-

Posts

120 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by DC_Brasil

-

Hello everyone, I was wondering if anyone here has disabled the Gear Down light dimming that happens when you turn on the Nav lights. From what I understand, it should be a simple procedure of disconnecting a wire from the switch and/or the annunciator panel. However, the switch is easier to access and see behind. Personally, I feel annoyed but how dimming it is during daytime and for consistency of operation, I always fly with nav lights on. Has anyone done that? Pictures?

-

Yes, I did overtstate a bit. I meant to stress to not let the mechanic start pulling cylinders without first having a clear diagnostic for the problem. The OPs mechanic seemed to be spring-loaded to remove the cylinders (as many mechanics are, unfortunately) without having the issue pin pointed.

-

Most cylinders will have oil on the bottom wall after you shut the engine down. Oil is used to lubricate the walls and a thin layer is applied and scraped off by the rings during normal operation. When you shut the engine off, that hin film will flow to the bottom wall. That's normal and not result from corrosion or pitting.

-

Few considerations for @ajudson: 1 - when you say you definitely had 4 qts after that landing: did you measure it right after landing or with a cold engine? A warm engine will have plenty of oil still scattered around the internal walls and galleries and will most likely show a lower level than a cold engine, when the oil will have had the time to flow back to the sump. 2 - mild roughness or popping at 1000 rpm: have your A&P check the fuel flow setting on the injector distributor. My fuel system was overly lean and I would constantly get an unhappy engine at 1000 rpm (it would almost always quit if it hit 950 rpm). After it was adjusted, I got a normal running 1000 rpm and better cooling at takeoff power. 3 - valves sticking will cause a very noticeable effect when the engine is cold and it gradually disappears as engine warms. You'll be able to see lead bromide deposits on exhaust valve stems and valve seats with the borescope. Lapping the valves in place can clean much of these deposits. 4 - Ring flushing has nothing to do with sticking valves but, since your main concern began with elevated oil consumption and possible cylinder blow-by, it could help. Sometimes a cylinder ring may get stuck in place by oil sludge (our avgas burns reaaaally dirty). Flushing the rings is a cheap and minimally invasive procedure that has the ability to free up a mildly stuck ring. 5 - as @LANCECASPER said, make sure your A&P has checked the suction screen. 6 - what kind of engine/oil system gauges do you have? Legacy analog mooney or digital engine monitors? If you have digital data, you may benefit a lot from comparing oil pressure and temperature data from different flights. If you have analog legacy gauges, it wouldn't hurt to check the oil pressure gauge for proper operation/indication.

-

I would definitely reactivate the Savvy subscription. Unfortunately, many A&Ps are spring-loaded to suggesting removing cylinders and many, many times that's just unnecessary and makes the shop receive a large paycheck. You have to think of maintenance as a medical approach: you wouldn't want an exploratory surgery to find the source of a pain. First and foremost, as @PT20J explained, if the oil filter, suction screen and oil analysis are fine, high oil consumption is just a nuisance. Secondly, there are a few things that may elevate oil consumption. Most of them do not require a cylinder to be pulled. Those corrosion pitting on the cylinder walls do not look that bad. I have the same thing on two of my cylinder walls (my plane also had a time of disuse under the previous owner). Other than that pitting you seem to have good crosshatching. Have your mechanic tried flushing the rings? If he suspects blow-by is the culprit of the high oil consumption, it is more often caused by rings than mild pitting on the walls. What evidence you have regarding a valve sticking? Is the engine showing morning sickness? You can try lapping the valves in place. Have you seen lead deposits on valve stems or seat on the borescope images? If they were sticking, you'd be able to see some deposits rather clearly. Sorry to say, but your A&P seems to be shotgunning here. He doesn't have a diagnostic and have suggested a very invasive and labor intensive intervention. I would definitely try to find a cause than starting to attack the plane with tools. Don't get me wrong: ultimately there may exist the need for a cylinder OH, but you need to be certain of it. Also, don't fall on the "let's OH all of them just in case" trap. Only do what is actually necessary for safety of flight. Cylinder removal is a very invasive intervention, should be done by a specialized shop (not.on the field) and you'll have the risk of maintenance-induced failures. Keep that in mind.

