-

Posts

12,197 -

Joined

-

Last visited

-

Days Won

170

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Shadrach

-

Please report back on your experiences.

-

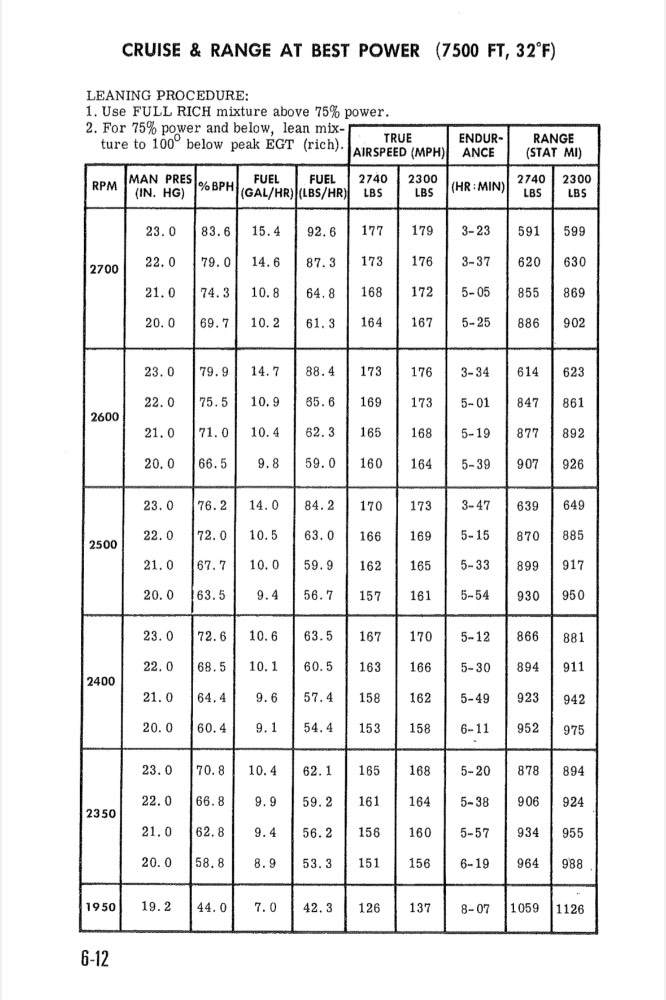

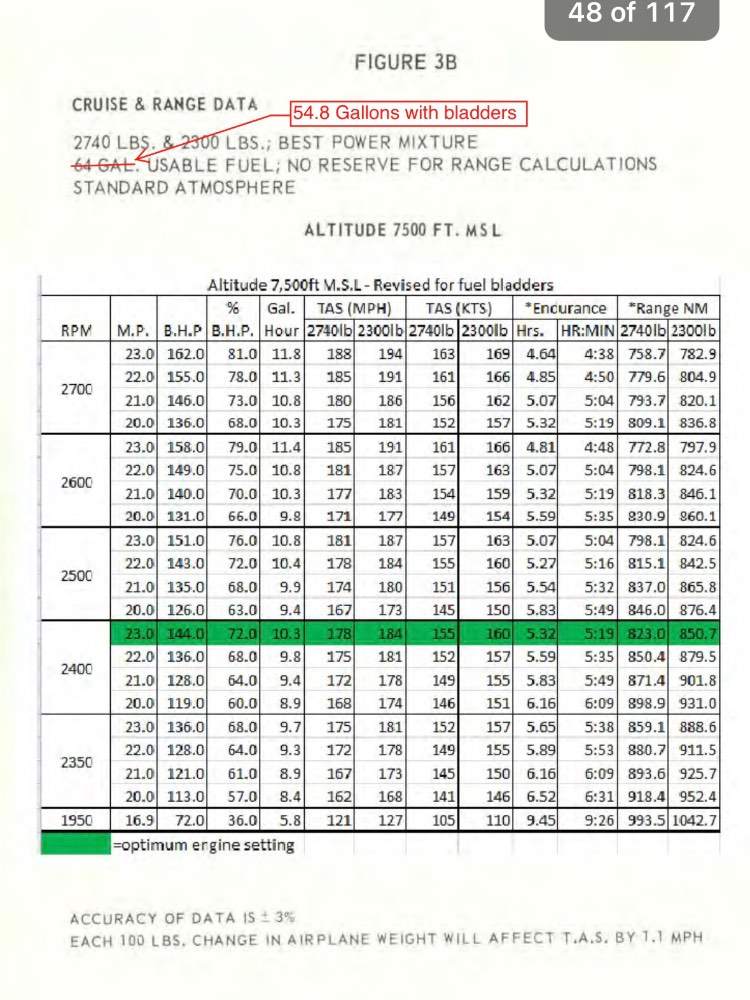

The early poh’s were optimistic. Someone gave the factory a dose of truth serum in 1968. 1967 AFM cruise numbers for M20F at 7500’ 1968 AFM cruise numbers for M20F at 7500’

