-

Posts

200 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by C.J.

-

Has anyone tried this? Avionics tech pitched this product as the least costly of two possible solutions. Running wiring through the PC access in the left yoke horn is no longer an option. Leather Yoke Handle Grips | Aircraft Spruce

-

My mechanics do not recommend Triad and stated this last year during annual - "Triad is definitely NOT one of the better shops for overhaul". I don't know a thing about Watson pro or con. My choices would be Poplar Grove, Zephyr, Bolduc, Penn Yan.

- 18 replies

-

- watson aero

- triad aviation

-

(and 3 more)

Tagged with:

-

Right wing just outboard of MLG.

-

Make mistaken assumptions much?

- 16 replies

-

- 1

-

-

- 205

- special edition

-

(and 2 more)

Tagged with:

-

@Ragsf15e Do you know who did the leather-wrapping on your yoke? It's the best quality I've seen on the older style yoke, especially at the PTT & the cover plate around the clock. I'm debating whether to just repaint mine versus splurging $1750 for leather. The repaint option keeps winning the debate. The price difference is substantial and could buy a lot of gas instead.

-

Great suggestion and I did just that 2 weeks ago. They do excellent custom work, but their quote was just too high and at least for me, SCS provides very good quality for price. The local shop is actually reupholstering the seats. They had some leftover leather in the color I wanted from a Citation job, along with a gap in their schedule to accommodate my project so despite the substantial $$$ I felt it was totally worth it.

- 16 replies

-

- 1

-

-

- 205

- special edition

-

(and 2 more)

Tagged with:

-

I wish I'd had that info 2 months ago but hey, no problem, the glue removal process is finished. As far as fumes are concerned, I wore a respirator and goggles. Without them my throat & eyes get extremely irritated accompanied with a headache. Even just a whiff of orange or yellow degreaser makes me nauseous Solvents & I just don't get along - brake cleaner being the worst. I find it amazing the mechanics in the shop breath those fumes on a daily basis totally unconcerned with their likely long-term health issues.

- 16 replies

-

- 205

- special edition

-

(and 2 more)

Tagged with:

-

When I read the online directions to fold the pie pieces under, it did seem an odd solution, so I'll cut those off too. I'd be concerned the edge of the circle would eventually fray. Maybe super-glue the edge to bind it, although the webbed carpet backing seems strong. I'll try it without velcro first and see how it goes. Thanks for the pirep. I hear you regarding the glue. Spent countless hours removing the old asphalt/tar-like glue off the floor. Acetone had no effect, but mineral spirits worked fairly well. Definitely nasty work. In the end I scotch-brite wheeled off the remainder. I didn't bother with nosewheel well - I'll just glue on top of the OEM glue.

- 16 replies

-

- 205

- special edition

-

(and 2 more)

Tagged with:

-

@Joris Just got the carpet samples from SCS two days ago. Outstanding customer service. Far better-quality carpet than Airtex IMO - provided you choose wool. For a M20C they provided two patterns, so I'll need to measure tomorrow to see if either will work or if a custom kit will be necessary. @Z W How did you go about measuring for the fuel strainer cut-out (or did SCS cut it) and did you glue down all the carpet down or use velcro strips?

- 16 replies

-

- 205

- special edition

-

(and 2 more)

Tagged with:

-

@Mooneydreamr Sent you a PM re: rotating beacon

-

Finger 4 Formation - Excellent photo.

-

What is the original shock panel angel/tilt in degrees?

C.J. replied to Zippy_Bird's topic in Vintage Mooneys (pre-J models)

@Zippy_Bird I just went through this whole process for my 1965 C's shotgun panel which was 14 degrees. You can e-mail support@mooney.com and provide your s/n 1285 & N9353M and ask for the panel tilt angle(s). Mr. Crawford will more than likely include an attachment of 2 blueprint type drawings for your plane. I suspect it will be for 14 degrees as well. The shop installing your instrument should know how to measure your panel tilt angle with the aircraft sitting on the ground. If not, they'll put it up on jacks to the aircraft's zero degree pitch AND roll angle and then measure the tilt angle for the lower portion of the panel. Your digital instrument should have a range of acceptable panel tilt angles. If for example the range is a maximum of 10 degrees and your lower panel being 14 degrees, then a 4 degree wedge will be placed between the back of the panel and the instrument bringing it into compliance. Hope this helps. I am not an avionics installer or A&P/IA. I elected to pull my entire left & right panel and install a custom panel set at 8 degrees. I had a new attitude indicator built to 8 degrees and put in a used turn coordinator that was calibrated to zero degrees and used an 8 degree wedge. Work should be complete in April. Best of luck, C.J. -

