-

Posts

324 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by gevertex

-

Appears to be right mag #3 based upon the EGT being a lot lower in the picture. Right is always lower RPM than left in my plane.

-

This is my first M20. I have since learned to lean enough that the engine won't throttle up to start taxiing. I then have to add some mixture to get moving. Run up with leaning has cleared the issue every time. I have not had it happen since winter started. A&P was convinced it was a fowled plug. I did manage to snap a photo of the engine monitor at run-up on each mag when it was marginal.

-

Not good signs from a couple shops unfortunately. As I understand it, a newly overhauled engine should not be seeping at cylinder bases so soon, but it's otherwise relatively common. I can get over having cylinders that will only last another 300-500 hours as long as that failure happens slowly with plenty of notice and not suddenly while I am flying. Inspections incoming.

-

I did not know there were different standards for overhauling cylinders... That's not good news. The good news though is up until recently oil consumption had been as low as 1qt/10 hours. The not good news is I was getting a fowled plug that I had to clear on about half my flights, but lately that hasn't been a problem. Perhaps it's the colder weather. I have been running Phillips XC 20W-50. I'll get the spark plug checked. I do have a cheap bore scope, but I wouldn't know what to look for. I'll get an A&P involved through Savvy.

-

I have chrome cylinders.

-

I appreciate all of the help / recommendations. I'll definitely be getting this engine looked at further given all of the seepage/leaks. I am going to go ahead and get the offending line tightened up, cleaned up, and give it a run / check. The rest looks minor enough to me that I could fly it to the closest shop to get a more thorough inspection / those issues corrected.

-

Agree, planning to get it looked over.

-

I'll write up the facts and you can take what you want from it. My situation was difficult. Lynne did the pre-buy and discovered the need for an overhaul (cylinder at 38/80 PSI and copious amounts of metal in the oil filter, and some history that had not been satisfactorily dealt with). I agreed to buy the airplane anyway for a significant discount. Lynne sent the engine off to Jewell for overhaul. Shortly before the engine was supposed to arrive back at Foothills, I found out from a 3rd party that Lynne was leaving and was trying to sell the shop. This was obviously really bad news for me as the airplane wasn't going anywhere and Foothills is in a pretty remote area with no other mechanics near by. Lynne left a couple days before the engine arrived at Foothills. So I was pretty stuck. I called other mechanics to see if I could get someone up there without luck. I was out of options. Luckily John bought AGL. However, John's list of items the airplane needed far exceeded Lynn's from the pre-buy. John recommended. -Overhauled oil cooler (old one had metal contamination in it) -New propeller (initially recommended overhaul, but blades didn't pass spec so ended up buying new) -Overhauled propeller governor -New oil hoses -Engine mounts -I am sure there was more Me being the type to want to fix/replace things before they break, especially in the engine compartment, I went for all of these. Annual happened a few months after that, and several more things were found -Dual mag in need of overhaul (~670 hours) -Ignition harness with missing parts (harness needed to be replaced as parts were not individually available). Harness looked end of life so it was on my list anyway I opted for several more items to be done as I was getting a new glass panel and didn't want any trouble. -Overhauled alternator -Overhauled voltage regulator Subsequently found a loose exhaust and intake header tubes, and the issues this post is about. I will say the engine runs fantastic. Very smooth. The only thing of note the occasional burble at idle, but I am told this is pretty normal for lycoming engines.

-

Yes. I have seen this. Sorry this happened to you. Unfortunately all of this started coming out after I had sent the engine to them. AGL Aviation had recommended Jewell so that is the shop I used. I really hope mine does not go as sidewards as yours. I did let Savvy know who rebuilt it. Luckily, I did not have them reinstall the engine. Engine, Magneto and all accessories were installed by another shop.

-

Jewell Aviation out of Kennet, MO did the engine. AGL Aviation did the engine reinstall. Carolina Avionics did the avionics install including the engine sensors.

