-

Posts

45,222 -

Joined

-

Last visited

-

Days Won

381

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Posts posted by carusoam

-

-

Cabin air has two types of systems… older is slide gates… newer is butterfly valves…

slide gates require a minimum of annual maintenance, to clean and lubricate…

butterfly valves are better, but use a rubber seal that needs a replacement every decade or three…

A damaged piece of rubber can easily get in the way of a proper seal.

ram air is similar, moving parts and rubber seal… but way more important to have operating correctly… Any parts released by the ram air door are sent directly to the engine… no filtration in between.

inspecting the systems can be a bit challenging… depending on how much mechanical skills one has.

Always good to have a pair of manuals on hand… parts and service barely give enough information. But they are a great place to start…

may help to have a friend to operate the lever in the cabin, while the owner’s eyeballs are on the other end…

Some of these systems have enough resistance to hold them in position. It may be possible to clean and lubricate them so much, that they move on their own….

By the time an owner has gone through these efforts… it is an easy discussion with the mechanic to show them what is going on…

PP thoughts only, not a mechanic…

Best regards,

-a-

-

It’s a simple collection of parts…

With a horrendous amount of installation…

Expect it to be super expensive, and be done by a super qualified shop…

The hardest part is probably installing the filler parts in the fuselage sheet metal….

See if you can get a discount price for two….

Best regards,

-a-

-

-

3 hours ago, RescueMunchkin said:

I'm new to Mooneys and am curious why an open passenger compartment door coming open in flight is much of any issue - shouldn't the airflow around the plane keep it reasonably close to the closed position?

cabin doors stay open about an inch or two…Most people opt for the land and close the door option… getting distracted trying to close the door near the ground, while flying, is a set-up for a different problem…

baggage doors also stay open about an inch or two… at traffic pattern speeds…. A couple have been known to pull the door support apart, and bend the door over the top of the fuselage….

The baggage door hinge is mostly stronger than the door when pulled slowly…. If the door snaps open in cruise flight… this is an unusual situation…

PP thoughts only, not a mechanic…

Best regards,

-a-

-

A collection of updated details…

https://aviation-safety.net/wikibase/371054

1) Ground track looks like a classic set-up for base to final stall spin.

2) Tower ATC guys were discussing losing the Mooney on base.

3) Local news found a ‘Mooney expert’ who opined about losing a baggage door and how it can hit the tail structures… and went on to describe a stall type of accident.

4) Plenty of errors in all of the ‘technical descriptions’. Details of the baggage door hinge were il-informed

5) I only know of one baggage door being pulled off, and it was during cruise flight, at speed…

6) Doors don’t typically get pulled off at pattern speeds…

7) It can be a bit like having a hurricane inside the cabin, lots of paper and stuff flying around….

8) our cabins are usually a bit under a vacuum in flight… so when we use the alt static valve… we get a slight change in IAS…

9) Check the POH for any additional insight on the ‘emergency procedure’

10) I have tested both doors on the M20C, and M20R, before graduating to the PIC oversees the closing of any and all doors…

the baggage door gets left in only two positions… full open, or fully closed…. (A pain when the Robinsons are having an active day)

remember the list… Aviate…etc.Inviting @mike_elliott to the discussion…. And including @midlifeflyer (in case he is familiar with the plane)

Prayers for the lost airmen…

Best regards,

-a-

-

1

1

-

-

3 hours ago, LANCECASPER said:

@Alan Maurer's Ovation (N913ND) had the Top Prop from the start. (https://www.aircraft.com/aircraft/200807015/n913nd-2008-mooney-m20r-ovation2-gx)

Lance,

that’s a lot of mis-matched spinners…

Do the Ultra’s carbon fiber cowls carry on the tradition, or did they get designed to fit the H prop?

hmmmmm….

-a-

-

Scott,

I admire Byron’s work.

But, the H spinner is still too small….

L/R has a step.

T/B still has a step.

It sure looks better when the top cowling line matches the spinner!

I would really like to have a prop guy define what is really happening here…

what would it take to get a spinner of the right dimensions…. If this is the true issue.

What would that spinner parts cost be?Best regards,

-a-

-

Key details to consider…

1) How long have you had the Hartzell TopProp?

