-

Posts

77 -

Joined

-

Last visited

-

Days Won

1

Minivation last won the day on February 13 2021

Minivation had the most liked content!

Profile Information

-

Gender

Male

-

Location

Suffolk, VA

-

Reg #

N28FY

-

Model

M20J (Mod Works 210hp Conversion)

-

Base

KPVG

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Minivation's Achievements

-

You very well may be right. However, the concern here is that the EIS exhibited the same problem with the P-lead pickup interface or the UMA tach sending unit, which works completely independently from the mag. In my opinion, this points to a fundamental flaw in how the GEA24 (all variants) defines what counts as a pulse.

-

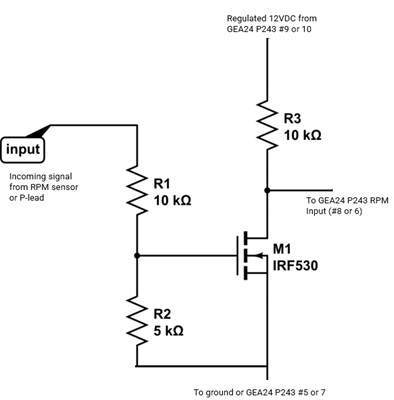

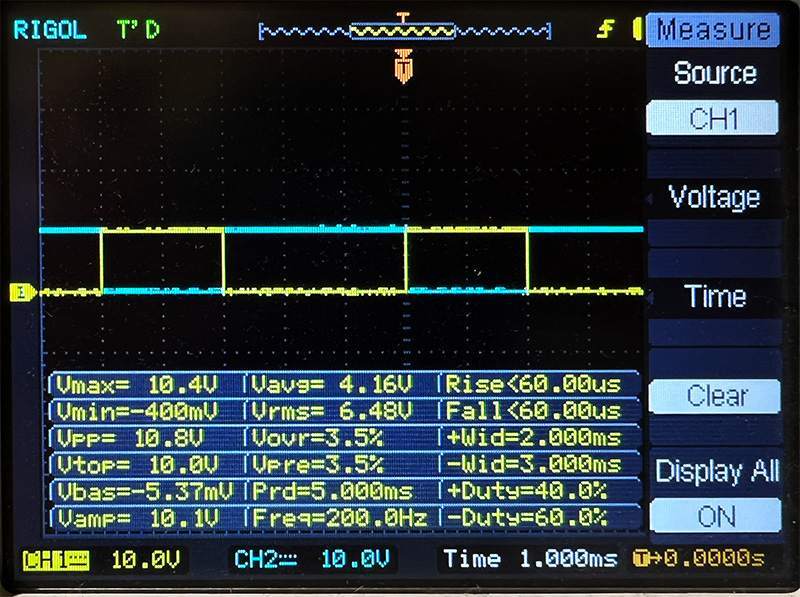

I realize that this thread is over half a year old at this point but I am following up in case anyone else runs into this issue in the future. After nearly a year, we have finally isolated the root cause and have managed to resolve it. The bottom line is, the RPM signal being sent into the GEA24 sensor adapter is a pulse signal, and the duty cycle of said pulse signal must be greater than 50% in order for the GEA24 to process it properly at higher frequencies (i.e. RPMs). In other words, for every high-low period in the signal, the signal must spend more time in the "high" state than in "low." Since my last comment on this thread, we have tried installing magneto filters, rerouting cables to avoid high-noise areas, swapped the GEA24, swapped the GI275, and even replaced the P-lead interface with the UMA T1A3-4 tach drive sensor (approved for GI275 EIS since July 2025) all to no avail. We tried all sorts of experiments, including rotating the tach sensor with a drill (to simulate the engine rotating), powering the EIS (GEA24 and GI275) with a regulated power supply, powering just the RPM sensor with the power supply, and even testing a Hall-effect RPM gauge from Amazon and hooking it up to the UMA sensor to verify it played nicely with the Amazon gauge (it did, beyond an equivalent of 5000rpm). Eventually, we removed the GI275 and GEA24 from the airplane and constructed a basic wiring harness in the workshop. We have an oscilloscope and signal generator, so we had the signal generator feed into the RPM input port of the GEA24 to emulate a sensor (with the o-scope monitoring it). After playing around with the waveforms a little, we found that the duty cycle of the RPM signal directly impacts the EIS's ability to properly resolve a valid RPM reading at higher RPMs. Duty cycle | Max RPM before fail | Failure mode 15% 1200 rpm Fluctuates, then drops to 0 30% 2400 rpm Fluctuates, then drops to 0 50% 4000 rpm Fluctuates, then drops to 0 70% 4000 rpm Red X 85% 4000 rpm Red X The above data implies that in any case, the EIS (as configured for a Lycoming 6-cyl direct drive engine) only goes to 4000rpm before failing the RPM, likely by design (a Lycoming spinning at 4000rpm is ... bad). However, we can clearly see that the RPM performance drops sharply at duty cycles below 50%. As a side note, this may explain Garmin's position of the magneto being "at fault" regarding the erratic RPM readings on select EIS installations. I haven't had the opportunity to explore the magneto P-lead output on an oscilloscope but