1980Mooney

Basic Member-

Posts

3,208 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 1980Mooney

-

@PeteMc For reference hangar-planning.pdf (aopa.org) untitled (aopa.org) For the record: Ground control - AOPA UNDERSTAND YOUR GROUND LEASE

-

@PeteMc This one too into Word when downloaded TEMPLATE-Hangar-Rental-Agreement.docx (live.com)

-

@PeteMc This one downloads into Word model_lease_agreement.doc (live.com)

-

@PeteMc airplane hangar rental agreement - Google Search Literally every municipal airport Hangar Agreement in the US will appear. Here is one from EAA chapters.eaa.org/eaa55/-/media/5a6f918190404eb19ea7117e6eaf8450.ashx

-

attached now

-

The first article highlights some of the issues. https://shackelford.law/news-aviation/aircraft-hangar-lease-what-can-a-tenant-expect/ Here are some templates - they are customizable with a PDF app. There are some free ones online like Candy PDF to Word. The ones for Georgetown, Spanish Fork and Sweetwater have a lot more boilerplate. https://crp.trb.org/acrpwebresource6/wp-content/uploads/sites/13/2018/02/TEMPLATE-Hangar-Rental-Agreement.docx https://www.dot.ga.gov/InvestSmart/Aviation/Forms/SampleLandLeaseforHanger.pdf https://ftp.txdot.gov/pub/txdot-info/avn/model_lease_agreement.doc T-Hangar-Lease-Agreement.pdf (flywenatchee.com) Microsoft Word - Updated Privately Owned Hangar Lease Agreement (ventura.org) 3.7.14-City-of-Georgetown-Airport-Ground-Lease.pdf Hangar Ground Lease Agreement (spanishfork.org) https://sweetwaterfbo.com/wp-content/uploads/2020/02/Aeronautical-Use-Hangar-Lease-2019-Form-Fill-REVISED.pdf

-

Really? I just came up with 24 different leases on the first page of the search.

-

Here is a 2017-2023 "SuperCub.org" thread on problems with Sky Tech starters in Lycoming installations. Apparently, the legacy starters had lots of problems - they were basically crap. Owners with fleet visibility witnessed multiple failures. Things have gotten better apparently. But rather than argue with every pissed off owner, regardless of legacy or more recent purchase, they just give buyers their money back - like you. disappointed in Skytec starters (supercub.org)

-

Which model? year?

-

"all parties have to have the feeling that they are getting a good deal" - that is really important. It sounds like the other 3 partners were subsidizing your flying since you flew it 3/5 of the time - but they felt good about it perhaps because they didn't have the time and you made sure it was ready to go. A quick calc shows that you paid 41% of the total (fixed monthly and variable operating) cost annually while flying 60% of the time. IF it works then it works. Back in the 90's there was a Comanche, N5788, tied down next to me at KIWS. It was in a partnership like yours with 4 partners. One day a partner flew to New Braunfels and back. On approach to KIWS, the pilot said she heard a loud bang when extending the landing gear and claimed there was a loss in power. She landed short of 15 at KIWS striking the concrete culvert before the runway. The nose gear was sheared and the mains were punched through the wings. None of the 4 onboard were injured. When the NTSB ran the engine they could find no problem. I heard that there was enough insurance money for repairs but the partner that formed the partnership was so upset that he just wanted to cash out and leave it with the other 3 partners. Last I saw it, it was on wooden pallets next to my plane. It was sold salvage, took a few years but it was repaired and is still flying. However that was the unhappy end of the partnership In the 2000's there was an older Bonanza partnership with 4 partners in the hangar next to me at KSGR. One partner had more means than the others but somehow the costs were shared. It worked well and they flew a lot. The lead partner then came into some more money and bought a brand new G36. The partnership was harmonious enough that it continued with the new Bonanza although the lead partner apparently bore the cost of acquisition.

