-

Posts

12,156 -

Joined

-

Last visited

-

Days Won

170

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Shadrach

-

It probably is. Much of the fleet is underinsured.

-

80 is several decades out for me, but my experience with my senior pilot friends is that those that have a long term relationship with a specific insurer can expect continued coverage into their golden years until they have a claim, then all bets are off. My late (RIP) flight instructor flew until he lost his medical in his late 80s or early 90s. He told me that coverage was never an issue.

-

Go to the shop and find your seats. Trying to piece something together from spares is going to be significantly more challenging and expensive in the long run. Even if you have to spend a full day in the shop, it will be time well spent.

-

2 engines still making same mistakes

Shadrach replied to 201er's topic in Mooney Safety & Accident Discussion

I know that you think this is a really insightful comment but it’s well understood by anyone that’s been flying long enough to have experienced the uncomfortable position of being behind an airplane. I have never had a forced off field landing, but I do have first hand experience with the site picture out of a B55. -

2 engines still making same mistakes

Shadrach replied to 201er's topic in Mooney Safety & Accident Discussion

1) Presumably, if you’re trained to fly a multi engine aircraft, you feather the prop when you lose an engine. 2) Presumably if you’ve been checked out in a Baron, you should know how to access the fuel in the tanks. 3) I think it unlikely that he did not see the car that he hit. I think it’s likely that he was simply hoping that traffic would pull away from him as he slowed in the flare. Fuel contamination would qualify as being dealt a bad hand. If this was fuel mismanagement followed by not completing basic procedures, followed by landing on a car, I will struggle to sympathize. If you look at the altitude fluctuations in flight it looks like he was maneuvering and practicing stalls. This segment of Flight data looks particularly interesting: -

Door opening in flight

Shadrach replied to Sinclair51's topic in Mooney Safety & Accident Discussion

Your experience bears absolutely no resemblance to my experience when intentionally opened the door in flight to retrieve a seatbelt tail, but then I was much slower. In the summer, I frequently open the door right after touchdown with none of the violent oscillations you describe. How does a door swing open 2-3 feet into a 175mph slipstream? Seems like that defies physics. And then there’s the “drag and partial stall”…none of this seems plausible. -

How many people lost an Alternator/Voltage Regulator in flight?

Shadrach replied to Yetti's topic in General Mooney Talk

I wasn’t so lucky as my breaker was seated as it should be when I checked it. It was too damn cold here for me to bother decowling the plane after my return. I’ll check it out this weekend. I’ve already order a replacement. If it’s not needed, I will keep it as a spare. -

How many people lost an Alternator/Voltage Regulator in flight?

Shadrach replied to Yetti's topic in General Mooney Talk

This thread jinxed me. Just had a charging system failure yesterday 30 mins into a cross county flight. I wonder if the cold temps hastened the generator’s failure, I preheated but the airplane was a cold soaked 12° when I started. Don’t recall the temps at 9,500 when it failed. It’s a terrible time to work on airplanes in an uninsulated hangar. -

2 engines still making same mistakes

Shadrach replied to 201er's topic in Mooney Safety & Accident Discussion

Neither engine feathered. Master still on. These guys did a great job… I have two kids. My son sits right behind me on the driver’s side. I hate to think of the outcome if there had been a passenger in the rear seat of that Toyota. -

Making sense of NTSB report for M20F N9339M

Shadrach replied to DXB's topic in Mooney Safety & Accident Discussion

I have been landing Mooneys for about 27 years (almost half my life) and have logged 100s of landings into <1600' strips. I am long term member of the church of energy management. Do you have any short-body time? The short body feels very different from a mid-body in the flare to touchdown. I suspect it has to do with the shorter arm (and moment) from the empennage to the center of lift. -

If one does not differentiate between a catastrophic powerplant failure and an issue with a single mag, the number is going to seem needlessly scary.

-

You live in the right region for avoiding snow. Common in the Mid-Atlantic to encounter snow squalls. It's fun at night...you can turn on the landing light and tell the kids that you've accelerated to warp speed.

-

Greetings Meshach, I am questioning why the play is only evident when the flaps are fully extended. Seems like it would manifest anytime the flaps are deployed.

-

Making sense of NTSB report for M20F N9339M

Shadrach replied to DXB's topic in Mooney Safety & Accident Discussion

I agree completely. This came as huge surprise to me. Flying both aircraft on the same day cemented it. -

Making sense of NTSB report for M20F N9339M

Shadrach replied to DXB's topic in Mooney Safety & Accident Discussion

It’s not a limitation. As you know, the only limitations in the AFM/POH/OM are in the limitations section. In my view, the genesis of the discussion was born out of the recommendation in an Mooney Owners Manual that certain pattern speeds be used without any consideration given to weight. The real-world operating weight of my aircraft can vary by more than 800lbs. That represents an 11mph difference in stall speed. Approach speeds are up stream of stall speed. It’s a good idea to be well-versed in calculating the appropriate V speeds for a given weight. Overtime, one gain the ability to interpolate the appropriate approach, speed without having to use calculator. The full flap vs partial flap discussion was born out of this previous discussion as there is no data in any of the manuals that I have seen for partial/no flap landings. While a pilot can easily calculate stall speed and the associated approach speeds from Vso at MGW, I know of no simple method for calculating partial flap landing numbers, though I’m sure with enough effort, I could derive something based on calculated landing speed and weight. One would think that interpolating would be sufficient. I suppose it is for most of the people most of the time. But some of the time… I lean towards full flap landings because they typically yield the best result and I have data for them. That being said, I recently started flying a C model and I am quite surprised by how differently it behaves in the flare. I have flown both it and my F model in the same day and I can grease the F model on smoothly, but the C seems to have an extreme deck angle before the wing pays off and it plunks on with a thud. I’m going to try some different landing configurations to see if I can prove my touchdowns. -

Starlink Question that needs another thread I think

Shadrach replied to cliffy's topic in Miscellaneous Aviation Talk

That will do nothing to stop their ability to sap and impurify all of your precious bodily fluids... -

We are in a paradigm shift in general aviation...getting less for more is the new norm. Pricing has spiked across the board, but at least things are taking a lot longer.