2) know the cowling was designed to match a McCauley spinner…

3) Hartzell didn’t have the right sized spinner to match our cowl…

4) They promised a replacement soon…. More than a decade ago…

5) the diameter looks about a 1/2” shy of what it needs to be…

6) meaning it looks like a 1/4” step between the edge of the smaller spinner, and where it needs to go to be flush…

7) overall, it makes the prop look like the engine is drooping…

8) look closer… to see if the prop shaft is centered in the round hole

9) I’m still a bit bummed by this situation..

Built on Honor, but not sized appropriately…

PP thoughts only, not a mechanic…best regards,

-a-

-

2

2

-

-

The long bodies take this discussion to the next level…

The Ovations have a jack point designed into the engine mount…

and for total confusion of the new mechanic…. The placard on the outside of the cowling simply says ‘jack point’

it would have been a bit nicer… if the placard said ‘Jack point on engine mount, under cowl, look in the baggage compartment for a set of points used for jacking’

Losing a part of a prop blade in flight… will surely test the strength of the bolts holding things through the firewall….

My M20C broke the welds off a lower leg of the engine mount, releasing 1/4 of the connections to the firewall…

Flying around for a few months not knowing of its new condition… was interesting…

The signs were not extremely obvious to the casual observer….

1) variable engine sag, slightly more than usual one day, then near rubbing on the cowling the next…. Then back to slightly more than usual…. Problems don’t usually fix themselves… not even partially…

2) small air bubbles vibrating in the compass… but no obvious increase of vibrations being felt.

3) Last flight was to an MSC…. When an ordinary mechanic could have seen what was happening…

yikes…

Decision to upgrade one way or another followed that experience…

PP thoughts only, not a mechanic…

best regards,

-a-

-

A couple of ways to attack this challenge…

Airpath is the standard compass maker found in most Mooneys…

Aircraft spruce carries all the parts needed for OH, or just filling, including new seals and a fresh compass calibration card… or a complete swap for new…

for a pre-flown replacement direct from an actual Mooney…

contact Alan…. At Mooney Parts R Us… @Alan Fox

there are better compasses available….

there is also a reason why you may be asking about fixing the old compass… when the problem is not the compass itself…

this is called degaussing….

there is a nice steel tube frame that can get accidentally magnetized…

When this occurs, the compass can slow/stall during standard rate turns…. Then accelerate to catch up… making partial panel under the hood exercises impossible to accomplish…

For degaussing the airframe… there are plenty of discussions around here somewhere….

its not a common occurrence… unless you bring a giant vacuum cleaner with a big electric motor inside the cabin….

modern Mooneys actually got a SS tube down the center, where the older Mooneys got a more magnetic sensitive steel…

PP thoughts only… my first attempt at training for the IR went on hold for this reason…

Best regards,-a-

-

i’m back….

