redbaron1982

Basic Member-

Posts

765 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by redbaron1982

-

My question was regarding engine cleaning... and I did get some information regarding that, like which types of sprayer to use, or if it was ok to use a sprayer at all, etc.

-

Yeah, I wouldn't generalize. I have had already a bad experience by assuming some given plastic would be compatible with some given solvent. There are some good compatibility charts, like this one: https://www.plasticsintl.com/chemical-resistance-chart For instance, Teflon (PTFE) is one of the most stable plastics. The challenge is knowing all the different types of plastics that there are in an engine compartment...

-

For sure, but I think is necessary for everyone that does not agree to share that with the management. So the management can have an idea if it's just one crazy person, or everyone is asking protesting against the same thing.

-

Yeah, I saw that. I think I will talk to them, just to find out if they are reasonable or not. For me doesn't make sense that you cannot change the oil in your hangar or that they qualify that as major repair when is something the owner can do without supervision.

-

The engine is not super dirty, I should want to remove some patches of oil and also clean near the exhaust port of each cylinder because there are traces of exhaust leaks, and I want to see if those are all or new. I don't plan on doing a mess in the hangar, I would put something in the floor to get all the drippings. But anyway, as with any maintenance, even inspection sparkplugs, I'd inform the airport authorities and ask for authorization. As a side topic, I've read somewhere that an airport that receives FAA funds cannot prevent you (as long as you're qualified or working under the supervision of a qualified person) to do maintenance on your airplane in your hangar, as long as it is safe and does not have an impact in the environment.

-

I thought brushes were ok! That's why it's always good to check! Thanks!

-

Regarding the vacuum pump, I do have one, and yes I have in mind not to spray over it. I'm planning on cleaning using some brushes like the ones used to clean the inside of bottles, so it's no that I'm going to be spraying/splashing the Varsol.

-

Hey, I think the answer is "no, there is no problem" but before making a mess, I want to double-check. Is there anything I should protect while cleaning the engine with Varsol (i.e. mineral spirits)? And by this I mean plastics or other materials that could be affected, for sure I know I should keep the solvents off the alternator and other electrical equipment. But apart from that, is there any gasket, sealant, hose, or other plastics that could be affected by Varsol?

-

I think is not wise under any circumstances... Gear up landing, off field landing and damage to third party to property etc.

-

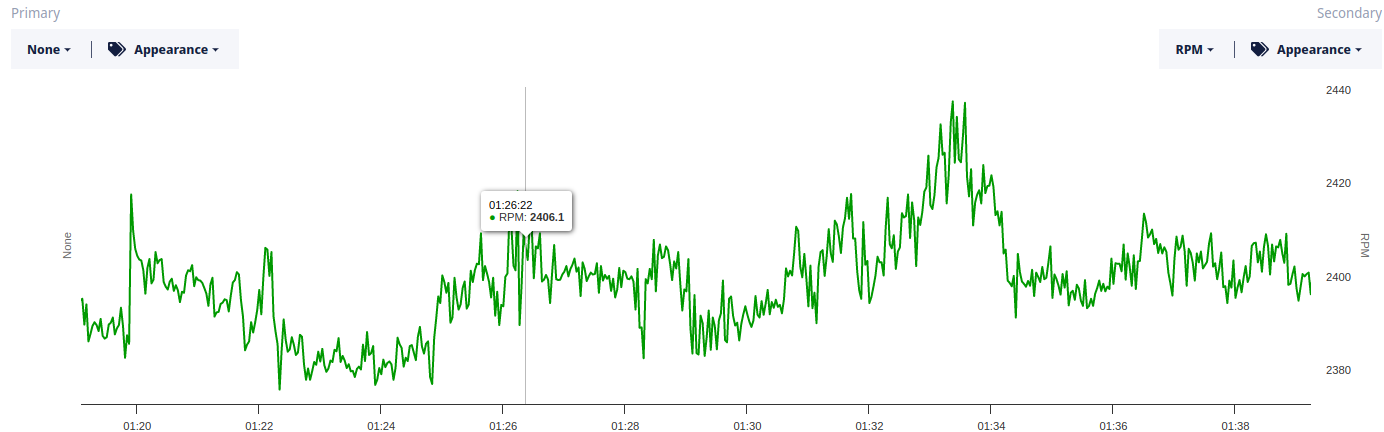

This is how the GI 275 look like when uploaded to Savvy: It has a "resolution" of .1, which doesn't make much sense as for sure the precision is much less than that. In my case, different from what the OP mentioned, I don´t feel or hear anything. I agree that most likely is electric noise. Something that does I see is when switching magnetos sometimes the RPMs indicated jump to more than 3000. Again, no feel or hear, that is for sure electric noise. I wonder how the GI 275 is measuring the RPMs. It should average at least one second of pulses to get the reading, but most likely it is not doing that.

