-

Posts

182 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by BaldEagle

-

Evening all, I’ve decided it’s way past time to maintain an electronic logbook and want to copy everything from my paper logbooks into something. I still plan on maintaining my paper logbook, at least initially. This is mainly to mitigate the impact of losing my original logbooks, but it will help categorizing totals for insurance purposes, etc. What are you all using? I use ForeFlight in the cockpit, but don’t want to be tied to it.

-

I have a similar setup (EFD1000 Max and PMA450B). I don’t think there is anything on the audio panel to check: the audio output from the Aspen is a wire from the back of the Aspen to the back of the audio tray and is always on. You can check the volume setting for audio alerts on the Aspen by going into the Installer menu described on the bottom of page 135: https://www.aircraftspruce.com/catalog/pdf/11-16466.pdf I don’t think Aspen want their end customers poking around in here, but you can check and set your audio alerts output volume here, which is probably the first thing your avionics shop will do in any case.

-

Well that was embarrassing. Before you get your checkbook out and wheel your flying machine over to the avionics shop, check that the small DIP switch in your Lightspeed headset battery compartment is set to Stereo and not Mono (the factory default) to enjoy features like IntelliAudio. Like the manual says so, in bold, that I was too lazy to consult. The PMA450B is awesome, very highly recommended upgrade.

- 104 replies

-

- 4

-

-

-

Just installed my shiny new PMA450B and was particularly excited to experience the Intelliaudio feature only to discover that it appears my airplane is wired for glorious mono sound. Has anyone rewired their airplane for stereo? How involved is it?

- 104 replies

-

Troubleshooting Aspen Evolution Pro Max audio issues

BaldEagle replied to BaldEagle's topic in Avionics/Panel Discussion

Resurrecting this thread as I resolved the issue with the Aspen PFD background noise by replacing the GMA 340 audio panel for a PS Engineering PMA450B. Technically it’s not resolved I suppose, but I think the PS Engineering unit constantly samples the incoming audio and is filtering the noise out. -

I have the vents on my J and just covered them up when I refurbished mine.

-

Just ordered and coupon works as described.

- 104 replies

-

- 1

-

-

Thoughts on replacing inop 2nd VOR head

BaldEagle replied to BaldEagle's topic in Avionics/Panel Discussion

Thanks all for the feedback. For now I’ve decided to just replace the failed CDI as I found a serviceable replacement for only $245 which buys me a little more time while I decide on the upgrade path. -

I just did mine. I didn’t have much luck with a heat gun so filled with a polyurethane filler, sanded, covered with a 1mm layer of closed cell foam and then wrapped with ultrasuede with a French seam stitch on the front. It was a full weekend’s work, not including the 6 hours learning how to operate a vintage Singer sewing machine. Edit: mine was also in 4 separate pieces held together with tape, but easily repaired with fiberglass and epoxy resin.

-

My No. 2 VOR head has failed. Is there any point in repairing / replacing these things given that VORs are on their way out? My primary Nav/Comm is an IFD440 and Aspen PFD Max. My second Nav/Comm is an ancient Colins VFH-251. I still get VOR2 input to the Aspen (and I can still ident it, which confirms it's the head that failed), but it functions as an RMI. What would you do? One thought is to replace VOR2 head unit with a GI275 for CDI + AI backup, and retire the vacuum driven AI and pump at the same time. Or just mark VOR2 INOP and wait for it to go the way of ADF / Loran, etc.

-

Experience with Coast Aircraft Maintenance at KMYF

BaldEagle replied to mikefox's topic in General Mooney Talk

I believe it was about 28 hours labor. To their credit they said they hadn’t done one on a Mooney for a while and quoted high 20-something hours, so no nasty surprises when I picked it up. LASAR, who does this all the time and have really got the work dialed in, quoted me only 16 hours, which is great if it wasn’t for the logistical challenges of trucking up there balancing work obligations. Edit: I ordered the windshield directly from GLAP and had them ship directly to the shop so was only quoted labor. -

Experience with Coast Aircraft Maintenance at KMYF

BaldEagle replied to mikefox's topic in General Mooney Talk

Nope, but I used Advanced Aircraft at MYF to replace my windshield about a year ago. Busy shop with a good reputation; they do a lot of work on Mooneys. I’m going to have them replace my gear pucks next. My plan is to alternate between owner-assist annuals in my hangar and every other year have a competent shop do it (to mitigate risk of missing something important), which will likely be Advanced Aircraft. -

You all got lucky. I just found out that a former employee of mine died from COVID-19.

-

Mine has been maintained by 3 or 4 well known MSCs over the years (albeit not recently), so you never really know when you’ve got 40+ years maintenance history and several owners, so your observation is well taken

-

For a meticulously maintained Mooney, I'm finding all sorts of crazy stuff. I pulled the sonalert to find a RadioShack part number. Well that's not in the parts manual. Replaced with correct part (Mallory, which I was able to get from Amazon for $19) and the problem is solved.

-

So this is annoying. The AP / pitch trim warning sonalert no longer stops making a noise when the pitch trim switch is turned on (after the "beep beep beep" or auto pilot disengaged. Instead it produces noise constantly but at, I would guess, about 30% volume. Any ideas on how to diagnose this issue? It's not loud enough to hear in the cruise, but is loud enough to hear over an ANR headset with the engine idling. I can only stop the noise by either pulling the 50amp Aux CB or holding down the autopilot disconnect button on the yoke, so it seems something is still sending some current to the sonalert when it shouldn't, or the sonalert needs replacing (?)

