Skyland

Verified Member-

Posts

91 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Skyland

-

Following up on my recent dual mag failure that resulted in an off-field landing just shy of an airport in my M20J. Luck was with me that day to find a smooth field and no damage to the plane. If only there was a way I could have extended the glide to make it just a bit further to the runway. Turns out there is a way but it seems to be a secret. To my knowledge I’ve never received training for it and don’t recall ever seeing it mentioned in a POH. Simply pulling the prop control back to course pitch on a windmilling propeller extends the glide a considerable amount. I set about collecting some data today. Flight test in calm air and light winds. Starting at 7000MSL, idle cut-off, windmilling propeller, 90 KIAS, 10nm glide. First test, prop control full forward in flat pitch. Descent rate of 750fpm, over the airport at 1500MSL. That’s 550ft/nm. Second test, same starting location and parameters except prop control pulled full back to course pitch. Descent rate of 600fpm, over the airport at 2600MSL. That’s 440ft/nm. If my math is correct, that’s a 25 percent better glide. Wish I learned this previously but if there’s ever another engine out pulling the prop should be an automatic reach. Fly safe.

- 60 replies

-

- 10

-

-

-

Dual mag failure, off-field landing

Skyland replied to Skyland's topic in Mooney Safety & Accident Discussion

I’ve thought about that so many times after the fact. It was so close. Another half mile after that 20 mile glide would have made the airport. I’ll experiment with the prop settings at altitude in a glide to see how evident it is. Make sense though, like downshifting a car descending a steep grade. -

