-

Posts

343 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by gevertex

-

Overdue update. Shop fixed RPM sensor and it's dead on now. They commented they are using a p-lead based sensor. I did get % power to show, and calibrated the fuel flow. It looks a lot closer now than prior. Engine has ~27 hours now. Airplane has been flying pretty good. Getting her flying at least 2x a week at this point.

-

Was there any wind during landing? I've noticed a gusty cross wind that kicks up after landing can sometimes cause me to need to react quickly with the rudder pedals to prevent a runway departure. This mostly appears to be related to slop between the nose wheel and rudder pedals. I'd check to see if you have any slop either between your rudder and pedals or pedals to nose wheel. Might be illuminating.

-

Just wanted to add that I came back to this after the fact and agree with you 100%. It would have made a lot of my progress a lot easier.

-

I might need to look at the calibration. I'll try one more time first though when the RPM is working properly and set it exactly to book numbers (including mixture) / check the fuel flow. Interesting on % power, I hear it's in the config. I'll ask the avionics guys. That would be even easier than a key number for sure.

-

~20 hours on the engine. So yes, thats a good point. It's not done being broken in yet.

-

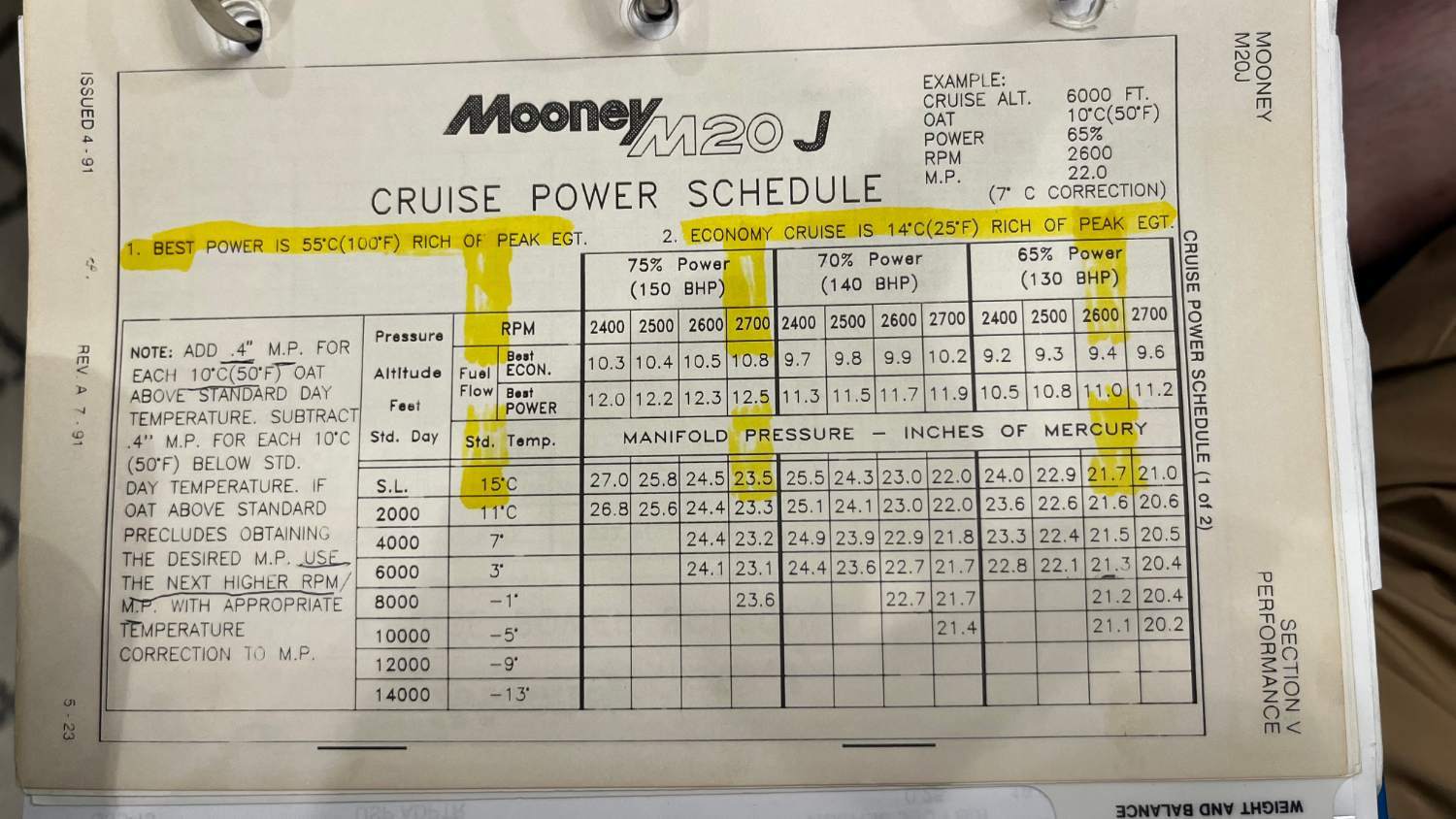

Good tip on key numbers, I just read about them as a result. I like the concept. Makes power management a lot easier. I am currently running it full out for break in. I did have the prop back to 2600 roughly but with the inaccurate RPM decided to push it up to 2700 for the picture so that I could compare TAS and power setting to POH more easily later. I was just a little surprised that the indicated airspeed wasn’t higher, but looking at the book + historical photos in cruise that is the same speed I was making prior to avionics install. So it checks out. I was just able to dig up this photo I took prior to the install. Everything looks identical except RPM and Oil temp. Hopefully those are resolved. I plan to pickup fly her again next weekend.

-

Oil temp probe was replaced subsequent to this. Oil pressure was also turned up subsequent to this. Good point on the CHTs. What would you expect for that fuel flow? Cowl flaps were closed fully FWIW. I landed once I realized Oil temp was probably incorrect.

-

Thanks! RPM sensor is malfunctioning in this pic. Prop is set to full forward though (2700RPM). Throttle is also full forward (still in break in period). I am running a little rich (127ROP) need to run it leaner.

-

Been flying a bit, but been working on the list of squawks (down to the last two now). This airplane sat for long time before I had it and I've been slowly dealing with all of the issues. Question for the group. How does this look performance wise. I know the RPM sensor is off (it was fixed after a second visit back to the avionics shop). Prop is set for 2700rpm in this photo. Airspeed seems a little low to me, but looking at the POH the TAS is 6kts under. Fuel flow also seems a little high. What does anyone who has experience with this model think? I just don't have a ton of experience with this airframe, so hard to know that is normal. I was expecting closer to 155kias from my limited experience prior to the avionics upgrade.

-