I suppose that different condensors/capacitors in the mag may directly impact the waveform, and in turn, the "duty cycle" despite it not necessarily being a clean-cut two-state pulse signal. Going back to the issue at hand, the UMA tach sensor, by construction, has a fixed duty cycle of 1/3, or 33%. Looking at the inside of the sensor reveals that the unit is nothing more than a wheel with a permanent magnet embedded somewhere in it, and this wheel rotates in close proximity to a PCB with a Hall sensor on it. Unfortunately this doesn't help the cause, but what can help is if the signal could be "conditioned" to an adequate format before being passed onto the GEA24. In this case, "inverting" the signal such that at 0V (low), the output is 12V (high) and vice versa, would effectively increase the duty cycle from 33% to 67% with minimal impact to the geometry of the waveform. There are several ways one can accomplish that, but ideally the "signal conditioning" circuit needs to (1) be reliable for long-term duty, (2) have fast switching characteristics, (3) be simple to construct (KISS method), and (4) be resilient to environmental variables like temperature and humidity. One possible method from this discussion is using a transistor, such as an IRF530 MOSFET, to drive the gate (or base in a BJT) to cause the transistor to conduct or cutoff between the drain (collector) and source (emitter): In the above circuit, the output signal is held at the MOSFET drain-to-source voltage. When the input is pulled high, the MOSFET starts conducting and effectively diverts the power passing through resistor R3 straight to ground. Thus the output voltage sees almost 0V. But when the input drops to a low voltage state, the MOSFET stops conducting and the output is virtually held at near 12V (assuming the GEA24 itself has a high impedance, which it does, so that only a minimal amount of current flows through it). I'm sure the real electrical engineers will hate me for the simplified explanation, but that's really the heart of the circuit. No circuit is perfect and the primary concern with this design is the MOSFET's ability to react quickly enough to sudden changes in the input signal. However, the IRF530 exhibits sufficient switching performance and testing with signals up to 13kHz (for the UMA T1A3-4 tach sensor which produces 2 pulses per engine revolution, that's equivalent to 390,000rpm) demonstrated that the circuit was still able to maintain a duty cycle of greater than 50% even with the imperfect rise/fall characteristics of the MOSFET. (Testing the circuit at near 13kHz. Yellow = input, blue = output) (Testing the circuit at 200Hz - equivalent to 6000 engine RPM. Yellow = input, blue = output) In the image above, the GI275 can be seen indicating RPM well above the 2200-2300rpm failure threshold I mentioned in my previous posts. In fact, this is near full power with the manifold pressure running well above ambient. Granted, the troubleshooting and testing here was all done with the UMA T1A3-4 sensor, which obviously works a bit differently than the magneto P-lead interface, so if anyone else is having issues and would like to keep the P-lead interface while implementing a solution, then a thorough review of the behavior and characteristics of the P-lead signal would be warranted.