Dual mag failure, off-field landing

Skyland replied to Skyland's topic in Mooney Safety & Accident Discussion

QAA -

Dual mag failure, off-field landing

Skyland replied to Skyland's topic in Mooney Safety & Accident Discussion

My dual mag was overhauled by QAA. Trade in, I sent them back my core. -

I’m well overdue explaining my off-field landing incident on May 9 of this year, as a result of the D- 3000 dual mag failure. Caution – long write-up but hopefully there are some takeaway points of value here. My wife and I departed from our home base in California for the Chicago area in our M20J as we’ve done many times before. Day 2 we took off from Page, AZ - direct Albuquerque - direct Salina, KS. Enroute at 11.5K nearing Albuquerque we began to hear what sounded like a very faint rattle emanating from the belly area. Listened for a bit and it started to get more frequent. Began troubleshooting to see if it might be engine related. Changed prop, mixture, throttle, pump, tanks with no affect. Best I recall all items on the engine monitor appeared normal. No change until switching to Left mag – nearly dead. Right mag was better but rough. Immediately turned to nearest airport. Declared an emergency with ABQ approach and informed the controller of my situation. Unfortunately, Double Eagle was a couple miles beyond the FF glide ring. Within the next couple minutes the left mag completely failed and had only partial power on the right, but that also failed in the next few minutes. Now it was truly an “oh darn” moment, or words to that effect. How both mags checked good during preflight and both were now failing was not a good feeling. All I knew was I needed to make the best of a bad situation. I tried to reassure my wife that the plane flies perfectly fine as a glider now, we have about ten minutes to reach the airport or find a good place to land and we’ll be alright. We gained some ground on the glide ring as we continued but were battling some 40kt headwinds. Kept the aircraft clean and the glide speed faster than normal in an attempt to minimize time in those strong winds. Glider pilots minimize their time spent in sinking air by flying faster for the same reason. I kept Approach informed of our progress, that I had no power, that I thought it was a dual mag failure and that I might not be able to make the airport. Then came the standard issue question - say number of souls on board and fuel remaining. My wife remained remarkably calm throughout and even helped by scanning around for possible landing locations and obstructions. The fact that I am a fairly experienced glider pilot did help immensely in my opinion. During the entire power-off descent and landing it all seemed rather normal to me because every landing in a glider is an engine out landing. Airports are nice but fields work too. Approach handed me off and Tower had already cleared out traffic for the inbound emergency and cleared us for any runway but winds were strongly favoring 22. It is so gratifying and special to know the ATC professionals will do everything in their power to assist an aircraft in distress. Despite making up some glide distance, it was looking very iffy that we would be able to make the runway. Several miles out we identified what looked like a good open space short of the airport boundary clear of power lines and obstructions. It was our go to place if needed. At about 1000AGL those hangers, roads and fences on final approach looked like something we might not clear. Without hesitation I told the tower unable to make the runway and we're going for the field. The last thing I wanted to do was to try for the airport at all cost only to stretch the glide with disastrous results. As much as I love my Mooney the thought went through my mind to use the plane to save us. I rolled out parallel to the active into the strong headwind, lowered the gear and flaps and did a nice smooth full stall landing on the sandy desert floor. We looked at each other, did a quick embrace and said somewhat jokingly, well that wasn’t a bad landing. We ended up about 100 yards from the airport fence. Tower controller was watching the entire event and offered a big compliment. I let them know that the airplane appeared undamaged and no injuries. Emergency personnel soon began to arrive, followed by airport and FBO staff as well as the FAA. The largest fire in NM history was in progress and the last thing anyone wanted was an airplane crash to spark another blaze in the windy desert scrub. Everyone, and especially me, was relieved that the Mooney was sitting there unscathed. No damage to the prop or even the gear doors, not a scratch that I could see. Full stall landing into a strong wind on the semi-soft surface made for a very short landing. FAA measured the roll out at 322 feet. The two gentlemen from the FAA were extremely nice but also professional. In fact one of them owns an F model so we bonded a bit. They did check the airplane for fuel and oil just to make sure I didn't do something really stupid. They took pictures of the plane as well as my documents and the airplane documents to verify everyone and everything was legal and current. Basically a ramp check in the desert. They also requested I send them scans of the latest annual logbook entries when I returned home. After everyone was satisfied we were fine and all the paperwork was done, one of the maintenance guys offered to help with his small Jeep and a tow bar. It was an easy pull to perimeter road and onto the ramp. Given the situation I’m extremely grateful for the outcome. Day VFR at cruise over a desert having just flown over rugged terrain. Luck played a big part but I’ll take it. Those sounds at the beginning of the event were likely afterfires in the muffler due to incomplete combustion in the cylinders. One would think EGT would be spiking but the JPI 830 didn’t show that and the engine data doesn’t reflect anything out of the ordinary either from what I tell. So what happened? The next morning I met an IA at the plane. We pulled the infamous D-3000 dual mag and right away observed that neither set of points was opening. That's on a recently overhauled mag with 209 hours on it replaced two years prior. Something caused both rubbing blocks to wear down prematurely – and remarkably simultaneously. I’m going with lack of lube because it appeared the oil pads on the points were dry with some fibers scattered about inside the distributor cap. But both sets, and simultaneously? Other commonalities to the failure could be bad surface finish on the common cam, contaminated lube, defective rubbing block material. So, bad parts or a bad rebuild? The FAA says they are looking into it but who knows how long that will take or if anything will come of it. Maybe if more failures occur it will become a higher priority. In the meantime the mag was field repaired (points adjusted and oil wicks lubed, engine timing set) and I flew it back to my home base. It just came out of annual with an emphasis on looking for any possible damage due to the off-field landing. As mentioned, not a scratch or any problems found. I subsequently made that Chicago trip, without my wife this time, and the plane performed perfectly. I plan to have the point gaps checked every 50 hours to see if there is any trend or cause for concern. Lessons learned. When something doesn’t feel or sound right it might be worse than thought. Wasted a few precious minutes troubleshooting before turning to the airport. Pulling back the prop might have improved the glide. Never trained for it, only read about it and being task saturated at the time didn’t think of it. Forty plus years and thousands of hours, mostly in Mooneys, without an engine failure doesn’t mean it can’t happen. I fly a Mooney for safety and its good looks, but also for its efficiency which means I frequently fly direct. Been rather cavalier about flying over inhospitable terrain. My glider buddies call that Tiger country. Glider experience helped. Kept things somewhat routine. Stay current and legal. You never know when a ramp check can occur. Practice various emergencies. Commit important procedures to memory. Single pilot ops too task saturated or no time to look it up. Squawk 7700 in an emergency. Didn’t think of it and wasn’t my highest priority. Hopefully missed my one and only opportunity. ATC already had me as an emergency. Add more items to the survival kit. Could have been far from help or injured. Love Mooneys but hate dual mags. I don’t want this incident to significantly change my flying. Unfortunately, it’s changed my wife’s flying. It was a rare event and the odds of it happening again are highly unlikely. However, the reason for this failure is largely unknown. I’m still flying with the same mag but checking Left and Right in flight now and especially before entering IFR conditions, nighttime or Tiger country. Fly safe.