-

I am very comfortable with falling leaf stalls in my F in the clean configuration. I’ve held full aft elevator for over 1000” of descent with minor rudder inputs to keep roll deviations less than 20°. However, things are quite a bit more dramatic with the gear and flaps down.

-

I’m still t to hung to figure out why your mission warrants a turbo?

-

At 2200lbs, you should definitely be 150kts or more leaned for best power at 7500’.

-

Scott, Those are really good numbers. I am not trying to pee in your cheerios here but some Aspen installations have the propensity to overstate OAT which in turn can inflate calculated TAS. Have you crosschecked the primary thermometer with the Aspens OAT reading? A 3 way GPS speed run on a smooth day is the closest we can get to determining actual speed.

-

Perhaps I am misunderstanding the situation, but it seems to me that once returned to LASAR, the parts are rapidly turned around for shipment back to the owner. It would be nice to have some transparency on the issue.

-

Years ago I bought a few NOS 10A Klixon switches from an eBay seller. He must have bought a large lot of them because he had over 50 in stock. Several years later my 10A boost pump Klixon switch developed an “auto shut off” after a few minutes in operation. There was no PMA stamp on the original switch nor was there a stamp on the NOS switch. Just the manufacturer and PN. An IA friend told me the NOS switch was a paper weight without an 8130. I decided to take a text poll of some of the IAs in my contact list (5 IIRC). The majority of the participants (which included an FAA PMI) understood that the switch could be ops checked, installed and the aircraft returned to service. What was surprising was that 2 working IAs believed that a perfectly good, NOS part was a paperweight because traceability and airworthiness was dependent on form 8130.

-

My assumption that this is an FAA issue is just that, an assumption. However, If it is indeed the case, I’m curious why they needed to inspect every part rather than a sample from the batch. If the parts are defective, then by all means, recall all of the parts and issue refunds or offer replacements inside a specified time frame. If the parts are not defective and no physical changes/modifications are being made before returning said parts to the customer, then this looks like a bureaucratic goat rope to me…

-

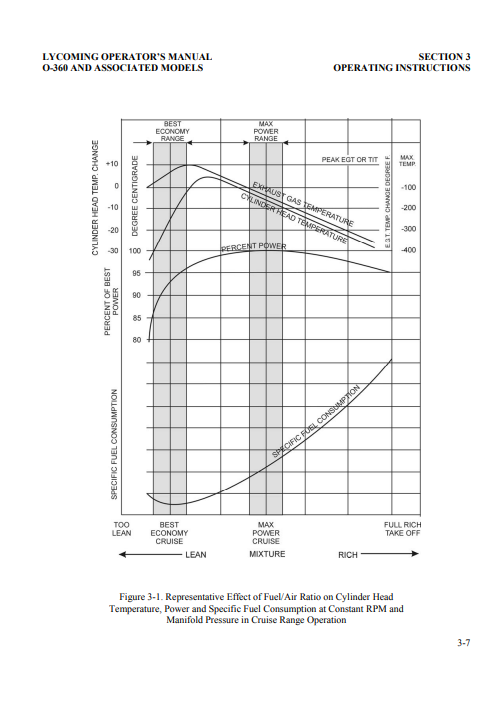

When running LOP, I choose the mixture setting that is as close to peak as possible that yields healthy CHTs taking into consideration the OAT. As I get higher, that setting gets closer and closer to peak EGT. At DAs of 10K or more I run 100ROP. in most cases, I am shooting for maximum speed per unit of fuel. At a given manifold pressure and RPM, the intersection of best speed and fuel burn is peak EGT. It is near best BSFC and before significant power loss, but well after peak CHT. It’s not ideal, but it’s a close to ideal as there is for NA operations.

-

Best Sealants for Fuel Access Panel Screws?

