Hradec

Supporter-

Posts

144 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Hradec

-

Stuck Fuel Tank Access Covers

Hradec replied to Zippy_Bird's topic in Vintage Mooneys (pre-J models)

I didnt want to mention heat gun, but that's exactly what I used. but my tanks were vented a very long time and there was to danger of fire or explosion. heat gun was definitely helpful along with phenolic and plastic scrapers. thin putty knives. -

looking for this cover (MLG disc stack coolar bolt cove)

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Thanks for your Ebay link. I offered $40 and the deal was made. thanks Glenn -

looking for this cover (MLG disc stack coolar bolt cove)

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

I considered it, but there is so much work I still need to do to complete my renovation. I figured I would have someone else make it to save me some time -

Difficulty installing landing gear truss

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Thanks for the input. Somewhere I have seen it read that you could modify the existing part by machining the corners off of this bracket 510046. My bracket has been changed or modified To the proper status. So many new parts and and adjustments. Not much room for all that monkey motion. Gear is in and clearances good now. New shock disks installed. She will be sitting on her gear in a week or two. First time in 4 yrs. Thanks Glenn -

Difficulty installing landing gear truss

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Most likely the truss and link bushing replacement. -

Difficulty installing landing gear truss

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Well I pretty much have it resolved, however now I have interference elsewhere. The truss pivot bolt head is hitting. Parts manual calls for an6H21a Service bulletin m20-212 replaces there bolts with NAS1306 bolts,these have a considerably thinner head but the length called out for in the sb is too short. I want to replace bolt A.. remove an6h-17a install nas1306-21h. Will be too short. My goal is to replace an6h21a bolt with an Nas equivalent but with a thinner head. Specs say nas1306-26h is the one to use for my 1964 m20e sn 311. Any one run into this bolt interfering. This is not the an26-17 with the thin castle nut that hits. I have this resolved. Thx Glenn -

Hi, I'm a bit frustrated after renovating my landing gear and rebushing the truss and the link. I installed the right main landing gear with the trust and the link attached to the main landing gear. The truss is about a half an inch away from being bolted to the spa. I know that this area can accept a thin Shim as well as shimming the landing gear fore and aft movement. But this will definitely not close the half inch Gap. What am I doing wrong? The truss and the link we're rebushed using recommended clearances of .002" by Dan at Lasar. I was going to work on the left main landing gear tomorrow to see if I have the same problem there. Any recommendations? Is the clearance on the truss and Link too tight? Is slop required in order to attach the Truss to The Spar? Thanks Glenn 1964 m20e Trying to finish up the aft stub spar and upper spar cap replacement

-

Mine was on the leading edge in that area. Removed it and plugged the holes with cherry rivets

-

I'm interested in purchasing the teflon seals also. I sent a msg a few days ago. Thanks Glenn

-

Landing gear bushing/bearing alloy

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Lots of people are doing this repair, just need the alloy number. I will reach out to the people recommended thanks -

Landing gear bushing/bearing alloy

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Yes -

Landing gear bushing/bearing alloy

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Maybe I need to clarify the bushing hole in the landing gear Parts is oversized. Hoping to find the correct bearing alloy -

Landing gear bushing/bearing alloy

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Bushing/bearing hole is oversized. -

Need to replace the bushings on my truss and link. They are worn and will have to go oversize. Anyone know what the alloy number is. I have heard it is bronze aluminum nickel. The bushings that came out are silver. Just not sure of the alloy number so I can have my machine shop ream out the parts and make custom bushings. Thanks Glenn 64 m20e. SN 311

-

Gear shock disc collar orientation

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

It doesnt mention the orientation of the collar -

Hi, I replaced the shock disks on my nose gear and the collar that secures the stack has a bevel that was on top facing fwd. Now I am doing the main landing gear disks and on one gear the collar had the bevel facing down and aft. The other gear had the bevel facing up. What is the correct orientation of the collar bevel? Thanks Glenn 64 m20e. SN 311

-

Wow thanks for all the detailed information in the replies.

-

As my 5 yr renovation project is winding down I was wondering if anyone has refinished their wheels/rim. What are they made of? Aluminum? Magnesium? Was thinking about blasting the wheels,alodining and painting. Any suggestions or recommedations? Thanks Glenn

-

The imperfectness of the original polysulfied sealant is probably the whole reason they used it. Yes it may leak after 20 yrs, but if structure work needs to be done, solvents exist that will soften it to the point that plastic scrapers can remove it. The efc 100 polyurethane (at least in Mooney's) is permanent, making structure repair and service if not impossible, at least very impractical. From what I recall in all my info gathering and talking to all the players, a couple hundred mooneys were ruined.

