-

Posts

15 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by msh9

-

ALRIGHT, sorry for the delays. First, thank you all for the many suggestions. The suggestions to watch the engine monitor were good; incidentally the plane was also having a JPI EDM 900 installed while this was being done. With that said, today, the mechanic tried swapping out the ignition harness with another one. SureFly works beautifully now. Looks like the issue was the new harness we previously ordered to go with the SureFly was setup for right rotation instead of left. Two cylinders were swapped and the leads mislabeled. Very frustrating that it took us this long to figure out and partly because we assumed the new harness we ordered was good. That's what we get for making assumptions. In any case, that's getting returned and hopefully we'll have everything back together soon. Thanks again everyone!

-

Thanks for all the replies! The mechanic I'm working with said they re-checked the leads on the new harness today and they go to the right cylinders. We tried installing the unit with the ignition advance off (it was previously on) and that was better at idle, but still quite rough. Starting the engine in that configuration also was challenging, as if the SureFly was unit was doing nothing. Regarding the comment about timing, the SureFly is indeed timed to TDC of cylinder #1. My comment had to do with making sure that the dip switch settings were set to 25 degrees to match the existing right hand mag's timing.

-

Hey all, thought I would throw a post out there to see if anyone with experience could help. I just got my IO-360-A1A back from a tear down / IRAN due to a case crack and decided to replace the left mag with a SureFly unit. The issue is that the engine is now incredibly hard to start and runs rough on both mags. Once started it runs happily on the old, existing, right mag. My mechanic and I are pulling our hair out over what's wrong. I'll list the things we've tried, Double checked the engine ground, we're using a new copper braid from the engine to the firewall Double checked that the p-lead is the correct, advance wire, used with the origin SoS system and original left mag Ensured that the SureFly was installed timed to TDC on cylinder #1 with dip switches set to 25 BTDC base timing Bought, installed, and tried in both directions the expensive $300 mag drive gear (I originally had the the single woodruff slot drive gear) Checked for split timing between the two mags. My engine has the older base timing of 25 degrees BTDC. We bought a New Horizons Maggie harness for use with the SureFly and we've checked that the leads are good I am currently using massive spark plugs (will use fine wires in the future, but the current set of plugs all test fine). We also re-gapped them to .032. The engine is behaving like the surefly is mistimed and firing at the wrong time. We just cannot figure out why though. Any thoughts? I really appreciate the help!

-

Has anyone here practiced a runway turn back in their Mooney? I've practiced some of the elements of it at altitude but not close to the ground. This video just came out from ASI where they tried turn backs in a couple different planes including a Bonanza. The Bonanza did not make it back to the runway after a simulated engine failure and I wonder if our Mooney's climb and glide profile makes it more similar to the Bonanza.

-

I've had a decent experience with Cascade Aircraft Mgmt so far (haven't finished my first major piece of work with them yet); good communication, reasonable per hour rate, and they have a fair number of Mooney's in and out of the shop. I was going to say you could call Advantage Aviation at South Valley Regional; they have some Mooneys based at the field there but gear up repairs may be a little outside of what they do and usually they seem really busy.

- 25 replies

-

- 1

-

-

- mechanic

- aircraft mechanic

- (and 7 more)

-

Generally speaking repairing and refinishing the interior furnishings are considered preventative maintenance. You still have to follow the regulations though. I wonder if this is one of the situations where you can follow the AC which allows you to comply with the modern Part 23 regulations or the regulations that the aircraft was originally certified under (CAR3). I don't have a link offhand but I believe that Part 23 and CAR3 both have language on burn resistance requirements.