Shadrach replied to MrRodgers's topic in General Mooney Talk

I seal off the fuel pick up and tow it to the wash rack for a thorough flush. I think that when sealant fragments are found in a gascolator screen it is often from an old repair that was not thoroughly flushed. -

Probably more at full rich if factoring in temperatures that accompany such conditions. I only mention it as an example of my comfort running LOP at high power. On other hand, there are very few scenario where I would choose LOP above 5000’ DAs

-

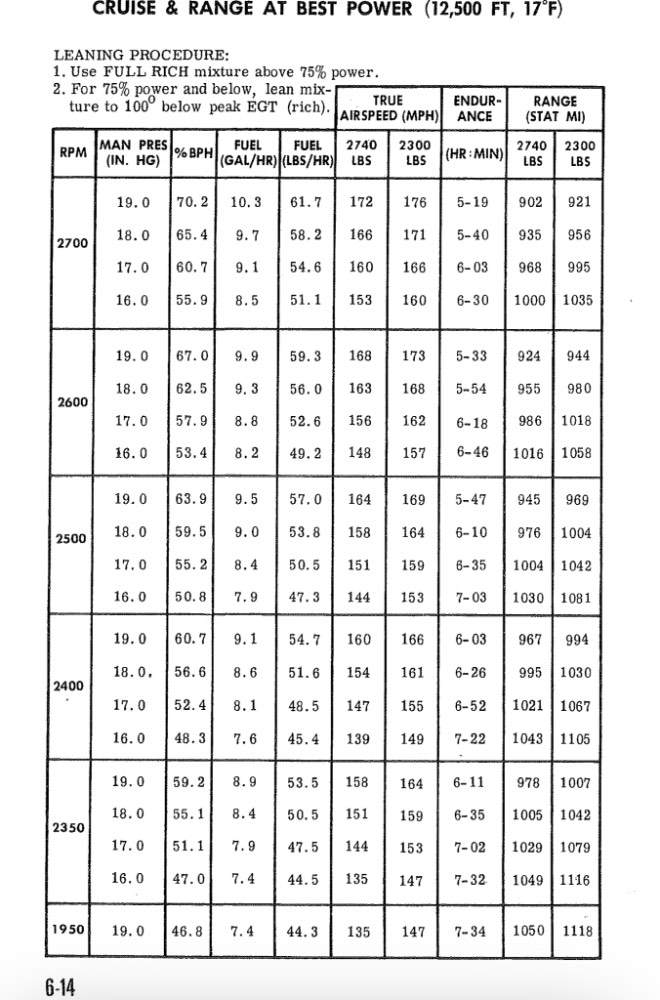

No question that a turbo affords you choices that NA operators don’t have. Whether those choices are worth the cost, heat and weight depends on the mission. I think you may be underestimating how well the NA birds do below Oxygen altitudes. My plane is vey useable up to 12’500msl even in the months where the DA might be in the mid teens. I’m not concerned with mixture setting up high, only available power and fuel burn. Does it make book numbers? Close enough.

-

Instrument Approach Gear and Flap Sequence - A survey

Shadrach replied to midlifeflyer's topic in General Mooney Talk

Do you have a prohibited RPM range? -

I don’t have reliable data yet. I am in the process of fine tuning my totalizer. I would guess low 11 to high 10gph range depending on temp and pressure.

-

The breakfast burritos at the Jolly Kone in Bridgeport are worth the wait time and the payload they displace…

-

Ram air Open. I have logged many hours at 2500msl WOTRAO in the winter when the DA at that altitude is about -500MSL. 30”inhg, 2500rpm and 40LOP on richest cylinder 157KIAS (which corrects to about 155).

-

Frictional loss questions are above my pay grade which is why I asked George about it. I am comfortable running my IO360 LOP at at max achievable manifold pressure any altitude. I frequently fly at sub sea level DAs in winter time @2500rpm WOT RAO. I simply not WOT, full rich CHTs and shoot for slightly more conservative numbers on the lean side.

-

Major versus minor alteration; voltage regulator

Shadrach replied to Jetrn's topic in Modern Mooney Discussion

The same mechanism that took the Soviets to “We pretend to work and they pretend to pay us”… -

Well, next time just say 65% so it does not trigger the crowd that thinks “you loose a lot of speed cruising at 65% LOP compared to 65% ROP”…

-

Best Sealants for Fuel Access Panel Screws?