- 53 replies

-

- 25

-

-

-

Same problem here. The heading bug is always left of center to fly a course. It was about 10 degrees off previously but after making the trim pot adjustment on the Stec30 the closest I could get it is about 3 degree left offset. That was a couple years ago and I’ve been living with it. When flying in GPSS mode with the 430W it also flys with the same 3 degree course offset. So both heading mode and GPSS mode have the same offset thus pointing to the autopilot. I’m on a trip from CA to TX at the moment and on the second leg of the flight that offset problem became suddenly worse. It’s now at least 30 degrees. IOW, I need to set the bug 30 degrees left of center to fly a course. When I center the destination (Direct To) on the 430 and engage GPSS the plane veers right, I think trying to fly the offset but I didn’t let it get that far. Overcast at my destination and didn’t trust the autopilot for either an ILS or RNAV so I hand flew it. Troubleshooting suggestions very welcome.

-

Firewall hole for ram air cable

Skyland replied to John Martindale's topic in Modern Mooney Discussion

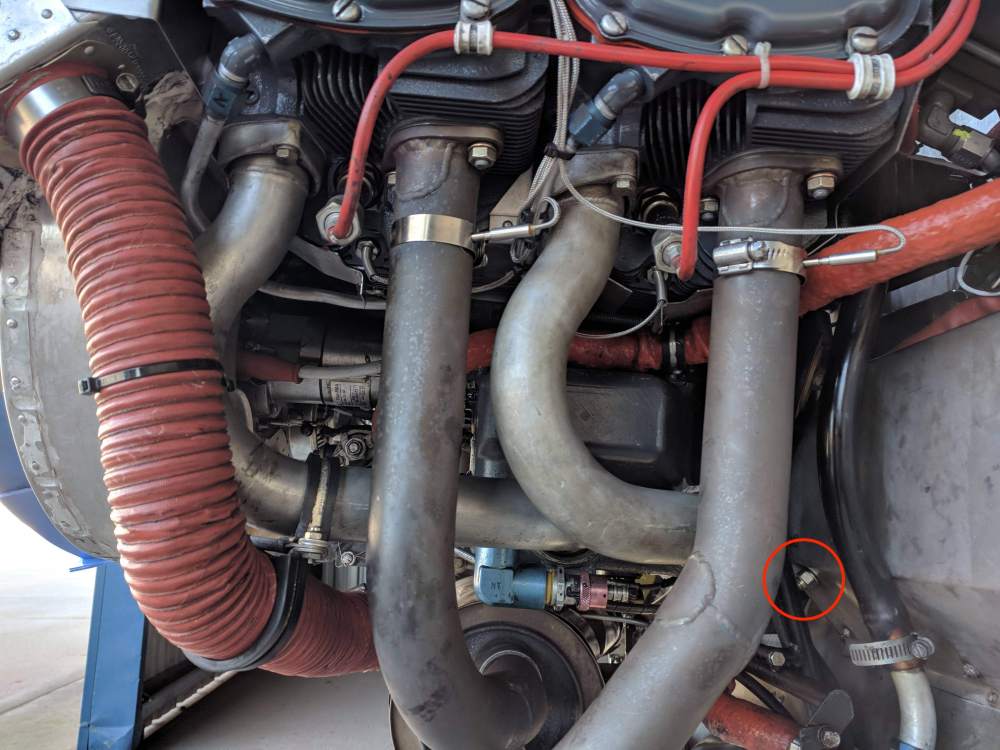

John, I just recently did the SB to remove the ram air system on my '79 J. Picture shows a 7/16" (as I recall) nut and bolt used to plug the firewall hole from the removed cable. ---Ken -

