louisut

Verified Member-

Posts

74 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by louisut

-

Garmin GI275 Install in a 305 Rocket

louisut replied to Austin305Rocket's topic in Avionics/Panel Discussion

The pre-tax quote was $7.3k for the ADI and $8.7k for the HSI or $15k for both. The optional OAT sensor was $1k and synthetic vision another $1k. We opted out of the synthetic vision for now. After tax on the parts, $18k is in the ballpark. Options considered were a 10" G3X + GI 275 for $28k or a 10" G500TXi + G5 for $41k. The G3X couldn't drive the Century but the G500 could with the GAD43b adapter, hence the GI with the G3X and the G5 with the G500. Engine monitoring would have been an extra $10k on both. In retrospect, an extra $10k for a larger glass panel may have deserved extra consideration. However our original intent was to fix some funky behavior with the autopilot. While multiple signs pointed to a failing ADI, we thought it prudent to hold back a little in case the AP needed further service too. -

Garmin GI275 Install in a 305 Rocket

louisut replied to Austin305Rocket's topic in Avionics/Panel Discussion

It was 40-ish hours plus cost of parts (two GI 275s--one with ADAHRS, one with ADAHRS + AP, the GTP59 probe, and GMU11 magnetometer). Your cost may vary depending on the rates in your area. -

GI 275 and KFC150 - attitude source?

louisut replied to elimansour's topic in Avionics/Panel Discussion

Another data point: we have a plane in the shop now getting its ADI and HSI replaced with dual GI 275s. One is the ADAHRS variant and the other is the ADAHRS+AP, which will be the primary attitude source for the Century 31 autopilot. This was the main consideration over the G5. The GI should talk directly to the autopilot. The G5 could send heading data to the autopilot (via the GAD43), but could not act as the attitude source, and so we would have needed to keep the vacuum system--a non-starter. Replacing the working autopilot with the GFC-500 wasn't in the budget; it would have been about $35k for the dual G5 + GFC-500 vs $15k for the two GIs. One GI will be configured as the primary ADI and the other an HSI and standby ADI. With the GTP 59 OAT probe, the ADI will also display a mark for standard rate turns. This means these two instruments will replace the steam ADI, HSI, airspeed, altitude, and turn coordinator. Pretty capable little instrument it seems. -

Help with Garmin 530W and programming

louisut replied to Greg Ellis's topic in Avionics/Panel Discussion

No, you got it. If you use Foreflight, you can get started in the right direction by entering FZT/334/11. A Flightstream 210 would make it much easier to program the 530W since you could then send it from Foreflight with one button. It's a nice accessory if you fly IFR often. -

TIL there's an official Rocket drain tube. The one I've been using is a DIY section of CPVC which friction fits snugly in the drain. I'm not sure on the exact specs, but here's the printing on it. The top row looks like a UPC: https://www.upcitemdb.com/upc/611942124107

-

The drain itself (the fitting) or the drain tube?

-

Up to your budget I think. Mid-continent sells a "nice" clock which has USB ports: https://www.aircraftspruce.com/catalog/inpages/mci_10-06963.php?clickkey=6755589

-

Replacement Landing and Taxi Lights for M20R

louisut replied to TGreen's topic in Modern Mooney Discussion

I recently replaced the GE4509 incandescent landing lights in my M20K with a Rigid Industries 63010 ($65 from Amazon) and an AeroLED Sunspot 36 LX 01-1030-L-A ($350 from Aircraft Spruce). Both are PAR36 replacements and fit perfectly. The AeroLED is brighter by just the slightest amount, but I'm not sure it's worth 5x the cost. The beam angles are nearly identical. Both are much brighter than the Whelens from a few years ago. If I were to do it over, I'd just get two of the Rigid lamps; IMO there's not a $570 difference. Rigid is a reputable maker and higher quality than generic PAR36 tractor light LEDs. -

While Continental's engine manual specifies 32 or 36, the Rocket's flight manual supplement specifies 32, so I'd go with that. During the last annual, we found 36 fine wires (RHB36S) in the plane. The A&P said hotter plugs can be installed if there are fouling issues or in cooler climates. We replaced them with RHB32S

-

Not in my experience. I've used various cards of different brands and sizes to update a 650, including an MMC card in an SD adapter. No issues with any of them. As I mentioned, the Garmin utility formats the card when you run the updater.

-

I know you mentioned trying two SD cards already, but have you tried a third just to check? Any aftermarket card works. The databases are small, so any spare one you have sitting around will work. There's nothing special you need to do as the Garmin app formats the card before writing the database.

-

Make sure the write-protect tab on the memory card is not inadvertently sliding to read-only. I had trouble updating a GTN650 once. The database wrote to the card fine, but nothing happened when I booted up with it. It sounds similar to what's happening to you. It turned out the write-protect tab was loose and sliding to read-only when I inserted it into Garmin. For whatever reason, this prevented the Garmin from recognizing the updates. FWIW it was an aftermarket Sandisk 2 GB card.

