-

Posts

343 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by gevertex

-

This is one blade after run-up and 5x prop cycles. You can see some light streaking on it. This is new. I never noticed any streaking prior.

-

Flew to breakfast Saturday and noticed some light streaking on both blades of the prop after the flight. The prop has roughly 30 hours since new and is about a year old. I've never seen streaking before. I took off the spinner to take a look and get some pictures. I wanted to get your thoughts. I ran up the airplane twice and cycled the prop 5 times each time per McCauley's recommendation in Service Letter 1998-24 and did see some very light streaking afterward on one blade, barely noticeable. I cleaned the spinner inside and out before putting it back together. Thoughts?

-

Get very comfortable with the airplane before putting in a new panel. The complexity of verifying everything was working properly was compounded for me significantly because I did not know what the airplane's normal baseline was for various sensors. I also had a new engine, so this complicated things further. I love the layout, it's perfect. I spent a lot of time figuring out where everything should go and I don't have any regrets there. I don't miss the lack of a nav radio at all. It'd be nice to have a backup to GPS, but worst case I can still take radar vectors.

-

I know others have posted about it, but I was shocked that it actually worked. I took my ignition key to ACE Hardware and they made me two copies in ~5 minutes for $8. Lowes didn't have the blanks. I have the key that looks like a filing cabinet key. Cheapest part on this thing .

-

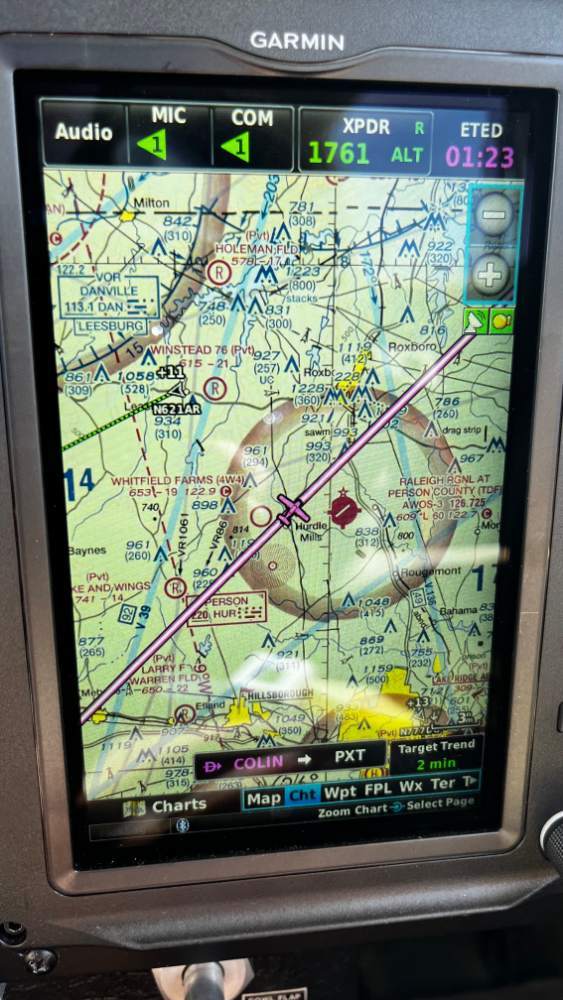

I set it to unrestricted for the flight this morning, seemed to work great after that. No missing traffic that I could detect. Now to figure out this AOA

-

-

I'll check this week when I go flying.

-

So then this is possibly a leak somewhere in the engine when the plane is at rest, not something happening while running? The other cowl flap looks the same. I wonder how a localized leak would cover both cowl flaps (just curious).

-

I've taken the approach of making sure I am above 6 before takeoff. I don't check the oil after the flight, only before the next flight.

-

Question for the hive mind. I noticed oil on both cowl flaps this morning during pre-flight. This picture is from the cowl flap below the exhaust. The other one has a similar amount of oil. The engine can hold 8 quarts of oil, and I noticed it'll loose 3/4 of a quart every 3 hours or so until it gets to ~6 1/4 quarts and from there oil consumption is very low. I flew it an hour at the 6 1/4 qts level and didn't notice any consumption during that hour (I waited until next day for the oil to cool to measure the level). I have heard you should run these engines at 7 qts, but 6 1/4 seems a low place for the level to stabilize. I am still in the break-in period with ~30 hours total tach time on the engine. Any ideas what this is from? Is it normal? I couldn't think where the oil would be coming from under the exhaust. On the other side there are several tubes just inside the engine cover above the cowl flap and IIRC one of them can vent oil.

