outermarker

Supporter-

Posts

251 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by outermarker

-

The issue with a push to start, is that you won't hear the SOS before starter engagement.

-

Earlier this year, I replaced the main gear tires with Goodyear Flight Custom III. This tire provided 10 years and 100's of hours of worry-free service. The inner tubes were from a vendor I couldn't find anymore, so I purchased Aero Classics Butyl Leakguard tubes because they were the only inner tubes with a 70 degree bent stem. The valve stem doesn't touch anything, including the dust cover. And yes, I cried when I wrote the check.

-

Something I noticed as I reinstalled the seats on the seat tracks with the new rollers. The distance from the roller surface, and seat track is very close. I measured the diameter of the original roller and the roller I bought, and they were the same. However, it won't take much wear before there is metal-to-metal contact when trying to slide the seat. I would suggest a harder material to use as a roller, such as the same hardness as the original roller.

-

Smirking here...the question was if anyone has used mouse milk to remove the fuel stain. "I saw on a previous post that someone had great success using mouse milk to remove a gas stains. Not sure if the details but has anyone used it with any success? I’ve read all the threads on out other suggestions to remove stains, but it seems like limited success with everything else." So, to answer the question, I have not used mouse milk to remove the fuel dye stain. However, I have also removed the stain by using fuel on a cloth. The dye transfers to the cloth easily, without much rubbing effort.

-

PC Wing Leveler help needed

outermarker replied to MarquezJC's topic in Vintage Mooneys (pre-J models)

During a taxi, as you make a turn, the yoke should move in the opposite direction (it's trying to correct). If the yoke doesn't move, or if the yoke moves in the same direction, you have a leak. The rudder servos are the easiest to check. The aileron servos are a bear to get a wrench on... unless you do what Don Maxwell does, which is to drill a small hole in the aileron where the servo attaches, just large enough to get the socket through to secure the servo. I took out all the servos and inspected for pinholes or bad tape. This is easy to do. put a hose on the end of the servo. Put the servo in water and apply a slight positive pressure. This could be done by blowing into the tube. This will expand the rubber boot to expose all leaks. Fixing pinholes or small tears are covered in a Brittian guide. Realize that when the servo is put back into service, it is operating under vacuum, meaning that the rubber will be against the metal can, which can hide small leaks. That is why I tested with positive pressure under water. Using the proper tape is important too. -

Engine won't start when hot...

outermarker replied to rwabdu's topic in Vintage Mooneys (pre-J models)

Should that be? I would think you would prime few seconds then turn off the fuel pump. An 1/8" "cracked" throttle yields about 1000 rpm when the engine is running. Anything more than an 1/8" open could cause a flooded condition and really make it difficult to start before the battery drains. What does the manual suggest for hot starts? Difficulty in starting could also be caused by the engine timing being off a touch. -

Engine won't start when hot...

outermarker replied to rwabdu's topic in Vintage Mooneys (pre-J models)

What is the whining noise? I know it is not the SOS. -

If you are not an A&P/IA the labor costs are higher to inspect the wood wing. Additionally, the controls on the wing are made of fabric. With the extra costs spent on annual inspections, and only having a 150hp engine, you might be better served by buying an early 1960s model, which is all-metal and features a 180hp-200hp engine. I've owned both versions. I flew a 1958 M20 for 10 years, but that was when there were more people still working on wood and labor was ALOT cheaper.

-

Intake rubber accordion boot

outermarker replied to Pete 379's topic in Vintage Mooneys (pre-J models)

It is well known that those who have "ram air" on the mid-60's E & F Mooney's barely saw a 1" increase in MP. It was more of a marketing feature. Is there a "kit" to eliminate the boot? I would rather have the comfort of knowing all air is going through a filter than trying to increase MP by 1". -