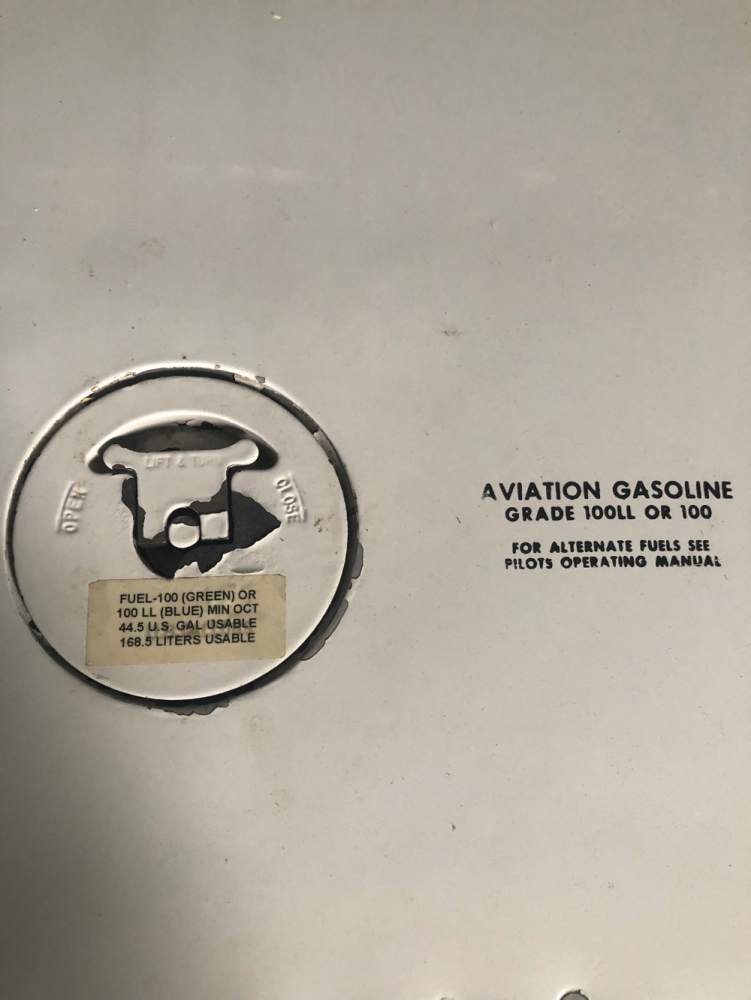

pics I took of my O1’s fuel tank bits and pieces…

Filling a tank beyond its 44.5g limit… takes patience.

a large air bubble is captured above the fuel neck….

all of that air needs to move through tiny air holes, specifically put in a few wing ribs….

there are matching holes at the bottom of the ribs to allow fuel to drain towards the pick-up tube.

all of that air makes its way to the vent uphill….

As the tank fills… the head pressure to move the air gets less and less…

How was that?

This is one of my favorite discussions… I first met @Cris on MS, discussing how to increase the fuel capacity for his soon to be Screamin’ Eagle.

He returned the favor several times… as I followed his guidance for the Standing Ovation upgrade, and other things…

cap with labels near by

cap opened showing the locking ring

down the dark hole with the tube like fuel neck…

probably need to brighten the screen to see it better…. Start by looking at the vertical weld line that is barely visible in this pic…

cap chain dangling for length reference…

dollar bill to reference the length of chain links…

other places limitations are posted…

fuel selector valve, on the floor, centered between pilot and copilot seats… easy to reach!

fuel cap label indicating gallons…

fuel level indicator, gallons.

Fuel tank vent… found at the uphill end of the fuel tank. Seen from under the wing.

mechanical fuel level gauge, designed for partial tank filling, accurate while on level ground.

tank looks empty in these pics, actually has 10 gal in it…

Sparkles in the paint mixture look more like chips in the paint here…

best regards,

-a-

-

1

1

-

1

1

-

-

19 hours ago, Shadrach said:

Non pressurized turbines answer a question that no one is asking.

no one informed is asking….

for the less informed…

That question starts to get formulated…

1) If I had the dough…

2) The reliability of turbines is…

2a) diesel is… more available, lower cost, lead free, higher specific energy….

Then reality strikes…

3) The engine efficiency is low… flying even faster doesn’t make the efficiency get better.

4) The engine efficiency gets worse below the FLs…

Then the question usually gets dropped…

5) Usual mission isn’t served very well climbing all the way to the FLs….

6) T/O distance isn’t spectacular…

7) Masks on a family of four with a small dog…

8) Hot section inspection/ OH… huge investment spread over many thousands of hours…

9) No way to upgrade a non-pressurized cabin to pressurized…

10) the TN’d IO550 looks like an easy step up compared to the turbine…

It does look and sound cool though…

Best regards,

-a-

-

1

1

-

-

On 3/22/2024 at 2:06 AM, Fly Boomer said:

Was the turbine a factory project. Many of the changes Mooney made were driven by outside sources. Sounds like a project for Rocket.

In 2008, Mooney signed a deal with RR for a project that never left the ground before the economic disaster put everything in disarray…

the engine they were going to use was an existing small helicopter design based on low(ish) altitude efficiency….

Rocket engineering had awesome skills for putting interesting engines in Mooneys and Pipers…- Mooney Missile, IO550A, 300hp

- Standing Ovation, and O3, IO550G or N, 310hp

- P46T

best regards,

-a-

-

1

1

-

Leaning in the climb… (towards the center of the cabin)

The O1 has a calibrated EGT gauge to make it easy…

a blue box on the EGT gauge keeps things between 2-300°F ROP…

At Ford, Quality was Job #1…

At Boeing, Quality was a vendor challenge…

I would gladly consider a diesel option… where is that turbine Mooney project lately?