-

Any partnership is hard - especially those in which a lot is at stake (investment, ongoing cost/responsibilities and liabilities for actions of the partners). It is dependent upon the rules you devise to manage it fairly and the partner you select. Legally?- you need to put the plane into a LLC to protect your estate against actions of your partner (primarily while your partner is flying in the event of an accident). The LLC will carry insurance for Hull loss if either you or your partner has an accident Your estate remains liable for your actions as PIC You have your own Liability insurance for that Your partner carries his own insurance for his Liability Is it worth it? Well there is a "hassle factor" in any partnership but first you need ask what is your "mission"? Right now it sounds like you are just piling up money and setting it on fire. You don't use the plane to go anywhere and apparently don't fly much at all. You have fixed costs burning money You have variable operating costs - you are running it on the ground for extended periods to exercise the engine while not flying it What is your "mission" in 2024 and beyond? Weekend warrior flying to get $100 hamburgers? Work on your Instrument ticket? Fly you or your family somewhere on holidays? If you know your mission then ideally you find a partner that complements your mission If you and your partner have the same mission there could be conflict over when you both want the plane for the Fourth of July or Christmas, etc. - more sharing If you can only fly weekends then a partner that is retired can fit well. If you are still interested there are a few good posts on MS regarding what rules you need to include in the LLC

-

You are right to not feel comfortable heading out across the country with this current "starter system" condition". As @RoundTwo said "but it doesn’t yet sound like you’ve proven that the problem is the starter itself.". I say "starter system" because it is a system of wires, crimped connectors, bolted connections, solenoids, starter windings, brush contacts, Bendix, (and battery which you said you feel you can rule out) etc. and any "foreign material" that might contaminate it. Any single or combination of multiple weaknesses or failures can lead to starter problems. You said that you saw smoke on the pilot's side which you think is from an electrical event. That would mean high current with high resistance somewhere - hot enough to burn things that are not supposed to burn. Or it could mean hydrocarbon contamination on the starter motor or solenoid contacts that burned - but there should not be any there. Now you say that the problem is intermittent. It would be ideal if you could find the "hot spot". You may be right that replacing the starter, and disconnecting and reconnecting everything may solve it. But if the intermittent problem is not the starter, you risk AOG at some distant airport. Just my 2 cents.... Edit - if you search Mooneyspace or Beechtalk you don't find any threads on "smoke from a starter" and nothing "intermittent smoke". There is one in an experimental forum where they put the wrong solenoid in during an engine upgrade. There are some in automotive forums and it is related to the starter solenoid. Smoke from an intermittent electrical event that I don't understand would scare the crap out of me.

-

"Smoke" (other than coming from the exhaust on start) is always a bad day on an airplane..... That must have been some smoke if you could see it while cranking the engine - I am assuming with the cowling on! Glad you didn't have a fire and made it home safe.

-

Engine Droop - M20J with the A3B6D Engine and Hartzell prop

1980Mooney replied to StevenF's topic in Modern Mooney Discussion

The second half of your post is about rigging. 1/2 inch alerion droop on each side is common. Spec is 0 to 2 degree droop on the travel boards, With the gap tolerances in the rod ends they tend to ride up higher in flight and generally a little above the flaps..But the 1 inch difference in flight is not normal. However do not mess with the rigging until you fix the engine droop/alignment first. You will just be chasing your tail. There is static rigging and dynamic rigging. Since you are in the UK here are 2 excellent KNR Shoptalk articles that are clear and pragmatic. Also see the discussion in Mooney Flyer on page 8. As Clarence (MSC in Ontario) advised: Flight control rigging is not too hard. Locate and replace all worn and sloppy rod end bearings. All are essentially the same, lock the two yokes together with a straight edge across the control wheels. Adjust the lower center bell crank under the floor with the off set per the manual or install the rig pin per the manual. Adjust the left and right wing bell cranks per the manual by use of the wing push rod.. Adjust the left and right aileron short rods from the bell crank to the aileron for up to two degrees of droop in the static position, generally more droop for faster planes. Adjust the left and right flap up stop bolts to zero degrees as measured with the correct travel board. Test fly the plane. You should end up with aileron and flap trailing edges aligned at cruise speed with the ball centered. If not you will have to make small adjustments. (this is the "dynamic rigging" and may include adjusting {bending} the aileron tabs carefully) I never bend the aileron trailing edges with wide vice grips as shown in the manual. I use two long boards clamped to the trailing edge with many clamps so I end up bending the entire edge a very small amount and never end up with waves caused by vice grips. Clarence https://knr-inc.com/shoptalk-articles.html?view=article&id=75&catid=25 https://knr-inc.com/shoptalk-articles.html?view=article&id=106&catid=25 https://themooneyflyer.com/issues/2017-OctTMF.pdf -