-

Making sense of NTSB report for M20F N9339M

Shadrach replied to DXB's topic in Mooney Safety & Accident Discussion

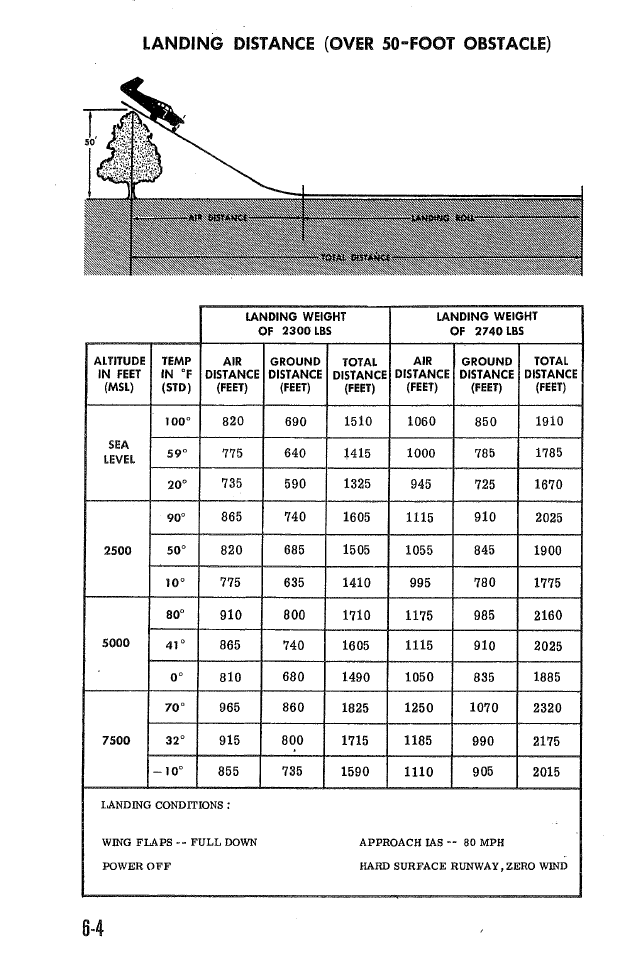

That's not lading data. This is landing data: Note that I do not believe for a minute that the test pilot generated the published landing distances for 2300lbs by flying the approach at 80MIAS. -

Making sense of NTSB report for M20F N9339M

Shadrach replied to DXB's topic in Mooney Safety & Accident Discussion

I think full flaps is the way for all of them if you want to use the published data as a guideline. I don't know of any Mooney POH that provides landing data for configurations other than full flaps, but I could be wrong. -

Making sense of NTSB report for M20F N9339M

Shadrach replied to DXB's topic in Mooney Safety & Accident Discussion

That is indeed sound advice. Those old books are vague though. Does flaps deployed mean partial flaps, full flaps? Interestingly, if one runs the numbers for a M20F/J, 1.3 x clean stall at max gross is 90mph...so the number makes good general sense. What does 90mias look like if it's just me and half tanks (~2100lbs)? In that case, 90mias is 1.66 X clean stall speed. No big deal but certainly leaves extra energy to bleed off during the approach. The manual also says to trim for 80MIAS hands off, full flaps on final. That is almost precisely 1.3Vso at MGW. What about with just me and half tanks? In that case, 80MIAS works out to 1.47Vso. Arriving at the threshold at nearly 1.5Vso in a Mooney or any sleek, low wing, single, presents some challenges. General numbers are a good initial guideline, but it's good to know how and when those guidelines should be adjusted. As a community we have had many, many RLOC incidents from aircraft arriving at the threshold with excessive speed -

Making sense of NTSB report for M20F N9339M

Shadrach replied to DXB's topic in Mooney Safety & Accident Discussion

The 67 F has hydraulic flaps. It’s conceivable that the impact caused the system to lose pressure, I appreciate te intent of what you’re saying about the stall horn in the pattern. However. I have flown in turbulence severe enough to sound the stall horn in cruise. On really gusty days, the stall horn will bleat well north of safe patten speeds. To be clear, all evidence suggests that this pilot simply to sow and lost control. It’s a dubious accomplishment running a Mooney out of energy short of the runway. Mooney pilots are typically more adept at screeching off the departure end in a cloud of tire smoke… -

Making sense of NTSB report for M20F N9339M

Shadrach replied to DXB's topic in Mooney Safety & Accident Discussion

This report could have been more precisely written. Here is my guess after 25 years of flying an M20F. With two up front, little in the baggage compartment and a few hours of fuel on board, the trim would likely be near full nose up if not at the limit. My F will hit the nose up limit when light with nothing aft of the front seats. If one goes from power off, full nose up trim to full power, full nose up trim, it's conceivable that they could be overwhelmed by the control forces and depart controlled flight if already at the ragged edge of a stall. -

I have never forgotten one, but I did have an "auto-opening" pitot cap stick in the down position on a night departure in a rented C172. I had two passengers on board and the RTB combined with me getting out, twisting that cheesy cover off the pitot tube and throwing it into the woods really scared the back seater. The rest of the flight was uneventful, but we nearly scrubbed the second departure because she was so rattled over that stupid thing.

-

How long ago was your system renewed? My boots are 58 years old and still supple (knock on wood).