-

Posts

29 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by dogbocks

-

I took the dimmer wire off the nav light switch and ran it to ground through a mini toggle labeled "Day/Night", this way I can run the Nav lights full time if I wish and still see the gear lights. Ah good idea, I need to get that done next time I am in the avionics shop, that nav light dimming always drives me crazy.

-

Yeah those thermo-formed sheets of plastic behind the nav lights the plane comes with just look like such garbage. I wanted to replace those, also it bugged me how it didn't hide the inside of the wing outboard. Took a good amount of work to make those new covers, I don't have a 3D scanner, so I just kept measuring with calipers, 3D printing something and revising it. I think it took 9-10 rounds of prints, but finally got it there. Luckily the printer did most of the work

-

-

I love how back in the day, you could not wear a headset in a Bonanza and have a normal conversation during cruise. I guess airplanes have all gotten much louder since then?

-

On an M20R I think the stick would be dry around 20 gallons or so, not sure about a J....

-

Just wanted to add: "hardware store" countersunk screws are 90° counter sink angle. All A/C countersunk screws are 100° angle McMaster has 100° stuff, CAD plated too, and sometime can have much faster shipping than Spruce, depending on where you live.

-

Hey Freddy, I am not at RHV, but at Watsonville, so kind of local. Maybe we could meet for a $100 burger sometime.

-

For those that tie down their aircraft...

dogbocks replied to AlexLev's topic in General Mooney Talk

I live in the Bay Area and keep my airplane outside due to a 10+ year waiting list for any hangar with is a reasonable drive away. My airplane is about 3.5 miles from the beach. At the same airport, there is a new carbon cub on the ramp, several other cloth airplanes, a Cirrus jet and you can find many, many brand new Cirrus's. I am sure in SoCal there are countless new Cirrus on ramps. The corrosion you need to worry about here is nothing compared to the gulf area of the US. Also it basically never rains, is never humid and the wx is always mild. The main thing is my airplane is just always super dirty, which gets annoying, but not the worst to deal with. -

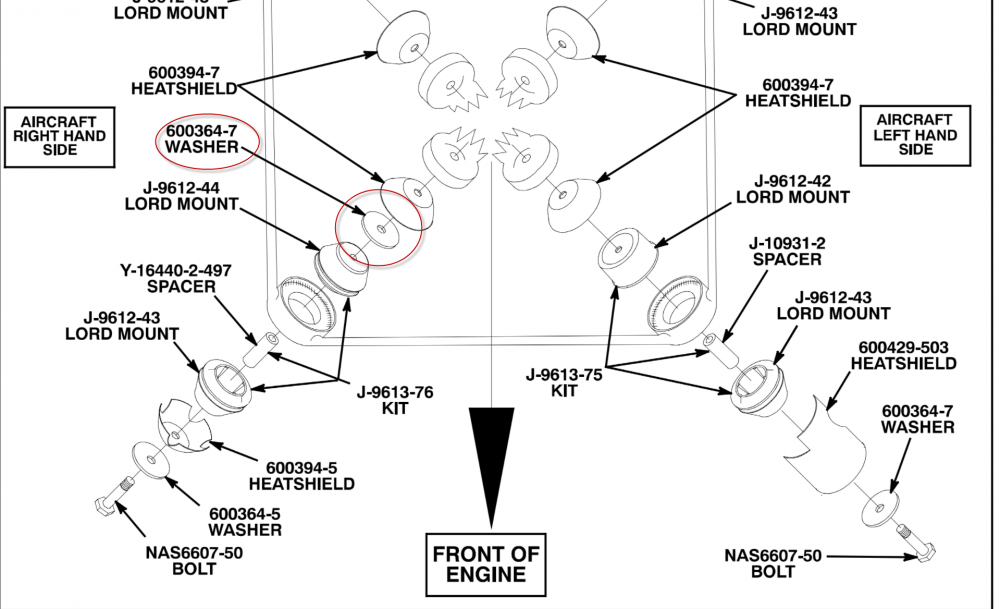

At first we just removed the front 2 bolts, and slide the washers in. Things were so miss aligned, we ended up taking out the rear bolts too, and re-aligning the whole engine with all 4 bolts out. Then, we put in the front two first and the rear two last. Maybe if you are very clever and very patient you could remove the front bolts only, lift the engine up, slide the washers in and put the front bolts back in, but while I planned to do that, it did not work out that way.

