Hradec

Supporter-

Posts

125 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Hradec

-

Removing urethane efc100 fueltank coating

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

I contacted paul, he was really great. My call sent him down memory lane There was a 2 year period around 2000 where about 100 aircraft had their tanks resealed with the efc100 urethane stc. His process wont budge the material The urethrane is great until you need to remove it, then you are screwed! I called FFC. Apparently the military had its 707 aircraft use this system, it was great until it came time for removal during heavy inspection. They went back to the old school prc polysulfied sealant. Apparently the contractors had to follow strict environmental guidelines. The removed it with the combination of 15000 psi power washer and mechanically removing it with scrapers, it was a horrible job -

Removing urethane efc100 fueltank coating

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

You had the same stc applied to your tanks with the urethane? -

Removing urethane efc100 fueltank coating

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

No leaks, pulled the skin back to do an upper spar cap. I have to remove the stuff to rivet it back together, clean it up and reseal -

Removing urethane efc100 fueltank coating

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Where do I get this stuff and is it safe for aluminum. -

Removing urethane efc100 fueltank coating

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

I called them, no answer. I called the company that holds the stc, it has been sold, but they were very familiar with the product, they still use it in the military. Their tech guy was suppose to call me on the removal process. No call yet. I put samples in mek, acetone, paint stripper and choke and carb cleaner. In almost 2 hrs soaking not much action. -

HELP! I'm in the process of replacing my aft stub spar and now a top spar cap. The spar cap repair requires I open up the fueltank. I realized that my tank doesn't have the typical polysulfied sealant. It had an stc in 2002 to install a urethane coating EFC100. How do I remove this stuff? Mechanically?with chemicals? Dynamite? I did some research apparently it is tough stuff and used in some military aircraft fuel tanks. The coating is almost an inch thick in some areas. I am sure my fuel capacity is reduce by multiple gallons because if the thickness of the urethane.

-

Aft stub spar replacement beginning

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Yes, yes, yes!!!! My drilling assistant is moving back to europe in the next couple of weeks. My wife and I took a weekend sheetmetal class last winter at the EAA museum. My wife is a great sport, but if we are to remain married, I prefer she not help me buck rivets. I'm an a&p for an airline, actual an avionics crew chief. Bucked a few rivets in school, spent a few weekends helping g a friend build an rv7. Any help by someone with more experience than me would be great. I'm at KLOT Lewis univ airport Thanks Glenn -

Aft stub spar replacement beginning

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

-

Aft stub spar replacement beginning

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Update..... As I was laying on my back installing clecos and match drilling the new aft stub spar, I was thinking to myself " I see the light at the end of the tunnel". It was at the same moment I found some hidden top spar cap corrosion I over looked. It's bad, needs replacement. I visited with the awesome crew at Don Maxwell. Part is available. I have ordered it and started drilling. Dream of having the plane finished next summer has been kicked down the road a bit. Glenn -

Very exciting! I'm at the same airport as Nidal. We have been following this, we very excited for him and his system. I hope to install one in my mooney when I get her flying next summer. Aft stub spar replacement in progress. Glenn

-

I've always been told never use petroleum products around oxygen(vaseline) beeswax is the thing to use.

-

Aft stub spar replacement beginning

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Before mooney closed they said they had everything in stock to assemble it. When I got ready to purchase it, mooney closed. I panicked. I recall seeing a very old post of a guy on mooney space having a new one for sale. I reached out and he responded very quickly. Still had the part, but no mooney. Made a quick deal, flew out to seattle and drove it back to chicago. Started the removal process probably more than 3 weeks ago. Between work and other responsibilities I managed to get it out. Now cleaning the filthy plane and priming before the wx turn in a few days. Glenn -

Aft stub spar replacement beginning

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Stub spar is out, took about 3 weeks. Next job is clean the airframe, prime before the wx gets cold in a few days.goal is to fly it next summer. Will spend the rest of winter installing the stub spar. Glenn- 38 replies