-

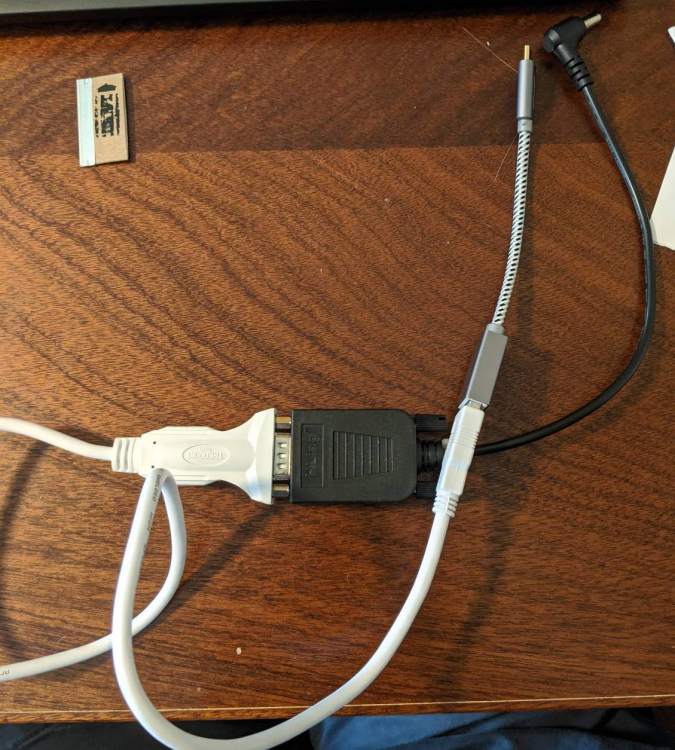

To start with this is not an original idea, credit to @Deb for linking to a post on BeechTalk about another person, Mike Dodge, that wrote a little Android application for pulling data over the JPI serial connection. I'm just adding some additional notes to help with others using that post for their benefit. I have a JPI 700 with fuel flow and a serial data connector in my plane. I have wanted to get data off of it and into Savvy Analysis for a little while now. For various reasons I'm not a fan my 'easy' options, I objected to paying $200+ for the little USB box or sending the unit back in I also objected to ~$35 dollars for JPI's serial interface cable Nothing against JPI here or other's taking the above approaches, I just found these prices high relative to their component costs, taking the unit out is too much hassle, and I wanted the convenience of using my cell phone for data capture. I opted instead to build my own cable and use the app linked from the above post. For me, this means I can transfer data to my cell phone at the end of a flight. No laptops. No USB sticks. The major caveat here is that this is Android only until some enterprising individual writes an equivalent iOS app. Components are as follows, 5.5 mm OD x 2.5 mm ID Right Angled Power Cable YIOVVOM DB9 Breakout Connector to Wiring Terminal RS232 D-SUB Male Serial Adapters Port Breakout Board Solder-Free Module with case(Female Serial Adapter) TRENDnet USB to Serial 9-Pin Converter Cable, TU-S9, Connect a RS-232 Serial Device to a USB 2.0 Port, Supports Windows & Mac, Supports USB 1.1, USB 2.0, USB 3.0, 25 Inch Cable Length, Plug & Play USB C to USB Adapter, CableCreation 0.5 Feet USB-C to USB-A 3.0 Female Adapter OTG (on-The-go) Cable, Compatible with New MacBook (Pro), Dell XPS 13/15, Galaxy S20/S10/S9/S8 etc, Space Gray I included the Amazon links, the links may break but hopefully they give an idea of what to search for in the future. Total cost at time of purchase was ~$36 including a serial to USB-C converter which needs to be purchased if using the original JPI cable with a modern laptop. Assembly consists of connecting two wires. JPI, perhaps envisioning that people would want to do this, helpfully provides the serial pin out assignment here under the FAQ heading "Black PC Interface cable pin assignments." And finally the completed cable, Using the app is fairly straightforward, basically install, hit the start button and then start the data dump from the JPI unit. I hope folks with these older JPI units find this helpful as another way of easily getting data off of them.

-

- 2

-

-

.thumb.jpg.388849a8d3b211220e4f2c83e217d972.jpg)

Aft CG or Fwd CG... where are you operating?

msh9 replied to Yourpilotincommand's topic in General Mooney Talk

I have an M20E with a battery, whelen strobe, and autopilot servos/electronics in the back. I just had it weighed a few months ago, Empty weight: 1670.4 (despite @cliffy's comments about what you're supposed to do for CAR3, the shop weighed it with full oil and included that in the empty weight...) CG: 46.57 With full fuel, 3 people, and 50# of luggage I am at the edge of the envelope depending on the weight of the backseat passenger. With only two people in the plane, I would have to be carrying some seriously heavy luggage to put me outside of the plane's envelope. -

I have a M20E based in Salt Lake, by mid-morning in the summer the DA is typically 6700'-7200'. I don't necessarily make drastic changes to my technique. I always brief what I'm about to do before doing it, typically some flavor of, Apply gentle back pressure at 70 MPH to start lifting off Initial climb out at 85 MPH Gear up when I feel there is a comfortable amount of air beneath me, usually ~100' AGL Start accelerating, wait a beat, and then bring the flaps up At this point I'm normally past 90MPH and accelerating to 100 for a Vy climb to 1000' AGL. Some notes, I have an early M20E with the lower flap speed and a manual gear. Even at high DA the flap speed limit and the speed limit for my arm to bring the gear up come up pretty fast. My normal technique is to tidy up and set for Vy quickly because of those low speed limits. I suspect you can be a little more leisurely about things in a later model M20. 75% of rotation speed at 50% of runway used is a rule of thumb I have used before at new to me airports. One other thing I do, I use a gopro to film my take-offs and landings for review later. I use the take-off footage to roughly estimate the real amount of runway used. After the flight I note how much runway was used in the video and correlate it to the DA around the time of take-off. It's not super accurate, but I am slowly making a scatter plot chart those shows a nice correlation between DA and runway use. The other nice thing about this is these numbers are accurate based on my (sometimes lackluster) technique instead of a factory pilot.

-

Agreed. I think I would recommend them in a pinch. I just don't think I would go to them for an annual next time.