-

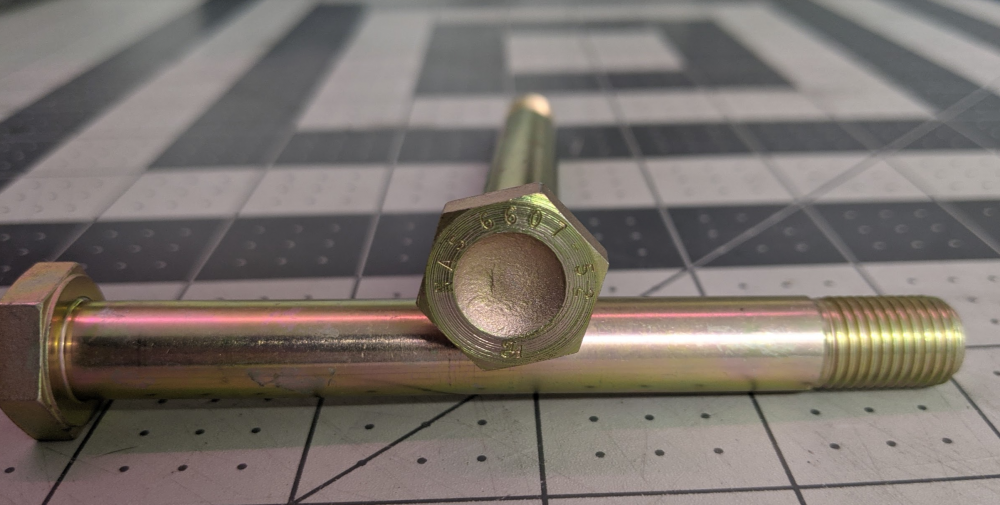

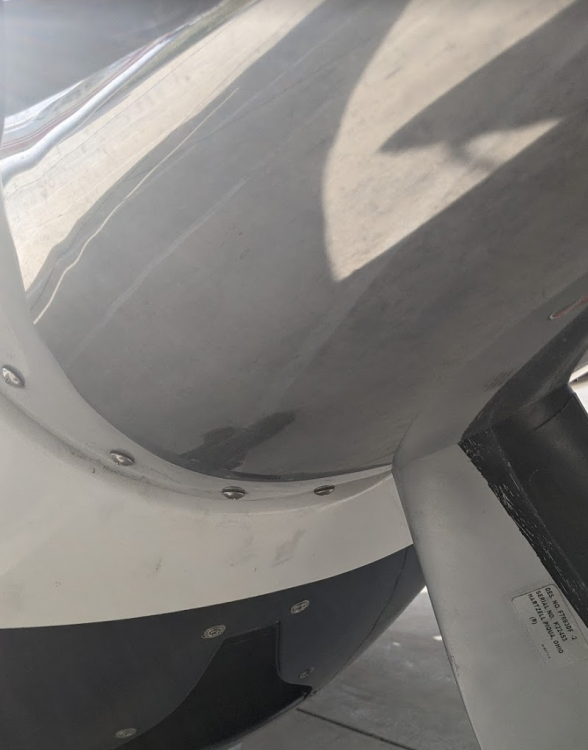

Hey guys, OK I got the washers installed this weekend. First of all I got the wrong bolts, so that delayed things. The motor mount bolts are 7/16 (AN7) and I ordered some AN7-52 because I knew I needed them to be 1/8 inch longer than the -50 bolts that are in there to account for the 1/8 inch washer. Well it turns out that NAS and AN bolts have different lengths for the same dash number. Didn't know that. So a AN7-52 is way too long, you need a NAS 7 bolt in -52. Turns out a NAS 7 bolt in that length is very rare and no aircraft hardware suppliers had it in stock and it was going to be hard to track down. Then I found out that Mooney in Kerrville has them in stock, probably for this exact reason. Wish I knew that when I ordered the spacers! You can see in this pic the bolt is just less than 4 inches long. A AN7-52 is 5 11/32 long. It is a real PITA to install those. Took me and my IA about 3 hours and a record amount of swearing. Once you disconnect 2 mounts, getting it all to line up again is not fun. Ok so the verdict: I didn't get any great side view pics, I can take some next time I head to the airport, but here it is all back together with the 1/8 inch spacer. Once I go this top cowling back on I was thinking crap....that didn't do anything, but then when you look at the bottom cowling: I realized it is much better. Before there was a 1/4 inch or more gap on the top and the bottom cowling was exactly flush with the spinner. Now there is a nearly equal gap all the way around the spinner to the cowling. Maybe a 1/8 or so. So the spinner is now lined up pretty well with the cowling, its just now I am noticing the spinner is slightly too small as pointed out earlier in this thread. Well anyway, it was a worthwhile improvement.

