Sabremech

Supporter-

Posts

2,113 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Sabremech

-

As an A&P / IA, it’s not up to me to make substitutions on the materials used to make an o-ring. It’s up to the manufacturers of those parts to change the material. I strictly work off of what’s in the IPC for the aircraft I’m working on. I can tell you other than looking at the P/N and the cure date, I don’t look for what it’s made out of. You’re putting mechanics in jeopardy by coming up with substitutions and acceptable data. Something goes wrong, and we’re left to hang. I understand what you’re trying to do and applaud you for it. What I don’t like is putting more onus on mechanics with gray areas for us to have to muddle through. Thanks, David

-

@George Braly, I should not have to change a thing to use any fuel. Requiring any owner to pay that bill means your fuel isn’t right. It’s ridiculous to push more costs on to owners for something that should be plug and play. I assume G100UL is more expensive than 100LL. How much more, I don’t know since it’s not available to me in the Midwest yet. As it stands right now, I wouldn’t use this fuel until the engine manufacturers approve it. I have no intention of training to become a glider pilot in my Mooney.

-

Based on the G100UL fuel leak thread what's your position?

Sabremech replied to gabez's topic in General Mooney Talk

Kind of think this says it all. Not approved by the engine manufacturer is significant. -

-

Based on the G100UL fuel leak thread what's your position?

Sabremech replied to gabez's topic in General Mooney Talk

The bigger question is why should we replace parts and do maintenance, some very intrusive and time consuming, to use a different fuel? This should be a straight replacement with zero maintenance required other than ongoing. Why do we as aircraft owners and mechanics have to continue to bear the cost of this? It’s a sure way to kill off more of GA all in the name of safety again. I like Mike Rowe’d safety third more and more every day. -

Based on the G100UL fuel leak thread what's your position?

Sabremech replied to gabez's topic in General Mooney Talk

I am an A&P with an IA and I’m not going to go outside what is listed in the manufacturers IPC unless the part is obsolete and not obtainable. Then I’ll work another way to find a part that will work in form, fit and function. There’s millions of o-rings of all sizes including metric. Why do I want to take on the liability of researching to find an alternate O-ring and not be sure it’s correct? What owner wants to pay for my time to research this and hope it’s right? This is a no win for mechanics. -

Based on the G100UL fuel leak thread what's your position?

Sabremech replied to gabez's topic in General Mooney Talk

We use the part numbers listed in the relevant IPC. When I order o-rings, I don’t get to specify what it’s made from. Unless the manufacturer updated their IPC to include alternate P/N’s made from different materials, we risk not using the correct parts and potentially causing other issues, which could be catastrophic. -