The shop is just about done with the corrections. To the point made earlier, the RPM sensor has been a bit of a problem. They were only able to get to ~100rpm of the measured value. Good news I didn't share earlier: Useful load is now 1039lbs. Net removed ~50lbs of stuff from the airframe. It was really hoping to get useful load over the 1k mark. Now it's firmly there.

-

Its interesting, I wonder how this is supposed to work. Usually with halls effect sensors you have a magnet mounted to the spinning part you want to measure RPM of and then the sensor mounted to something fixed near by (in this case the magneto case). It's usually pretty straight forward unless there is a lot of EMI nearby. I wonder if you lost your magnet or if the engine bay is a particularly EMI rich environment. I can imagine a magneto would throw off plenty of EMI.

-

That doesn’t sound fun. RPM is pretty important. Hopefully mine is easier.

-

Welp, hopefully they can get it fixed quickly. The more you know, right?

-

Looks like the shop will take a look at it again this week. Hopefully more bleeding as suggested will take care of it.

-

Good question. I didn't have the sense to check it when I was there. Shop is taking a look today. I'll let everyone know what they find. I did notice some fluctuation on the RPM value while on the ground a few times. Might be a bad / loose sensor.

-

It's something similar to this. A&P showed me one time in the shop. https://www.pilotshop.com/catalog/inpages/jpi10-05459-61.php I believe it works on halls effect.

-

Right side speed brakes. Left side is quiet. There is only 1 RPM reading. Settings were set to 2600 RPM and engine sounded like 2600 RPM. Plane climbed well also, but RPM read only 2270 I will definitely make some adjustments at some point, there was just enough that I sent it back to the shop.

-

Flew the new panel for the first time Friday. It was pretty awesome. AP worked great! Unfortunately there were a few squawks, so back to the shop it went. First one I am most concerned about. AHRS on G3X tumbled on run-up during second flight and tumbled again on takeoff attempt. The G5 looked fine, but I got an exclamation on the screen when this happened. I aborted the takeoff. Voltage reads 30v when at full power and produces an alarm. RPM reading wasn't correct. Read 2270RPM when at 2600RPM while in flight. Stall horn is inoperative The Electric trim switch on the yolk is reversed. Up goes down, down goes up. That one scared me for a second. Speed brake motor now runs continuously after first activation. AFAIK, this did not happen prior to the panel install. No speeds were configured on airspeed indicator. Missing at least white, yellow ranges Lean assist did not appear when leaning engine in split screen mode Oil pressure alert is set too high and goes off while at ground idle (1000rpm) Fuel tanks not properly labeled Fuel quantity not correct. Showed 59 gal after an hour of flying. Started with 62 gal.

-

I got it back and brakes are spongy. They seemed to modulate better and I could stop the airplane fine, but had a hard time holding it during run up. Any tips?

-

Another update. At annual (with a 3rd shop A&P/IA), brake fluid was discovered to not have been fully flushed, was way overdue for a change. Fluid was described as gummy. Master cylinder needs to be rebuilt. Ended up with 3rd shop as plane was in for avionics refit when annual expired. Good thing too as it looks like they found the problem. If it comes back working well then I likely found the problem. I thought it had been flushed, but maybe not. Need to double check the logbooks.

