Skyland

Basic Member-

Posts

88 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Skyland

-

Why You Don't Fire A Gun in the Air....Ever

Skyland replied to GeeBee's topic in Miscellaneous Aviation Talk

I'll add to this. Some 20 years ago at KRHV I found a bullet on the ground under a hole in my hangar roof that just missed my Mooney wing. More recently at neighboring KPAO a bullet went through my friend's Eagle wing walk. Probably the best location as the repair is invisible now. -

Fuel selector to OFF. Connect a rubber hose to the fuel vent and blow into it to slightly pressurize the tank. Check the cap seal with a soap solution. SBM20-229A.pdf

-

Dual mag failure, off-field landing

Skyland replied to Skyland's topic in Mooney Safety & Accident Discussion

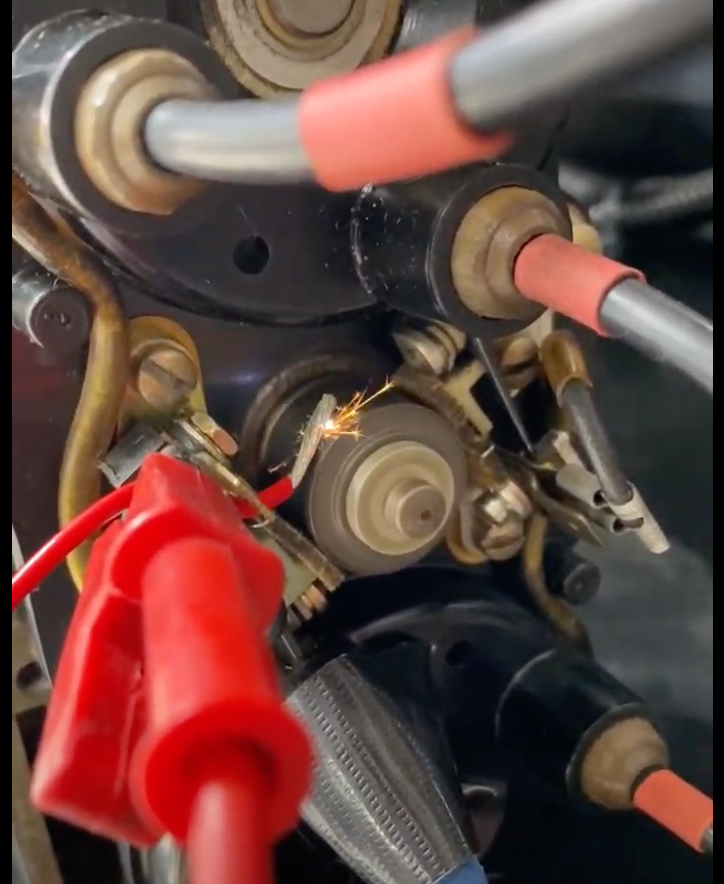

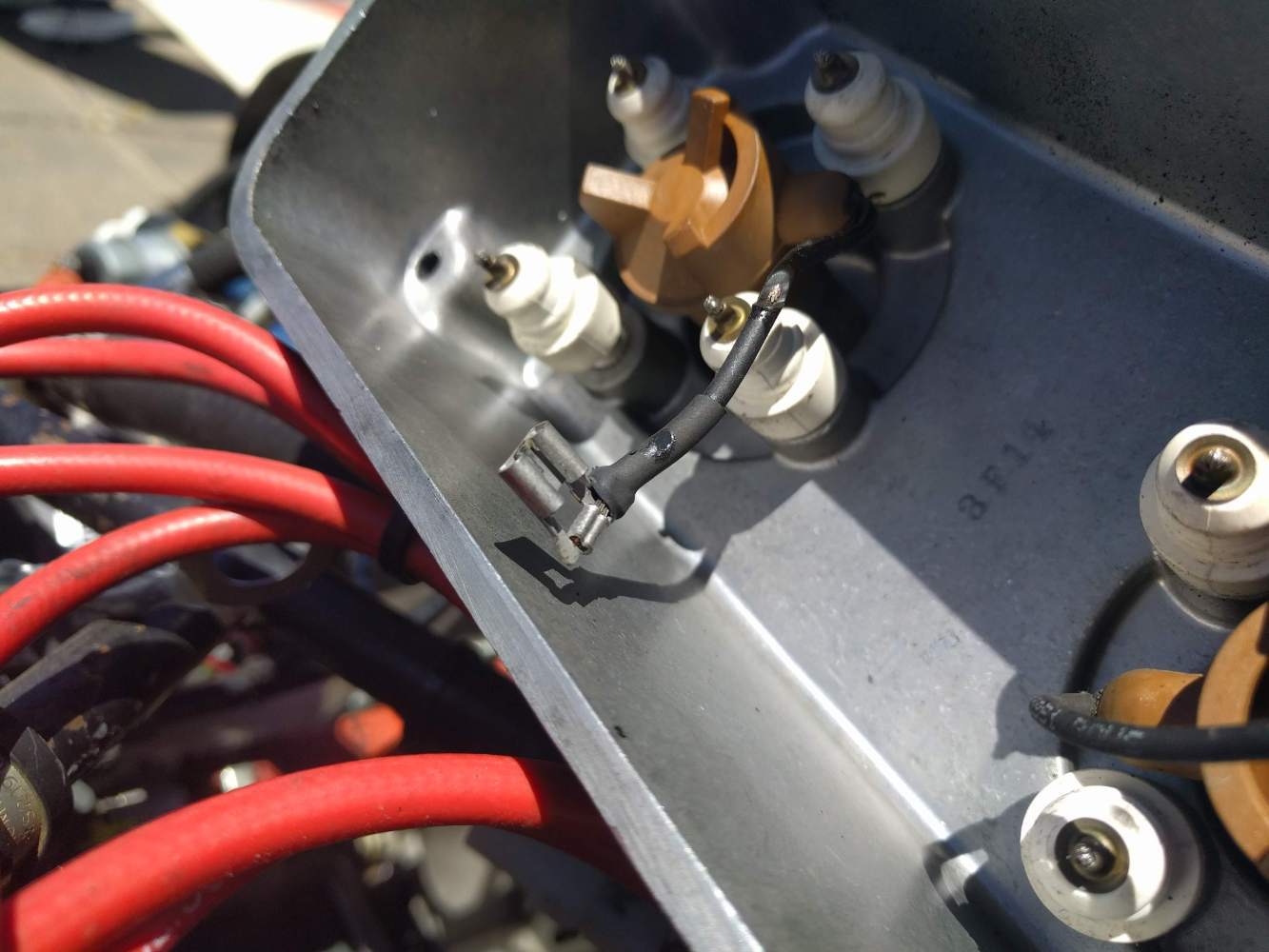

Connecting those two wires is exceedingly difficult. I watched the guy who did mine complain profusely about how hard is to get your fingers in there to plug them in. He used hemostat pliers, I think, and ended up twisting one of the leads which ended up rubbing on a rotating part which lead to my in-flight dual mag failure. That arcing wire didn't just ground out one mag, it produced a high resistance short against the rotating magneto cam. That produced heat, enough to heat up the cam to melt the point rubbing blocks thus closing the gaps on both points. That cap should be designed with a plug and socket to make it impossible to misroute those wires, and make it a lot easier to install the cap. Barring that, use caution plugging in those wires correctly. -

Nose Gear Door Linkage Replacement

Skyland replied to Samir13k's topic in Vintage Mooneys (pre-J models)

The piano hinge fingers appears to have significant wear. When the doors are are wiggled the door hinge half will move fore and aft and it might be interpreted as bad rod ends. The slop in the hinge is not that big a deal but if you want to replace the piano hinge it's a standard part and not all that difficult to replace but requires match riveting onto the doors. -

Nosewheel Steering Disconnection on Retraction

Skyland replied to moosebreath's topic in Modern Mooney Discussion

Genius example. Thanks for sharing your model. -

I just completed my lower 48 last year as well. Looking at Alaska next. Appears Canada doesn't like our Basic Med. Anyone have any hopeful info. Suppose I could go get a third class before the trip.

-

Been following you. What an exciting adventure. Congratulations on a safe trip and welcome home.

