Sabremech

Supporter-

Posts

2,149 -

Joined

-

Last visited

-

Days Won

28

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Sabremech

-

Having done plenty of shock disk changes, I don’t see how this would make a difference to shock disk longevity on the nose gear. They are under heavy compression all the time unlike the main gear. I could see this helping possibly extending the life of the mains but not sure by how much. Are they worth the investment on any other model than the long bodies? I’m not sure. David

-

Moved an M20 recently. Removing the tail section isn’t that bad. You’ll have some bolts holding it on to the steel cage structure, then the rivets on the skin.

-

You can if LASAR gives a new authorization letter which they should if they want good customer relations. Now that will most likely incur a fee.

-

Hi Doug, I’ll be in touch soon. I’ll look through my files for the drawings in the next day or two. Thanks, David

-

Transponder and Garmin GDL 82 for sale

Sabremech replied to Sabremech's topic in Avionics / Parts Classifieds

Sold! -

Transponder and Garmin GDL 82 for sale

Sabremech replied to Sabremech's topic in Avionics / Parts Classifieds

Updated pricing, Sandia STX-165 transponder-$750. Garmin GDL82 ADSB-Out - $750 Would like these to go to a good Mooney home. -

Hi David, I have all the data I need to move the down and uplock blocks to a PMA part. I refuse to do it at this time as the OPP disagreement still stands between MIDO and myself. I turned my PMA back into them out of protest with their actions. I will make OPP downlock blocks but until this issue is resolved, can not do as a group in MIDO’s determination. FSDO is absolutely fine with the group making the needed parts. I don’t know of anyone in the group that has removed their downlock blocks over the letter. I informed MIDO that any owner that does should sue them if they have a gear collapse due to a worn downlock of which Mooney has no published wear limits. Thanks, David

-

Sure is a way to get my blood boiling again! Funny how Eric pointed out other groups doing exactly this and it still being brought up at IA seminars as the perfect way to stay within the regulations and keep the old birds flying. David

-

LASAR turned on the vintage Mooney community several years ago in regards to the owner produced parts. Funny how they have a short term memory and now want us to support them? No thanks.

-

Changed directions on my project so have a Sandia STX-165 and Garmin GDL 82 package available. Asking $2000 OBO for the package. E-mail sabremech@gmail.com

-

Lasar Aviation Mooney Assurance Program - Really?

Sabremech replied to PeteMc's topic in General Mooney Talk

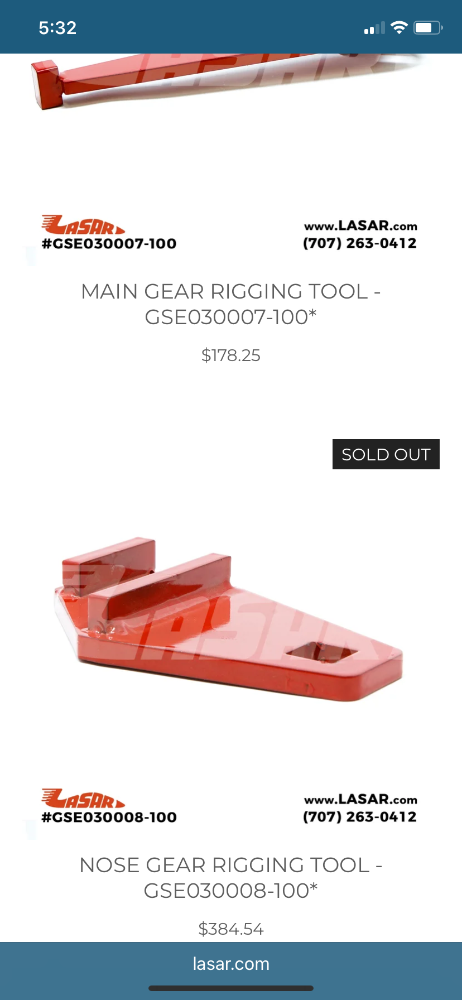

Is this price part of the new 30% across the board increase or a typo? $384.54 for the nose gear rigging tool? I sell a complete set of these tools for what you have this one tool priced for now on your website. Please tell the Mooney community this is an error, or don’t and help my sales! -

Let's buy Mooney - Crowdsourced Version - Straw dog.