I already spoke with Rob at Flight Enhancements about estimated labor/paperwork time, however I'm curious what others actual install times were. My interior has already been removed. Thanks, C.J.

-

Definitely in the middle of maintenance. I'm praying it will all be completed in 8 weeks. The avionics tech actually needs to add one more shunt. Good catch though. I needed to do some unskilled labor myself before he could continue with all his work. Restoring a 59-year-old airplane is not for the faint of heart.

-

I'm not really "planning" on tying down during or flying through any heavy rain, but you know how that goes. I'm getting really good at cleaning with nasty solvents lately. I decided to install Soundex while I was tearing up the interior anyway. After persuading the '65 version of sound/temperature insulation panels off the skins I decided to clean the glue residue with acetone. Then of course I felt compelled to get an Airtex interior, so I decided to remove the asphalt-like adhesive that held the carpeting down. Looking forward to the day I can ditch the neoprene gloves & the respirator and fly again.

-

@0TreeLemur Thank You. With new avionics soon to be installed I definitely needed a solution to the 59 year-old weather-seal.

-

I'd like to replace the avionics access panel's rubber seals on my 65 C which are deteriorated. I looked for a part # in the IPC but found none. I have emailed Frank Crawford at Mooney Tech Support and am awaiting a response. In the meantime, I wondered if someone on MS had some input. 2nd question is what's the purpose of the foam rubber squares glued to the inside of the access panels?

-

Daytona Aircraft Services. Call me when you have a part number?

C.J. replied to Jrags's topic in General Mooney Talk

Right here on Mooneyspace.com - click browse then click downloads. Lots of manuals you can download from there. Hope that helps. -