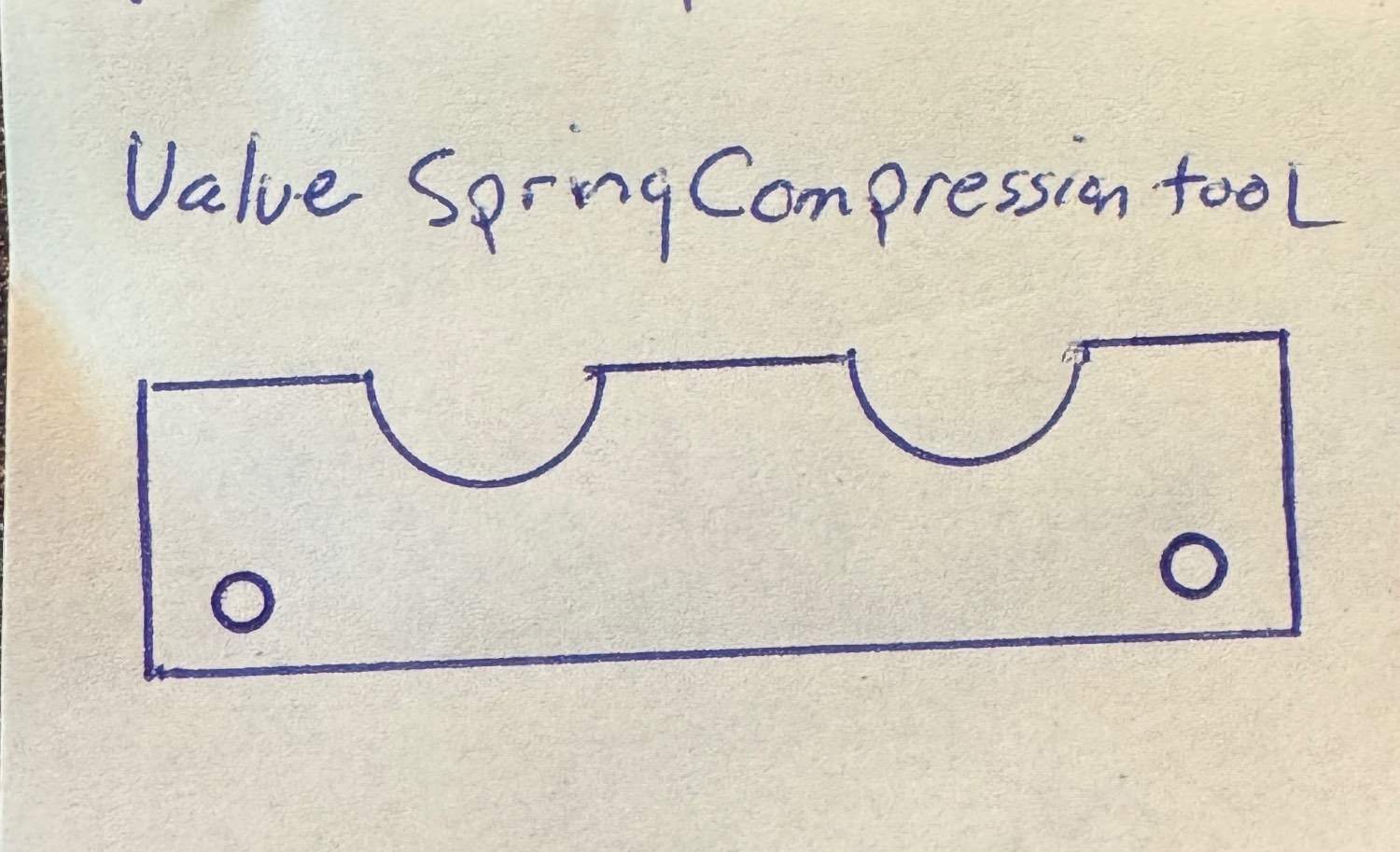

Has anyone made a simple valve compression tool willing to post a drawing with dimensions? Something like the attached file. thanks

-

I assumed as much. I was hoping from all the past and present owners that someone, or many, have used these products and could provide testimony that the products won't harm the fuel tank sealant.

-

PC Wing Leveler help needed

outermarker replied to MarquezJC's topic in Vintage Mooneys (pre-J models)

Does it bank with more than you in the airplane? When you taxi, does the yoke move opposite in a turn as if to correct for the turn? -

I read that both Decelin (better than TCP) and Techron are approved for Continental and Lycoming engines. Does this also mean these two products won't harm the sealant used for Mooney fuel tanks? Will MMO harm the fuel tank sealant? thanks!

-

I don’t get an opportunity to give back and I’m so grateful to everyone who gives me help. This is an opportunity to perhaps help others. For those changing their tires and tubes I’ve enclosed a photo of the 70 degrees valve stem installed on the main tire. I used a Harbor Freight mini tire changer($56) to break the tire bead. Some hiccups I encountered. I wanted to use new bolts, washers and nuts on the rim halves. What I had was too long so additional washers were used. The bolt p/n in the Mooney parts manual was 1/8 too short. Also, the nut is a high temperature nut. Aircraft Spruce only has Nylock for that size. Nylock can be used on the nose wheel. What I learned was that I should have checked the Cleveland Parts Manual for the bolt length. So much for a DIY project!