As suggested by many, before ordering and changing parts, it is best to diagnose the problem. Starter/battery problems can be frustrating. Yes changing things may do it but it might be overkill. Here is a guided step by step diagnosis procedure: https://skytec.aero/aircraft-starter-performance-issues/ And a kitplane/experimental hands-on testimonial: https://www.kitplanes.com/starter-trouble/

-

That was manufactured by CONDEC (now Eaton) and apparently worked on by Vickers (now Eaton). But the pic is to small to read much other than CONDEC and Vickers. It looks like it has been overhauled at least once by Vickers (Eaton). Too bad Clarence isn't here anymore to answer your question about the numbering.

-

I don't know if the serial numbers are sequential. Here is a pic of one at BAS that shows an old Consolidated Controls label but also a separate Vickers label. Perhaps it is an overhaul by Eaton. On Edit - look at the one posted by the OP. It has 2 labels also!

-

Mooney shifted from Dukes actuators to actuators made by Avionics Products Company (Denville, NJ) on the M20J starting with serial number 24-0378 in 1977. Avionics Products Company (Denville, NJ) was owned by Consolidated Controls Corporation (CONDEC) which was purchased by Chicago industrialist Farley in 1984. Avionics Products Company sold actuators to Mooney labeled under the name Avionics Products Company (Denville, NJ) Some are just labeled CONDEC - Consolidated Controls Corp. like the OP picture above. The acquisition went badly for Farley and Farley sold CONDEC to Eaton in May 1986. So in 1986 Eaton inherited Avionics Products Company actuators - they changed the labeling at some point to Eaton. I have seen some labeled with Eaton Valve and Actuator Div. (El Segundo, CA) In 1984, Libbey-Owens-Ford (L-O-F) acquired Vickers Inc., a leading maker of hydraulic and electrohydraulic systems, from the Sperry Corporation. (no relation to the Vickers PLC (UK). L-O-F combined Vickers with Aeroquip, which they had purchased in 1968 and renames it Aeroquip-Vickers In 1999 Eaton acquires Aeroquip-Vickers The Vickers Aerospace Actuators and Controls Div.is located in Grand Rapids, Michigan. There are Mooney actuators labeled with only the Vickers name (Vickers Aerospace Actuators and Controls Div.- Grand Rapids, Michigan) It is not clear if Vickers made any actuators before the Eaton takeover. More likely Eaton consolidated all Mooney landing gear actuator manufacturing in the Vickers division. However, the actuators labeled with "Vickers" do no say that they are a division of Eaton. At some point in the early 1980's GEC (UK) (that is General Electric Company UK no relation to US GE) also became a supplier of actuators made in Whippany, NJ GEC sold actuators to Mooney labeled with the name GEC (UK) Aerospace Inc. (Whippany, NJ) In 1989 GEC and Siemans jointly acquired Plessey PLC (the focus was upon the telecom and electronics businesses) GEC (UK) Aerospace Inc was dropped into a Plessey company with all the businesses that did not fit with the overall acquisition focus on telecom/electronics. Actuators were then labeled with the Plessey name only. The deal went badly (along with the entire "Dot-bomb" era) Things were sold off. I think the Plessey "Electro Mechanical Div" just atrophied away and shut down. Today Eaton is the "last man standing" in Mooney gear actuators for J and up.

-

"I can't legally fly my 262 in my boxer shorts with full fuel." The irony in this reality is that all Mooney's since the first M20B in 1961 to the last Acclaim fly on the same wing. The same wing lift that would legally only fly 2,575 lbs in 1961 would legally lift 3,368 lbs nearly 60 years later. And then the Factory had owners salivating that GW might increase another 300-400 lbs on the same wing with only landing gear mods to Long Bodies. So that would be 3,800+ lbs on the same wing that you fly on. The only difference is the power and technique to fly the plane. Indeed, Rocket Engineering boosted the MGW on my Mid Body J from 2,740 lbs to 3,200 lbs with the addition of 100 HP. There were no modifications to the flight controls or fuselage - just more weight in the nose and more weight in the tail to get a signoff from the FAA that was more agreeable back then. It is a paper exercise. Legal maximum weight and safe maximum weight in a Mooney are two different things.....