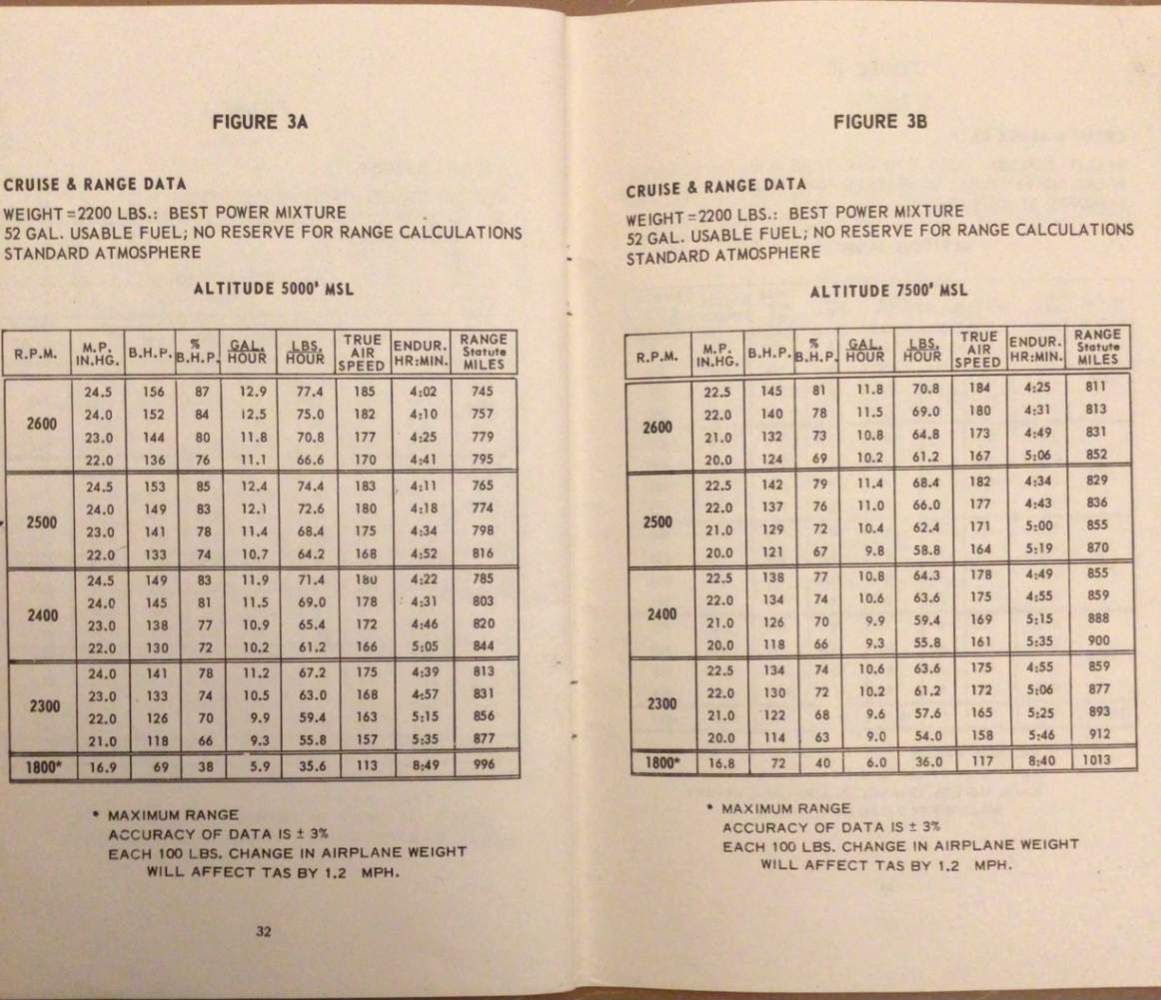

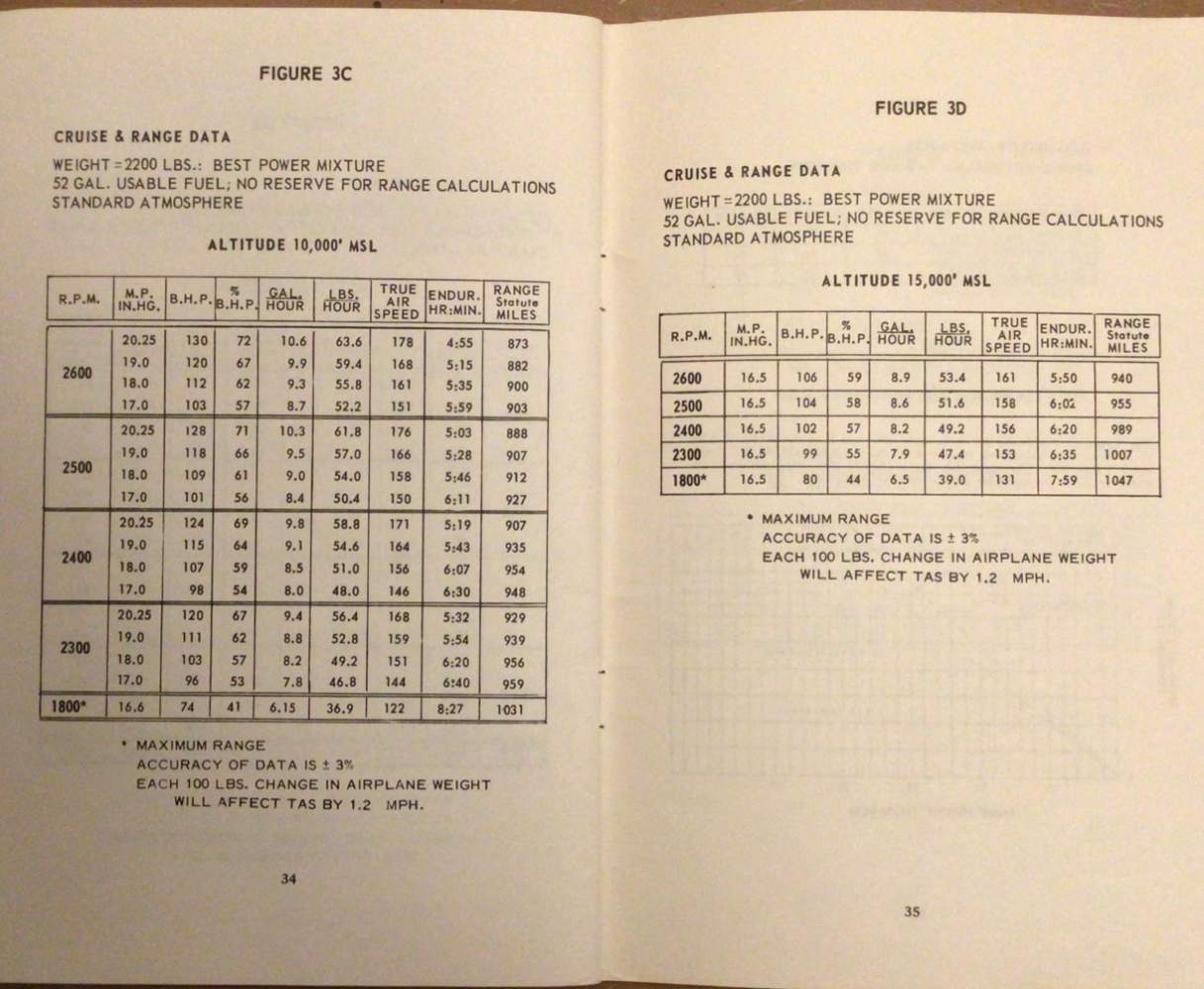

I considered a 200HP Arrow II and rented one for 7 hours before buying my M20C. I'd flown a C for COM/INST & CFI-I ratings in 77-78 & taught in a T-tailed Arrow IV in 79-80. I'd advise against a T-tailed Arrow due to poor pitch authority during take-off/landing but either a 200HP Arrow or a M20C (or E) would be a good choice. Test fly all of them & then decide which is the right choice for YOU. The claim of 140 KTAS in cruise from a 180HP Arrow is wishful thinking. Referring to the graphs below a 200HP Arrow II is capable of 140 KTAS given the right conditions, but I wouldn't count on it most of the time. An Arrow cabin seems more spacious but with a front seat passenger, staggering the seats is necessary for comfort & I doubt if there's more than an inch difference in cabin width. It handles well, stall is docile power on/off, dirty/clean thanks to that Hersey Bar wing but the trade-off is a nauseating ride even in light turbulence. During the time I was actively looking, Arrow II asking prices were nearly always more than a M20C. Mooney versus any Piper or Cessna single brings to mind the old saying "this is NOT your father's Oldsmobile". Push-Pull rods vs cables, laminar flow wing w/ flush rivets vs fat cambered wings, one continuous wing vs a left/right wing assembly & steel cage cabin for structural