Best regards,

-a-

-

Dude!

This was a favorite topic for José…

He used avgas to wash the sludge out of the oil pan…

Sludge is a mixture of 100LL additives and oil….

it has a tendency to pile up on the bottom….

the challenge being….

it is hard to tell how much of the gallon of gas actually drained back out….

any gas left behind in the oil, will evaporate as it gets hot…

but it also affects the viscosity…. This is where most people decide that it is very challenging to get this right…

it would be really cool to have clean looking oil for 50 hours…. Instead of it changing colors after the engine is first started…

PP thoughts only, not a mechanic…

Best regards,

-a-

-

Hey DKK…

sorry for coming in so late…

I have a couple of thoughts to share…

There are two models of cylinders for the IO550 the G and the N…

Gs are known to be very robust…

Ns are better known to have crack potential… they have the fancy cooling fins, and the cylinder weighs a few pounds less than the G’s…

Before getting too deep, let’s discuss compression testing for Continental cylinders… be sure the mechanic is following the procedure, with the proper orifice for the test… when the mechanic is not familiar, you get a common low compression reading.

Also… often, the rings align… and give a crummy reading too… fly it, test it warm… and try again.

Both cylinder types are equally susceptible to how the plane is flown…

Turbo normalized engines can be run hard, and often experience suboptimal cooling at altitude…

If the prior owner preferred to run his plane in full flaming dragon mode… it is possible to wear out a set of cylinders in 1k hrs….

Often, new owners find out that they have mismanaged their cylinder temps and don’t get to the halfway mark….

Nothing wrong with full flaming dragon mode… from a technical point of view… it is the ultimate go fast mode. It costs a bit more fuel and a TOH earlier than a similar bird that is flown LOP, at a bit slower speed….

A knowledgable owner or mechanic can use a dental camera and inspect the cylinder walls for the cross hatch pattern that is supposed to be there… this tells more than the single compression test…

If the cylinder bore is polished smooth in spots… it is probably time for an cylinder OH…

same thing for the valves… same camera…. The valve surface should look like a pizza…. Nice concentric patterns…

when there is a hot spot visible at the edge… it is time to get that valve situation fixed… not something you want to wait on.

valves don’t last very long once they stop rotating. The constant rotation each cycle keeps them evenly cooled….

Sticky valves have a tendency to stop rotating… and their heat damage begins to appear….

Cylinder health has little to do with the rest of the engine… they are most sensitive to air cooling issues, and how hard they have been run…

The NA IO550 on the Acclaim’s sister ship… the Ovation, is known to make it to 2k hrs without any cylinder issues…

Key things about temp control…. The G1000 has a white box for leaning ROP in the climb…. Keeping CHTs below 380°F in the cruise is best for their longevity… tough to do in very thin air….

See if you can download the flight history from your engine monitor… this will tell you a great deal of what to expect before peering into the cylinders with your dental camera…

Fortunately, the TN’d IO550 is quite popular… it isn’t unique to Mooneys…

Setting up the FF properly is important… at idle, and at full throttle…

Keep in mind… you need to know what rpm your engine is turning… most Acclaims start life limited to 2500 rpm…

The really loved Acclaims get their rpm upped to 2700rpm with a FF to match…

at 2500rpm you may see 25gph… 280bhp

at 2700rpm you may see 27+gph, with a preference for a higher number closer to 30+… 310bhp

The IO550 in this application is very stout. If you are climbing full throttle to the FLs… be sure to follow the procedure for leaning during the climb, keeping an eye on TIT, and watching the CHTs…

All stuff you probably remember from transition training….

PP thoughts only, not a mechanic or CFI….

fun stuff you learn over the years… Go MS!

Best regards,

-a-

-

Got my PayPal issues straightened out… next up, I’ll get these pics uploaded once the PayPal payment goes through…

-a-

-

20 hours ago, Rick Junkin said:

Thanks Anthony - yes, still wanting pics of the various filler necks.

Cheers,

Junkman

A few pics as promised Rick!