-

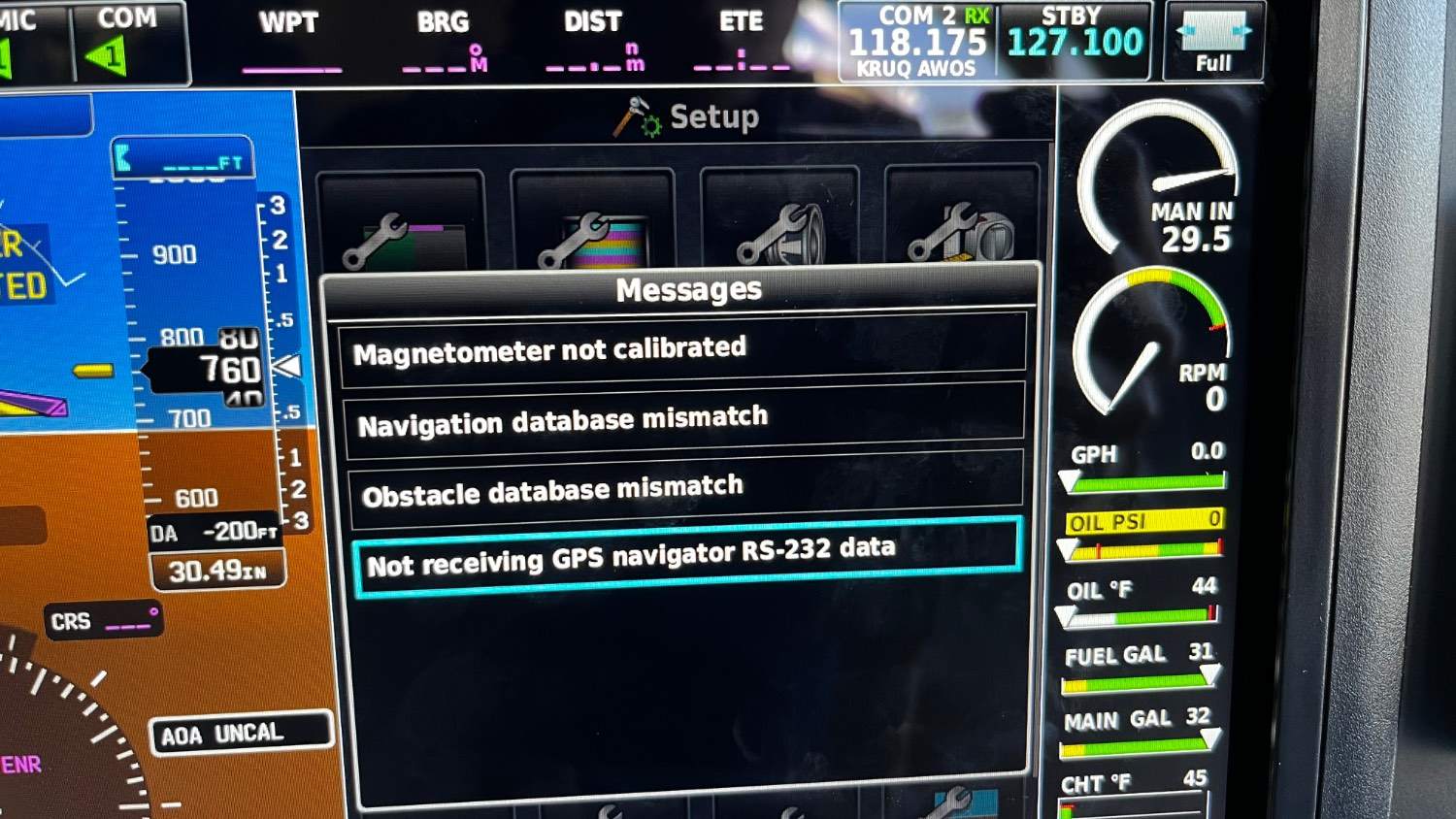

I like to be proactive in understanding issues. Agree the magnetometer calibration and database mismatches are easily solved issues by the installer. Just trying to get educated on what the RS-232 issue could be. The navigator was powered on and everything else appeared to be working. I could even see HSI input on G3X from the navigator. Probably just misconfiguration like you say. I'll check with the installer after the annual is complete.

-

-

Does anyone have any experience with the RS-232 issue I am seeing? Is that likely to be fixed by a DB upgrade or is this a missing / broken physical connection. I had understood that RS-232 is a backup bus for the IFR GPS to talk to the G3X.

-

New Magneto to arrive Monday. Finger crossed.

-

That's a good idea getting a passenger involved. I can't wait to try it. Just waiting for a new dual magneto... Any day now.