-

Posts

1,408 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Rick Junkin

-

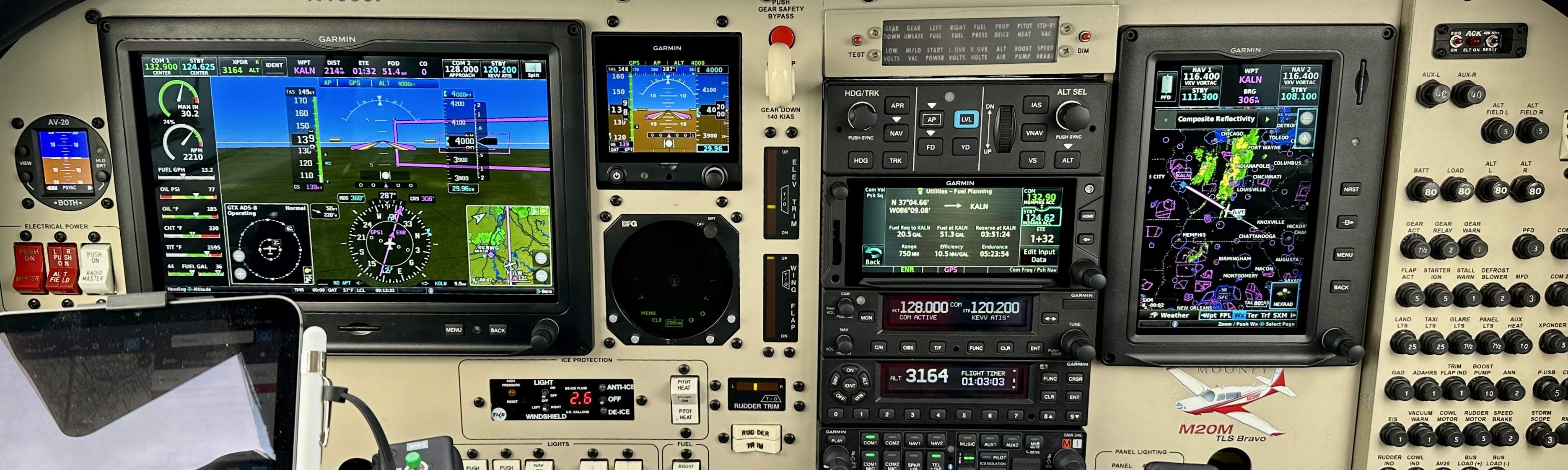

Cylinder Wear/Oil Leak during Bravo Prebuy

Rick Junkin replied to Starlifter27's topic in Mooney Bravo Owners

The repair history and current condition do not sound/look normal to me, but I'm not familiar with the specifics of what was happening with the aircraft produced in 2005 (mine is an '89). I'm curious what caused the cylinder issues early on, and how the current owner was running the engine. If he was running it in "full fire breathing dragon mode" as @carusoam would say, meaning consistently at 34/2400 for max performance in cruise, that could possibly explain the cylinder and valve life issues. #1 and #3 are definitely in trouble. It may not be too late to save them by lapping in place, but I wouldn't bet on it. 800 hours over 17 years is enough to make me go "hmmm...." but if as you say the airplane was flown regularly over that period, 4 or 5 hours a month, I'd be less concerned. Still, with all of that cylinder work I would want to know more about operation technique and specific issues that may have plagued that vintage of the TIO-540-AF1B. That said my cylinders were overhauled and flow balanced by the previous owner about 370 hours ago and all still have nice symmetrical exhaust valves and the engine only burns about a quart every 25 hours. My oil consumption is NOT normal, most Bravos appear to be more in the 10 hour/quart neighborhood. But I also run an extremely conservative 30/2200 in cruise, LOP at 13.8gph. Let's see what other Bravo folks have to say about their experience with exhaust valves and cylinders in general. I'm thinking you'll want to ask the current owner some questions about how he ran the engine. I'm assuming this is a one-owner airplane. Cheers, Rick -