-

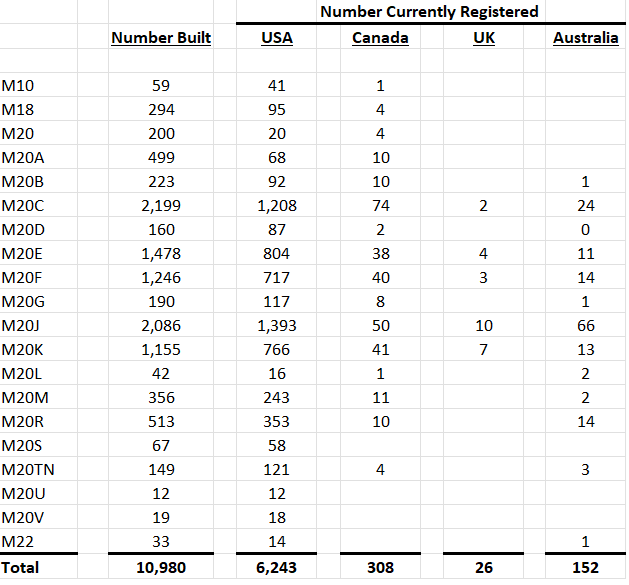

The registered aircraft numbers came from the FAA, Canadian Civil Aircraft Registry, UK Civil Aviation Authority and the Australian Civil Aircraft Register databases. The original numbers produced come from the "Mooney Chronology" https://www.mooneyevents.com/chrono.htm and from 2005 on from the GAMA database production reporting https://gama.aero/facts-and-statistics/quarterly-shipments-and-billings/. You can look at the serial numbers too with the more modern models. In the 50's-60's Mooney just added a sequential serial number to each plane as it was built regardless of whether it was a C, D or E. Ownership changed and practices changed. At least the J and newer make some sense. According to the "Mooney Chronology" some serial numbers were skipped occasionally even with the newer models. I would guess that the worldwide number of Bravos still flying is around 300 or less.

-

Daytona Aircraft Services. Call me when you have a part number?

1980Mooney replied to Jrags's topic in General Mooney Talk

I think a lot of owners here are unrealistic about the entire parts situation. Time and time again many think there is a market for third parties to start building Mooney specific parts that are slow to come from the Factory. Many compare it to the classic car era of the 60's-early 70's (models which typically had sales in the 100's of thousands every year). Look at the numbers. The OP is looking for parts for a M20G. There are only 117 registered in the US and another 8 in Canada. And not all are airworthy and flying. The parts he needs from time to time may or may not be shared with other models. And as @PT20J says there were changes made in production of many specific models. Third parties like McFarlane will chase Cessna 172 because 44,000 have been built - and Piper PA-28 because 33,000 have been built in various flavors. Mooney? - that is a small market to gear up for. -

Daytona Aircraft Services. Call me when you have a part number?

1980Mooney replied to Jrags's topic in General Mooney Talk

Except that the M20TN IPC (Illustrated Parts Manual) is not in the downloads. However you can find it in a couple of the discussions in the Acclaim Owners Forum. There is a December 2006 version of the M20TN Service and Maintenance Manual incorrectly posted in the Engine Reference Manual section of the Download Forum. (link below) There is a December 2007 version of the M20TN Illustrated Parts Catalog (IPC) posted in the Acclaim Owners Forum (link below) As @PT20J says it is best to get it from the Factory with updates but if they are slow to provide it or it is more of an introduction for learning the online versions are a good starting point. -