-

- 15

-

-

Any recent Smooth belly mod for m20e

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

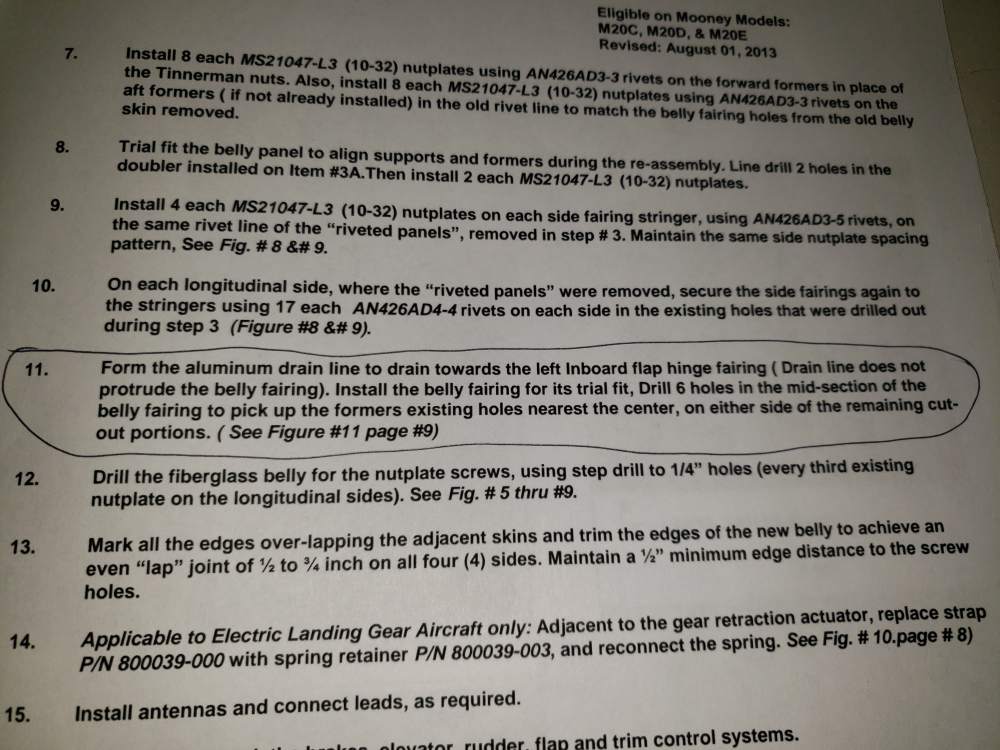

Thanks for the pics and info. Was trying to convince myself it was worth it. Just got my ppl. This plane I bought hasn't flown in 5yrs. Friend says just make it airworthy and fly it save some money if I have cam corrosion. I I however feel if I am there, I'm going to make it right and make it easy for me. By the way, lasar was kind enough to send me a copy of the stc to determine if it would be a helpful purchase in my aft stub spar endeavour. This stc says the tube does NOT go through the belly panel. Not sure how they want it routed. -

Any recent Smooth belly mod for m20e

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Thanks for sending the picture. I was just at the hangar under the airplane and just drilled out the rivets of the 2 center belly panels realizing it's going to be a pain to reinstall. I have a copy of the stc and looks like some stringers and formers get removed. It is going to allow for amazing access. Really looks like it will be a time saver in reassembly after my aft stub spar replacement and in the future for lubrication and inspect. Looks like I'm going to pull the trigger. What antenna is mounted to your panel? -

Any recent Smooth belly mod for m20e

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

How thick is the panel? How thick at the fwd leading edge and aft edge? -

Any recent Smooth belly mod for m20e

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

I got my plane for next to nothing, had 2 incidents one in 1965 and then again in the 70s. So much monkey motion in the belly of these planes. Will make it much easier for me to maintain it. Going to have the belly pulled and riveted panels removed. I think it will be a time saver for reassembly and then again a time saver in the future. -

Any recent Smooth belly mod for m20e

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

I couldn't remember where I saw it for sale, thanks. At $2500 the one at lasar is new and cheaper. -

Any recent Smooth belly mod for m20e

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Who makes/markets the carbon fiber belly for the m20e? -

Anyone do the smoother belly mod recently on an M20e? I'm in the process of changing the aft stub spar due to corrosion. I have to drill out the 2 riveted panels in the belly and unscrew the other panels. They are dirty, grimy, need paint. A dozen different fastener sizes. Riveting the 2 panels back in will be time consuming. Is this mod a sensible use of time and money? I will be doing all the work myself (ap/ia minimal GA experience) I was looking at the lasar mod. No change in wt and balance. I believe 4 panels are removed, some stringers, lots of screws and clipnuts. Glenn

-

Aft stub spar replacement beginning

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Got a few layers peeled away today. The aft stub spar painted white is the gear well side, doesn't look to bad. The other side of the same part shows the real damage. Black marker shows all the popped rivet heads. I dont know when splash guards were installed on the landing gear on mooneys, this one did not have them. Maybe the splash guears could have helped? Glenn -

Aft stub spar replacement beginning

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

-

Aft stub spar replacement beginning

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Hoping to have the old one out in a couple of weeks. Typical corrosion in the extrusions a dozen rivet heads popped off from exfoliation corrosion in aft part of gear well -

Aft stub spar replacement beginning

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

-

Just want to tell the forum I'm beginning to replace my aft stub spar on a 64 m20e. I was able to find a new one on the forum. I removed the main landing gear and started drilling rivets out. I will drill until it gets too cold in the hangar. Then I will go through the gear in my heated garage. Plane is at klot if anyone wanted to take a look or help. Wish me luck. Glenn

.thumb.jpg.735db3de7ed7fef0382dc762b35fb086.jpg)

.thumb.jpg.7f27bb55ae69d18491cb86cd20ead5a6.jpg)