Couldn't have said it better myself, Skip! Oh wait... Not better, but different: Cool, two votes for proper nose tire pressure to get best performance from the Sidewinder. Cheers, Rick

-

Is your nose tire inflated to full pressure? My Sidewinder becomes less capable when my nose tire is down a few PSI. Just something to check if you haven't already. Cheers, Rick

-

Thanks for the suggestion. My wife uses Flonase (fluticasone) so Im going to try that for a few weeks. If I don't have good results from that I'll try Nasacort (triamcinolone, same as Kenalog) next. I have regular appointments with my ophthalmologist and will be able to keep an eye on any intraocular pressure changes (very bad pun intended). Both fluticasone and triamcinolone are on the FAA "go" list. Cheers, Rick

-

I just read this article and discovered I had not properly researched my over the counter allergy medication of choice - it is no longer my choice! This is required reading for anyone not already in the know regarding the FAA OTC approval list. Beware the sedating antihistamine. https://medium.com/faa/allergies-and-allergy-medication-7715c91c3736 Cheers, Rick

-

With a little patience to slowly stretch and work them on, these windscreens fit nicely on a Bose A20 headset mic at a fraction of the OEM and aftermarket replacement costs. I imagine they will fit other brands as well. https://smile.amazon.com/gp/product/B005LR0ETO/ref=ppx_yo_dt_b_asin_title_o03_s00?ie=UTF8&psc=1 Cheers, Rick

-

- 3

-

-

-

Need help troubleshooting CDI glideslope

Rick Junkin replied to Seth1001's topic in Avionics/Panel Discussion

I had something similar and it was a wiring problem. I believe it was at the connector, bad crimp or recessed pin that lost contact. A check of the connectors for pin and crimp integrity is a starting point, followed by ringing the course indicator wire for continuity. Cheers, Rick -

At the risk of further hijacking this thread, My experience is similar to Art's. My CHT's are ~300+/- on approach at 22'/2200 and drop about 20-30 degrees by landing after I open the cowl flaps and adjust power for descent from the FAF. Lycoming recommends cooling at a rate of less than 50 degrees F per minute to avoid shock cooling so my engine stays well within those parameters. https://www.lycoming.com/content/how-avoid-sudden-cooling-your-engine I also keep the mixture leaned until my final GUMPS(F) check at 500' which helps keep the temps from dropping too much. Just for fun, here's an article that is sure to induce some visceral reactions in both directions: https://www.avweb.com/ownership/shock-cooling-time-to-kill-the-myth/ Be sure to read the comments section. Cheers, Rick

-

Part of the issue at hand with pitch is the memory aid of, "power up, pitch up, clean up, cowl flaps open". It's great as a memory aid as long as we have thought through what it is supposed to be prompting us to do. The smoother we can be with each action the easier it is for us to manage. Here's the technique I established for an instrument missed approach in my Bravo. I use the same technique for a balked/bounced landing. Power up - Smoothly increase power to climb/takeoff power as required. Confirm prop and mixture are full forward. Pitch up - SET PITCH to climb pitch, ~8 degrees, and trim to keep it there. For my Bravo that requires immediate simultaneous forward pressure on the yoke and electric trim switches and a fairly large boot of right rudder. The purpose of this step is to get me moving away from the ground under control before I go to the next step. Clean up - I don't do this in the order called out in the flight manual. I retract the gear first, partly because it's the bigger drag reducer and also because it doesn't cause much of a pitch force or lift change while I'm still closer to the ground. But the bigger reason is I have no selectable intermediate position when retracting my flaps. I don't want to be distracted looking at the flap indicator and trying to manually stop the retraction at ~10 degrees while dealing with the associated pitch force change as the flaps retract. So I get the gear confirmed up and then I start the flaps up as I accelerate and let them retract fully while I focus on adjusting the trim to hold 8 degrees of pitch. Aside: The flap switch on my Bravo (actually an original TLS, #19) has three positions: UP, which fully retracts the flaps; OFF (center position) which allows me to stop the flaps at any position; and DOWN, which is a momentary contact position I must hold down until the flaps have deployed to where I want them and then release it to the OFF position. It takes about 1 second to deploy to the takeoff position, nominally 10 degrees, and another 6 seconds to fully deploy to 33 degrees. Retraction times are slightly less. I just looked at the flight manual and it says the flap position switch is supposed to function differently with an UP, TAKEOFF and DOWN position. Great, more research for me to do. Cowl flaps open - This is a CONFIRM step for me, as I open the cowl flaps when I put the gear down at the FAF or when entering the VFR pattern. Cheers, Rick

-

For reference the CFI rates I've been seeing advertised are $100-$150/hour. I may be looking in the wrong places. Cheers, Rick

-

The airplane had Champion massives and stock Lycoming injector nozzles when I bought it in 2016. I had a GAMI spread of about 0.7gph and was able to run about 20 degrees lean of peak but it wasn’t terribly smooth. It would run uncomfortably rougher as I continued to lean past 20 degrees LOP. I installed the fine wires about 6 months later. I immediately found the engine started easier and ran smoother but it wasn’t until I installed and tuned the GAMIs (4 iterations of injector swaps) that I was happy with how the engine was running with a 0.3gph spread. I am able to lean the engine to about 100 degrees LOP with it still running smoothly and then it starts to stumble from too lean a mixture. 50 degrees LOP is the point of diminishing return and only required for “higher” power settings. With my settings of 2200/30, 20 degrees LOP is plenty but I found I can run 40 degrees LOP with minimal speed loss and save a little more gas and keep the cylinders about 10 degrees cooler. Cooler is better. Within reason of course. Cheers, Rick

-

Are you set on the Clear View products? I've always used Plexus with outstanding results. https://smile.amazon.com/Plexus-Plastic-Cleaner-Protectant-13-Ounce/dp/B00092CKN4/ref=sr_1_2?crid=2I7HBPR7N5LNV&keywords=plexus+plastic+cleaner&qid=1648938106&sprefix=plexus%2Caps%2C158&sr=8-2 Cheers, Rick

-

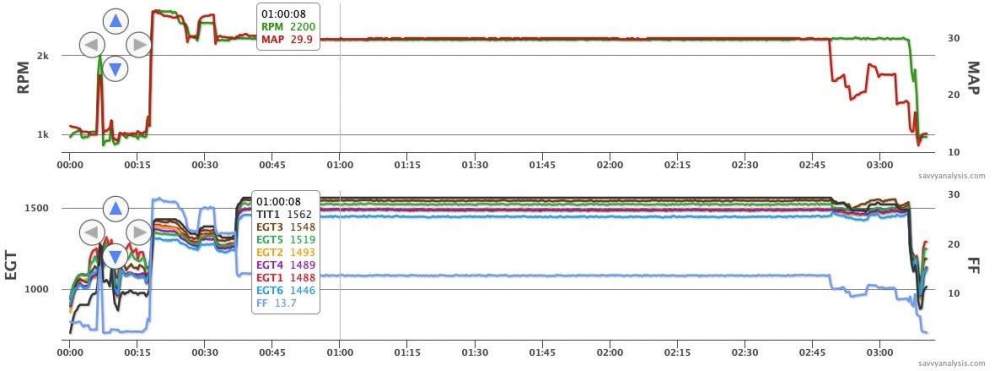

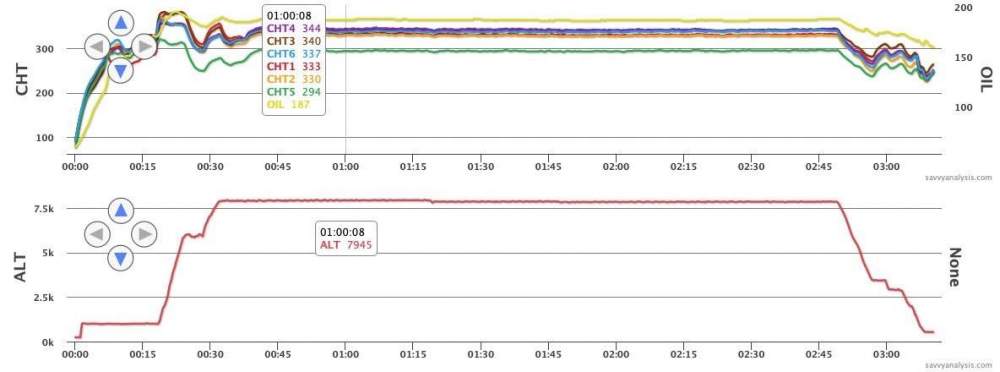

Here's some JPI 830 data from my flight from Gatlinburg to Alton IL yesterday that shows some real numbers for a Bravo running 2200/30, 13.7gph and 40 degrees LOP at 8,000 feet. This power setting consistently yields an indicated airspeed of 143kts which gives me 180KTAS+/- in the mid to upper teens but the westerly winds at altitude yesterday were horrendous so I settled for 160KTAS at 8K. My #5 CHT is from a ring probe and reads 50 degrees lower than the OEM gauge, so add 50 to the #5 CHT value. For reference I have GAMIs with a spread of 0.3gph at peak, Tempest fine wires (URHB32S) and a dynamically balanced prop/engine. This power setting is very smooth, much quieter and I believe less fatiguing. I'm meticulous with my maintenance and so far it is really paying off for me. Cheers, Rick

-

I discovered this "power assist" technique for my Sidewinder today. 11 pounds of chocks hanging from the drill handle made a difference. I was holding the chocks while moving the airplane back into the hangar and needed another hand to push her back in over the hangar lip. So I draped the chocks over the Sidewinder handle and proceeded. After which I thought, "Hey... not a bad idea." Cheers, Rick

-

In Great Britain they call unlicensed drivers "learners", and make them put this sticker on their cars when a "learner" is at the wheel. There was a USAF Strike Eagle instructor at RAF Lakenheath that would put one of these on the canopy when he was flying with a newly-arrived pilot going through the squadron's Mission Ready upgrade training. Pretty funny. There was quite a bit of press when the FAA implemented the "learner" terminology. As I recall the main emphasis cited was inclusion. For instance the thought was referring to someone training for his instrument/commercial/ATP as a "student" is inappropriate. I don't agree, but that was the FAA position. Cheers, Rick

-

I've done a lot of high risk flying. When I say high risk I mean things like flutter testing at mach 2. Or with unfriendly people shooting at me. I'd like to offer perhaps a different perspective on the question of confidence. Please bear with me. Some of this has already been said, but I'll repeat it for context. We've all lived through a period where we we were too ignorant of the risks we were facing to be afraid, and we managed to survive. Then as we gained experience and learned from our poor decisions we became less ignorant of risk, but were still willing to accept a fairly high level and relied on our overconfidence in our perceived skill as mitigation. Throw in youthful enthusiasm and a lack of recognition of not knowing what we didn't know, and we gave ourselves opportunity to have more experiences we learned from that allowed us to develop judgement. Poor judgement at first maybe, but improving as we learned from our own experiences and improving even more when we discovered how to learn from other people's experiences. And the more we learned, the more we started to understand how much we didn't know, and things started to change in the way we thought. And in how we assessed our capabilities and the risks we were presented with. We became more mindful about consequences and risk mitigations. We developed good judgement. Now, whether we decided to employ that good judgement, or not, is unique to each individual. But I believe good judgement is the keystone to confidence. Assessing our own capabilities and the risks we are facing, using our best judgement, leads us to good decisions to which we are confident we can execute. As our knowledge increases and our self-awareness improves our judgement will tell us what we can and can not do. Over time our judgement may tell us we are not willing to accept the same risks we accepted earlier in life. Or even yesterday. I don't see this as a loss of confidence, I see it as growth in good judgement. The FAA calls good judgement good Aeronautical Decision Making. There are lots of good tools to help us make sure we don't overlook anything. Now, you could say, "I've lost confidence in my ability to...", and I think this is where Mike is coming from, but those kind of statements beg the question - why? What's the root cause of the loss of confidence? A simple root cause analysis technique is the 5 Why Analysis. I'm sure many are familiar. In this case the first question is, "Why have you lost confidence?" Once we have an answer, we ask again, to that answer, why? Repeat 5 times and we have a high potential of determining how to regain our confidence. Or, we may determine that the cause can't be remedied. Either way, we have a path forward. Thanks for staying with me this far. Tying it all together, and bringing it back specifically to flying, add proficiency to the equation. Proficiency and good judgement provide a basis for confidence in our ability to complete today's flight, or confidence in our decision to cancel. Proficiency is just that, being proficient in everything we'll need to do, or may need to do, on our next flight. Don't confuse that with currency. My good friend Jack Waters will be talking about this very subject at the Mooney Summit in September. So my personal answer to the original question? Nope. I haven't lost confidence. I'm more confident every day in my ability to exercise good judgement and assess what I need to do to be ready for my next flight, including a short field landing or an approach down to minimums or both if required. And I'm confident I won't go if I'm not ready. Cheers, Rick

-

@xcrmckenna Here are the pics of the lip on my hangar. Sorry, the first one refused to rotate to the proper orientation. The other two show the height of the lip and the length of the taper. When my Bravo has full tanks I need to angle it into the hangar slightly so that only one main is hitting the lip at a time. The sidewinder doesn't have quite enough oomph to go straight in and get both mains up and over the lip together. Cheers, Rick

-

Congrats! All the instrument rating requires is time, study, practice, and most importantly continuity. The more often you're able to fly with your instructor the easier it will be for you. Good luck, keep us posted on your progress! Cheers, Rick

-

Thanks for the quick response!

-

@CAV Ice How about for a M20M no-hazard installation? I think I have the same issue. Cheers, Rick

-

Hey @PJClark, My X3 is working great for me. I used less than 100PSI on a round trip to Panama City Beach, about 4 hours of flight time at 15-16K using a cannula and the X3 on the "conserve" setting. I don't have an inline regulator installed. Based on the testing I did my O2 system output pressure stays under the maximum limit for the X3 so the inline regulator wouldn't be required. You might try removing the inline regulator and see how it works for you. But first it might be prudent to take the same kind of measurements I did to ensure your O2 system isn't really putting out more pressure than the X3 can handle. If your airplane has a factory altitude compensating regulator on the tank then you are probably ok. But there are a number of regulator configs so you want to be sure. I measured a delivery pressure of 8.5PSI on the ground at 1,000' PA so if you can duplicate that you may not need to repeat the airborne tests I did. I had kind of a Rube Goldberg set-up to test the delivered O2 pressure. I didn't have a pneumatic pressure gauge handy but I had one of these: I connected a length of O2 tubing to right seat Oxygen port and connected the other end of the tubing to the pump using an inflator nozzle attachment that fit snugly into the tubing. I turned the pump display power on at the check altitudes to take the pressure readings. Worked great, as would any other pump that displays the "tire" pressure without the compressor running. Of course if you have a pneumatic pressure gauge connected to the length of tubing, that would be optimum and provide a continuous reading for your observations. Give me a call if you want to chat, I think you have my number. Cheers, Rick

-

Vacuum Cleaner For Aircraft Cleaning?

Rick Junkin replied to GeneralT001's topic in General Mooney Talk

Here's what I use for both the cars and the airplane. I set it on a seat and go to town with it. LOTS of suction and capacity, and very easy to clean. https://smile.amazon.com/Milwaukee-0880-20-18-Volt-Cordless-Vacuum/dp/B001AHMQ90/ref=sr_1_5?crid=I54HH5C6QCE9&keywords=milwaukee+vacuum&qid=1646928966&sprefix=milwaukee+vacu%2Caps%2C112&sr=8-5 You may be able to find it cheaper at your local Home Depot. Cheers, Rick