-

In my M20J the RPMs always fluctuate +/- 20 RPM. I thought this would be normal, as 20RPM in 2500 is less than 1%. Should I try to understand why is fluctuating? I don't hear any change in RPM, I just see the value changing in the EIS.

-

I would add on top of this that the price you pay for the airplane is not the true driving factor for cost ownership. In a 150k airplane you can be easily paying north of 50k to get the engine rebuilt, or 70k to get the latest avionics or if you find structural corrosion you would pay at best 40k, and at worst you would scrap the airplane.

-

How to get back in shape the POH/AFM

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Cool, looking specifically for AFMS I could find for instance the supplement for the GI 275. Seems I have some homework to do now! Thanks a lot for the help! -

How to get back in shape the POH/AFM

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

I'm talking just about the binder. So if I take off all the sheets from the original binder and put it in a new binder, is it a legal POH? Where can I get those? I understand that it's not the manual of the equipment but something specific for the AFM. For instance I do have the supplement for the Garmin 430 and it's a much more reduced version than the actual 430 manual, but it's organize like a AFM: with normal and emergency procedures, limitations, etc. Following @kortopates advice, I got the adLog system. It's really well organized and helped me get the ADs under control. -

How to get back in shape the POH/AFM

redbaron1982 replied to redbaron1982's topic in General Mooney Talk

Thanks a lot for the detailed answer, @EricJ! I didn't know about https://cares.faa.gov/home! It's a very good resource, and seems very well organized! I wish AD search site would be as clean as this one, lol! Aero Space gives you a similar report, but you have to pay. Two follow up questions, Do I need to keep anything from the original binder if I change it for a generic one? I mean, it has some "placards" like the type of fuel that the aircraft can use. Updating the WB with the last modification performed (removing an old engine monitor and adding a GI 275) has to be done by an AP right? Is not something I can sign as an owner/ppl? -

So, as I continue putting everything in order for my "new" M20J, it's now the time for the POH (which includes WB, Equipment List and supplements). The previous owner seems that was not very "diligent" with this, so I have a few questions: Is relevant to keep all the WB history or just the last one is enough? My knowledge tells me that just the last one, but I'm asking because this POH has WB dating to 1986. My last WB is missing, as it does not include the installation of the GI275 EIS. What's the best way of getting the aircraft in a legal state? Take it to some place where they can weight it and start fresh? How do you guys recommend to get the Equipment List up to date? I was thinking of "replaying" history, starting with the initial EL, and from there walk through every form 337 and adding/removing to get my latest version. Finally cross checking with the things I can visually see are installed in the airplane. How reliable is Aero Space reports to get all the Forms 337? I seriously doubt that I have all the forms. When I purchased the airplane I run a report from Aero Space and I have a list of Form 337. Can I take those as the source of truth? I'm quite sure I'm missing some entries in the POH of supplemental data. For instance, there is no entry for the GI 257 EIS. Having the Forms 337s and all the list of STC, is there a way to download the pages that I should add to the POH? How I know if I have the latest version of the POH? Mine has only one revision applied. On a more cosmetic side, is is possible to get a new binder? The one I have is not in a great shape, and is also a bit small. Sorry so many questions, but I think is better to have one boring post rather than a lost of individual ones. Thanks a lot! I have to say that MS is helping me a lot with getting my M20J to a decent state again.

-

My recent experience of transition from a Piper Warrior to an M20J was quite uneventful/smooth. I'm a PPL with IR, 95% of my time was in a Warrior II and the remaining 5% was in a Cessna 182T for my HP endorsement. I didn't have a complex endorsement when I started transition training to M20J. My main concerns: energy management while descending and things happening faster were not an issue at all. Landings were a bit trickier, but my landing sucks in general, so nothing new there. I even had two events of bouncing in landing, one with my CFI and another solo, and in the first bounce I just went around and it was quite easy. So, my conclusion, an M20J is not a difficult plane to fly. Maybe an M20K with it's original engine has a much more difficult engine management workload.