Sabremech replied to Yetti's topic in General Mooney Talk

Now that you have that cool auto-pilot, come North! I’ll be retiring from the full time work in January and have 2 Mooney’s that I regularly work on and do their annuals. I have an E model in for annual right now! David -

Congrats Don, Now to venture out! David

-

I have my reasons but I will not be supporting the new LASAR at all. I was a customer when it was owned by the class act of Paul and Sheri.

-

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Sabremech replied to cliffy's topic in General Mooney Talk

Yes and no. There’s issues between FSDO’s and MIDO on this. To this day, FSDO’s are saying at IA renewal clinics that owners can get together to share in the cost of making the same unavailable part as a group. So, do we need to ask every FSDO and every MIDO if they agree on this or just the one covering the geographical area you are in? All communications with the FAA in regards to parts should be recorded or in e-mail format only because it’s likely you’ll need to remind them of what they said! -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Sabremech replied to cliffy's topic in General Mooney Talk

Once you tell said reputable gear manufacturer it’s for an airplane, most are going to say no thanks! Been there done that with machine shops. Most won’t touch anything that goes on an airplane. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Sabremech replied to cliffy's topic in General Mooney Talk

Even for Money? Nope! -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Sabremech replied to cliffy's topic in General Mooney Talk

My point is that Mooney is not going to give or sell you the drawing or approved data. So, AI isn’t going to do you much good in producing the part. You’re missing quite a bit in making a part. Who here commenting about OPP parts has actually made a part using the OPP rule? I have! -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Sabremech replied to cliffy's topic in General Mooney Talk

Answer: you do not need the approved data to manufacture an OPP part. If you have an original part, you can reproduce that part. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Sabremech replied to cliffy's topic in General Mooney Talk

Been there done this with the gear up and downlock blocks. Did the lab analysis for material specification etc. Had drawings made, machined a first article for test fit and function then finalized the part. This was not a new design, this was copying an original or PMA part. No blessing needed to do that. There are parts such as the Gear set that aren’t advisable to do as OPP parts. I chose not to do them! -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Sabremech replied to cliffy's topic in General Mooney Talk

There’s always someone taking it to the nth degree. The OPP parts will be documented in the logbooks if the owner is ethical and not trying to put a part in that he machines up with his Harbor Freight lathe in the garage. The point is that the OPP part meets or exceeds the original designed part and you won’t be looking for a lawyer. I briefly thought about the 40:1 gear sets and decided that I did not want the liability by producing them, not even PMA versions. There are plenty of parts on my Mooney that I would have no issue making my own parts for it. They would all be documented in the logbook so there would be no need to disclose it. If you don’t like it, go buy another Mooney. It’s really that simple. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Sabremech replied to cliffy's topic in General Mooney Talk

@Cliffy, You do not need the manufacturers drawing, DER approval or approved data for an OPP. What you do need is an original part to use to make the new one and be able to prove your part meets or exceeds the original part if ever challenged by the FAA to prove it is an equivalent. Of course having the drawing would be optimal but not likely from Mooney, DER would be nice but not required as well as some sort of approved data. You quoted the OPP rule fairly well but then went off course with what I’m disagreeing with you here! I have done OPP parts as we all know and have had numerous conversations with the FAA on this topic. The one inconsistency is the FAA between offices. -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Sabremech replied to cliffy's topic in General Mooney Talk

Once $28K came from ABS. The other $500K came from an estate specifically for overcoming the ruddervator skin issue. Maybe we need to form the American Mooney Society and as a group of owners and maintainers tackle our most pressing problems. Have the AMS work the parts that are needed and not available at true cost to the members. It could be setup as a not for profit entity for the benefit of its members. @cliffy Care to try something different than the promises generated by AI from LASAR? -

NEW NEWS FROM LASAR AND MOONEY AS OF 10/2/2025

Sabremech replied to cliffy's topic in General Mooney Talk

@cliffy ruddervator skins are now available for V-tail Bonanzas from SRS Aviation. They are also selling them for LESS than when they were last available from Beechcraft. Hmmm?? What? Less? How can that be?