redbaron1982

Basic Member-

Posts

740 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by redbaron1982

-

I don't understand, aren't corrective glasses allowed for 2nd class and class 1? Or the 25/20 was with corrective lenses? Great work following all this process through the end and congrats on your renewed 2nd class medical.

-

Engine misfire on climb and cruise

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Spark plugs, I'll have those checked next Monday. -

Engine misfire on climb and cruise

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

I want to take advantage of this to give a quick PIREP on SavvyAviation, I think most of you guys are already familiar with it, but anyway. Great service, great value. For me is a no brainier to have their analysis service. The cost/benefit is huge. The value of your engine, aircraft and even more your life way outweighs the yearly cost of Savvy. -

Engine misfire on climb and cruise

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

BTW today I checked to see if I could see anything obviously wrong with a lead wire or anything else and although I didn't find anything I did find that the leads are touching sharp aluminum edges. Is it ok to have this kind of things after a annual from Maxwell? For me is seems like it should have come up in the annual and be fixed. Suggestions on how I can fix it? -

Engine misfire on climb and cruise

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

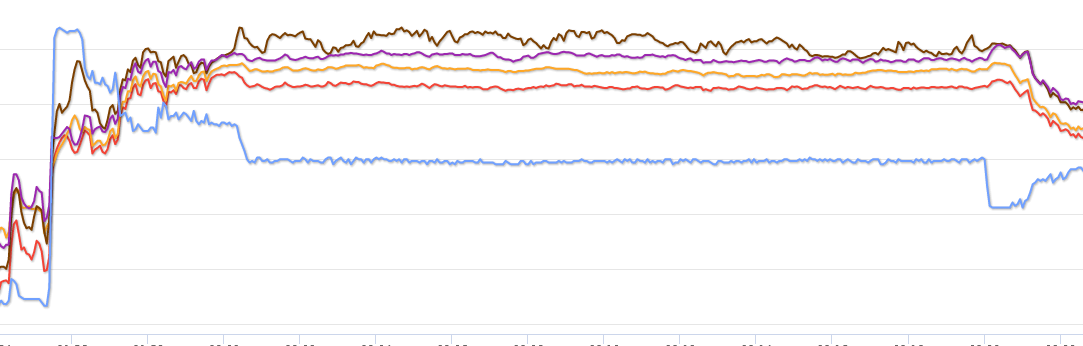

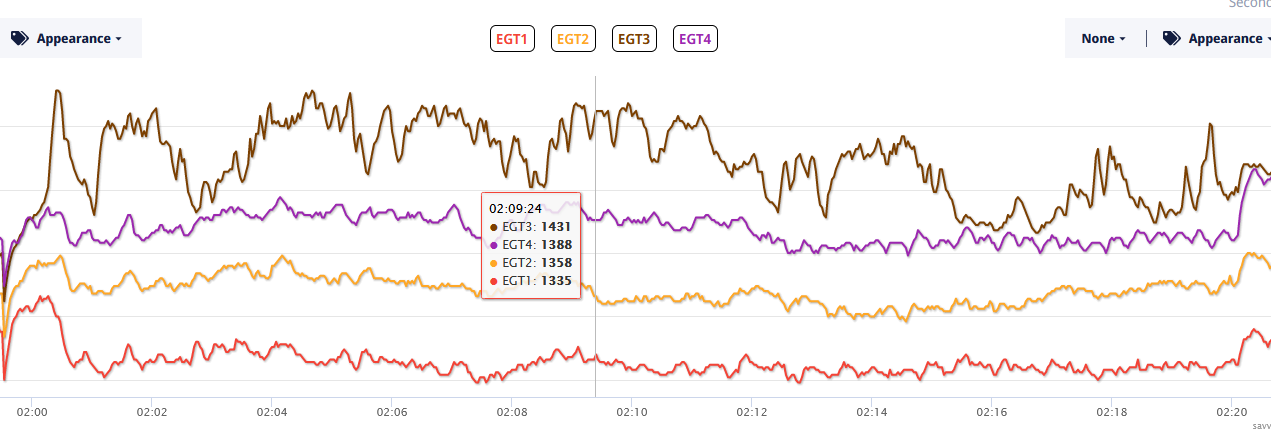

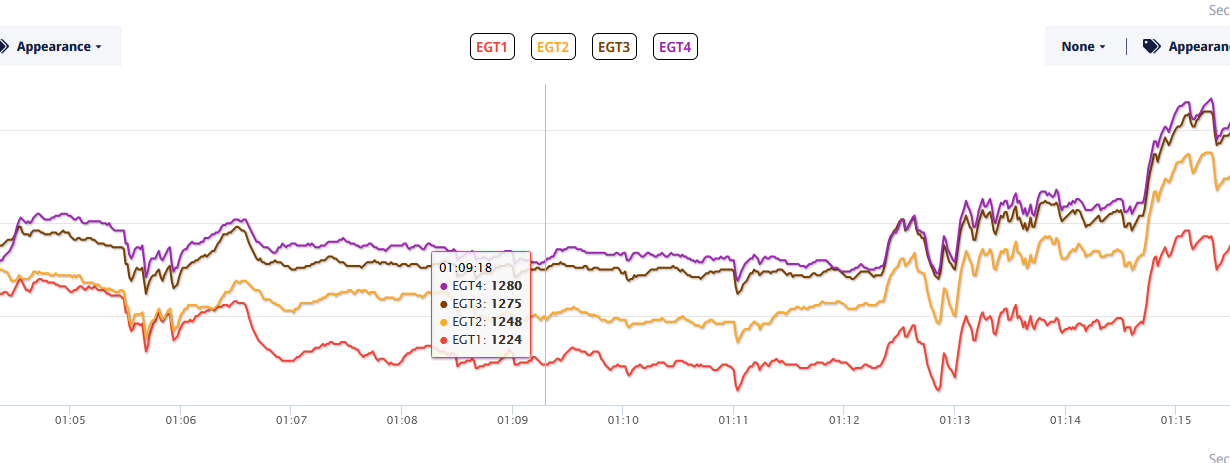

Hey, a quick update on this, I got a reply from Savvy (great first impression, they process my case in less than 6 hours!) and they say that there are misfires in Cyl #3, most evident at the end of the flight. Now that I know where to look it does seem that EGT of Cyl 3 is not correct. This is the last part of the flight, where according to Savvy there were a lot of misfires: And here a previous flight, without misfires: In the first one Cyl #3 is not tracking the other cylinder and seems to be more erratic, while in the second one, they all move more or less in sync. I will get the Cyl #3 spark plugs checked. -

Engine misfire on climb and cruise