The cost to maintain a GA engine has been skyrocketing. @Fritz1 's all in "overall" numbers may have been accurate at one time but they don't even cover the cost the Lycoming engine when it is sitting in Pennsylvania ready to ship. And @Pinecone's numbers are accurate although AirPower has none in stock. Lycoming just agreed to a new union contract in September. We don't know the terms but the Union turned down a 25-32% wage increase offer in June (per the local newspaper). I suspect there will be price increases when new stock ships. And a Factory Rebuild price needs to include removal, shipping, tax in some locations, new engine mounts, and IRAN -engine mount , oil cooler, hoses, auxiliaries like electric fuel pump etc. and re-installation. I would think someone needs to budget at least $120,000 for a future Bravo Lycoming Factory Rebuilt. With these absurdly high prices it is natural for owners to seek qualified independent shops for overhauls. Not a lot of owners can write a $120,000+ check for what is in reality an overhaul. The owner writing the check has to believe that he is getting a lot of real value. Put another way - if you were looking at 2 equivalent Bravo's, same year, same avionics, paint, interior,: One had a Factory Rebuild 7 years and 450 hours ago - flown by 3 previous owners One had a reputable shop field overhaul 7 years and 450 hours ago - flown by 3 previous owners Would you pay any premium for "Factory Rebuilt"? Or would how the 3 previous owners flew and maintained the Bravo actually overshadow any perceived benefit of a a Factory Rebuild?

-

Avweb says that Lyc and Cont only began offering "rebuilt" when the new airplane engine market tanked in order for the Factories to go after the "overhaul" market with an FAA blessed "marketing distinction/advantage". They note that the Canadian Aviation authority does not recognize "zero time" rebuilt. To them a "rebuild" is just an overhaul of a used engine plain and simple. Please explain how a used Lycoming crankshaft within new limits makes it any better than one with slightly worn journals. A Lycoming crankshaft can go four sizes, Standard, M003, M006 and M010 on the rods and mains. Journals are resurfaced and new proper bearings are used to provide "factory" clearances between journal and bearing. Lycoming does not track individual part duty time - a "within factory limits" crankshaft might have undergone more cycles than one with some journal wear. A Lycoming approved oversize bearing kit to accommodate journal size/wear should provide the same performance and life as the "factory limit" bearing. Maybe I am missing something. https://www.avweb.com/ownership/the-zero-time-myth/

-

Comments to both posts above seem to be referring to independent shops doing overhauls vs Lycoming Factory Rebuilt. However, if you focus upon buying an "overhauled" engine from the Lycoming Factory Overhaul inventory there does not seem to be any difference in quality or precision of the build when comparing Rebuilt to Overhauled - "All Lycoming factory new, rebuilt and overhauled engines are built on the same production assembly line. The same skilled workers build all types of engines, new or overhauled, 4-cylinders or 8-cylinders, and naturally aspirated or turbocharged." Both Rebuilt and Overhauled reuses many used parts. The price difference on AirPower for a Lycoming TIO-540-AF1B Factory OH vs Rebuilt is about $10,000. It seems that one is primarily paying for an extra year of warranty and "zero-time" written in the logbook. From the Lycoming Website Factory Rebuilt – Every part used in building the engine meets or exceeds new part specifications; or the engine is like new. It has a zero time since new and a zero time since major overhaul. Some parts may be used, but they meet the same specifications as a new part. Like new engines, this engine carries a two-year factory warranty up to the hourly overhaul period listed in Service Instruction 1009. This engine choice is for the customers who are looking to have a return on their investment by adding value to their airframe. Overhauled – The parts used to build the engine meet or exceed service limits and specifications. The engine carries the previously accrued total time since new, but has zero time since major overhaul. This engine also carries a one-year factory warranty up to the hourly overhaul period listed in Service Instruction 1009. An overhauled engine is best for the customer who is looking for the most cost-effective option, or for those who accrue hours very quickly and will likely run the engine through the next overhaul cycle. Some parts are no longer available new from the original equipment manufacturers, such as dual magnetos from Bendix/TCM. In these cases, those parts are overhauled by a reputable overhaul facility. All Lycoming factory new, rebuilt and overhauled engines are built on the same production assembly line. The same skilled workers build all types of engines, new or overhauled, 4-cylinders or 8-cylinders, and naturally aspirated or turbocharged.