Yet another technique for the list. I use a small plastic funnel with a few feet of clear vinyl tubing attached. Place the funnel under the bottom rear of the filter holding it in place with a piece of safety wire. Then using a scratch awl, punch a small hole at the back of the filter (closest to the pilot side direction as possible), unscrew the filter about 1/3 turn, punch an air hole at the top and let it drain. If the oil is warm it only takes a few minutes to completely empty the filter. ---Ken

-

Sticky Valve and intake valve cupping on IO360

Skyland replied to M20S Driver's topic in Modern Mooney Discussion

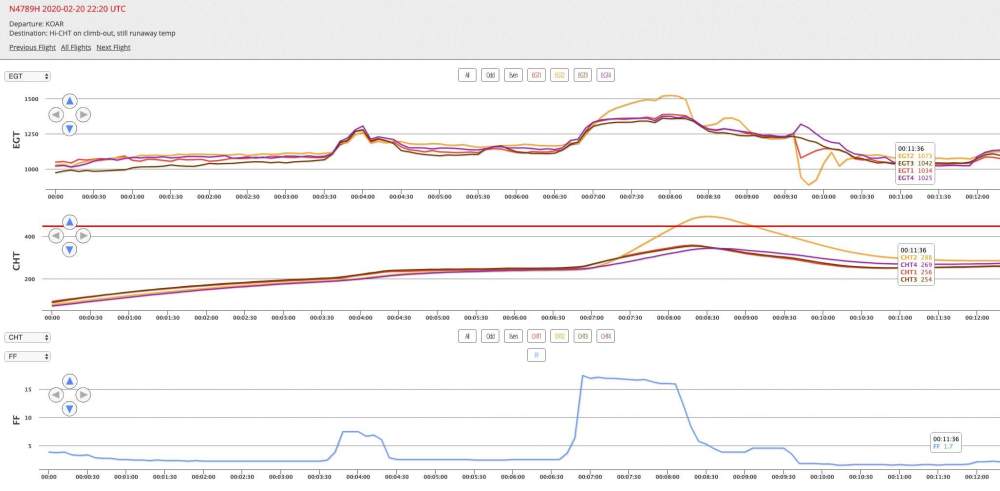

Hi folks. Back to follow-up on my engine adventure. My first post in this thread describes the event. With the engine roughness we thought at first it was a stuck open valve. Turned out to be a worse problem with the #1 intake valve cupped enough to lose compression in that cylinder. In an attempt to make the short flight home, we removed the valve rotator cap to get that valve to fully close. Full power run-up, and take off were normal until about 600 feet when compression again was lost in that cylinder and engine began running very rough. Same scenario, intake valve #1 cupped even more in that very short amount of time. (Pic 1 shows the cupping measured at 0.365". Don't know what a new valve measures but it's not nearly this much). A week later we installed a loaner cylinder in another attempt to get the plane home. Again, run-up and takeoff were normal then engine roughness soon after. Lost cyl. #1 in flight but was able to continue home to a safe landing. Pulling the prop through again got zero compression in one cylinder. So just what is causing a #1 intake valve to melt (tulip) three times? The Sacramento Sky Ranch Engineering Manual seems to describe this scenario and attributes it to a pre-ignition event possibly caused by magnito cross firing. Pre-ignition is a very destructive event yet the piston and cylinder appeared fine. I was close to the 500 hour mag O/H so we installed an overhauled mag. In taking apart the old mag there was a very suspicious burned spot on the phenolic distributor block (see pic). We hoped this was the root cause. I elected to send out all four cylinders to Gibson Aviation for a complete top overhaul since there was about 1300 hours on the factory O/H. They replaced the #1 tuliped valve, of course, but said all the pistons and cylinders and seats were all in spec. I elected to go .010 over with new pistons, in part, to improve oil consumption numbers. Very professional workmanship, I might add. During the engine downtime I installed a JPI 830 engine analyzer to replace the old school factory single cylinder analog CHT and EGT. Fast forward another few weeks with engine all back together. Ground run-ups fine with nice graph and numbers on the new JPI. First flight takeoff normal until about 600 feet, then the JPI start flashing CHT overheat (see pic). Cut power and landed. WTF? Problem still there, except this time indicating it switched from cylinder 1 to 2. My IA now suggested the fuel divider. We did a fuel flow test and all injectors pumped fuel equally into the four jars. Decided to disassemble the fuel divider for inspection and cleaning. One of his A&Ps took it apart and threw it in the ultrasonic cleaner before I had a chance to examine it. I wanted to carefully inspect to see if there was any proof of visible blockage. But reassembling the divider and reinstalling it on the plane proved successful. After 14 hours on the engine not a hint of the former problem. JPI graphs and numbers repeatedly look nice and even. Problem occurred primarily during climb outs and changed from cylinder 1 to 2. It's still hard for me to believe an intake valve with relatively cold air rushing past it can be softened by an overheated cylinder without affecting the piston, cylinder or seat. So a clogged fuel divider seemed to be the culprit causing a lean mixture in one cylinder. I would think an ultra lean mixture would be way out of a stoichiometric ratio thus causing a cooler incomplete burn. Apparently not. Any expertise here to explain this? Best regards, Ken- 16 replies