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Now that you guys mentioned, the debris for sure are from the sealant. The color matches the sealant color. Regarding the misfires, they were not too many, maybe in one pattern lap we had 2, and then in another we had none. The ones we had they seemed to be just one misfire, not noticeable change in RPM/MAP. After the first couple of misfires we did a runup and both mags seemed to be ok. -

Engine misfire on climb and cruise

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

I'm reducing RPM/MAP @ around 500f AGL, when I don't forget (again, transition training and complex endorsement all together). I'm leaning in the pattern and while taxiing, maybe I have to do it more aggressive. Anyway, I'm always flying with a CFI that owns a M20J as well and have lots of hours, so I'm confident I'm not doing anything too off, otherwise he would bring it up. One additional thing, when I swamp the tanks, there is no evidence of water and the aircraft is always hangared. What I do see, a tiny bit, are small debris, not much, but a few. Seems red, like rust. I mentioned this to the CFI that helped me bring it home (not the one doing the transition training now) and he disregarded that as not important. -

Engine misfire on climb and cruise

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Mags were recently (10 hours) overhauled by Kelly Aero. If it's the mags then it could be something that was not left in the right way. As additional information, the airplane has been grounded for 14 months due to a big repair, I don't know if it is something that could affect (small debris in the fuel or whatever). It's also out of a fresh annual from Maxwell. -

Hey guys, yesterday I was doing pattern work with my CFI for the transition training and we felt a couple of misfires, the first one on the climb out after the second TO of the day. You can see that before the next TO (3rd one) we did a runup and everything looked ok. But we kept having some misfires while climbing out or at cruise, on both tanks. This is the link to Savvy: https://apps.savvyaviation.com/beta/shared/flight/6722994/0f7ce7f1-730e-4526-8f41-e9d9caad11c1 I've already requested them to do an analysis of the flight, but additional opinions are always welcome. BTW: the oil pressure is not working ok in the GI275 (it is in the old analogue gauge and was in the green, between the lower limit on cruise or mid way in the green at full power) Thanks.