-

We received a response from Garmin aviation support, which basically can be summarized to "the magneto is at fault." I don't disagree with that statement -- perhaps there is something inside the magneto that is causing the P-lead pulses to become unreliable, but our testing of the magneto with reference to its functionality for the engine reveals no immediate airworthiness concerns. RPM drops at prescribed run-up checks are nominal and the classic mag ground check is OK as well. It goes without saying the magneto timing to the engine is OK as well. In my contact with them I also asked them if they had any intention to add alternative methods to interface RPM, but they have ommitted this question altogether. To be fair, I don't expect Garmin to somehow make their P-lead RPM pickup interface more reliable on their end, but I most certainly would appreciate it if they seriously looked into a tang-driven pulse generator solution that would (1) offer Bendix dual mag operators a known, low-risk alternative to the P-lead pickups, and (2) be a solution that would be nearly universally applicable to any piston engine. For now, it has become my policy not to recommend the Garmin EIS for dual magneto-equipped aircraft until more options are made available for them.

-

@Shawn26 Does your Mooney by any chance have a turbocharged Lycoming 540? The Saratoga I'm dealing with has a TIO-540-S1AD that goes up to 36" at sea level. I just noticed in some of the video documentation from my run-ups that my "2350 rpm" border so happens to correlate where the MP exceeds atmospheric (roughly 30" where I am). The Bendix D3000 on this plane isn't pressurized, so I can't see a valid reason why MP would affect the magneto's operation, but it's something that got my attention.

-

I understand that logic. I see UMA also makes a tach generator that taps in to the original tang drive (T1A3-4) and that is TSO'd. Legalities aside, the technical issue still remains: the unit would output 2 pulses per engine revolution so unless Garmin adds a provision to define a sort of "K factor" for this, this solution will not work.

-

I just came back from the shop after adding capacitive filters to see if that helped. It did not. At this point we are running out of options, and running out of time (the aircraft is due for an annaul at the end of this month). Out of curiosity, what would the UMA sensor that is reportedly compatible with the D-3000 be? As Jetdriven mentioned, the issue behind trying to use a UMA hall-effect pickup is the fact that it spits out two pulses per engine revolution. This would not be a problem if Garmin incorporated a pulse ratio software setting, but evidently that is not on their radar. If things get really bad, I forsee a need to remove the GI275 and install a JPI instead.

-

I'm installing a GI275 EIS with GEA24 on a Piper Saratoga SP (PA-32R-301T), also with a D3000 dual mag, and having the SAME issue. The RPM works OK until I reach about 2350rpm, at which the tach goes erratic and jumps +/- 100rpm. The problem persists regardless of which mag I select on the ignition switch, but goes away when I retard the power below 2350rpm. So far, I have checked (1) proper pinouts and installation of proper in-line resistors per Garmin's manual, (2) proper supply of power and clean ground at the GEA24, (3) proper shielding and ground return of the p-leads, and (4) proper contact of the P-lead compression fitting to the mag itself. I have even refabricated the entire P-lead and RPM pickup cables from scratch. So far, none of these have solved the issue. Garmin support suggested doing a factory reset of the EIS (which I did) but that did not yield results either. Just adding one more case study to the list. I'll bring updates once we solve this issue.

-

I think owners of these kinds of planes largely fall into three categories: 1) Didn't realize how involved ownership is, couldn't handle it and ended up burying their head in the sand 2) Used to fly it actively but life got in the way (family, business, etc) and they just don't have the time anymore 3) Have both time + money but no interest but wants to keep it as a "financial investment". The first group are usually found in the rural airports where tiedown fees are dirt cheap or don't exist, thus keeping the airplane "there" doesn't have immediate costs. The third group is rare but I've seen them before. It takes them a few years until they finally dig into the numbers and realize their mistake. I've ended up becoming good friends with some in the second group. Basically, as an A&P, I offered to restore them to airworthy condition and keep working on them on my spare time (they pay for the parts), and in exchange for my work, I'm named insured and fly the planes whenever I want for oil + gas as long as they're not flying. And whenever they want to fly, they have a turnkey plane. As a result, I'm babysitting three 172's which is more than enough to keep me busy. I'm not an owner yet but it is my hope that I'd find one of these kinds of planes and make one my own.

