-

Posts

3,261 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 0TreeLemur

-

Ok. I'll contact him. Thx.

-

Gimme a break. I haven't got to that yet! I used 2K paint, which is supposed to cure for 20-30 days before cutting/polishiing. I can't paint the shadow until after that step.

-

yes, but they don't have letters 0.4" tall.

-

I've got a Brother labelmaker that's nicer than that - But I want an engraved label that is 2" wide, 3/4" high with letters 0.4" tall. Thickness 0.025" - 0.05". White letters on matte black finish.

-

I found them online. I ordered something from them before. Good company. But, I just need a little 2" x 3/4" engraved label with a sticky back. Probably cost $3.00 from the right place. A place with "Aircraft" in their name will probably be 10 times that...

-

-

Changing tail number on airplane. Need new engraved plastic label for panel. Anyone know a place that makes such things? Thx.

-

Last fall I reserved N201Y. The FAA approved the change so I spent today painting white where I'd sanded off portions of a "2". My J had N202Y, which is ok, but kind of like a vanity plate that just doesn't quite make sense. Tomorrow I paint the blue portions of the "1".

-

-

For incompressible flow (M<0.3), streamline curvature explains >95% of the pressure distribution on an airfoil, with viscosity (vorticity) playing a minor role. Downwash has very little to do with lift produced by a wing. Lift results from either angle of attack and/or asymmetry in the airfoil itself. An asymmetric airfoil like the one on our favorite airplane in normal cruise has 0-degree angle of attack! How much downwash do you think that is that causing? As Skip pointed out in the wind tunnel photo above, which is a symmetrical airfoil at a high angle of attack, the net vertical velocity component around it very nearly zero. In the case of a symmetric airfoil at 0-degree angle of attack, the lift is zero because the streamline curvature is the same on both upper and lower surfaces. But as the wind tunnel photo shows, angle of attack greatly modifies the flow field and results in a lot more streamline curvature above the airfoil than below it. That's all there is to it. No magic. Once you get into the compressible flow regime, then the magic starts to appear along with a few demons.

-

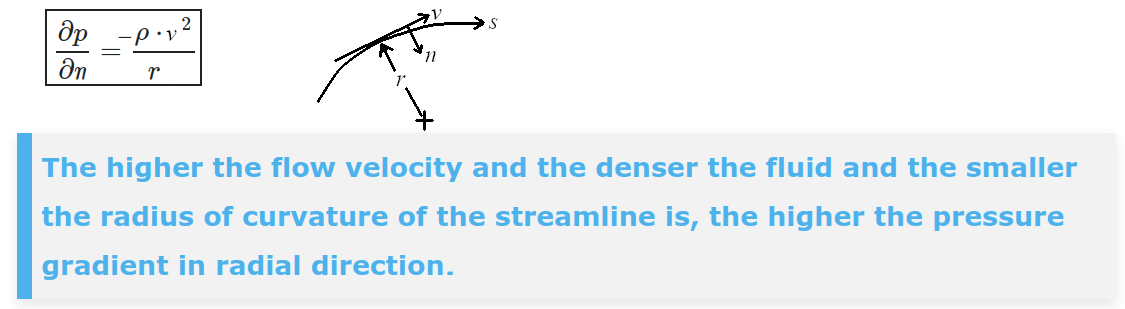

One of my favorite views of lift generation in action. Streaklines in a wind tunnel at an angle of attack near stall. Newton's second law F=ma written perpendicular to the streamlines does a better job of describing the physics that produces lift better than any other equation. It clearly shows that streamline curvature produces a pressure gradient in the direction opposite of the radius of curvature. The minus sign indicates that the pressure decreases in the direction pointing towards the center of curvature, the n direction on the figure. The wind tunnel observation also shows why our stall detectors are placed where they are.