-

Thanks Skip, it totally make sense. I didn´t thought about the edges of the touch up being too thin and deteriorating. What I saw in youtube, at least the ones that you cannot see where the touchup was done is to do it with a pen/pencil, as you mentioned, and then using a very fine sand paper (1000 and up) make the touch up flush with the rest of the paint. After that, regular polishing should bring the gloss back. That's what I'm planning to do. Will try in one of the old touchup to see if I can make it "disappear".

-

I am almost convinced on doing the following to fix some the small places where there is chipped or lose paint (mainly in the rivet heads): First I'm doing a thorough cleaning (quick clean with detailer spray, then clay bar, after that Chemical Guys V36 and then Chemical Guys V38). This has the intention to bring the current paint as similar as possible to the original color. So far in the areas I've tested the results are great. Second, use scotch brite to remove any lose paint and also to remove some previous touch ups with pens. The color match but you see a small bump whenever the pen was used due to much paint accumulated. Third, treat with the adoline pen. Fourth, use some spray can of Matterhorn White to repaint these areas, trying to blend with current paint. Fifth, last pass of the newly painted areas with V36 and V38 polishing compounds to help with blending. First question, what do you think of this? Does it make sense? Second question, regarding the Matterhorn white in aerotouchups.com, there are tons of different types, one seems to be brand specific (Beechraft, Cirrus) and others just different numbers, like K8704-2KA Matterhorn White 2K Aerosol or AF402-2K Matterhorn White 2K Aerosol. So which of all matches the best a 1985 Mooney M20J? Final question, does anyone know were to get like a color chart for Mooney? Mine is white with two tones of blue stripes. I've checked the POH and I don't see the color specification anywhere. Although not now, I'm planning on eventually doing some touch ups in the blue parts so I´d like to know which color to use. As reference, this is my aircraft: photo Thanks!

-

TKS taking forever to wet the panels

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

It's non FIKI, so no backup pump -

TKS taking forever to wet the panels

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

If you can share photos too would be awesome! -

TKS taking forever to wet the panels

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Can you send me a couple of pictures of your setup? I'm in Houston area, I should start doing some long XC closer to the summer (whenever I've finished my transition training and get more acclimated to the airplane) If I haven't figure this out by then for sure I will ask yours! -

Hey, As I continue testing everything equipment in my new (to me) Mooney, one that is giving me a hard time is the TKS system. So the thing is that it hasn't been exercised for 14 months (long repair). I run it some days ago, and no wetting at all (and no visible drippings anywhere). The fluid level indicated 1.7 gallons. The windshield de ice works OK. Today, while the main pump was running, I use the windshield because I read that this can help with priming the main pump. So it did something, one wing was wet the first couple of feet, the other one was wet about 4 feet and one of the horizontal stabilizer panels dripped a bit from the part closer to the empennage. The main pump run for 1hr approx. and 20 minutes intervals I run the windshield pump just in case it helps with priming. As you can see I still have loooots of TKS panels not getting wet. Two questions: Should I continue running the main pump every time I go to work (I'm doing a deep cleaning outside and inside) in the airplane or if after 1hr not all surfaces are wet I should stop and get the system inspected? Is there anything else I could do to make wetting all the panels faster?

-

Gi 275 indicating 130PSI oil pressure

redbaron1982 replied to redbaron1982's topic in Engine Monitor Discussion

Thanks @AVDB, the GI275 is installed with a GEA 24. Being that the information you shared is on the electrical side, do you think this might an electrical issue more than a sensor / sensor installation issue? -

Hi all, One of the issues I need to fix with my new Mooney is that the Gi 275 is indicating extremely high oil pressure, even with engine not running. The value for sure is wrong, the old analogue is indicating values that make sense: no pressure when engine not running, in the green with engine running, higher when engine is cold, a bit lower when engine is warm. I'm going to take the aircraft to an avionics shop that is in my home airport for a software upgrade on the Gi 275 and also to take a look at this. Just so I have some background to discuss with the shop, what could be causing this issue? At some point I thought a broken wire, but the pressure was fluctuating, although just barely (from 135 to 133 or something like that). Would this be more an electrical connection issue or the sensor itself? One year ago when the airplane was ferry for a lengthy repair this was working ok..