-

I have installed a Concorde RG24-11M in my 1990 J model in December 2024. No complaints so far.

-

+1 for flight control rigging!

-

This topic is so relatable ahahahahaha My wife has never been enthusiastic to fly, even on airlines. When I bought the Mooney she was really reluctant. She's very sensitive to motion sickness. First tip I'd give is take it incrementally. Do not put new people to GA on a long XC unless strictly needed. I'd make short 1hr flights here and there to make sure they are fine with the many aspects of flying that may surprise the unwise like the persistent turbulence of lunch time, clouds, winds, etc. We've had a 6hr flight this year and it really wore her out. It was a very warm and bumpy day, so sick bags were ready to go. The FBO thing is for real! My wife now loves the Rockstar feeling of being treated the same as those guys stepping out of a Gulfstream. Good clean restrooms make a ton of difference for them and I also enjoy a good coffee before a flight. Flying in the morning: can't stress it enough. One other thing that can surprise first time flyers is ATC communication. My plane is based in a towered field inside a busy class C terminal area, the first time she flew with me, after the flight she confessed she was scared to death... she thought something was terribly wrong because of the very intense radio chatter all the time ahahahahah As for kids: I'd also take them on short and incrementally longer legs. Even if they're used to longer car trips, kids sometimes can't control bathroom stops. In a car you pull over anywhere and if it's serious enough, baby wipes will make do. Not so simple in a plane. One last thought: Starlink. Buy the darn thing.

-

I constantly fly my J at 10 or 11K without O2. I carry a finger oxymeter and also have the garmin watch (although I take its o2 readings with a grain of salt). I never took it higher because I don't have O2 installed and I suspect I'd lose efficiency from the NA engine.

-

Do you also have them fornthe mooney flight surfaces travel board?

-

How many people lost an Alternator/Voltage Regulator in flight?

DC_Brasil replied to Yetti's topic in General Mooney Talk

I've experienced both. First it was a VR (I have the old electrodelta VR802). Luckily it failed on the ground. It was removed and repaired. The technician that worked on it said it was a bad resistor (or something like that) very easy and cheap to repair. E few months ago I had the alternator go out right after takeoff returning home from an airport about 250nm away. After takeoff it went offline. I tried the checklist items without success. I was taking off an airport with absolutely no resources for a repair so I elected to continue flight on battery power to a larger field 20mins away. I informed ATC I could lose radio contact any minute and pushed on. It was a national holiday, so I had to find an FBO to park, find and A&P to see the plane next morning and get on an airline flight back home :-( It wasn't before a whole week I could go back to get the plane. It turned out to be broken field wire. We ended up redoing all connections to make them firmer. -

Hello everyone, I have seen some pictures of some modern looking rocker switches but I can't seem to find out if they are approved for use in certificated airplanes. I've found some models on aircraft Spruce but they all seem to be for experimentals. Can anyone point me to the correct brand/models? I'd love to have modern looking switches to replace my M20J rockers.

-

Avionics Upgrade Completed – M20J 1980

DC_Brasil replied to unicom's topic in Avionics/Panel Discussion

Yes. There are many features it adds which the old non-WAAS GNS430 doesn't have: Holds Parallel track Airways Waypoint Alt constraints VNAV integration G3X can send Flt Plan to the GPS Smart Glide Plus the added benefit of ADSB in/out for the GNX375. -

Avionics Upgrade Completed – M20J 1980

DC_Brasil replied to unicom's topic in Avionics/Panel Discussion

Nope... I have the old grumpy non WAAS GNS430 -

Avionics Upgrade Completed – M20J 1980

DC_Brasil replied to unicom's topic in Avionics/Panel Discussion

Very nice upgrade. Very similar to what I did with my M20J. I didn't have the cash to put in a new GPS, though. Now I am contemplating purchasing an used GNX375 to have a modern GPS, ADSB and retire my old King KT76A transponder. -

Older Voltage regulators like the one I have in my 1990 J are actually not very complex equipments. They're circuit boards with very simple and easy to find components like resistors, capacitors, etc. An electronic technician can easily work with them to troubleshoot. Most of the times (not always) electrical problems are easier to pinpoint than mechanical. You can get point to point readings with a multimeter to isolate where some faults are coming from.