Shadrach replied to MrRodgers's topic in General Mooney Talk

FYI - Less is more regarding soapy water. It need not look “milky”. Just capable of suds. -

Major versus minor alteration; voltage regulator

Shadrach replied to Jetrn's topic in Modern Mooney Discussion

I don’t see how you get bitten by reading the words as they’re written. Interpreting this as a major alteration would require ignoring the regulation as it is written. I have seen an odd culture within the DOD industry. I heard the term “courtesy 337“ used by a chief maintenance inspector on several occasions. One was specifically regarding the removal of carpeting from a King Air. My response is how is that a major alteration and how is it a “courtesy”. His response was the ASI at the FSDO appreciated the documentation. I understand that it’s important to maintain the relationship with the FSDO, but absurd is absurd -

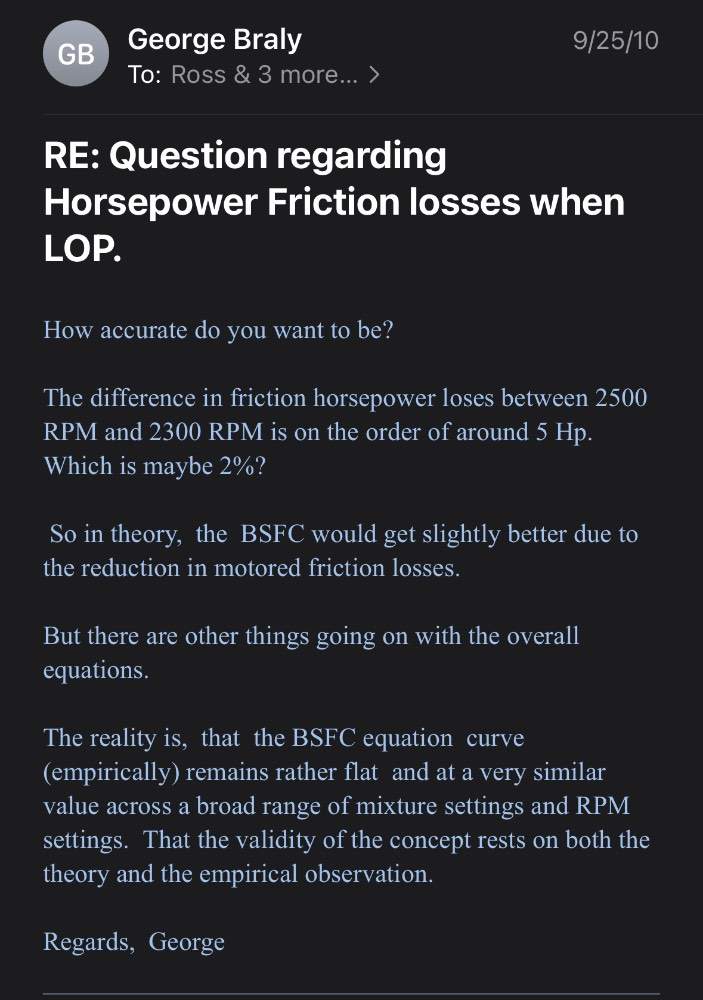

More or less. There are marginal differences with RPM changes. Friction losses affect power output. Is it a lot? No. I asked our favorite “Attorney/Salesman” about it back in 2010 and he had this to say:

-

Major versus minor alteration; voltage regulator

Shadrach replied to Jetrn's topic in Modern Mooney Discussion

Suggesting that a there is a strict interpretation of the definition as written that make this a major alteration is a mistake. Words mean things. Major alteration means an alteration not listed in the aircraft, aircraft engine, or propeller specifications— (1) That might appreciably affect weight, balance, structural strength, performance, powerplant operation, flight characteristics, or other qualities affecting airworthiness; or (2) That is not done according to accepted practices or cannot be done by elementary operations. So, does it meet any of the criteria in (1)? W&B - No Structural Strength - No Performance - No Powerplant operation - No flight characteristics - No Other qualities affecting airworthiness - Well this is the catch all, but I would say a good test of whether it affect airworthiness is whether or not It affects the physical operation of the aircraft in an measurable way. In other words, are there operational parameters in which the replacement VR would operate differently than the original? If the answer is no, it’s very hard to make the case that it affects airworthiness. As far as (2) goes, I’m assuming you wouldn’t even be considering the installation if you weren’t able to do so in accordance with practices acceptable to the administrator. So what we have here in essence is a reading of the actual reg versus an interpretation that is not at all commensurate with the actual definition codified in the regulations by the FAA. People have to stop playing this game. We have a responsibility to ensure that regulations are interpreted as they are written. -

1080lbs useful? It might be the most expensive pre-J model, but it is also likely in the top ten if not top five of all Mooneys for real world load hauling. Properly planned, that bird will take four 175lb adults and 100lbs of baggage ~600nm and land with VFR reserves. It is nearly a perfect family plane.