-

-

Idea (and question) for cleaning 430W buttons contacts

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Just to add something, in case someone else is crazy enough to give this a try: * Make the punctures right in the letters. It seems that the rubber is transparent, paint with black. If you puncture the black part you'll remove the black paint and whenever the lights are on you will get a bright spot there. If it happens that, you can fix with a sharpie. * When you press the trigger on the contact cleaner, make sure you first hear the liquid going in and wait for it to finish. If you don't hear anything it is because the tip of the needle is still in the rubber. If you take out the needle before all the pressure is released you will get a splash of contact cleaner that you will have to clean. -

Idea (and question) for cleaning 430W buttons contacts

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Hey guys, I want to give you an update on this, just in case it might be useful. First I want to clarify that I did take into consideration your comments and risks, mainly on creating a entry path for dust that could eventually make things worse. I think this risk is not significant because the puncture is so small (and rubber tends to fill in back the puncture) that not even water goes through it. This is how vaccine vial works, you puncture through a rubber cap to get some of the liquid out, and you can do it several times. So I tested today in the morning first in the MX20 (that is an obsolete equipment that I wouldn't be too sad if it breaks) and it didn't damage the equipment and the buttons were much more responsive. With this added confidence I did it in the G430 and same result, unit works perfectly and buttons are very responsive. Now the only thing to see is for how long the buttons will continue to work. -

Would like to ditch my vacuum system

redbaron1982 replied to M20 Ogler's topic in Vintage Mooneys (pre-J models)

How much of a useful load increase it's expected by removing completely the vac system, the AI and DG? I read that is not much. -

I can print to whoever want's them, you would have to pay for the shipping only. I'm in the Houston area.

-

Idea (and question) for cleaning 430W buttons contacts

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

There are good pictures here (https://onedrive.live.com/?authkey=!ABSujBZG6gUB7g8&id=8712D784B64E679!95504&cid=08712D784B64E679) from a guy that disassembly it. Why the contact cleaner would help? The actual contacts are this small metal things that with time they get dirty from the same stuff that is used to protect the PCBs. The problem is not itself the springiness of the key, but in my unit once you pressed and overcome the resistant of the rubber pad you need to continue pressing using the tip of your finger to actually make the button work. In the flight school were I used to fly there were 430W units like this (and some transponders as well) but there were others that once the button was depressed it would work, without having to put extra force on it. -

Hi, Something that I'm trying to improve is the feel of the avionics buttons (mainly in the 430W). They are really hard to press. Which is not only uncomfortable, but also it adds to the work load when flying IMC. I tried spraying contact cleaner on the side of the buttons, with no success. Which makes sense because the gap between the button and the from panel is small, and there is a rubber membrane underneath as well. I saw a post in other forum that completely took the 430W apart to clean the PCB, which even being an electronic engineer I don´t feel comfortable doing (apart from being illegal for sure). I don´t want to pay an avionic shop what I think is going to cost a lot of money (>1000usd?) to get it refurbished. So I have an idea and want to share it with you to have your opinion (and maybe it can be helpful for some of you as well). I thought of attaching a G25 needle (0.5mm outer diam) to the end of the plastic tube from the contact cleaner, like in the picture below: The idea would be to perforate each button from the side to get underneath it and then send a small amount of contact cleaner down into the PCB. I tested with a TV control remote (which the buttons are the same technology as the 430W) and didn´t break it. You can´t even tell there is a puncture in the rubber. The spray get out of the tip of the needle without problem. So, what are your thoughts? More important this is if you see any risk of doing this.

-

I'm planning in getting this to touch up mainly around the rivets, that is my where the paint in my Mooney chipped off. My question is, as I can see the aluminum, should I first apply some anti corrosion?