisturbed. Any ideas on what I can look for before I just take it to a shop and start paying for someone to figure it out?

-

Tight Landings, Take Offs, and Close Calls!

wombat replied to Tim-37419's topic in General Mooney Talk

That first plane looks like Bryan Painter's plane. Don't know if he still owns it. Update: He doesn't, but I don't know when that video was from. I'm pretty sure he painted it (haha) so this would have to be after he bought it. But he was very much into doing this sort of thing, so I would be not at all surprised if he's the one that was flying it for this video. Survey (and FAA) says no: https://www.flightaware.com/resources/registration/N5842Q Date Owner Location 24-Jun-2019 BRADFORD MICHAEL SAN JOSE CA 28-Mar-2019 TAYLOR GAIL L RED BLUFF CA 14-Mar-2018 CARTER TERRANCE B SACRAMENTO CA 14-Feb-2018 PAINTER BRYAN J RENTON WA 07-Nov-2014 PAINTER BRYAN J AUBURN WA 10-Feb-2012 PAINTER BRYAN J FAIRFIELD CA 25-Jul-2008 PAINTER BRYAN J TACOMA WA 18-Jul-2008 REGISTRATION PENDING TACOMA WA 02-Jun-2006 ORR RONALD L BRYAN TX -

Want a Mooney M20 but no hangars available.

wombat replied to thevaliant's topic in General Mooney Talk

I recommend getting the plane whenever you want. They are airplanes, not marshmallow peeps. They won't melt in the rain or the heat. Sure, it's less good to leave them out, but you still have a plane you can fly, even if it sits outside. -

Sorry to hear about your fuel tank problems. I took my Rocket with Monroy long-range tanks to Wetwingologists last summer to have all of them resealed. He was on time and on budget. It's only been 6 months, but no leaks yet.

-

It's interesting how the climate that people live in seems to determine what they consider to be "too cold". My Midwest friends don't do anything special if it's above freezing. My Northern Midwest friends will preheat if it's below 10F, but still fly. My California friends will preheat below 60F, and won't even try to fly if it's below 40F because it's too cold and will 'damage' the plane regardless of preheat. Continental's recommendation (for a TSIO-520-BE) is to preheat for 30+ minutes if the engine has been below 20F for 2+ hours. But they also have procedures for starting if you do not preheat below 20F. For good engine longevity, follow the manufacturer's recommendations with a little extra leeway. (Don't run quite so hot, don't start it quite so cold.) For best engine longevity, submerge the engine in oil and never run it.

-

New Flying Club Forming at Auburn, WA S50

wombat replied to Steve Hughes's topic in Miscellaneous Aviation Talk

I had some extensive discussions with my insurance agent last year. For 1 to 5 people, from an insurance perspective it's just a co-ownership situation, regardless of how you have formed the group's finances. For 6 to 9 people, it's a 'club' and the rates are roughly 2X the rates for co-ownerships. For 10+ people, it's a 'rental' and rates are roughly 4X that for co-ownerships. This does not mean you can rent it, but that the rates are similar to what they would be if it was a rental aircraft. -

I've found that I can 'trim' the plane slightly by moving my body forward or back in the cabin. Even leaning forward or back can have an effect I can see. If the autopilot is on and in altitude hold mode it'll correct for it, but movement within the cabin can cause slight pitch and roll of the aircraft.

-

The only time I wish I had thinner shoes is when I'm providing instruction to PPL students or new tailwheel pilots. In those cases I want to feel what they are doing on the rudder without putting enough pressure on that they might feel what I'm doing which could cause them to change their behavior or think I'm trying to take over.

-

My typical rocket weight in flight is about 3,000#

-

Then my 75% LOP power fuel flow is 16.697 GPH. The ROP numbers in the POH for 75% power are for 20 to 21 GPH. Quite a difference.

-

Please don't mis-understand my position here. I'm not planning on taking any blanket statements and going out and operating my engine this way. I am gaining academic knowledge which I can perhaps use in a thoughtful manner to expand my engine operations envelope. But in the continuation of this pursuit.... If we take 305 HP as my 'max', and then anything less than 228.5 HP is < 75%. So 228.75 HP / 14.9 gives me 15.39 GPH; therefore any time I'm at 15.39, if I can get the engine to run smooth (and the temperatures to be OK, and the MAP & RPM combo is OK) then I'm not hurting the engine, regardless of what position. the levers are in. @Fly Boomer Continental says 470 is OK. Nobody here seems to believe it, and I'm not getting anywhere near that temperature on my engine. But that's why I picked 390 as an "OK" temperature.

-

Looking for PIREP on Wet-Wingologist East

wombat replied to FLYFST's topic in Modern Mooney Discussion

I had Edison at Wet Wingologists seal my tanks (4 tanks total, since I have the long-range Monroy tanks) in June of 2023. No leaks so far. He was accurate in terms of budget and time. I'm a satisfied customer.