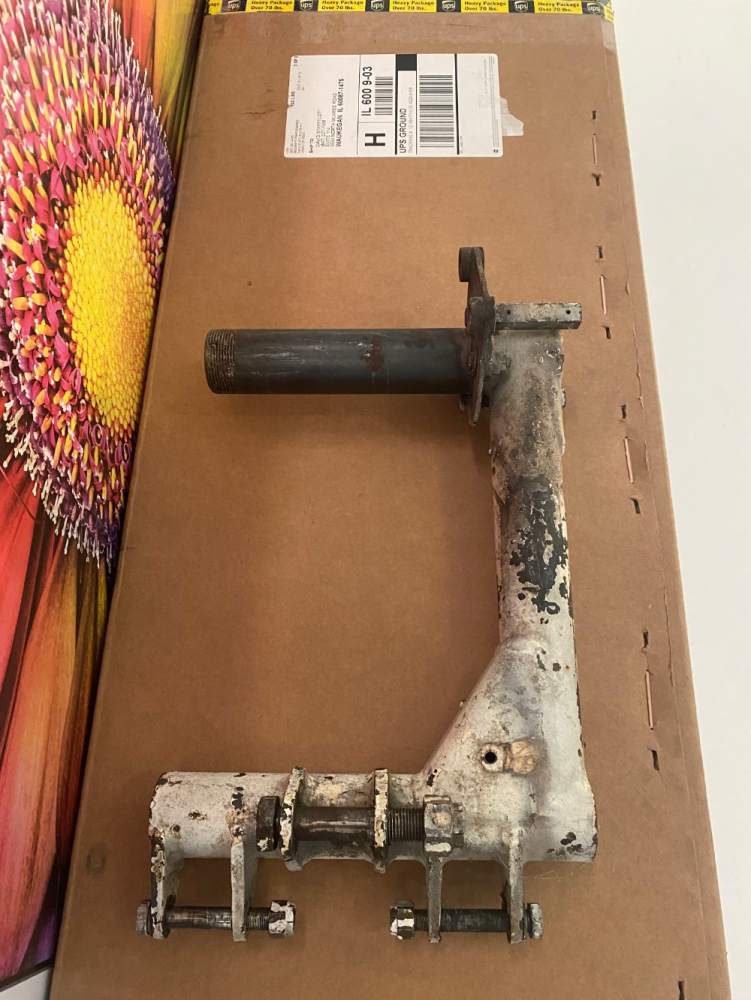

Those downlock are perfectly legal!

-

Repair schemes for undercarriage

Sabremech replied to Barneyw's topic in Vintage Mooneys (pre-J models)

Good day, I have a left side spindle assembly and will check in for a right side when I get to my shop in a week or so. Would be willing to sell this and ship if you’re interested. David -

Repair schemes for undercarriage

Sabremech replied to Barneyw's topic in Vintage Mooneys (pre-J models)

All international shipments are extremely complicated with each country having different requirements. It’s a nightmare. David -

Repair schemes for undercarriage

Sabremech replied to Barneyw's topic in Vintage Mooneys (pre-J models)

I may have some. I purchased some used gear legs a number of years ago. It will take me two weeks before I can look in my parts bins. David -

I’ll have to give that some thought. There are certainly more parts useable between an A and a C versus the M20 I have currently. David

-

Hi Matt, Good to hear from you. It’s going to be impossible for me to leave it 100% original. I do have an interested party that I talked to about my plans and they love it. They feel the same as I do in regards to the rear windows. We’ll see what does or doesn’t get done! I’ll have to post pictures of the fuselage covered under a sheet now! The corporate job is crazy busy as always. That’s why the Mooney progress is much slower than I thought I could get done by now. As for Warbird, we have the jets for sale. It was in our plan to sell them about now. The P-40 IRAN is coming along nicely but still expect it to be two more years before ready to fly again. How’s everything out West? David

-

I can’t tell at this time! Will have to be a surprise! David

-

Good morning Barney, This is the standard break apart position for all Mooney’s. The number of bolts to hold the tail cone on has increased over the years by model. Thanks, David

-

NLG and MLG shock disc 3CRE-714 shock disc

Sabremech replied to Kodiakflyer's topic in Vintage Mooneys (pre-J models)

Great looking bird! -

Any information for the guy at Hinkley you can share? Not that I need another Mooney, but you never know what parts might be needed in the future. Thanks, David

-

NLG and MLG shock disc 3CRE-714 shock disc

Sabremech replied to Kodiakflyer's topic in Vintage Mooneys (pre-J models)

Hi Tom, I purchased the used parts I needed from Alan Fox. I believe he’s on MS but can message you his contact info if needed? Thanks, David -

Catching up a bit to the current status of the M20. Here’s a few more pictures of this bird. I love the old avionics switch which is a choke cable attached to two switches tied together on the engine side of the firewall. Simple but works. Also a few other pictures of the wood wing along with the instrument panel and aux fuel tank. David

-

Yep. I was amazed at what was underneath the barn dirt! I still have to clean the tailbone before re-installing it. I’m planning to rework the back windows as I absolutely dislike the teardrop window. Going to make it look more like the later C window. Perfect time to do this work is before putting the tail cone back on. David

-

First thing I wanted to determine was still in airworthy shape was the wood wing. Second was the engine internals and then trying to start it. The wing is in good shape with just a patch or two required on the fabric. The engine was borescope and looked clean and two short duns have been completed. The engine mounts were in really poor shape and the engine sagged so much into the firewall that I couldn’t get it to idle below 1300 RPM. Throttle was bound up with the gear warning switch that is mounted on the engine side of the firewall. New mounts were installed and waiting to run it again after upgrading the gear disks IAW S/B M20-161. Nose gear is almost complete then on to the main disk changes.

-

I can share with you the data you request. David

-

NLG and MLG shock disc 3CRE-714 shock disc

Sabremech replied to Kodiakflyer's topic in Vintage Mooneys (pre-J models)

Those are the old Firestone disks and are un-obtainium new. I just removed a set from my M20 and am complying with Mooney S/B M20-161 to install the later style Lord disks. David