-

I've had this problem. In my case it was the VR802 voltage regulator. A technician removed it and changed a fried component (very quick diagnostic and repair) and bench tested it. It has worked great ever since.

-

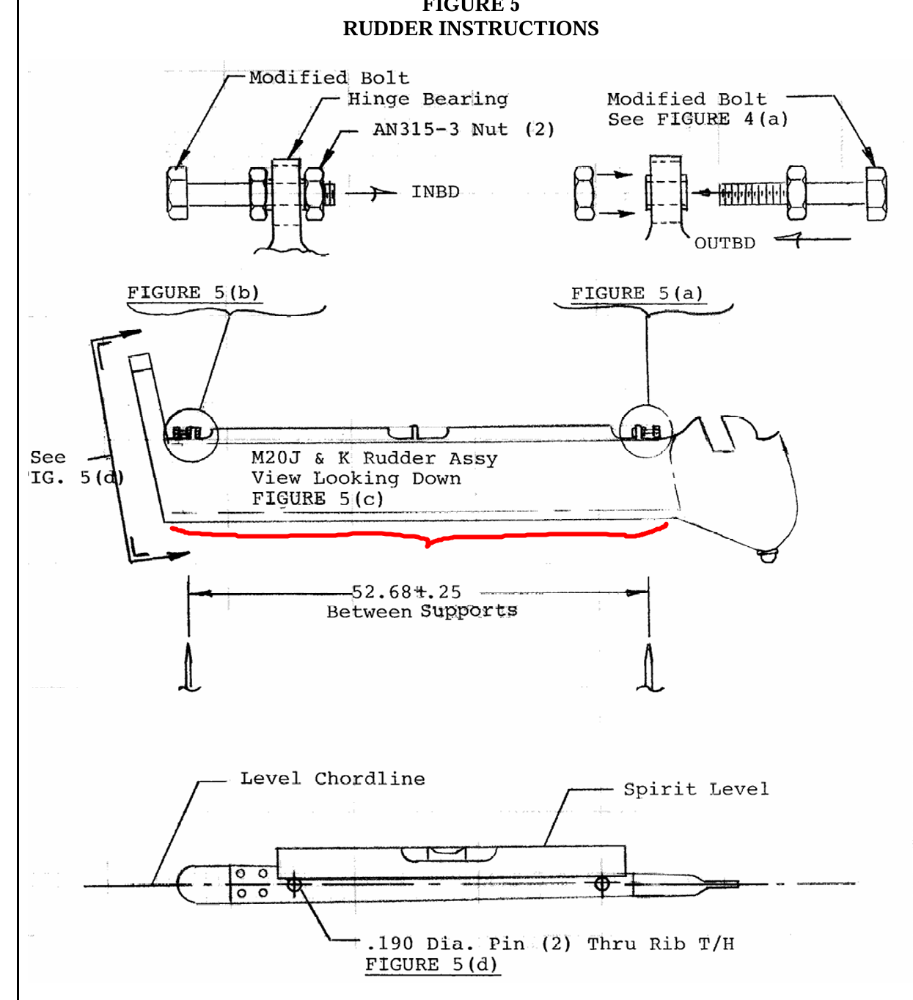

I have had a back-an-forth with Mooney support as well. My rudder is out of specs. I discovered it has been painted in the past without stripping the old paint and that is what is probably making it too heavy. I'll have to strip the paint, repaint it and redo the static balance check

-

+1 here. I would love the improved fuel consumption and cleaner burn (higher spark voltage) of the EIS. However, Electroair's website is kind of unclear about the single-drive dual Bendix magneto replacement. Although their engine AML says that Lycoming IO-360-A3B6D is an approved model, it lists the EIS 41000 as the installation model. However, their website shows the EIS-42000DM as the "correct" model ("The EIS-42000D Electronic Ignition Kit is a fully STC'd kit to replace the Bendix single drive, dual magneto with a complete, DUAL ELECTRONIC ignition.") Other things that caught my attention: all 41000 models have links to AML, installation instructions, AFM Supplement, etc. The 42000 does not. Their STC page does not show the 42000 anywhere. I contacted their distribution partner in Brazil and they said that their STC for the Bendix dual mag is not yet validated by ANAC (Brazilian civil aviation authority), but I am thinking that their FAA STC hasn't yet gone through for that specific model... or am I missing something here?