-

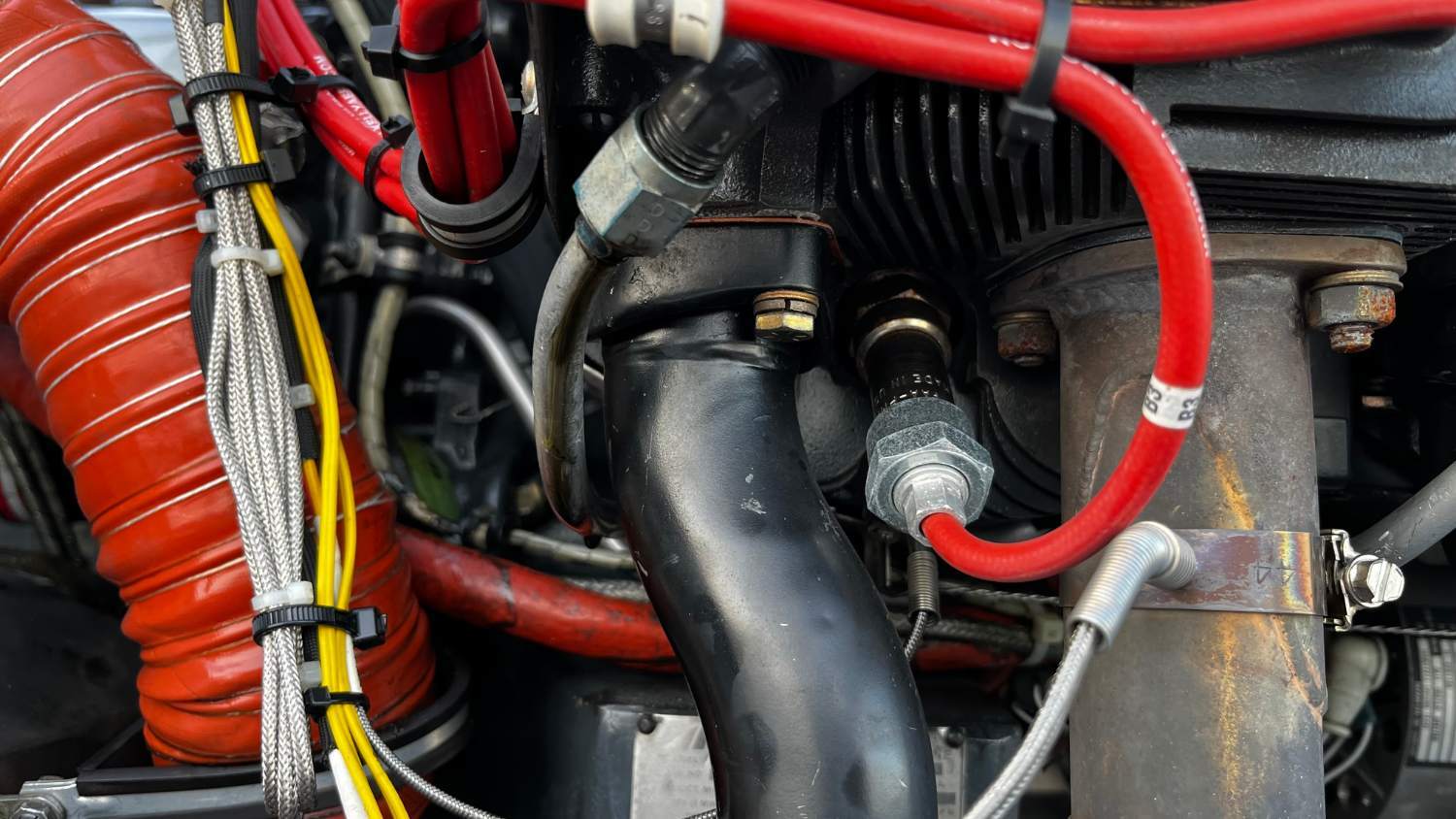

I went ahead and took off the bottom cowl and found a few interesting things. First, found what appears to be an oil line (is that an oil return line?) on cylinder #3 that had it's fastener backed off a few turns. It wasn't even hand tight. Most things under and around that were pretty much soaked with oil. Thinking that could be the primary culprit. I was able to confirm with a few other pictures two push rod tube seals that had some leakage. This is concerning as this is a recently overhauled engine. There may be good news there, it's possible this is old. I do remember after the avionics install seeing and asking about the clips that hold the push rod tubes in place. The A&P that I asked immediately indicated it was wrong and fixed it. So I am hoping the seepage is from before he fixed those. Also found some leakage from one of the intake header tubes. Looks pretty minor, but you can see where oil has leaked down the side of the tube all the way to the bottom. Also found a leaking oil pressure transducer. Also found a loose screw that appeared to be holding a fuel line. I did also find some brown oil looking substance between the crank case halves, but it's dry and appears to be some kind of sealant. Took a picture of the only part of the bottom of the crankcase half seam I could see and it looked clean also. Took a picture of the belly. It does look sooty, but I can't tell if this is too much or not. I have never cleaned down there. Most of the lower part of the engine was soaked in oil including wires leading to the alternator. This appears to be connected to the oil return line leak as those wires run up below that line. There was also oil on the bottom of cylinder #4. Most of the cylinders had seepage I could see. Also disappointing as this is a new engine. I definitely wouldn't expect any leaks from any of the seals attaching primary engine components this early.

-

Checked. It looked clean to me. Oil cooler is basically new too.

-

This was super helpful. I got the lower cowl off tonight! Luckily landing lights are in the wings. I’ll post an update shortly.