-

By coincidence I tried this exact test just Sunday. I had a turn of 290 degrees programmed in the IFD540 just to see what it would do. I expected it to anticipate the turn. With the Aspen in GPSS mode, KFC150 A/P in HDG mode. To my surprise the IFD took me over the waypoint and turned left 290 degrees. It seems that there is still some limit in the IFD software, where beyond a certain angle it requires a flyover. Good to know. I tried again and anticipated the turn using the heading bug in non-GPSS mode, and that works. Threads from the past like this one are very useful.

-

For some reason in my J CHT #2 is always about 20F cooler than the other three. Its the coolest cylinder. Always. One challenge I sometimes have in winter LOP ops is keeping CHT #2 above 300F. This happens up higher where it is colder and max power WOT is less than 65%. When that happens I'll run a little ROP just to keep that CHT up.

-

This evening I created a post and included a photo. It did not display. When I clicked "edit" the rectangular area where the photo should have displayed was just a rectangle filled with a single color. I tried .png and .jpg formats. Same outcome.

-

Comparing mine with the photo that Skip posted above, I don't see an obvious difference in terms of the location. The vane on Skips (top) seems to be bent down a bit more than the vane on mine (bottom). But the position on the wing seems quite similar. I'm really starting to suspect that the problem with my stall warning is in the mechanism rather than its set point. Like I wrote previously it does sound when I lift the vane during a ground check. I does not sound when doing a stall aloft or in the landing flare. The S&MM does have an entry. It is posted above. I'm not at that stage yet- trying to determine if it is a setting error or an internal switch mechanism problem. Plus the Phillips heads on the two adjustment screws on my bird are just about stripped. <image not displaying for some reason>

-

Having difficulty adjusting my lift detector. Despite the fact that it passes ground-test, it does not signal stall condition in the air. Thinking it might be an internal issue. I'm guessing that Mooney put that hole in the wing where it is for a reason. This poll will help me confirm that most are installed in the middle and that adjustment should not be necessary. Thx.

-

Next time you do it, take photos plz. Thx.

-

Reflecting on how good we have it

0TreeLemur replied to Bolter's topic in Miscellaneous Aviation Talk

If you want to go even farther, read about H.A. Collison. Here's a brief intro https://www.postalmuseum.si.edu/collison-ha He pioneered early skud running airmail in open cockpit biplanes in Wyoming blizzards. He was legend. Wrecked airplanes. Landed in 2-ft deep snow. Cheated death so many times. Check this out - the article on the right side of the page discusses him quite a bit. https://oregonnews.uoregon.edu/lccn/sn85042470/1923-08-22/ed-1/seq-1.pdf Sadly, he was the captain of United flight 4 that suffered a night CFIT about 11 miles NW of Cheyenne in Oct. 1935. https://en.wikipedia.org/wiki/United_Air_Lines_Flight_4 The accident was a real tragedy. Great video about that bit of history on youtube. -

Reflecting on how good we have it

0TreeLemur replied to Bolter's topic in Miscellaneous Aviation Talk

I did 11 years in Laramie, about 30 miles from there. Like many people who move to the pretty mountains at 7200 ft (ISA temperature =0C), where the wind from mid-September through mid-May is 240@18G41, it started out "voluntary". Towards the end of the 11 years it began to feel "involuntary". Needless to say, I didn't fly while I lived there. The colds air temperature while I was there was (no-kidding) -40. In the summer on a hot 90F day, the DA is 10,000 ft. Alabama is a much better place for the aviation minded, except it's been to damn cold of late for me. -

Stale thread, but I'll pitch in anyway: In my J there was a broken weld in the seat height adjustment mechanism that caused the pins to lift as the seat raised... Got that fixed at last annual. The point is you can't assume that the rails need replaced, several things can cause the pins to not function properly.

-

I experienced the same problem a few years ago. Some FSDO offices require an inspection by a designated inspector. The FSDO here in Alabama required me to pay for an inspector to travel to my hangar, walk around the aircraft, peruse the logs, and sign off on the ferry permit. The charge was ridiculous - about the same as what a DPE would charge for a check ride. Hopefully your FSDO doesn't have such a rule. Best to check with them first. It varies from one FSDO to the next.