Has anyone seen the attach a pic button from my iphone?

pics are…cap with labels near by

cap opened showing the locking ring

down the dark hole with the tube like fuel neck…

cap chain dangling for length reference…

dollar bill to reference the length of chain links…

other places limitations are posted…

Fuel tank vent…

note: there are no holes or any type of vent in the fuel neck…an error in my previous description…

filling the last few gallons takes time… the head pressure of the column of fuel is minuscule, and air has to get pushed all the way to the vent…

To post pics… it might require me to get my membership up to date!

-a-

-

1

1

-

-

2 minutes ago, Rick Junkin said:

Thanks Anthony - yes, still wanting pics of the various filler necks.

Cheers,

JunkmanShould take a day or two…

after that, send a reminder…

best regards,

-a-

-

Let me know if you still need a pic.

I have to work on that hangar home…

I would have posted a pic already…

Best regards,

-a-

-

On 3/13/2024 at 10:24 PM, exM20K said:

Second photo from China, I think. @carusoam to the white courtesy phone, please

Hey Dan!

see my response above.

Best regards,

-a-

-

1

1

-

-

Hey!

Sorry for the late reply….

in 94 the fuel neck was a simple tube shape with a large slot running down the side…

the slot allows for a fair amount of air to escape, such that the tank fills to the brim as air is vented through the rib’s tiny holes uphill…

thus the fuel nozzle can hang on the bottom of the neck without pulling out with the weight of the hose…

it had an ordinary Shaw cap.

looks like it is cut and welded from a heavy SS sheet material…

PP thoughts only, not a mechanic… all from old fuzzy memories.

My placarding is the standard old numbers from the POH…

those numbers are found in at least three places… cap, gauges, selector switch…

Best regards,

-a-

-

Way cool!

one of my favorite topics!

my ‘94 (O3 powered) O1 just became an O3!

But mine is more valuable than his…. My S/N is lower!!!

Whoever is doing the sales job on that airplane is showing that he is not as familiar with Mooneys as we are…The Standing Ovation is an Awesome Aircraft…

The O1 is super cool… it can be upgraded, at will, to be similar to the G1000 with waas capability, without the drag of working with both Mooney and Garmin…

Now…. If you have the unlimited stack of Benjamins in your aviation account…. There is no reason to avoid the Acclaim…

If you are still dragging teen agers around in the back, and never exceed 12.5k’…. Trying to get the right Acclaim will be an extra challenge…

15 years or so with the O1… I would gladly swap for an Acclaim….

just because…

PP thoughts only… +1 for Jimmy’s guidance!

Best regards,

-a-

-

2

2

-

-

My favorite example of product quality identified by brand name…

Quality engineers discussing the cost of quality… it can squeeze corporate earnings…

Then discussing cutting back on quality systems… it can crush corporate earnings…

What is Champion known for?crappy quality spark plugs where their resistance changed towards infinity over time…

they knew what was wrong, please buy some more….

What is Slick known for?

a disposable magneto. Inferior to the Bendix mag…

What is Maggie known for?

New kid on the block. Willing to sell a half set of mag wires for people upgrading to a single new electronic magneto…

Maggie has an MS presence around here somewhere…

the new kid has been around for a while…

Can’t stop with a partial list crummy quality players…. There are others in the penalty box…

Some have actually gotten back out of the penalty box over enough time…

Throw the Gill battery guys under the bus as well…. Two years of life when the competition goes closer to six…

Right up there with…

Ford Pinto

Chevy side saddle fuel tanks

GM ignition switches

Boeing Max single AOA sensor AP option for third world carriers…

Boeing outsourcing fuselages and not checking to see if all the bolts are installed in the plug door…

Boeing Starliner internal clock magically running 11hrs slow…. Let’s launch anyways. What could possibly go wrong?

Tacoma Narrows bridge AKA galloping Gertie…

Almost forgot… BK relabeling other company’s products… that hasn’t worked very well for Mooneys either…

Always good to compare the various suppliers…

Every one has challenges…

it’s how they handle the challenges that makes a difference…

Old rants only… not a mechanic…

Go Maggie!

Best regards,

-a-

Mooney Down (03/25/24) - Near St. Augustine-Northeast Florida Regional Airport, FL (UST)

in Mooney Safety & Accident Discussion

Posted

YT already has radio and gps data posted…

Prayers,

-a-