-

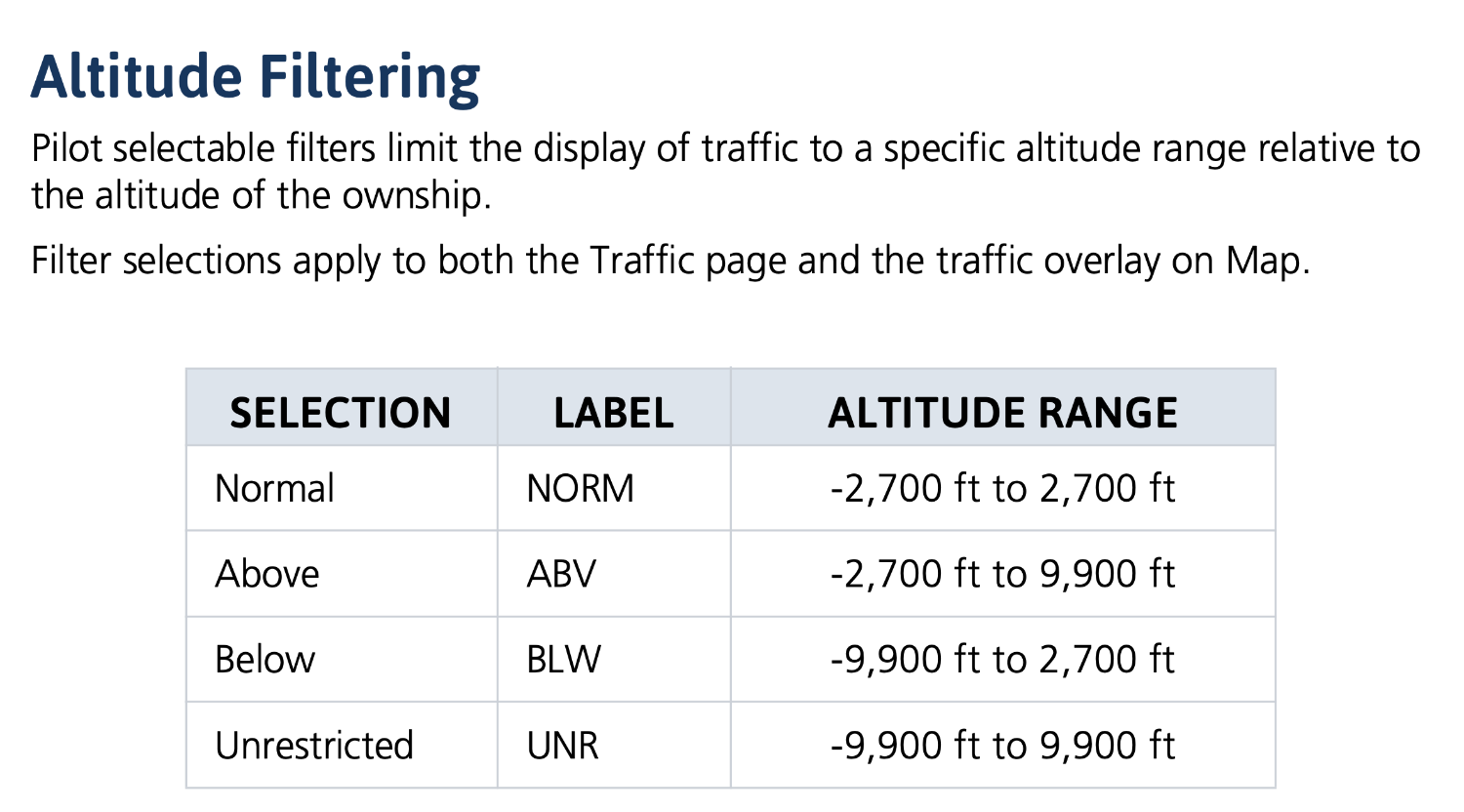

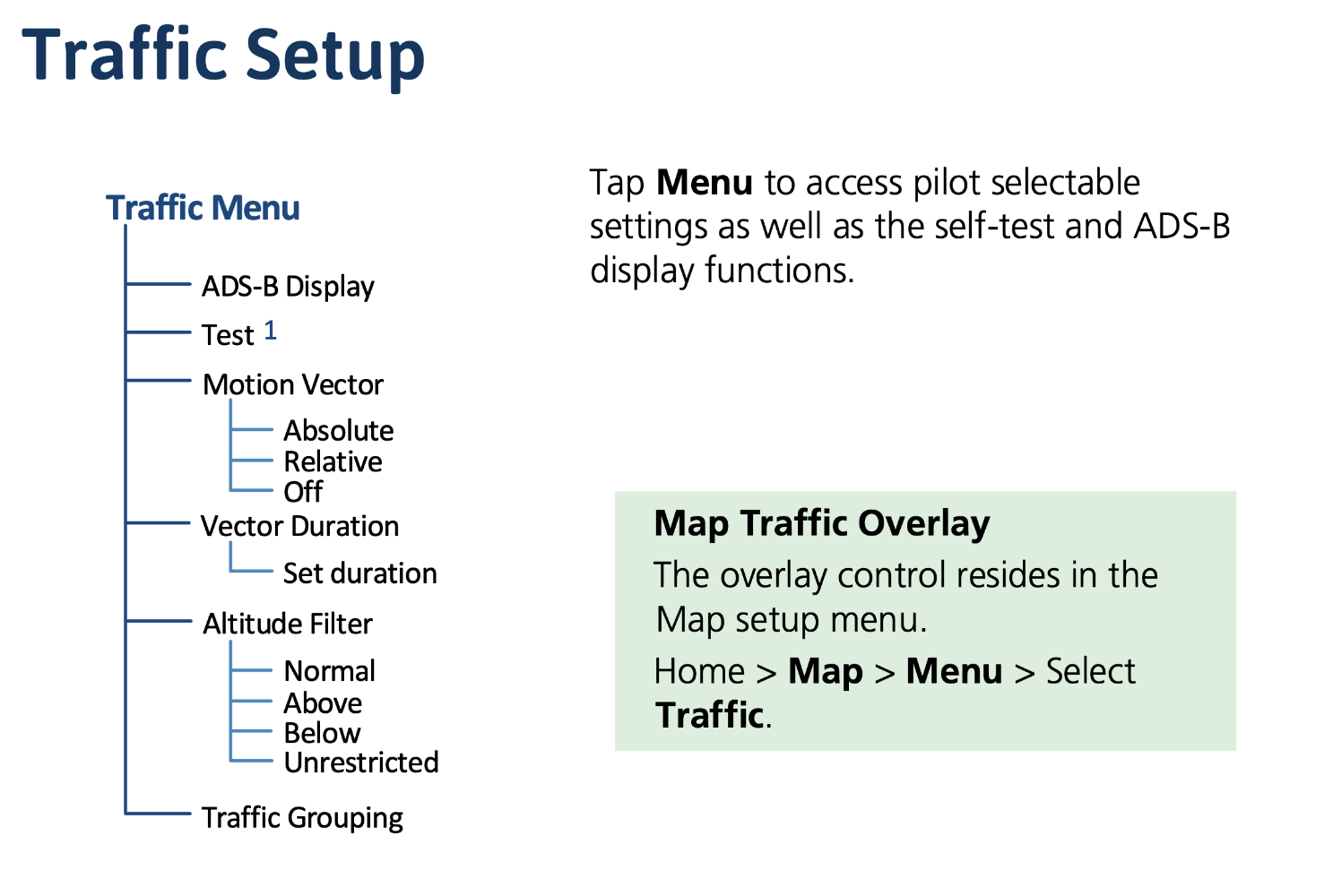

Thanks, that is really helpful. I read through the manual looking for references to altitude and found a few interesting things. FIS-B service is provided continuously, but ADS-R including TIS-B will only be broadcast by a GBT when an ADS-B participating aircraft is within the GBT’s defined service volume. In this case, a GBT will only rebroadcast TIS-B information relative to the ADS-B participating aircraft. Only traffic that is within 15 nm lateral and 3,500’ vertical of the ADS-B participating aircraft is provided in the broadcast. Non-participating traffic aircraft located farther than 15 nm laterally and 3,500’ vertically from the participating aircraft is are excluded from the information transmitted by the GBT. I take this to mean that this traffic would not have been rebroadcast by ground stations, so the only way for my Sentry to see it would be Air to Air. But then I saw the below: Full traffic services available for an ADS-B participating aircraft (ground linked TIS-B, FIS-B and ADS-R, and Air-to-Air ADS-B). If you are using the ADS-B receiver on a non-participating aircraft you may still see this when you are within the service area of any participating aircraft. As a non-participating aircraft you are only receiving TIS-B traffic information for traffic within 15 nm and 3,500’ of a participating aircraft. My read on that is as an ADS-B participating aircraft I do not have the 3500' limitation. I read the manual for the G3X touch and didn't find anything on configuring the traffic view to have a broader altitude restriction. Any tips for finding it?