-

Ah good tip, I think you might be on to something. I was there when we calibrated the FF. I don't remember the numbers but I remember it being right in the middle of the allowable range. My A&P and I figured that was where we should leave it and we did, but I think you are right, to keep things a bit cooler on T/O it would be better have the fuel flow on the higher end of the allowable range. I will have to try that.

-

Yep still 280 but with the 3 blade top prop already. planning on 310 at some point, just need to dig around in the couch cushions for 7 AMU FF- of the top of my head 23-something. It has was checked/calibrated last summer when trying to track down a hot CHT issue, so it is spot on according to the spec. Departing Mammoth, Truckee and Bridgeport (3800 foot runway at 6.5k feet) on hot days always get off the ground with lots of runway left, and *could* climb at 1000fpm, I would just melt the engine so I have to keep it to 400ish fpm at least until in cooler air. Not sure if that is a limitation for other Mooneys M20R or otherwise. Would be interesting to know.

-

I have departed truckee on a hot afternoon with 9k DA in my O2 at max gross. No turbo, it was fine. before anyone freaks out I checked the book and seemed like I beat the take off roll. Just have to keep the climb mellower than usual since the motor gets pretty hot.

-

With 130 hours total and no complex/hi-performance I bet the OP's M20R insurance would be $7k-$10k a year. No idea what it would be on the C182, maybe close. Anyway, insurance is a real expense now especially for a low time pilot.

-

I bought a 2001 M20R O2 about a year ago. I was also cross-shopping with a G1000 182. I went for the M20R since it was much cheaper (my O2 is not a DX G1000). I made that decision since I regularly fly a 710NM route and didn't want to have to make fuel stops and do it as fast as possible. Also I needed performance for the Sierras, which they both have and I could get a FIKI M20R. While FIKI 182s exist they are very rare. Since you asked for numbers: My O2 with 3-blade, 280hp and FIKI goes 170 TAS. Best between 6k-10k, but can go as high as you need. Without FIKI and a 2 blade people get 180-185 TAS. My 710NM trip takes about 4 hours and a few minutes wheels up to wheels down (in calm wind). I land with about 30 gallons of fuel still. When I bought it I only had a few hours high performance/complex from getting my endorsements. I did own a non-complex airplane at the time though. My insurance quote for the first year with 0 M20R hours was about $6k. This year with 135 hours in it its about $3k. In the first year I probably spent over $30k additionally on what I thought was a very clean "turn-key" airplane. Some avionics issues, replaced the HSI for $8k, bad autopilot roll servo $8K, new motor mounts $2k (common issue), all new LED lights to replace incandescent lights $6k, new carpet, 3 new tires.... Very extensive first annual $$$$.... so anyway, make sure you budget for that with any "new" complex airplane. I would really not count on leasing back a M20R as part of the plan. Once you learn to land a Long Body its easy, but random people with little to no experience will do damage. That would not be the case with a 182. Not sure about a SR20, never flown one. Also I would be surprised if your insurance would cover a lease back, I would guess not. Maybe the FBO's insurance would? Also I keep mine on the ramp since hangars here have 10+ year wait lists. No issues that any other airplane would have with that. I do live in California though where the wx is very mild. One thing that is undisputed: an M20R with a 3-blade is the best looking plane on the ramp, while 182s are about as vanilla as it gets