-

Skytec starter 149 NL high torque model question

Skyland replied to jamesm's topic in Vintage Mooneys (pre-J models)

Had to replace that shear pin on the same starter a few years ago. The starter would spin but wouldn't engage the ring gear. Don't recall anything abnormal that precipitated the event. It just sheared. There were two spares RTV'd under the base housing, like you're gonna need these some day. After getting the starter on the bench you'll need to drive the remains of the pin out of the shaft and gear, then press in a new pin. I got lucky that it occurred at my hangar before a pleasure flight, not away from home. Good luck. -

Stuck Fuel Tank Access Covers

Skyland replied to Zippy_Bird's topic in Vintage Mooneys (pre-J models)

Yes, scraping, heat gun, guitar picks. Be very careful not to bend the thin wing skins. Also, leave the screws in place backing them out a few turns. You can then apply pressure to the screw heads. I placed a board on the screw tops with bricks to apply a constant pressure, even overnight might help. -

40:1 Landing gear actuator gears

Skyland replied to Matthew P's topic in Vintage Mooneys (pre-J models)

Here's a post I wrote up regarding a Dukes replacement gear failure some years ago when replacement gears became available. Apparently the gears received were not heat teated as later told to me by the shop who installed it. -

Trying to troubleshoot my Coms. As stated in the title, when Com 1 (Garmin 430) is selected in the audio panel (KMA 20) and then Com 2 (old Apollo GX60, which works quite well as a Com) is monitored, the volume of Com 1 drops considerably. Conversely, Com 2 selected, then monitoring Com 1, the volume of Com 2 remains constant. Happens on all frequencies. Thought for sure it must be an issue in the KMA 20, so swapped in another KMA 20 and the problem is unchanged. Hum, could it be a wiring or grounding problem? Both radios transmit and receive clear and strong. Not a big issue but I like using the Garmin for Com 1 and like to monitor guard or weather on Com 2 without having to constantly adjust Com 1 volume. Ideas?

-

Thanks for the Pirep on the Death Valley airports. Seems the conditions haven't improved since I landed at Stove Pipe two years ago and drove to Furnace Creek and walked that runway a while back as well. The Park Service used to have a Cessna based at Furnace Creek years ago for patrolling the Park. Seems they're no longer interested in keeping up the airport. Too bad, both locations are well suited for fly in business. The hundreds of miles of paved roads in DV are generally in excellent condition, and they get repaired quickly after flood damage. Can't see why a mile of runway pavement is so difficult. There must be $$ available somewhere for some maintenance rather than just closing them. It's a huge Park, the size of Connecticut. The airports were there long before becoming a NP. Emergency usage comes to mind as well. Thanks again for the report.

-

@AndreiC So how's the Furnace Creek runway? It was closed last month for over a week and was hoping it was for surface reconditioning to improve the terrible bumps and pavement upheavals. I telephoned the Park for info but nobody returned the call. Looking to fly out there again this spring. Maybe a West Coast Mooney get-together?

-

I paid around 35 for the Jazzy motor/gearbox from eBay. Plenty of power and well built.

-

Search for Kobalt 24V battery adapter. I'm impressed by how much power that battery puts out. My original goal was to make a lightweight tug to bring along in the plane. This motor/gearbox is very well built and it all turned out to be a bit heavy and awkward with the protruding bits so it stays in the hangar. I really only use it when the ramp is wet and slippery. Otherwise I find it easier to push the plane the old fashioned way.

-

Here's my CB tug I cobbled together. Used a powered wheelchair motor and gearbox off eBay. Started out with a rubber capstan but it slipped too much on the tire when wet. Now use a HF abrasive sanding wheel that works well. The larger diameter of the new wheel raised the geometry so had to bend the handle for clearance. End of the handle is not in the picture but extends out like the hand tow bar. The switch plus fwd/rev is in the handle. All told only a little over a hundred bucks in the project and some home machine shop fun.

-

Any updates to gathering in Kerrville for the April 8 eclipse?

-

Antenna length is inversely proportional to frequency. The higher the frequency, the shorter the wavelength, the shorter the antenna. That's why I can't understand why a 406 antenna can't be offered in a short version. A quarter wavelength 121.5 antenna computes to about 62cm (24"). Could be it's wire wound and can be 1/4 that length (as I understand it) which is probably the length of the antennas under the tail fin. All the 406 antennas I've seen are straight wire whips and computes to about 36cm (14") 1/2 wave. That seems to be about the length of those. Additionally, don't the new ELTs transmit both frequencies? Maybe the 121.5 antenna is in the base while the 406 antenna is the wire whip. Any antenna gurus in the group?

-

I'd like to replace my 121.5 ELT with a 406 but reluctant to install a long whip antenna outside the fuselage somewhere. I like that the old antenna is hidden underneath the fiberglass dorsal fin. Any solutions to this dilemma?

