corn_flake

Supporter-

Posts

329 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by corn_flake

-

I designed a visor template for my M20E. Figure I would share them here if it is useful to you. You can buy 3mm acrylic glass in any color you want from Amazon. If you have access to a CNC laser cutter and a 3D printer, you can have your self a pair replacement visor in about 20 mintues. DM if you need help locating a place with a laser cutter. The visor clip is designed for visor rod that is 4.7mm. Visor Clip Flat Tight.stl visor.dxf

-

Brittain turn coordinator overhaul. Tc 100 evs

corn_flake replied to billy hellcat's topic in Vintage Mooneys (pre-J models)

Interesting..... Searching or Rate table come up with nothing. Are you referring to buying parts for DIY rate table? Care the share a picture if you made one? -

Brittain turn coordinator overhaul. Tc 100 evs

corn_flake replied to billy hellcat's topic in Vintage Mooneys (pre-J models)

Yeah, trust me. I tried to repair one my self. As soon as I realized I also had to build a rig to "turn" the coordinator 360 degree with exactly 2 minutes, I say, forget it!! I should let professional handle it. Keven did great work in bring it back alive!! -

For what it's worth, I made one 6 years ago using ABS. Smooth it out using acetone. It doesn't even look like 3D printed. It's still working fine today.

-

What's the verdict of the DLC on lifter? One of the shops I talked to say it's best thing ever come of genera aviation (exaggeration). They further added, if Lycoming had done DLC from the beginning, we wouldn't be see all the cam spalling.

-

I know some guys would justify the cost by assuming they could make the money back when selling the airplane, which is rarely the case. We are all nuts indeed. There you go, first step to recovery....

-

I was shopping for a place to overhaul my IO360 with angle valve. So I figure I share my notes here. Lycoming factory overhual - $58k + core Lycoming factory rebuild exchange - $64k + core Lycoming factory new - $105k (not sure if core is required) Lycoming factory rebuild exchange IO-390 - $88k Well known shops such as Firewall Foreward, CCS, etc - $53k Less known local shops - $32k to $40k. Lead time on non-factory overhual run any where from 3 to 5 months. Lycoming apparently is not interested in overhual business... Wait for it.. drum roll, 27 to 30 months months lead time!!! They also ask for 20% deposit while they holding on to that money for almost 3 years. Safe flying guys!

-

Ice on the bottom of the wings. Go or no go?

corn_flake replied to rwabdu's topic in General Mooney Talk

You should remove the ice before flying again. Now, the go or no-go decision should be based on the weather. -

Garmin 430w configuration page???

corn_flake replied to xcrmckenna's topic in Avionics/Panel Discussion

Changing the battery is a 2 minutes job. It takes longer to remove the cover. A competent repair person should be able to complete the task under 30 minutes, including polishing the screen. -

Barn find Mooney is it worth my time?

corn_flake replied to Tim VanDenHoek's topic in General Mooney Talk

engine overhaul alone is $45k. Sitting for 20 years is certain overhual is required. If there is corrosion on the airframe, cost goes sky high. That's not include overhual cost to stem gauge (assuming it has stem gauge) wil run you a few thousand.... The list goes on-and-on. As other have said, you could have buying a flying Mooney for less. -

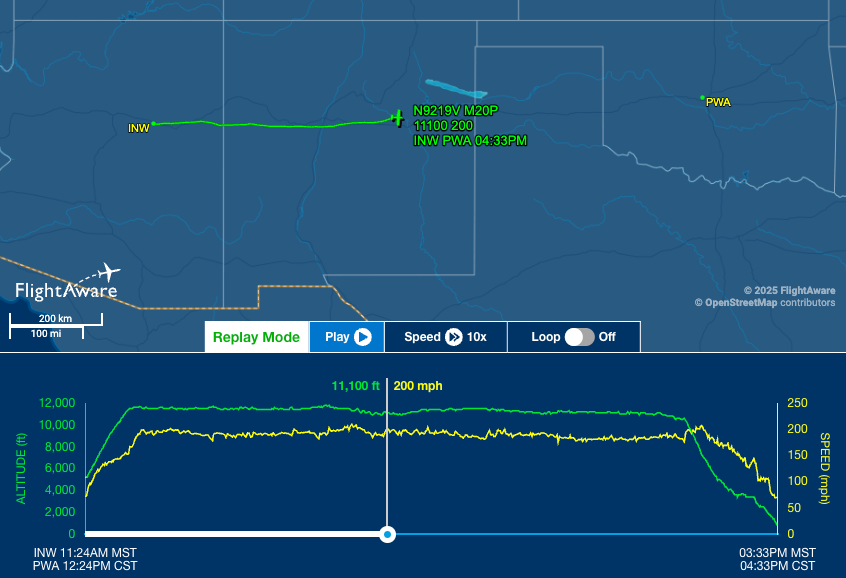

After owning my Mooney for about five years, my flights have more or less limited to California. This is the first time I took my Mooney across the country, or at least half way. 1100 nautical miles from California Central Valley to Oklahoma City with only one stops. 65.5 gallon total. Converted to statute miles, that's 19.3 mpg. Incredible flying machine. Of course 20+ tail wind helped a lot. At times, I was cruising at 180+ knots ground speed!!

-

Mooney PC and the Brittain AP

corn_flake replied to Mobius708's topic in Vintage Mooneys (pre-J models)

Impressive work @MikeOH on your website. Lots of good info. -

Torn Brittain servo boot

corn_flake replied to M20E for me's topic in Vintage Mooneys (pre-J models)

I will take three. PMed you -

Is it Starter Replacement Time?

corn_flake replied to Igor_U's topic in Vintage Mooneys (pre-J models)

Good Idea. I will need to check that next time when I'm at the hangar and report back. Thanks! -

Is it Starter Replacement Time?

corn_flake replied to Igor_U's topic in Vintage Mooneys (pre-J models)

@Igor_USorry to hijack your thread. But, I have been battling my starter for months as well. @N201MKTurbo My starter works fine except when the prop is pointed at about between 1 to 2 o'clock position when viewing from pilot seat. No click, no clunk, Nothing! If I get out the airplane and move the prop to any other position, say 3 o'clock, it will spin just fine. I'm puzzled as I'm didin't think starter's operation is some how linked to the position of the prop. Any ideas? -

WTB: Urgent - need M20J Mccauley spinner backplate

corn_flake replied to N177MC's topic in Avionics / Parts Classifieds

Where are you located? I think I may have one in my spare. -

That's good one. I need to add this to my regular practice. Flying the yolk on the right while sitting in pilot seat.