-

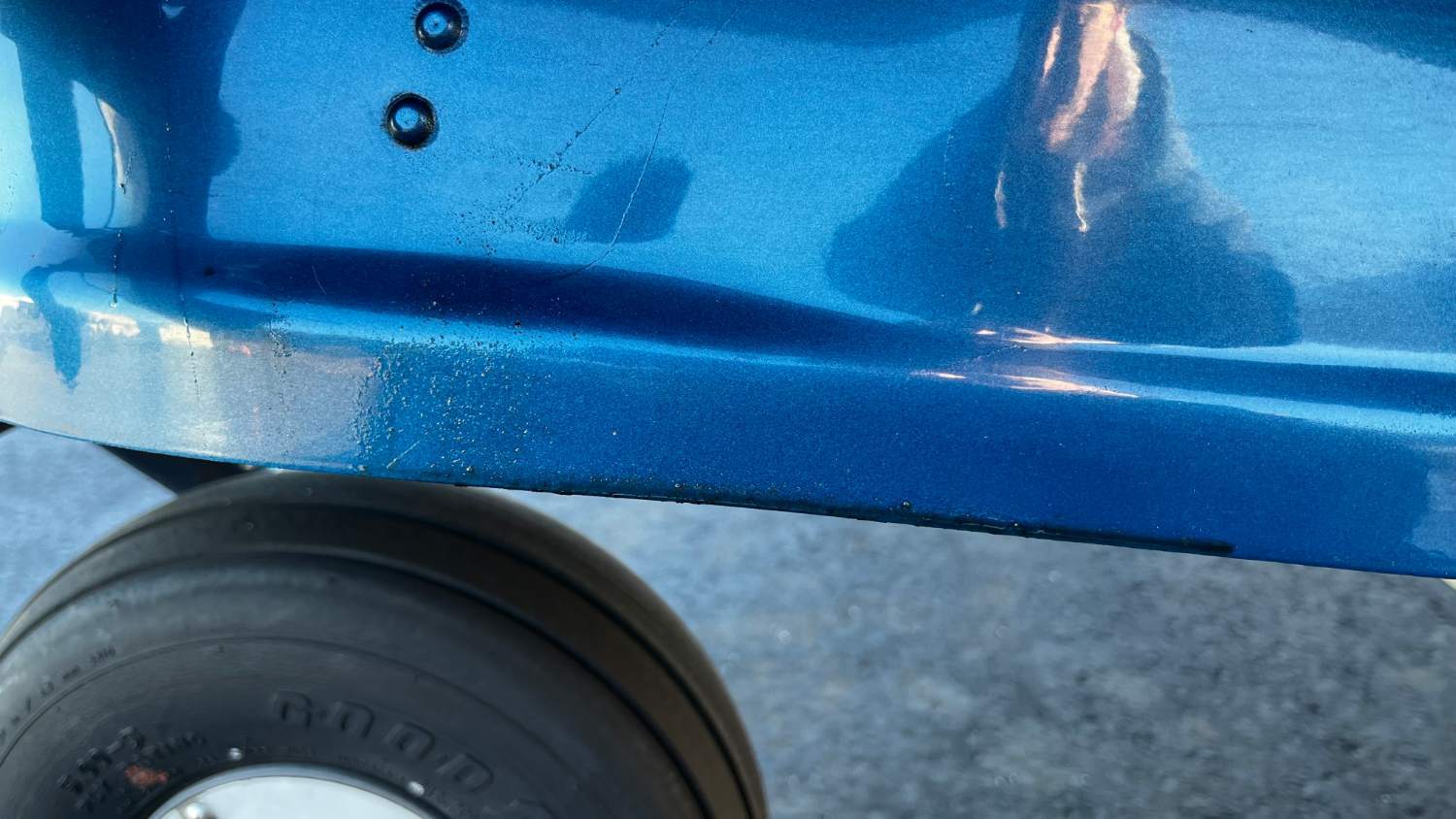

Mag seems to be clean Definitely didn't notice that level of leakage on the belly, etc. What got me looking more was the oil on the nose wheel door and the lower level of oil I noticed during pre-flight.

-

No. It's due for another oil change basically now. I am at 29 hours on this oil change.

-

Engine was overhauled ~70 hours ago along with all accessories. So really a significant amount of work. I had noticed some of this oil prior, and loose header tubes were found / corrected and cited as the cause. That fix it didn't seem to correct the amount of oil I was seeing in the cowl + this seems to be worse than prior given the oil quantity measured. I suppose I could be mistaken at the amount of oil lost (factors like temperature, slope of the ground, what else?) could impact measurements. Even so it's rather a lot of oil IMO. What do you think?

-

I had the top half of the cowl off yesterday. Need to figure out how to get the bottom half off, looks like detaching the cowl flaps actuator arm is required. It’s only been ~70 hours tach since overhaul.

-

I went to fly today and noticed that the oil was about 3/4qt lower than last flight. Measured 5.5/8 qts cold on Jan 21 and 6.25/8 qts cold on Jan 15th. Only 1.5 hours of flight time between measurements. So I started looking for oil and found a decent amount of oil. Pictures