-

Thought I would throw this out there to help future buyers like myself. Hopefully reviews of this sort are welcome here. I bought an early model M20E earlier this year and used Foothill Aircraft Sales & Service at Cable Airport (KCCB) for a prebuy that I then rolled into an annual inspection. There is a much longer story on the why, how, and where with regard to how I, located in Salt Lake, ended up buying a M20E located at KCCB without seeing it in person first during a global pandemic, but here we are. In any case, I decided to use Foothill for a handful of reasons, They had never seen the aircraft before based on its logbooks They are a MSC I didn't know any mechanics personally that I could rely on in SoCal Some other fun facts about this purchase, the prebuy occurred in late Feb., we closed mid-March, and the plane needed an annual done after March 31st. I am sure I could have worked something else out to get the plane to another mechanic, but having it all done in one place, by a MSC, at the plane's current location was attractive to me as a first time buyer. I now have ~50 tach hours on the plane since picking it up and feel like I can give a fair review. In brief-- Pros, They caught a lot of issues that would have been otherwise expensive to fix later including a logbook review that found some missing work from a prop strike inspection. Props for attention to detail in some areas. The final word on this will be when I take it to either KNR in Evanston or Cascade Aero in Boise for its next annual, but I'm not expecting much between Foothill's work and some minor things I am having done throughout the year. Lots of written estimates, they helped with negotiating the purchase price and understanding how we were spending money. Large changes in cost were communicated and approved in writing. This included things like discovering that the Hartzell H1 governor was done for. We discussed and I approved the cost of buying a new PCU5000. Cons, A little bit of nickel and dime action. I understand that running a repair station is hard and it's hard to make money in GA. It's also frustrating though to get charged near a full hour of labor for things like "tighten the set screw on the control yoke". That said, it was on the estimate so the person I really have to blame is myself for not knowing. Now I know. Poor communication. We used both phone calls and emails, stuff just got dropped on the floor. There were a couple items that I wanted looked at, that we discussed on both the phone and via email that never got done. Fortunately, none of the dropped items were airworthiness issues so it ultimately was fine. In another instance of poor communication, the original oil temperature gauge was inop. The original estimate included work to triage, this escalated into buying an overhauled unit from Air parts of Lock Haven. All fine, but I would have liked to be consulted before spending $600+ on my behalf on an overhauled unit. Given the choice I might have opted to replace the original cluster, but I wasn't given that choice at the time. Weird time saving choices. I had new AeroLed NAV/Strobe lights installed and paid for the time to run new shielded wiring, which I asked for and they recommended. On the other hand, they installed a uAvionix tailbeacon in the tail cone but did not run a ground wire for that. One of the few issues I have had with the plane in the last 50 hours occurred this week when the tailbeacon dropped out. It's in a local shop that I have developed more of a relationship with, we suspect the issue is just poor grounding of the unit and it should have been installed with a simple ground wire. The annual was fairly large and include a number of items, so I could go on with the pro/con lists. I hope the above was illustrative though. Overall, I'm not entirely unhappy with the work, but not pleased either, call it in the grumpy middle. I have no complaints about the pre-buy and would recommend using them for a PPI in a pinch. I won't be taking the plane back to them for its next annual though either. Hopefully this helps the next buyer in the SoCal / LA area make some more informed decisions. With 20/20 hindsight, I likely would have had Foothill fix a few key things on the plane and then move it back to the SLC area for its annual. That being said, COVID happened, they got most of what I wanted done, and everything needed to make the plane safe.

-

I am intrigued by this. I would love to hear how your process goes and if successful would certainly be interested in doing this for my own. Once question though, @Flybeech21 I saw earlier in the thread you mentioned doing this in part to access different avionics. I have a feeling that I'm just failing at reading comprehension, but I don't understand how swapping over to the primary category special airworthiness cert from the standard makes this easier. Is it that the primary category certificate does not require to keep to the aircraft to the original type design? --Edit-- Reread the thread and saw you're planning on adding it to the STC. Now I am doubly curious about your process and what you end up doing. Good luck!

-

Hey all, I'm new here! I'm part-way down the rabbit hole of purchasing a vintage M20 (no deposits yet just virtually tire kicking). One item I still need to address are my insurance requirements. The prospective quotes I've received so far want between 5 and 10 hours of dual instruction (Falcon on the low end and Avemco on the high end). My problem is that while googling around has turned up lists of CFIs in lots of places there don't appear to be any near me (KSLC). So my questions are: Does the collective here know of anyone near Salt Lake City that has M20C/E experience and can instruct? If not, what have other people done in this situation? Call around to find a CFI that's willing to travel? The aircraft that I'm looking at are in either Texas or California. Another option is taking some additional vacation when I go to finalize the purchase and do the training at the location I pick up the aircraft. Anyway just looking from some opinions on how others got their initial training done when they first bought a Mooney. Thanks!