-

Ugh, I've had to deal with this issue with the Continental IO-360-ES on the Mod Works converted 201 I fly. After the rollout, I'd turn off into a taxiway and then the engine sputters a bit then dies. Not a common occurrence, but more likely during hotter days. Same thing with a Baron 55 I flew for my multi training (IO-520-C). My quick workaround is to hit the LO boost pump after landing rollout. However, as others pointed out, the real issue is likely improper idle fuel metering. I'm not a powerplant expert but from what I'm aware of, the Continental fuel injection system requires some serious tinkering to get just right, and the average A&P doesn't have the proper equipment to do that as the tooling costs north of $2000 as far as I know. I'd recommend taking it into a knowledgeable shop with good Continental knowledge.

-

By "college teams" I assume NIFA? I used to compete from 2013 thru 2017. I recall there was one college that used PA-28's and SR20's for the message drop event (Purdue?). There also was a Mooney in the mix one year (don't know who), but I don't think their team used it for that event. Whether or not the object will hit the horizontal stab will depend a lot on the air resistance of the object and the airspeed of the aircraft. On the NIFA events the containers we threw were roughly 6x1.5x1.5" boxes weighing 2.5 ounces. On the 172's and 150's we flew it at 80kts at 100' AGL, and the bombardier threw it directly at the landing gear leg, and the wind would end up pushing it "backwards" (relative to the plane) so that the box passed underneath the stab. I don't think this technique would work on low-wing aircraft as the item would just hit the wing. Maybe throwing it towards the trailing edge might be better. One experience on the M20 I *do* have is spilling some coffee on the floor, soaking it up with a wad of tissue and throwing it out the window. When I landed an hour later, I found the tissue still stuck on the leading edge of the LH horizontal stab. I started bringing a small plastic bag on my flights to take care of my waste disposal requirements after that.

-

My friend is getting his second annual done at Freedom Aviation at Lynchburg VA. They may be a bit too south compared to where you're looking, however they're detailed in their work and do a good job at communicating.

-

Can KX-155 drive both a KI-206 and a GI-275?

Minivation replied to Flash's topic in Avionics/Panel Discussion

Green - lived there -or- flown to many, many parts of the state Blue - flown in a few times across multiple places Orange - flown in, looked around a bit (in AK's case, I flew a Citabria around the Matanuska Glacier area) Red - fuel stop -

Can KX-155 drive both a KI-206 and a GI-275?

Minivation replied to Flash's topic in Avionics/Panel Discussion

Turns out I posted slightly incorrect information. The autopilot works okay in lateral mode but cannot seem to hold altitude. So it's an issue independent of the GI275. (He did mention though that the GI275-STec connection worked a lot better when the GI275 was set to emulate the KI-525 rather than the NSD360 - The S-Tec can take either) -

Comanche 250 experience anyone?

Minivation replied to Mcstealth's topic in Miscellaneous Aviation Talk

I was involved in a very comprehensive annual on a 24-260B a few years ago and had the opportunity to get to know the plane inside out. Mechanically the airplane is solidly built, with the only real focus points being the stabilator and MLG structure. Others pointed those out already. One thing I will say with confidence is working in the engine compartment (and avionics) is A LOT easier than the Mooney! Early examples come with hand brakes which I'm not very fond of, but later ones come with the pedal brakes we're all familar with. Commanches are not as efficient as Mooneys but they make up for that with cabin space and better technical support IMO. Handling characteristics are a lot more forgiving, especially during landing, but you still want to nail your airspeeds. My hangar neighbor at KPVG used to own a PA-24 and he loved it. -

Can KX-155 drive both a KI-206 and a GI-275?

Minivation replied to Flash's topic in Avionics/Panel Discussion

Let us know how things go after your tests - I'd love to know how other setups work (or not). As for the autopilot - the GPSS functionality of the GI275 teaches some serious new tricks to those old A/P's. Glad to hear it works with your Century. The owner of the 201 I've been flying has since installed dual GI-275's as well but it doesn't seem to play nicely with the S-Tec System 60. He suspects it's an issue with the A/P though.