attached. Also found a screw driver hiding out... Now I know why the engine smelled a little like rubber after a long flight on a hot day. Opened a ticket with Savvy, but wanting to see if anyone here had any thoughts.

-

In gliders it's been a regular part of my BFR. One CFI made me do it at 200'. I also practiced it in a 172 with a CFI at an empty field. You can make the turn at 500', but you can't make the field unless the runway is long enough. With a 3200' runway we were about 1000' short of the field lined up with the runway. In the Mooney with a longer runway, I don't think it'd be a problem. I am at 500' while still over the runway at my home airport (7000' runway). Agree the key is to get to glide speed and don't rush the turn. It's a pretty good push to get from Vx at full throttle to best glide at idle.

-

Wow, that was fast! I was going to take them. only really needed one though

-

Panel Planning with G3X...what would you do differently?

gevertex replied to KSMooniac's topic in Avionics/Panel Discussion

GTR 20 is only COM (I have 2x GTR 20 already installed) https://www.garmin.com/en-US/p/140494 -

From cracked windshield to new panel

gevertex replied to Cruzjessew's topic in Modern Mooney Discussion

Very cool that Dynon supports those indicators on certified aircraft. Garmin has it too, but only on experimental.

.jpg.6bb6bb6d19327aa0656628119f977a17.jpg)