redbaron1982

Basic Member-

Posts

756 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by redbaron1982

-

Best power vs economy mixture setting

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

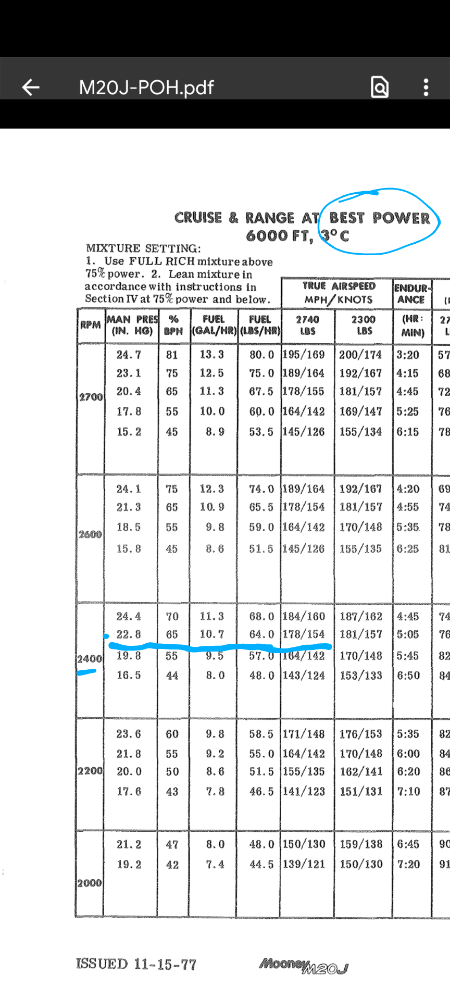

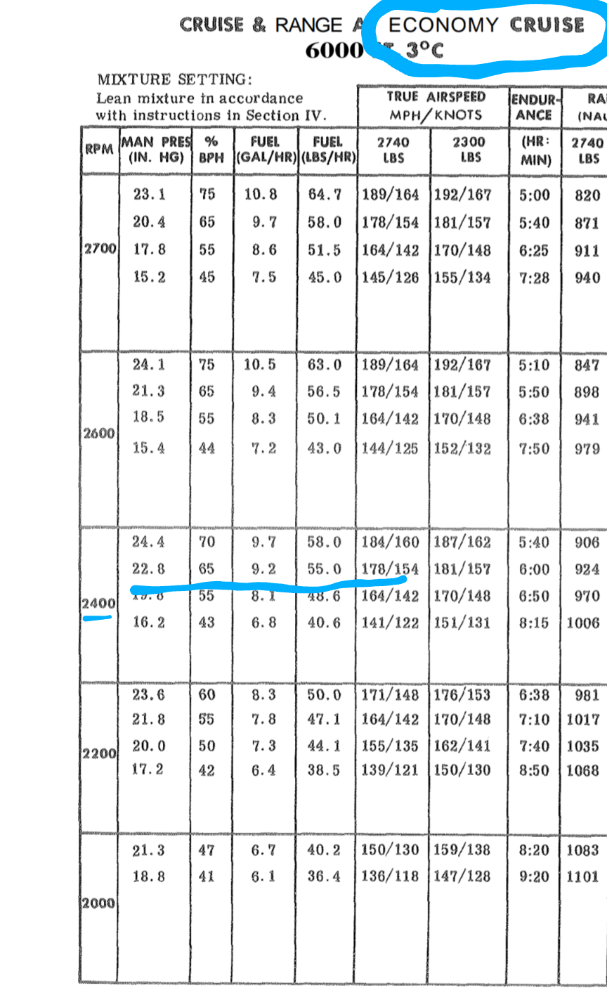

But then again, the M20J POH indicates that at 2400RPM and 22.8inHg both at best power and economy the engine produces the same power and the aircraft flies at the same TAS. The only difference is that with economy mixture it burns 12% less fuel. So I don't think I was confused, just didn't understand why it was that. -

Best power vs economy mixture setting

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Thanks @carusoam for the detailed explanation. I'll get the engine manual to see if I can have a more complete picture. I think my error is to consider best power as if it was actually more power, if you do 65% of nominal you don't have best or worst power, you just have the same with different operating conditions of the engine (hotter or cooler). -

Best power vs economy mixture setting

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

-

Since I did my PPL training I have a dumb doubt I can not find an answer to. Why we can best power mixture "best power"? Looking at the M20J power schedule at 65% (is the same for all, just to put an example), there is no difference between best power and economy: same rpm, same mp, same power, same TAS. The only change is fuel flow, from 9.2gph to 10.7gph. I get that the engine runs cooler with richer mixture, but why call it best power of it gives you the same power? Am I missing anything here?