-

Today I attempted to install a new LEAKGUARD tube with 70 degree stem on the main rim. The new tube has about a 1/4” of rubber at the stem base that has to seat through the stem hole on the rim. I could not get the rim mounted onto the tire and the valve completely through and seated into the stem hole. I gave up completely defeated. What’s the secret?

-

So, what tire and tube resolved this issue? Was a tube with an angle used, and does that tube hold air throughout the year? I'm asking because it is time for me to change my tires and tubes. I, too, have straight stems and live in fear of ruining the inner tube by pulling the stem away to check and apply air. Goodyear FS III has been on it since I bought it, and I'll assume the inner tube is also a Goodyear. The FS III is the only tire using Kevlar and has a speed rating of 160mph. Currently, a Goodyear FS III and tube are over $500; therefore, spending around $1500 for three tires and tubes and then the labor costs is a bit steep for the shallow pockets I wear. I have a lightweight, short-bodied E. A perfect scenario for me would have these elements. Inner tube: 1. the tube holds air throughout the year without leaking. 2. the valve stem with the metal cap on doesn't rub, lie against, or interfere with anything. Tire: 1. easy to balance or balancing is not required 2. good tread depth 3. resistant to dry rot or cracking after a few years Is there a tire and tube that meets all of the above? Surely there have to be people out there who are overjoyed with their tires and tubes AND happy with the price paid for the tires and tubes. I would really like to hear from you. thanks!

-

goodyear flight custom III's vs flight special II's

outermarker replied to eman1200's topic in Vintage Mooneys (pre-J models)

Isn't the main difference between the Goodyear Flight Custom III (with Kevlar) a higher speed rating of 160mph vs the FC II with a 120mph speed rating? I sure hope I'm not touching down at either of those rated speeds. As far as Goodyear tubes, they don't have a 70-degree valve angle. I have had Goodyear products for a long time. I hate the straight valve angle. I feel like I'm going to cut into the valve stem every time I check or have to add air. Will the 90-degree angle stem work (with the valve cap on) without hitting the dust cover? 600 X 6 6 Ply/5.00 X 5 4 Ply Package | Aircraft Spruce -

"I built an engine dehumidifier a few years ago using a Peltier cooler and aquarium pump." My limited understanding of a Peltier is one side is cold, and the other side is heat...depending on the amount of current you push through it. In order to maintain 90 degrees engine/oil temp I would think you would have to have a pretty large power supply and amps of current?

-

one thing to consider is the original ignition switch has a push to start feature. The reason is because of the plastic overlay. The nut tightens on the overlay. So, you don't have to overtighten the nut if you have to push. The other type you have to overcome the tension of the internal springs to engage the start mode. If the nut isn't tight enough the switch will rotate. Then you have to open the radio panel and reach in to hold the switch. Then get channel lock plyers to over tighten the nut (which will cut into the plastic overlay) hopefully enough without stripping the threads and not bugger up the nut surface. Then every time you go to start you will be aware that a bit too much pressure and the switch might rotate again before you get into the start mode. If you still have a plastic overlay, it is not worth changing the push to start feature for a twist to start feature. I know this because when I bought my Mooney it had a turn to start switch and for a long time, I thought it was correct...and for a long time I had from time-to-time issues with the switch rotating.

-

They do, three springs and caps for about half the price of a new switch. Bendix is really proud of their switch...the price reflects that pride!

-

I have been down this path a few years ago. I bought several used switches to take apart and swap innards and to see how it works. I also considered the rebuild kit from Bendix but even that was pricey! After I rebuilt switch worked but I still wasn't completely satisfied. So, I took the switch apart and under a microscope I saw where the key wears material away leaving you hunting for the sweet spot to where the starter will engage. The ACS switch your looking at uses a smaller diameter hole that will have to be considered. If you make a mounting plate for a proper fit you then have to attach the plate to the panel. There are a lot of wires behind the panel that drilling a few holes would make me nervous! So, when you consider the extra labor to mount the ACS switch that feels like it doesn't have the life cycles of the Bendix (or the price) have you really saved that much overall? I understand the ACS is certified for Cessna's so there is some quality with the switch. Since I have an Aircraft Spruce close to me, I had the advantage of actually going to the counter and comparing both switches. I left with taking a chance on rebuilding a Bendix over a new ACS for all the above reasons, mainly the smaller diameter mounting hole issues. Good Luck with your discission. Now I'm back considering paying that outrageous price for a new Bendix switch. It feels more robust than the ACS switch. Plus, it is an easier swap.