integrity, Johnson Bar low maintenance gear, a trim-able tail assembly & wide span flaps make a Mooney unique amongst the conventional bug-smashers out there. It has a good solid control response in routine flying & ride is far superior in turbulence to that of an Arrow. Stall is gentle with minor left wing drop w/ gear and flaps down, but the stall break while clean, with full throttle is abrupt accompanied by rapid left wing drop even with the ball perfectly centered. I operate 65% @100* ROP with my longest cross country from North Carolina to northern Michigan broken down into 2 or 3 legs. I have no speed mods but am equipped with Power Flow exhaust and flight plan for 135 kts @ 5000, 140 kts @ 7500 and 144 kts @ 10,000 interpolating between. My C can best those figures by a few knots. Best actual TAS at 10500 was148 knots. I typically operate at 2200 pounds GW. The 2 graphs are from the PA28R-200 POH @ 2650 lbs GW - TAS in MPH The 2 tables are from the M20C POH @ 2200 lbs GW - TAS in MPH Good luck with your search.

-

That ^^^^^^ plus they'll bring back the MMPI (Minnesota Multiphasic Personality Inventory) for currently employed pilots and for new hire applicants. Pretty much SOP in the '80s as part of most major airline's pre-employment screening process.

-

-

I used to car-pool with Fred Flintstone & Barney Rubble.

-

I'm at least that old too

-

@Fly Boomer How old are you?