-

Mooney down near PIA

redbaron1982 replied to The Other Red Baron's topic in Mooney Safety & Accident Discussion

I don't want to judge the pilots decisions, never been in a situation like that and don't know what tricks your mind can play on you, but it is shocking how he didn't land in any of the alternatives he had. If he as descending already with one tank dry, he could have safely land at KCTK, south of his flight path. When he declared, at 2.5kft he could have landed in 5LL5, a grass strip 1800ft long. Was north of his flight path, less than a mile away. I'm a relatively "young" pilot (in flight time) so I still do my homework for every flight, which includes looking around the airports of intended landing/takeoff for plan b's if something goes south while descending or climbing. Having the plan b in mind already usually speeds up decision making quite a bit. I wonder if with experience, complacency kicks in and thorough planning goes away. -

What to expect of an airplane that was sitting for long

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Yes, oil should have no more than 10 hours on it. I didn't know about the dehydration plugs, otherwise I think I would had ask the shop to put them. -

Hi all, On December last year I bought a Mooney M20J, and since then it has been a nightmare. Annual inspection took 4 months, and found wing spar corrosion and the shop was not able to fix it. So 1 month to ferry it to Don Maxwell. And now at Don Maxwell they are waiting for the part from Mooney that is supposed to be ready by end of August and the repair will end up by end of September. All in all, the airplane will have been sitting for 10 months (hopefully not more), with a few runups during the annual and for 2 days when it was ferried from Boston to Longview. What to expect when I finally get the airplane back? My main concern is if this will end up in a shorter engine life (corrosion due to the engine not running) or any other thing. Also any adivse on the best way to bring it back to regular flying would be appreciated. Thanks!

-

Hope didn't help in this one, this is the second big item that was not caught in a 17 hours pre buys inspection performed 2 weeks before, by the same shop that is now doing the annual. First finding, stub wing spar cap corrosion, still trying to figure out how much and who can do the job, but's going to be around 15k. This one, between 1.7k and 3k. MSC service is crap, at least this one. Now I'm in mode "I need to get this finished" and not complaining much, they have been performing the annual for almost 2 months already (they started on Dec 20th). Still they haven't given me a clear completion date for all the finding, and they are still coming up with "surprises". Anyway, this is already off topic, but I'm quite disappointed and feeling hopeless with this shitty shops.

-

Hi all, Sorry to make a silly question, but I couldn't find the answer online. What's the cost of a brand new magneto for the IO-360 A3B6D? My endless first annual now says that the magneto case is cracked, they are quoting me 1600usd to replace the case + whatever it cost to repair any damage part inside, or 2900usd for a overhauled part. A quick search for magnetos for IO 360 but other model give me a total cost of 1000usd aprox. Is the shop ripping me off?

-

Hi all, Hoping to get the annual on my newly acquired Mooney wrapped up soon, and having found corrosion on the wing spar cap, I'm starting to look for shop to do the repair (basically replace or if possible repair the RH stub wing spar lower cap. I prefer a shop in Texas, as I live in Houston, so far, I have this in mind: Don Maxwell Dugosh Swta.net Is there anyone else I should consider? I've contacted all of them, the best price so far was from Don, Swta.net requested for more pictures, that I've sent, but they never replied even after a couple of emails. So, again, the "winner" so far is Don, but I'd like to make sure I've explore all the possibility for this big ticket repair.

-

Paint touch ups (not for aesthetics)

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Fuel tank sealer would be the POR 15 fuel tank sealer? -

Paint touch ups (not for aesthetics)

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

And how you avoid that? Just not using stripper on the seams and removing the paint with scotch brite or something similar? -

Paint touch ups (not for aesthetics)

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

I have one more doubt I forgot to mention, my mooney has TKS, what's the correct way to protect it will doing this touch ups? I read that they are quite sensitive to clogging. I'm sure regular masking type my not be a good idea to cover the TKS on the leading edges. -

Paint touch ups (not for aesthetics)

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Hey! Thanks all for the feedback! It's reassuring knowing that I don't have dumb ideas! I think with the comments here I will go more with the stripping option more than the physically removing the paint. As of color matching, the wings (most concerning part right now) are all white, so I although I need to match the right white anyway, it's not as hard as a more complex pattern -

Paint touch ups (not for aesthetics)

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Hey, that looks great! So, we could say that is the result of an "amateur" job? Don't misinterpret it, it looks really good. Just one to understand if that's the result of a paint shop work or not. -

Hi all, While a wait for my recenlty acquired M20J to get to it's new airport (now under annual, and then some major wing spar cap corrosion repair) I'm trying to make a plan on what I'm going to do it (when I'm not flying!). Maybe because of this early experience with corrosion, and being the exterior paint not in great condition, I'm planning on doing some touch ups in all the areas where the paint is not ok. Main objective is to protect the aircraft, not to make it look great (although if I can make it look better it would be nice). I would like to do it myself, in a step by step approach, not all at once. I have a few questions: Is scotch brite a good way of removing loose paint on aluminum? Is ok to paint over existing paint? I don't know how much weight it can add to have an additional coat. As long as I stay away from control surfaces, is this something I can do on my own without an AP signing anything? My idea would be to, let's say take the left wing, go through all the areas where the paint is not ok, clean up the area, use scotch brite or similar to smooth the area and remove loose paint, treat the aluminum, and then paint over. I'm also evaluating paint the whole wing, just to improve the look. Then, at other time, move to the other wing. Then cowling, an so forth. At some point I would also do control surfaces, and for that I will get an AP to assist on removal, reinstalling and rebalancing them. So, what are you thoughts? Is this a good or bad idea? I know that sending the aircraft in for a full stripping and paint job is the ideal in term of results, but at this point I'm on a budget and don't want to spend north of 10k on this.