-

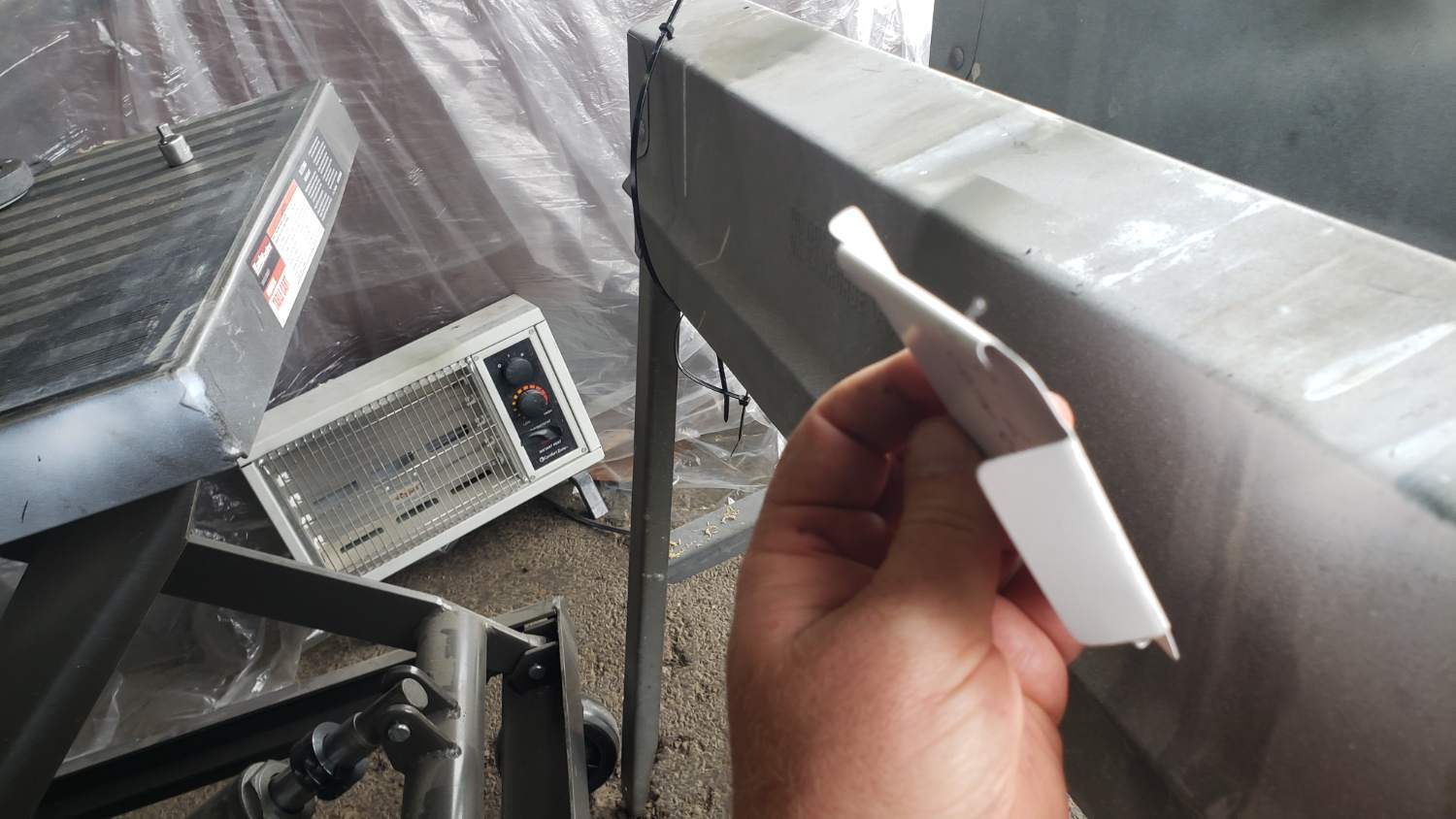

Not long ago somebody contacted me when they took they Mooney to Fort Lauderdale to get their tanks redone. Unfortunately they had this efc100 in their tanks. I told him what I did and told is tank guy to contact me. Apparently 15,000 psi water jet is needed to remove this garbage. I was replacing my spar cap. I used a propane torch to heat a thick metal putty knife. The hot blade removed excess polyurethane where it was thick and needed to be removed to remove and install hiloks and rivets. A heat gun was also used along with a temp sense gun to not over heat the metal. I did no remove all of it, just where it was disturbed to facilitate structure repair. Before I came up with this technique, I disturbed the whole tank. I ended up coating the entire tank with the seskents and process called out in the mooneys manual. Plane might be test flown before the end of the year. Glenn

-

As my spar cap and aft stub spar replacement winds down on my 1964 m20e sn#311. I have a question about the clamps securing the aluminum brake line entering the mlg wheel well joggling through the lighting whole through the rib and connecting to the flex hose. My airplane has small steel clamps with no rubber cushion on the. Just some friction tape wrapped around the line where the clamp is. Is this original? There is even a spot in the belly where the brake lines run parallel, the sam clamp and friction tape is used. Do you have this on your old mooney. My friend with a 1980 m20j has clamps with rubber cushions. What do you have, pictures welcome Ps Where the gadline connects to flex hose I have conventional rubber cushion clamps. Thanks Glenn

-

What are you going to use it for? If doing landing gear check I think the dial type is the best.

-

1964 m20e s/n#311 nose gear door rod end picture

Hradec replied to Hradec's topic in Vintage Mooneys (pre-J models)

Bingo! Thanks, for the picture and confirmation it is correct. Part number anyone? The parts catalog for my year is really poor. Possible service bulletin for update? Thanks Glenn -

Going through all the pushpull tubes and rod ends on my aircraft renovation project. The parts manual diagram is very poor for the nose gear door rod end. later models Parts catalog looks different. Is my part correct or is it completely wrong and as my friend said, a riding lawn mower rod end? Please share a pic of your rod end from same vintage mooney. Thanks Glenn 1964 m20e sn #311