-

Sticky Valve and intake valve cupping on IO360

Skyland replied to M20S Driver's topic in Modern Mooney Discussion

Side note: I like the map depicting states flown to (landed in, I presume). Couldn't find info on this site on "how to" so cobbled it together myself. Didn't mean for it to be so big. I'll try to fix that soon. Can someone offer a procedure? Back to my tuliped valve engine. Sky Ranch Engineering Manual by John Schwaner may have nailed it. On page 168, slightly paraphrasing, Pre-ignition causes slight engine roughness, extreme heating and pressure causing piston burning and intake valve stretching to the point where it no longer closes thus stopping the event. Pre-ignition can be caused by magnito cross-fire. Inspect distributor block for carbon tracking. Both pre-ignition and detonation can cause extreme engine damage in a short period of time while all the engine instruments are "in the green". This was written back in 1990. Multi-cylinder engine analysers of today would no-doubt flag these events. Okay, I'm sold. A quick visual of the piston and cylinder when I removed them looked good so I'm hoping no damage beyond the valve. I'll report back. I'm also close to the 500 hour mag O/H so that should take care of the cross-fire possibility. BTW, this is a 1200 hour factory reman with no log entries for previous cylinder work.- 16 replies

-

- 1

-

-

Sticky Valve and intake valve cupping on IO360

Skyland replied to M20S Driver's topic in Modern Mooney Discussion

Okay, just returned from a long drive working on my engine. Here's the scenario. My wife and I took the Mooney on a nice x-country trip from California to Maine, down the east coast and back again with a stop in Kerrville along the way for a factory tour (another story). The plane performed flawlessly the entire time. One month later and about five more hours on the engine we were enroute on a one hour flight when a subtle vibration in the engine began, enough for me to sit up and take notice. Lasted maybe 5-10 minutes then went away and landed uneventfully. An hour later the startup, runup and takeoff were all normal - until about 600 feet when the vibration returned followed by a loss of rpms and power. Circled the airport in a very slow climb while trying to troubleshoot. Tried L, R and Both, mixture, prop cycling, throttle changes, switched tanks - no change. All gauges in the green. Vibration now getting quite bad like running on just three out of four cylinders. Landed. Removed top cowling, cylinder 1 was noticeably cooler than the others. Pulled the injector and it was open and clean. Pulled the prop through it was evident there was no compression in one cylinder. Pulled number 1 spark plug to verify zero compression. Wife went from a little concerned to a lot disappointed. We missed our cruise departure in SD - but flew commercial to catch up with it in Cabo. Wife back to near normal. I had a mechanic look it over and verified the number 1 intake valve was stuck open. Though at first it was a stuck lifter, removed it, bled out the oil, reassembled, and the valve still wouldn't close to get compression. Removing the rotator cap on the valve stem allowed the valve to fully close and to attain hydraulic lifter clearance. Did a runup and the engine ran normal. Tried a test flight and got to 400 feet when the engine again began to run rough. Ya, my bad. So pulled the cylinder today and it appears the number 1 intake valve is badly cupped. Question is, how can an INTAKE valve get that hot by 400 feet? BTW, this is an old school '79 J model, single probe EGT and CHT. Engine analyser just appeared on xmas list. Cylinder and valves to be inspected tomorrow so more to come...- 16 replies

-

- 1

-