-

As you may recall, last year on May 9, 2022, I experienced a complete flame out and off-field landing just short of Double Eagle (KAEG) in Albuquerque. The root cause of the D-3000 dual mag failure has haunted me - until now. The mag failed at 209 hours after the overhauled exchange. Mags checked good upon departure but both point gaps closed to zero during cruise 1.5 hours after takeoff. The FAA sent an IA the next morning to remove the mag. The inspector found that both point gaps were at zero. Also, inside the cap was a condenser wire with melted insulation where it had been rubbing on the cam. The common thinking seemed to be that the burned and shorted condenser wire would have simply grounded out one mag leaving the other unaffected. The glaring evidence that everyone seemed to ignore was the burned and shorted wire was causing a much bigger problem. With the help of my local IA and his mag tester stand, we mounted up a dual mag and shorted out a wire from one point connection to the rotating cam. Sparks flew and temperatures rose quickly on the cam. So, what happened in my mag turned out to be an installation error with a condenser wire touching the cam that took 200 hours to finally wear through the insulation. The cam heated up softening both point rubbing blocks nearly simultaneously to the point of closure. It does baffle me that the mag is designed that it is even possible for this wire to be routed to cause such a problem. At least there's some satisfaction in knowing that the mag itself is rather robust as long as precautions are taken not to misroute the condenser wires in the path of moving parts.

-

Regarding the Dukes, back in 2003 in our 1977J partnership, I had the actuator fail on take off - at night, nonetheless. It resulted in failure of the gear to retract and the inability of the emergency extension system to operate. Here's what led up to this event. Mooney SB M20-190B calls for checking the backlash of the actuator worm and pinion gears every 100 hours. In our IA's estimation he felt there was excessive play, and since a new pinion gear was available we sent the actuator to a well known West Coast facility who specializes in actuator repairs. A new gear was installed and after installation back into the plane, the gear swing operated at twice the speed. Wham up, wham down. Didn't feel right at all. Come to find out there are 40:1 and 20:1 gears. Apparently, a new 20:1 gear was installed and the shop insisted all is fine. Well, slow forward a mere one month later and the system failed. Upon selecting gear up, a terrible grinding sound was heard. Immediately put the gear switch to the down position and more continuous grinding. I know, instantly reversing the motor is no doubt a big no no but it was somewhat instinctual trying to save the actuator. Pulled the gear motor C/B this time to stop the grinding. Continued climbing to a safe altitude and reported to the tower my issue. Circled in the area attempting to troubleshoot. Fortunately, the gear indicator in the floor was lined up indicating it failed in the down position. Don't recall the annunciator light status. Upon activating the emergency extension system, the handle just freewheeled. Oh oh, couldn't confirm gear was actually locked. Tower didn't seem too concerned and no equipment was called. Came in and made a nice soft landing and gently taxied to the hanger. Looking at the gear over center mechanism the next morning it was floppy loose. Couldn't believe the gear held. Called that shop to report what happened and their response was they received replacement gears that were not heat treated. Ya, thanks for letting us know. Probably explains the stripped teeth on the new gear. The original pinion gear was reinstalled and to my knowledge it still in the plane to this day, knowing the current owner.

-

Is a fuel selector valve rebuildable?

Skyland replied to ArrowBerry's topic in Vintage Mooneys (pre-J models)

This may help. It's for the Anderson Brass fuel selector but the process may be similar with different valves. -

Duel Magneto Retrofit to Two Sperate Magnetos

Skyland replied to scottt175's topic in General Mooney Talk

Maybe you just offered an explanation for my dual mag failure last year. The follower blocks on both points wore or melted down simultaneously causing both point gaps to go to zero. Turns out the A&P who installed the mag unknowingly had a condenser wire touching the cam or shaft. -

As long as we're waiting to hear back from the trim motor resolution... Lucas - "Inventor of the intermittent wiper"

-

Similar problem on a 77 J trim motor a while back. Removed the cover and discovered the brush ring had come loose. After reinstalling the brush ring the trim motor functioned normally again. Sometimes you get lucky. I like the electrical engineer's mantra in that most electrical problems are really mechanical problems - a broken wire, bad connection, cold solder joint, etc. The components themselves on a properly designed circuit are usually quite robust.