-

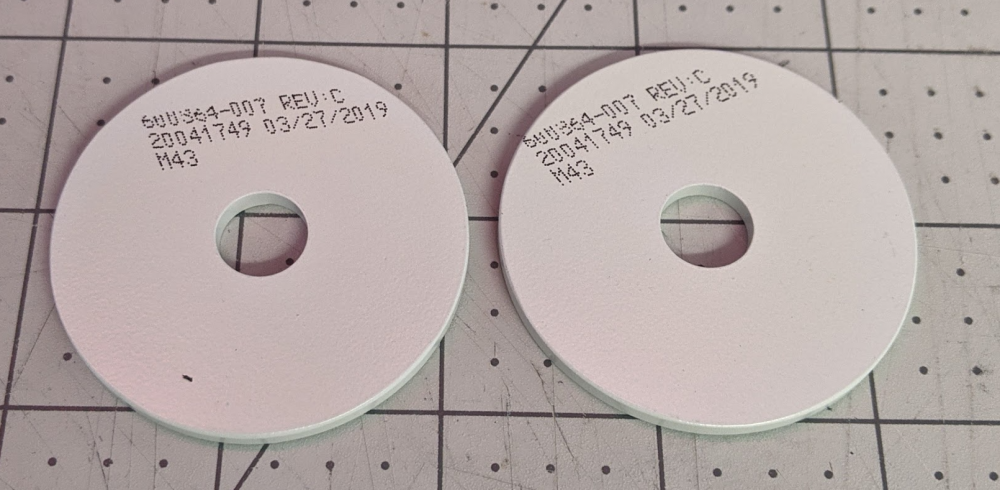

Ok I got the washers from Mooney in Kerrville via LASAR. They are 0.129 thick, 2" OD, 7/16ID. I will updated when I get them installed, might be a minute...

-

Depending on where it is leaking it might be an easy spot for a regular A&P to remove an inspection panel and reseal a small patch. Or it could be much harder to track down the leak and be hard to get to on the inside, or multiple leaks. A pic would be helpful.

-

Interesting, well call your MSC and order a couple 600364-7 washers and that should fix it, I will let you know when I get mine on, might wait until the next oil change though.

-

Yep that seemed to be the fix, thanks!

-

If you look closely, you can see the bottom of the spinner is lined up with the cowling and the top isn't, also the back of the spinner and cowling are not parallel. Its not an issue of the spinner being too small. Mooney in Kernville has some quantity of that 600364-7 washer. 2 are on the way to me care of LASAR. I will get them installed sometime in the next few weeks and update this thread. But yes this is a 3 blade Hartzell on an airplane that originally came from the factory with a 2 blade McCulley

-

Ok talked to LASAR (my local MSC) and they said to just add another 600364-7 washer on each front engine mount (right side will have 2, left will have 1) and that should do it. Just need to go to the airport and measure that washer and figure out what size it is, if I don't get a call back from Lasar or DMA. Also the -50 bolts might have to be swapped for -52 to make sure they are still long enough with added washers.

-

Hey guys, Just installed 4 new Lord mounts to fix my saggy IO-550. Well, after getting it all back together, the motor is in the exact same place. I am wondering if anyone else has had this happen? I am thinking maybe spacers under the lower engine mounts where it attaches to the firewall would be the fix? I was going to get in touch with a MSC and see what they think, but figured I would see if anyone here had any ideas. Pic is after new mounts are installed .