-

If you are new to airplane ownership I would highly recommend getting an expert advisor, such as Savvy Aviation, for both your prebuy and initial years. I wish I would have done that 2 years ago when I decided to buy an airplane. I don't know continentals, but Lycoming has a SI that indicates that any compression check difference between cylinders higher than 15psi should be checked. In your case you have 20psi between cyl #1 and cyl #5. Seeing the word corrosion in the items, I would ask them if they have opened all inspection panels and checked for corrosion in more structural things. This is based on previous experience, where prebuy did not include looking inside inspection panels and I had a 30k surprise one week after I closed the purchase. Now, what's next is 100% personal, I don't have a good feeling about a prebuy inspection that indicates, as one of the items, "oil is getting dark, about time for an oil change". Oil changes are a regular thing, doesn't make sense to point it out in a prebuy. Is like if they would put "Fuel tanks getting low, about time to do a fuel top off".

-

I wonder if a similar procedure but with Hoppes No 9 fluid could help remove the lead buildup from the cylinder!

-

Yes, when I was in flight school it was common to find the dip stick tighten too much, and more than once I unscrew the filler tube trying to check for oil. I think tighten it while hot a bit to much it make then extremely difficult to take it out when cold.

-

Hey, a question regarding replacing the gasket. I was looking in the torque and limit manual for the IO 360 and couldn't find any indication of the torque for the oil filler tube. The only thing I found online, and it was not in a Lycoming official publication, was 300 lb in, that seems a bit too much, as it is the same torque as the spark plugs. Does anyone know which torque value to use for the oil filler tube?

-

3 weeks, when I measure the second time, the 4+ qts, it was 2 days.

-

I'm leaning toward an issue with the rings too, although is not what I would like. In this case, my question is, if there are no indications, so I cannot pin point which cylinder is having the issue, then how safe is it to continue flying until it becomes clear which cylinder to pull out? I'd like to avoid pulling all four cylinders to see which one it is.

-

Hey guys, thanks for all the insights! All of the top plugs were bone dry. I looked at the bottom ones with the borescope, so I'm not 100% sure, but they looked dry too. The engine has 1200 SMOH. The last annual, performed 20 hours tach time ago (and 4 months ago) showed all the cylinders with compression in the 70's. Maybe something happened since the annual and now I have a cylinder with ring issues. With the borescope the amount of oil in each cylinder seems to be more or less the same, small quantity in the bottom part after a couple of days since the last flight. It is not very likely that all rings will fail at the same time.