-

Hey All, I've flown the panel quite a lot. I noticed ADS-B in viewed on the G3X Touch from the GNX 375. I compared that with Sentry and ForeFlight. I found the G3X is sometimes missing some targets on the map. The avionics shop chalked it up to a software issue, reloaded the software, and promised to look at it again if I continued having issues. They also mentioned that the G3X could be combining targets in a similar area. Interested to hear everyone's thoughts as none of this seems right to me.

-

I know the feeling. I had about a half dozen of those until the engine was finally ready.

-

Yes, I always run full rich for mag checks. I only leaned for ground ops and to clear a suspected fowled plug. Subsequent runup was at full rich and checked ok. When you say checking mags while lean will give me exactly what I saw, do you mean the excessive drop or fixing the excessive drop?

-

Left mag dropped 130rpm Right mag dropped 200rpm limits are 175 drop and 50 difference between both.

-

Good luck! Have fun!

-

Took way longer than anticipated in my case. If you truly haven’t been in the left seat in a year, highly recommend getting with a CFI beforehand and or bringing a CFI with you for your inaugural flight. If it were me, I’d hate to have a problem with a new engine and be a year out from my last flight. In my case, I hired a CFI to do the initial test flight and brought another CFI with me on my first flights after a long time not flying. I wish you luck, it’s exciting getting a beautiful machine like our Moonies are back after a long time down.

-

According to the logs, they were cleaned and gapped at annual about 20 hours ago.

-

Good point. I'll pull the cards and look at the data next time I go out to the airplane.

-

Hey All, Looking for some advice. My 92 M20J MSE has an overhauled engine and dual mag. I have noticed a few times on run up that the right mag drops a lot more than the left. ~70rpm more. It dropped today from 2030 to 1830 which is obviously higher than what is on my checklist. It runs smooth on both left and right. I do use pretty aggressive ground leaning. In the few cases I had an excessive rpm drop, I went to full power leaned out and stayed there for a minute or so before trying the runup again. Everything alway checks out during the second runup. Plug fowling is the obvious first possibility, but I thought I had eliminated that with aggressive ground leaning. Recently I have leaned so much that I had to richen slightly to make more than 1200rpm when pulling out of my spot. Are plugs just fowling or is there something else going on I should be thinking of? Thanks all

-

This happened to me. Trim switch on the yoke was backward after my avionics install. Luckily I recognized it was backward with just a few seconds of trim input once airborne. My mistake was checking the trim on the ground but not checking the direction. Lesson learned.

-

Thanks for the reply. Fair point on the order of operations for shut down. Checklist calls for master off first then alt field. Sometimes I inadvertently reverse those steps. I did just have the voltage regulator overhauled and this was happening before then also, so I don't think it's related to voltage regulator. Good to know this is common. My A&P didn't seemed concerned (it's a standup outfit, I trust them), but I wanted to understand it a little better.

-

There are a couple issues I wanted to get input on from the hivemind. Frequently, if I turn off the Alt field switch with the master on, the alt field breaker flips. It does not flip when I turn off the Master first. I have noticed a burble in the engine rpm once the engine is hot on the ground (need to confirm if it doesn't happen when engine is cold, but only noticed it so far after landing and taxiing). Every few seconds, engine will decrease 10-30 RPM and then go right back to where it was before. I might not have even noticed if not for the digital RPM readout. I can also hear it slightly in the headphones. Still happens even if the engine is very leaned out for ground ops.

-

Over due update. Had my first annual and a lot of other work done. Here's what I've had done so far since I got it Overhauled engine New prop New oil hoses / oil cooler Overhauled prop governor New scat hose Fixed brakes by rebuilding / replacing fluid Replaced baggage door and cabin door seals Second oil change New avionics panel New locks (baggage door lock was inop so replaced both locks with medco) New alternator Overhauled voltage regulator (was running hot at 30v) LED landing and taxi lights New battery (with engine reinstall) New stall switch I am sure there are more things that I missed.

-

Wanted to provide an update on this. Shop found significantly over due brake fluid which was likely the culprit. Described the consistency as like honey. Here was the work done to get it working like new: Rebuilt all master and slave cylinders Replaced brake pads Replaced brake discs with Black Steel Flushed fluid fully (removed all fluid and replaced with new) Bled brakes 2x (first time pedals were mushy, second time worked like a charm) Brakes are now very effective.