-

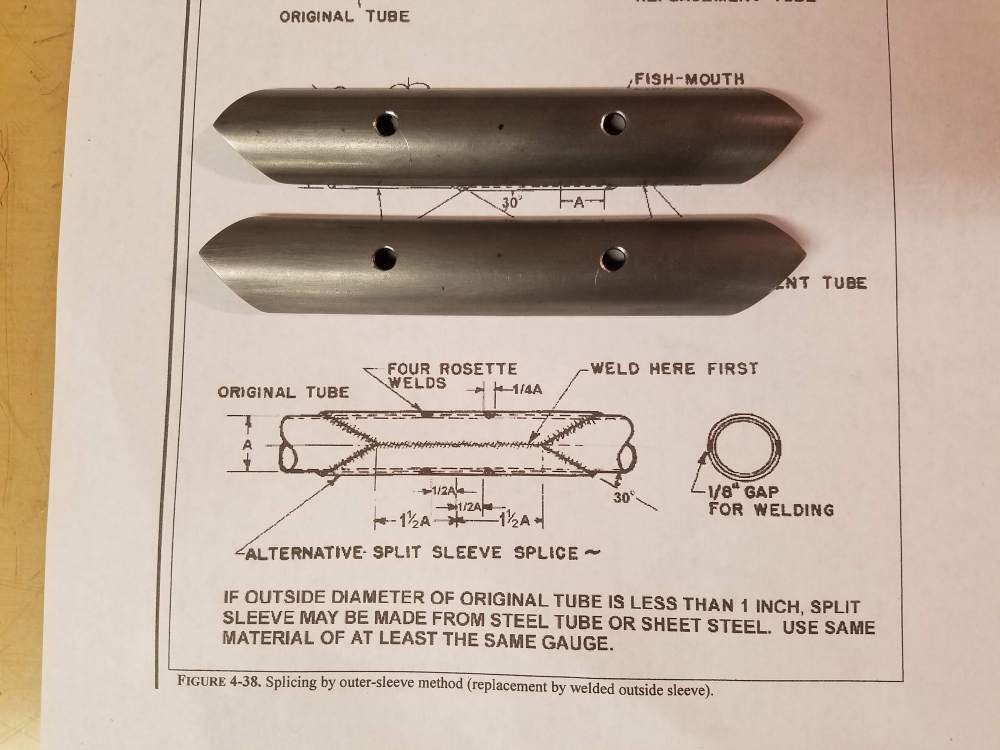

The weld repair went well. The rest of the frame was cleaned up and the whole thing repainted. Next time it's out we're going to investigate ceramic powdercoat. I believe the split sleeve splice process is the same for any tubing repair. Attached are some pics of the progress. Should be better than new now. before:

- 13 replies

-

- corrosion

- engine mount

-

(and 2 more)

Tagged with:

-

For posterity, Rocket Engineering indicated that the tubing in the truss is 0.058", and so the 0.015" already removed is definitely outside the 10% guideline. Our A&P is bringing in a welder to fabricate and repair the affected section. Rocket has signed off on this plan. Overhauling the truss starts at $11k ($4k for the truss + 80 hours labor to r&r the engine), so we're starting small first.

- 13 replies

-

- 2

-

-

- corrosion

- engine mount

-

(and 2 more)

Tagged with:

-

I'm not sure what he used to get the corrosion out. He said it was deep; you can see the gap compared to the ruler in the first pic. The wall thickness is what we're trying to find out now. He's contacted Rocket so it should in compliance with their ICAs, if any. If it's outside guidelines, the obvious option would be to send the truss out for overhaul. It'd be expensive, but that's the benefit of a four-way partnership I guess. The second option may be to have a metalworker replace that section in situ. While I'm not opposed to this, I'd be more comfortable about it if someone had done it before. If it turns out to be good as-is, I want to make sure we maintain it properly so that it'll last at least until the next overhaul.

- 13 replies

-

- corrosion

- engine mount

-

(and 2 more)

Tagged with:

-

Earlier this year I joined a Mooney Rocket partnership, though only recently have I begun flying it. The performance is phenomenal, especially compared to the Piper Cherokees I came from. As part of my checkout, I flew a 900nm trip in an afternoon and cruised easily in the O2 levels--something unimaginable to me only a few months ago. With the Pipers, I was very involved with the maintenance, and I've continued to be involved with the Mooney. We've had several large mx issues since I've joined, and though I'm fortunate to work with an A&P who is both meticulous and communicative, his time is limited, and so I'm hoping the collective experience of MSers will fill in my knowledge gaps. The latest issue is with the engine truss. One of the beams close to the turbo was corroded. If I understand correctly, the heat of the turbo corroded the paint, which opened the truss to additional corrosion. It's been cleaned off, but there's some question whether that section needs to be replaced completely. My A&P has contacted Rocket Engineering to see whether we're still within guidelines of AC 43.13-1B (where a 10% reduction in material is acceptable). In the meantime, I'm looking to learn more about it, how to avoid it, etc... in general, anyone else's experience with this. Thanks!

- 13 replies

-

- corrosion

- engine mount

-

(and 2 more)

Tagged with: