JoeM

Verified Member-

Posts

137 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by JoeM

-

I have boxes full of extra parts for these systems. If you still need a boot, I can test them and see which ones dont leak. PM me

-

3 of the 4 Mooneys I have owned, all based in Socal but flown over mtns in the western US, were either turbo normalized or turbocharged. I now am a partner in a NA IO360 J model, and I miss the performance. I just flew from CA to FL in a turbo normalized E model. We topped weather at 16K and were still climbing. I believe a turbo has saved my life at least twice. Turbo normalizing doesn't cost more if you don't run the engine too hard. The Rayjay has a variable wastegate so you don't use the turbo unless you want to, but usually no intercooler. The M20Turbo has a fixed wastegate so it is always running, but it has an intercooler which brings temps down about 20 degrees. Either is a big improvement over NA if you fly over mountains IFR. If I were in the OP's shoes, I would buy the turbo normalized Mooney.

-

Ly-Con options on IO-360-A1A Overhaul

JoeM replied to Vance Harral's topic in Vintage Mooneys (pre-J models)

We just overhauled the io360 A1A on our E model. Neither Overhauled nor Lycoming cylinders were available. The choice was OH Chrome or new from Continental. I know that sounds weird, but Continental bought a company that makes cylinders, and they now make them for Lycs. Expensive but available. I didn't want Chrome. We also bought a new cam and DCL coated lifters. J&J Airparts was great. Our original cylinders are waiting for oversized pistons (backordered of course) so we will use those on another engine we are getting ready to OH. -

I used Horton years ago when it was an avionics shop and they were just getting into annuals and other airframe maintenance. James is honest. I believe his son is involved now. I don't know how much Mooney experience they have. As a 5 year owner of an E (my 4th Mooney), I would not pay $3500 for a prebuy. It should cost $1000 or less. I would ask the seller to fly the plane to Socal or Phoenix to a mechanic that knows Mooneys for inspection. If you bring it to Socal, Steve Parkins at Corona owns and understands Mooneys (Including mine). If that is not possible, I would pay a local mechanic to do a borescope of the cylinders and try to get a look at the cam lifters (hard but possible), inspect the spar, empennage, wheel wells and pilot side tubes for corrosion, look inside the wings and interior panels for corrosion or fuel leaks, and test all the avionics in the air. Do a speed test to learn if it is rigged correctly. This group has given you a good list of gotchas. With a 55 year old airplane you will have stuff to fix - the key is to catch the items that can cost you huge sums or make your new purchase a problem airplane in the first year of ownership.

-

Hartzell spinner Assy, needs repair - 1967 M20F

JoeM replied to Igor_U's topic in Avionics / Parts Classifieds

THanks for responding. Those don't fit my plane. -

Need Help With A Part: Lasar DOUBLER - 680031-029

JoeM replied to PeteMc's topic in General Mooney Talk

I Saw that. The part number is the same but the picture is different. -

Need Help With A Part: Lasar DOUBLER - 680031-029

JoeM replied to PeteMc's topic in General Mooney Talk

I need to two doublers part number 680031-029 if anyone has spares. -

I have a complete Brittain system in my '65 E model, with altitude hold and pitch control. For 4 years I have tried to keep it working, buying parts Others were selling, rebuilding servos, sending parts to Kevin in Tulsa, and doing extensive testing myself. You probably know there are very few people who will work on them, and even fewer who are FAA certified. The company is essentially out of business. Jimmy Garrison says that it would add $2000 to the value of your airplane, assuming it worked. It probably won't. It would definitely cost more than that to install, troubleshoot, and attempt to repair. I am getting ready to take mine out and install an aerocruze 100 aka trutrak. Cost is about $7,000 for a good autopilot, admittedly not as good as Garmin. If you are so inclined, you can install it yourself under supervision. If it were me, I would not waste money on a Brittain system.

-

Aging airplane and systems: What would you do?

JoeM replied to Immelman's topic in Vintage Mooneys (pre-J models)

try to imagine your life without the plane. If you like what that looks like, sell. If you still want to fly, get another plane. Let this one be someone else's project. -

I have an extra left side yoke with PTT similar to Hank's (except it's for the pilot's side with the clock hole) if you need one.

-

I have removed and repaired the one on my 65E. I agree with lubricatiing it if possible at both ends, but it is difficult to replace the wire. It is one of those things that, if it ain't broke, don't fix it.

-

Part number? I have one recently removed in working condition from a 65 M20E I could find if you are interested.

-

My E model had 64 gal bladders when I bought it, which I thought was a plus. I didn't pay extra for them, but have enjoyed not having to worry about leaking tanks. The J model I now partner in has a leaky right tank so we are dealing with that issue again. Not much fun..... I think Jimmy is right, they are worth more than a plane without them.

-

Another option (which we just used to keep our plane flying while we get ready to install dual GI 275s) is to buy one of the many serviceable DGs available on the used market which other owners have removed to upgrade. This would keep your plane IFR capable, reduce downtime, reduce expense, and give you and your partners time to make future decisions.

-

I prefer an on/off toggle switch so I used this one https://www.aircraftspruce.com/catalog/elpages/togglevalve11-12168.php

-

Surefly mag installer in Los Angeles area

JoeM replied to AaronJr's topic in Vintage Mooneys (pre-J models)

Steve Parkins at AJO has worked on numerous Mooneys, including mine, recently. He is a perfectionist. PM me if you want his number. -

I installed Plane Power alternator and regulator in my 65E (under supervision of A&P/IA of course) and it works very well. Their customer service was fantastic as well. Joe

-

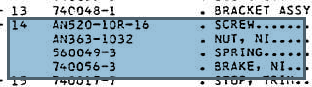

My E had the trim brake removed for an aftermarket electric trim which has now been removed inop. So I need the original trim brake spring assembly. The trim assembly p/n is 740048 and the attached pic shows the sub-assembly part numbers. I see several trim assemblies with different part numbers on Ebay, and I'm wondering if they are the same or were changed between 64-67? Or if anyone has just the screw, nut, spring and brake available? TIAA Joe

-

My aileron rod ends are worn and need to be replaced. They are pinned into the rod (pic below). My mechanic is trying to determine how to replace them and with what part number. Spruce carries threaded m34-14 rod ends. Is that the one? TIA

-

I have my G430 tray out (for another upgrade) and would like to prewire the GPS connectors for dual G5s. I believe the ADI requires two RS232 on pins 56/57. Are there other connections to the 430 for the CAN bus or HSI that I should prewire as well? Also, I am running the wire in the wing for the magnetometer and wondering how many wires I will need? TIA Joe

-

I know you are asking for navcom advice, but if you building an IFR panel, your AP becomes important too. Does your Brittain work? Mine does (with help from many here and Kevin Westbrook), but I am planning for a BK Aerocruze 100 as well. I have (and recommend) an Avidyne 440 which includes a glideslope and VOR capability. The com works well too. I bought mine used from Wentworth. Avidyne has great customer support.

-

Anyone who has installed a G5 magnetometer in a short body willing to fabricate one for me? I am getting ready to install dual g5s under IA supervision and would prefer to use someone's successful installation bracket rather than fabricate from scratch. TIA

-

looking for 1965 M20E SN 539 gear safe & gear unsafe panel lights (push to test, twist to dim)