Sabremech

Supporter-

Posts

2,144 -

Joined

-

Last visited

-

Days Won

28

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Sabremech

-

Based on the G100UL fuel leak thread what's your position?

Sabremech replied to gabez's topic in General Mooney Talk

I’m well aware of what Skydrol can do as I have worked with it in the past. It doesn’t have the effect you say it does on the corporate aircraft that I’ve maintained that have it. I still have Castor Oil in the top drawer of my toolbox. It’s clear you feel that you know more than many other members of this forum. -

Based on the G100UL fuel leak thread what's your position?

Sabremech replied to gabez's topic in General Mooney Talk

All of the fluids you mention “can” peel paint. It doesn’t necessarily mean it will. Do I care whether the FAA says it’s ok that it can peel paint? What does it matter that they supposedly say this? It would surely tick me off to no end that my $30k paint job gets screwed up by staining and possibly paint peeling. It sounds like you don’t care if your paint gets screwed up or not. The level of caring must be directly tied to your economic means to get it fixed. -

Based on the G100UL fuel leak thread what's your position?

Sabremech replied to gabez's topic in General Mooney Talk

From the FAA’s PAFI/ EAGLE unleaded fuel website, LyondellBasell/VP Racing are currently in the PAFI program. LyondellBasell/VP racing has passed the 150 hour initial tests and has moved on to the full scale engine and flight testing of their unleaded UL100E fuel. unless something has changed that’s not current on the FAA’s website, there is one company working through the PAFI / EAGLE process instead of the STC route. I also found Swift Fuels website to be an interesting read with their 100R unleaded fuel. They appear to be going the STC route with their version of unleaded 100 octane fuel. They recently posted information in regards to compatibility between their UL94 fuel and the GAMI G100UL. I understand they are competitors but the article in the FAQ section was interesting. -

They, along with aircraft manufacturers, are who should be working with the seal manufacturers to change the compounds that are used. It’s not up to me or any other mechanic to search out an alternate p/n to switch to viton, etc. I may very well have been installing them but again don’t specifically look at the compound they are made of. Part number and cure date are the main things I look for. As I stated previously, this also has the real potential for intrusive maintenance which we all know can turn quite expensive quickly. I hope that other true direct replacement fuels come to market that don’t have the reported issues this fuel may have. Thanks

-

Is a paint correction/ceramic coating worth it?

Sabremech replied to AndreiC's topic in General Mooney Talk

Hello Andrei, See if you can get a test patch done from the guy who travels. Have him explain his process then you can make a decision based off of seeing and hearing the processes of both. David -

As an A&P / IA, it’s not up to me to make substitutions on the materials used to make an o-ring. It’s up to the manufacturers of those parts to change the material. I strictly work off of what’s in the IPC for the aircraft I’m working on. I can tell you other than looking at the P/N and the cure date, I don’t look for what it’s made out of. You’re putting mechanics in jeopardy by coming up with substitutions and acceptable data. Something goes wrong, and we’re left to hang. I understand what you’re trying to do and applaud you for it. What I don’t like is putting more onus on mechanics with gray areas for us to have to muddle through. Thanks, David

-

@George Braly, I should not have to change a thing to use any fuel. Requiring any owner to pay that bill means your fuel isn’t right. It’s ridiculous to push more costs on to owners for something that should be plug and play. I assume G100UL is more expensive than 100LL. How much more, I don’t know since it’s not available to me in the Midwest yet. As it stands right now, I wouldn’t use this fuel until the engine manufacturers approve it. I have no intention of training to become a glider pilot in my Mooney.

-

Based on the G100UL fuel leak thread what's your position?

Sabremech replied to gabez's topic in General Mooney Talk

Kind of think this says it all. Not approved by the engine manufacturer is significant. -

-

Based on the G100UL fuel leak thread what's your position?

Sabremech replied to gabez's topic in General Mooney Talk

The bigger question is why should we replace parts and do maintenance, some very intrusive and time consuming, to use a different fuel? This should be a straight replacement with zero maintenance required other than ongoing. Why do we as aircraft owners and mechanics have to continue to bear the cost of this? It’s a sure way to kill off more of GA all in the name of safety again. I like Mike Rowe’d safety third more and more every day. -

Based on the G100UL fuel leak thread what's your position?

Sabremech replied to gabez's topic in General Mooney Talk

I am an A&P with an IA and I’m not going to go outside what is listed in the manufacturers IPC unless the part is obsolete and not obtainable. Then I’ll work another way to find a part that will work in form, fit and function. There’s millions of o-rings of all sizes including metric. Why do I want to take on the liability of researching to find an alternate O-ring and not be sure it’s correct? What owner wants to pay for my time to research this and hope it’s right? This is a no win for mechanics. -

Based on the G100UL fuel leak thread what's your position?