-

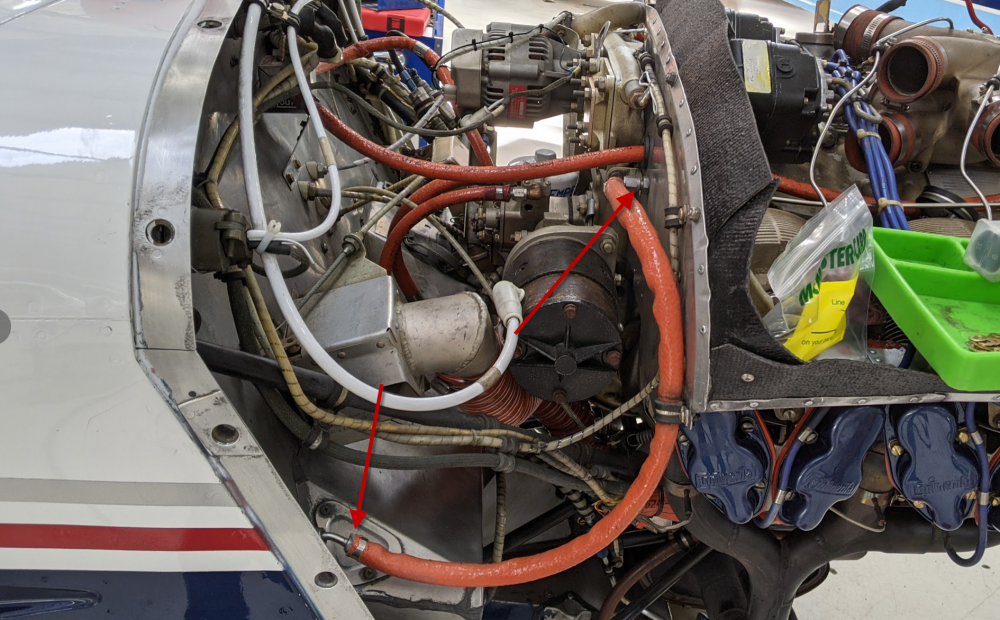

I am late to the party here, but have my motor a bit taken apart and had a chance to get some good pics. Maybe they will be helpful for someone. Red arrows show the fittings that the TKS fluid passes through, assuming that the hose isn't broken, I would guess its leaking from the baffle fitting of the fire wall fitting.

-

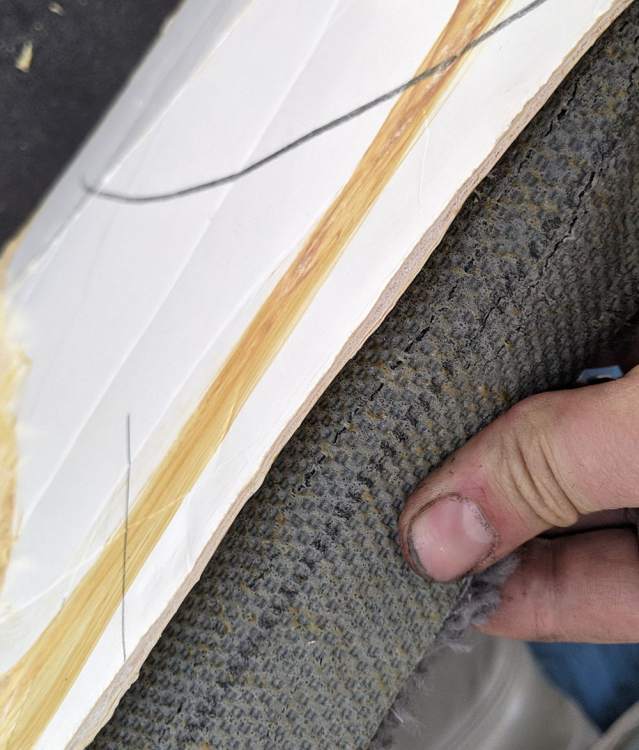

I am in the middle of installing a carpet from SCS now. Something I wish I knew before I started: Installing a carpet in a long-body is a lot of work, even with this pre-cut kit. Also I ordered some samples from SCS. I went with nylon with the 1/4 inch foam backing. Nylon isn't the sexiest material, but it machted the old carpet, which works with the rest of the interior. Also I think the wool looks good, but it has that vintage/classic look which I personally didn't like for a more modern airplane. Just my opinion though. I had the vinyl sheet style material installed in my Cessna which was great for a "utility airplane" but also not the right look for a nice long-body IMO. First of all, the carpet in my Cessna was all held down with gravity. That is not the case with Mooney. The carpet was all glued down to the floor, and after being pulled up the floor looked like this: It took a lot of lacquer thinner and scrapping with a plastic scrapper to get it to look like this: The next problem is the vertical walls of the baggage compartment are made from foam core poster board that the carpet is glued to. These are not reusable and have to be replaced with plastic backing that is custom cut. Here is a detail of how the carpet looks, this is nylon with the 1/4 foam backing. The piece in the middle did not come with foam, so it sits slightly lower. One last shot of the whole carpet:

-

Ovation Pre-Buy and Maintenance-Prone Areas

dogbocks replied to sbflyer's topic in Modern Mooney Discussion

Funny, my insurance only required 5 hours on transition training I was surprised it was that low. My instructor wasn’t even required to have long body time (all his time was in a J). definitely couldn’t fly that thing after 5 hours though, got some much better training from another Mooniac with lots of Mooney experience of all lengths and got sorted out with him. I have never flown a mid-body but seems like it’s pretty different.