-

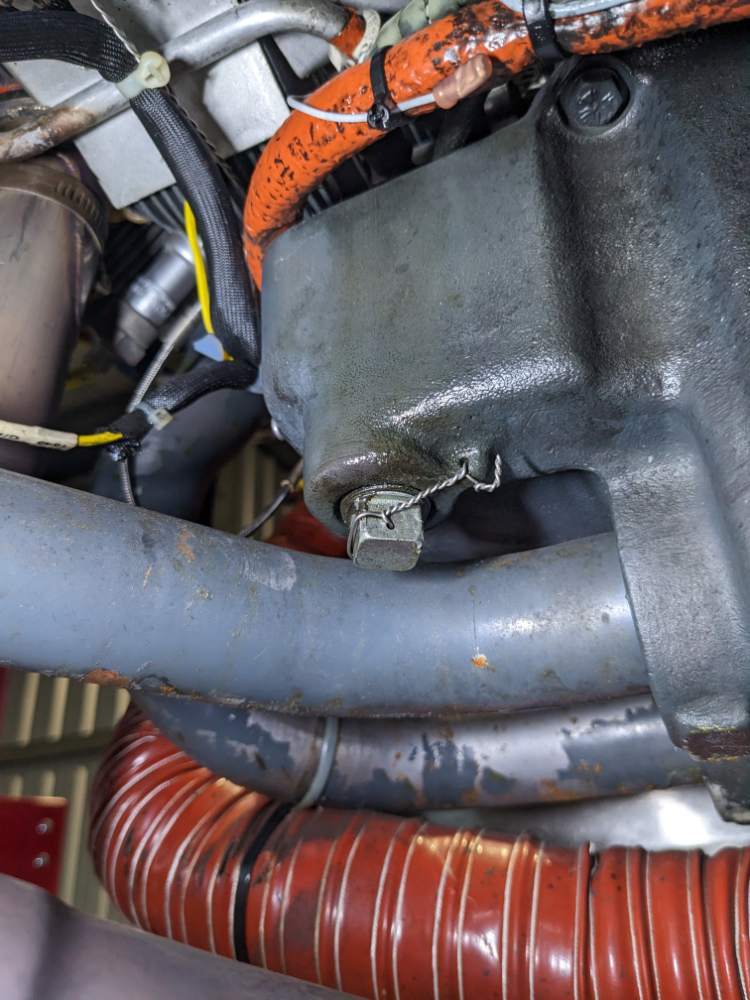

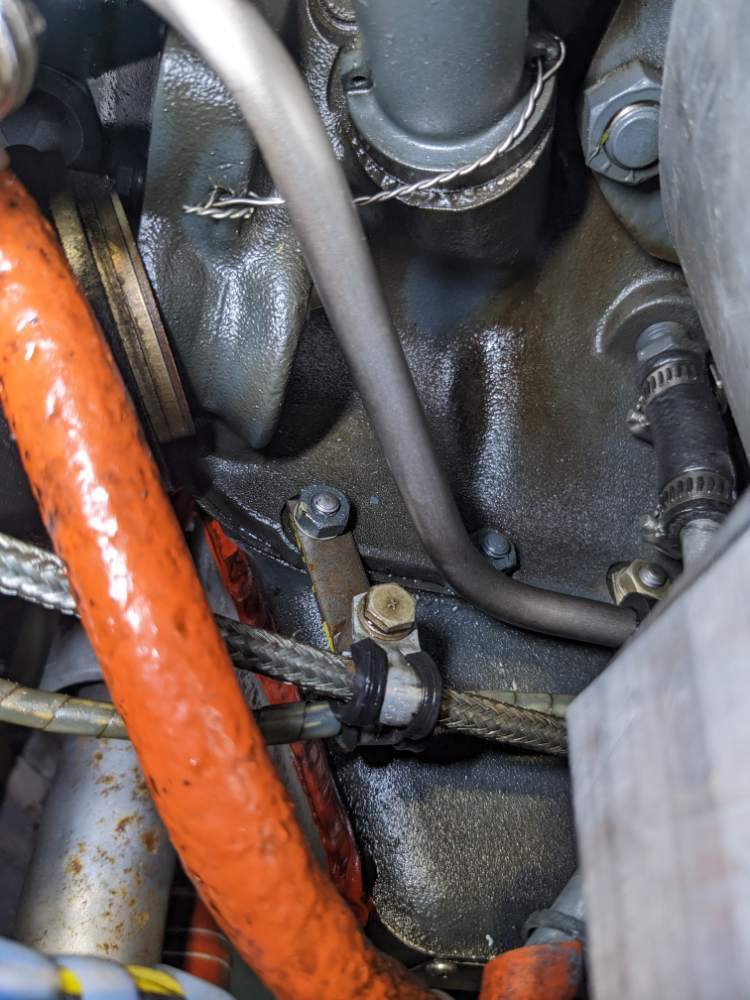

My last flight was a 3hrs flight round trip between KSGR - KBAZ - KSGR, crusing at ~65% power. The oil level at the beginning was just over 6qt, like 1/8" above the 6qt mark. I measured the oil level 2 days after I got back, and the level was 4.25qt. So this gives me a 1.75qt in 3hrs. Which is almost borderline with the maximum allowed oil consumption for the IO 360. I did a boroscope of the engine, didn´t find anything outstanding. Checked the exchaust and was gray and dried, so no oil there. No oil in the belly, so I assume that is not going through the breather line either. The only thing I could find was some drips of oil the bottom of the engine, that seems to trace back to the base of the oil filler tube. The oil filler tube seems a bit lose, not completely, but just a bit. Is it possible to loose this much oil through there? Strange is that I don´t see oil in the lower engine cowling. I'm attaching a few pictures of the oil I found in the bottom of the engine.