-

I have downloaded and have read the manual. The only question I have - and I want to check the mechanics are doing it right - is where along the length of the rudder is the correct spot put the scale support point (in red in the image below).

-

Hello everyone. I am having my 1990 M20J go through the 2900lbs gross weight increase procedure as per SL92-1. The shop is doing the rudder balance check as directed by SB-M20-252 but the rudder seems to be out of specs: the measured moment is not within limits and we'd need to add weight to the rudder horn counterweight. As we're discussing the best approach to fall within limits, I am suspecting the plane has been painted with a heavy coat in the past (before I purchased it) and it is affecting the surface weight. However, since I live in Brazil and there are very few Mooneys around here, I suspect there is also a possibility that the A&Ps at the shop aren't measuring the distance to calculate moment at the correct spot. Consequently, I'd like to ask members here if someone might have pictures of this balancing procedure and where they actually measured the underbalance weight. Thanks!

-

Hello 1 - lean so much as the engine will not develop meaningful RPM if you try to apply takeoff power. This will have two effects: lean operation at low power and protects you from inadvertently trying to takeoff forgetting to enrichen the mixture. 2 and 3 - Follow the most recent manufacturers' recommendations. For most of the Lycoming direct drive engines it will be Service Instruction SI-1132B. It says to do the run-up at 50-65% power and Best Power mixture. For most engines it will be higher than the POHs 2000 RPM. 4 - Takeoff is when we get as close to maximum rated power as possible. Aviation engines have large compression rates and will need excess fuel to allow for thermal protection against detonation. So it is NOT a good idea to takeoff very lean. Aspirated engines should be running at full rich unless density altitude is playing a role (about > than 3000ft you should find best power). Turbocharged engines will always "think" they're at sea level so you always takeoff with mixture full rich, unless your POH tells you otherwise. 5 - If you are looking for operating LOP the best technique is Mike Busch's big mixture pull until noticing a drop in power output. Then enrichen slowly to peak EGT, and then stablish the regimen you wish (LOP or at peak). After you do it a few times and establish your LOP operation you will start to notice the LOP fuel flow for different altitudes, as EGT will vary depending on atmospheric conditions and RPM settings, and relate it to a TAS. After a while you'll be able to do the big mixture pull, feel the engine loose a little power and then enrichen to a known fuel flow while crosschecking with airspeed. I my plane (IO-360-A3B6D) that equates to about 8.8 to 9.2gph up until 5500 feet and 7.7 to 8.2 gph at 11,000. For me it leads to a 139kts TAS. 6 - It really depends on your operation and how fast you wish to climb. You CAN climb LOP. However it will require monitoring temps more closely as your mixture will become richer as atmosphere becomes thinner. ROP climb will yield more power and a quicker climb. 7 - It varies. How high and how lean were you in cruise? If you were very high and running LOP your engine will show signs of over lean mixture as you descent. 8 - I have it in my After landing checklist: mixture ...... LEAN. Same as after start.

-

I believe that's the correct approach to take. However, as I explained before, I bought the Mooney and took it straight to the avionics shop (my first experience as an owner). I approached it as I would a very well recommended doctor for a surgery: I thought I needed not to know the tecnical details about the procedure to be executed. Certainly now, I see it is very different with aircraft maintenance.

-

Very interesting (negatively, of course) to see many similar accounts. Indeed, there seems to be a repeating pattern here. Unfortunately, Garmin doesn't publicly offer installation manuals or STC supplements unless you're an authorized dealer. So we actually have no way of knowing in advance what and how things will be done to get minimally involved.

-

Gear warning microswitch on M20J throttle

DC_Brasil replied to Martin S.'s topic in Modern Mooney Discussion

It is accessible from under the panel or behind the center pedestal? Anyone has pictures? I can't seem to find this switch or procedure in the Service Manual.