-

Hey, I was going to ask about the useful load gain by removing the vaccuum system, I've read two persons here mentioning 50lb by removing all the vaccuum system include the main and backup pump. I assume this factors in also the weight gain/loss of replacing the mechanical AI and HSI by the G5s. That's the number that we should expect by doing this upgrade/replacement? That makes going to G5s (or Gi275) even more intereseting. Regarding redundancing, I think having two G5s that can be one backup of the other, plus a Stratus+ForeFlight, is much more redundant than the original vaccuum with a single AI.

-

One off-topic recommendation, please make sure to discuss the detailed scope of inspection. I just had a major issue with an inspection that did not caught corrosion, and MSC are now seeing that I didn't ask for them to look for corrotion!

-

Need advice / sharing my concerns with someone

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

I think discussing who is to blame (if me or the shop) at this point has been already covered. I'm using AOPA services to guide me in possible solutions/compensations, but my main concern is getting the aircraft fixed and ready to fly again. Just as more context info, I requested the shop to do a prebuy and following that a annual inspection. The point was to due all the "inspection" part of the annual as part of the prebuy, and complete whatever was remaining (for instance wheel bearing service due or service the spark plugs) after the purchase. In the annual inspection report they stated: "Finish Annual inspection after Pre-Purchase." And also, at least verbally, they confirmed that during prebuy they opened or the inspection panels. Anyway, it could be as @JWJR mentioned, maybe the annual was done by a different mechanich, and that's why it came up. Also, I agree with @LANCECASPER that I have to value that they were honest in declaring the corrosion and also in saying that they are not able to repair it. So, at the end, they are not gaining anything with this. Also, they are helping me get the quotes from Don Maxwell and dugosh.com. Ando also they offered to help with the ferry permit. I'm not mad at them, nor I want to take advantage of the situation. I just want to try to come to an agreement that is fair. In my view, it is not fair for me to absorb all the cost of this. Anyway, if at the end there is no agreement and no legal way of getting a compensation of this, I will just move the page forward, enjoy the new aircraft, be 15k poorer but feeling confident with a safe airplane.- 290 replies

-

- 11

-

-

-

Need advice / sharing my concerns with someone

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Yeah, I've read those two post. There anyway the job was to replace the whole spar and not just the lower cap. I don't thinkg that the spar itself should be removed for replacing the lower cap. And that should save some work. -

Need advice / sharing my concerns with someone

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Just to understand a littlbe the extension of the repair, in the scenario of replacing the lower stub spar cap. If I understand correctly, this does not requires to remove the whole spar, right? being the false/stub spar and the cap, it requires to remove the skin (in this case the lower skin) by drilling out the rivers, remove the cap, also drilling out the rivets, then placing the new cap, rivetting, then replacing the skin, and revetting, right? I don't want to oversimplify it, my question is if such repair has a high risk of messing other stuff. I understand taking out the main spar, could lead to things not alinged correctly and such, but replacing the lower stub spar cap, can lead to the same problems? -

Need advice / sharing my concerns with someone

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Well I thought the same, "supposedly" Mooney said that as the corrossion impacted more than 10% of the material, it needs to be replaced. For me, from the picture itself, it doesnt look like 10%, anyway there is still not clean aluminum and more grinding should be necessary. I asked the shop to share with me the reply from Mooney, just to make sure that there is nothing lost in translation. -

Need advice / sharing my concerns with someone

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

The airplane has TKS, so I don't think it would 14k to replace the whole wing. Thanks though for the information. -

Need advice / sharing my concerns with someone

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Because of this I'm waiting also the response from swta, anyway, if repairing is 10k and replacing is 15k, I'd rather go with replacing the whole part. I know that is a cliche, but safety if my number one priority. More when I plan to fly with my family onboard. -

Need advice / sharing my concerns with someone

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Following up on this, Mooney have replied to the shop, saying that this will require replacing the stub spar cap. And the shop doesn't feel comfortable doing it. They are helping me contacting Don Maxwell and Dougsh for quotes on the work. I've also contacted a few days ago swta.net, still waiting to hear from then. No I need to get a ferry permit and a ferry pilot. And of course, try to get something from this MSC out, because I still consider them responsible for this. At least a refound on the prebuy and annual inspection.