Sabremech replied to gabez's topic in General Mooney Talk

We use the part numbers listed in the relevant IPC. When I order o-rings, I don’t get to specify what it’s made from. Unless the manufacturer updated their IPC to include alternate P/N’s made from different materials, we risk not using the correct parts and potentially causing other issues, which could be catastrophic. -

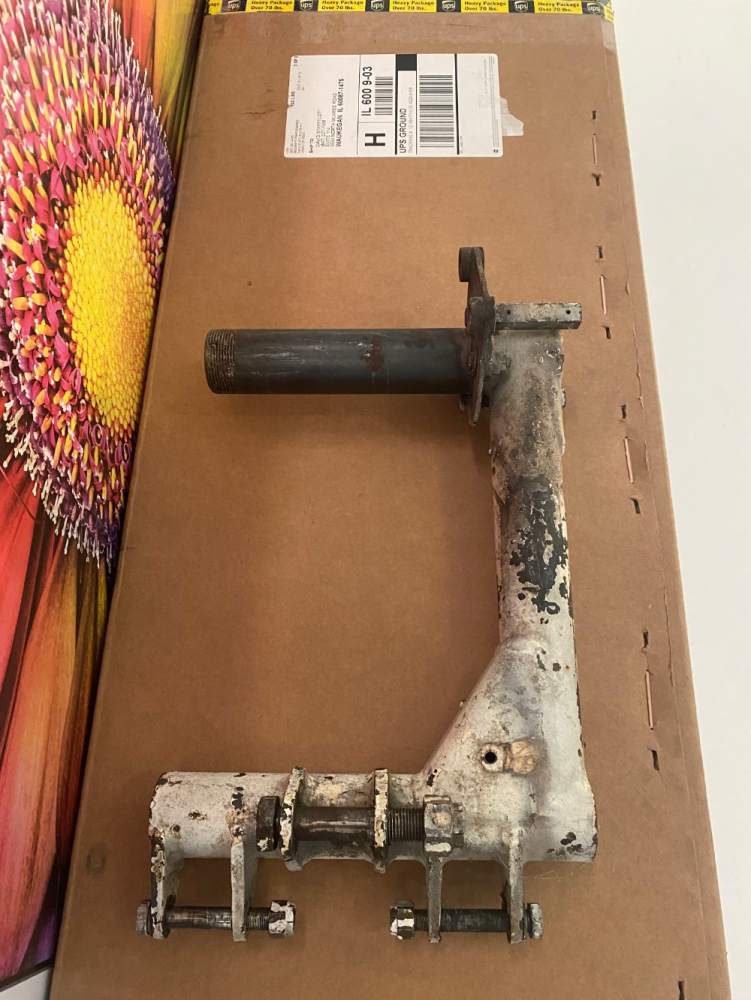

Those downlock are perfectly legal!

-

Repair schemes for undercarriage

Sabremech replied to Barneyw's topic in Vintage Mooneys (pre-J models)

Good day, I have a left side spindle assembly and will check in for a right side when I get to my shop in a week or so. Would be willing to sell this and ship if you’re interested. David -

Repair schemes for undercarriage

Sabremech replied to Barneyw's topic in Vintage Mooneys (pre-J models)

All international shipments are extremely complicated with each country having different requirements. It’s a nightmare. David -

Repair schemes for undercarriage

Sabremech replied to Barneyw's topic in Vintage Mooneys (pre-J models)

I may have some. I purchased some used gear legs a number of years ago. It will take me two weeks before I can look in my parts bins. David -

I’ll have to give that some thought. There are certainly more parts useable between an A and a C versus the M20 I have currently. David

-

Hi Matt, Good to hear from you. It’s going to be impossible for me to leave it 100% original. I do have an interested party that I talked to about my plans and they love it. They feel the same as I do in regards to the rear windows. We’ll see what does or doesn’t get done! I’ll have to post pictures of the fuselage covered under a sheet now! The corporate job is crazy busy as always. That’s why the Mooney progress is much slower than I thought I could get done by now. As for Warbird, we have the jets for sale. It was in our plan to sell them about now. The P-40 IRAN is coming along nicely but still expect it to be two more years before ready to fly again. How’s everything out West? David

-

I can’t tell at this time! Will have to be a surprise! David

-

Good morning Barney, This is the standard break apart position for all Mooney’s. The number of bolts to hold the tail cone on has increased over the years by model. Thanks, David

-

NLG and MLG shock disc 3CRE-714 shock disc

Sabremech replied to Kodiakflyer's topic in Vintage Mooneys (pre-J models)

Great looking bird! -

Any information for the guy at Hinkley you can share? Not that I need another Mooney, but you never know what parts might be needed in the future. Thanks, David

-

NLG and MLG shock disc 3CRE-714 shock disc

Sabremech replied to Kodiakflyer's topic in Vintage Mooneys (pre-J models)

Hi Tom, I purchased the used parts I needed from Alan Fox. I believe he’s on MS but can message you his contact info if needed? Thanks, David