-

It looks like what I have are “lightning proof” fuel cap o-rings, which makes sense as my J was previously based in Florida. It is approved for installation on my J by serial number but only if I have the O&N bladders (I don’t) or have Shaw 457 fuel cap (I have 431). So to be legal I think the only option is to use the part specified by Mooney and adjust the fuel cap nut as mentioned previously to make it fit so that I can close and latch it. And to be ultra cautious, pressurize the tank to 1/2 PSI per the SB to check for leaks. https://www.mcfarlaneaviation.com/products/product/CA38241/

-

The O-Ring listed in the Mooney parts manual does not fit my Shaw 431-9 fuel caps. Well, it does, but I am unable to twist the cap to close it. It seems that the fuel cap sits too high. The previous owner was using these: it has a lip on it. Anyone have a part number?

-

Decided to commit to getting my CFI/CFII reinstated per 61.199. Any of you worked with someone in this position? I've only got 800+ hours instruction given, mostly private and instrument instruction, and it's been more than a decade since my ratings lapsed. I did a FIRC, and realized that it's been so long I really need to start over from the beginning. Looking for some advice from people that have been through this before. Obviously I need to start with ground school. What's cool these days? I grew up with King Schools back in the day. CFI ground school course followed by CFII ground school course? Sufficient? My preference is to do the CFII check ride. I don't want to think about the flying component until I've brought my knowledge back up to spec, but obviously I'd be looking to do this in my own Mooney. (As there's no avoiding a check ride per 61.199, I did initially consider an MEI (new rating) as that would re-instate everything, but decided it made no sense as I don't have any interest in a 121 / 135 gig, or instructing in twins for that matter, so focusing on CFI/I only. Just putting that out there in case this comes up as a suggestion).

-

Not much flying here even prior to the pandemic as I was grounded for upgrades (new windshield and a couple of avionics upgrades), got the airplane back just in time for the pandemic, and then limited options for trips, which is why I bought the thing in the first place. So I’ve grounded myself again while I do more upgrades this winter. Total hours last 12 months = 46. I know, that’s criminal. And my instrument currency has just expired.

-

Well that was fun. I got the door window done in less than 3 hours. It was original. The pilot window... 8 hours. Additional tools required included a jig saw, hammer chisel, drill, sheet metal seamers, rotary tool, and a bag of abrasive pads for it. The pilot window had been replaced at some point in the distant past and whatever shop that did it either had not heard of a Mooney service manual, or decided that they knew better when it came to choosing the sealant. It was impossible to remove without deforming the aluminum skin. Lots of evidence that the original sealant wasn’t cleaned up properly and I only had 2 rivets to drill out. It was as if they drilled out the holes, with the wrong sized bit, but only had 1 size of blind rivet in their inventory, and was trying to get it wrapped up on a Friday afternoon. 2 rear windows to do next, and yeah, it’s the same sealant. I can’t wait.

-

Mine is also a 1978 J. I'll be doing SB 208 when the all the interior panels come off for refurbishment / replacement as it has spent some of it's life in Florida and PNW, but I'll certainly be looking for evidence of water ingress when I do the windows as well.

-

I pulled the interior door panel off to take a look. What's interesting is that the sealant that was applied at the factory (I'm assuming the windows are original as I don't see anything in the logbooks to suggest otherwise) is just pasted up against the side of the glass, which doesn't look ideal to me but I suppose it saves a lot of labor avoiding the cleanup.

-

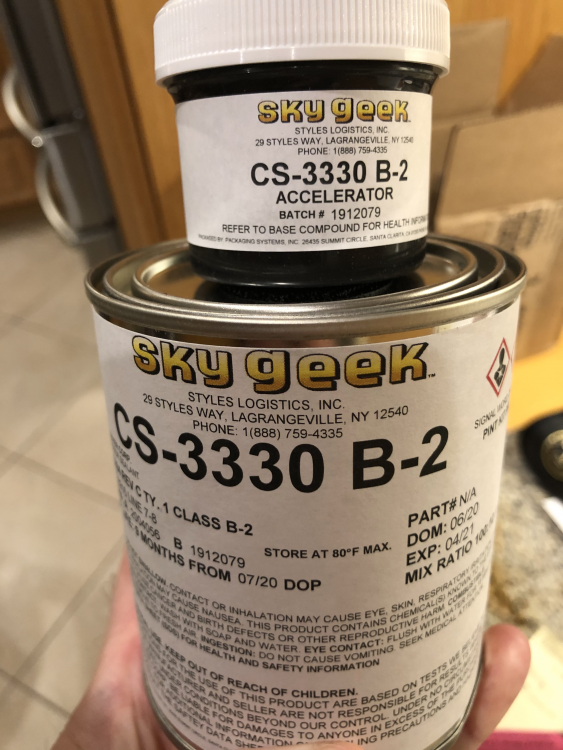

Apologies, I just moved the image so that it displays in-line.

-

For those that have replaced their side windows, what do y'all recommend for measuring, mixing and applying this stuff? I'm looking to do one window per weekend but might not have every weekend spare so not wanting to use the whole can all at once.