-

Posts

65 -

Joined

-

Last visited

Everything posted by Ed de C.

-

I've got a similar airplane: 2008 Ovation with 310hp STC, FIKI TKS, 77 ft cubed oxygen, Amsafe belts, WX-500 stormscope, Avidyne traffic, maybe a few other things. My useful load is 933 lbs. I can trace that back to the factory specs of this airplane and didn't see any obvious errors in the W/B worksheets subsequent. I've owned this for 9 months and have poured over the POH and the limited 310hp STC data. As the folks have said, you can use the Ovation 2 POH data for most of this. You'll get better climb at 2,700 rpm than the POH says by maybe 300 fpm (I see up to 2,000 fpm in Michigan winter at 120 kts and light). To set your expectations: The cruise speeds on the POH are unachievable in my bird with TKS. I see an honest 170 kts true at 13 gph LOP at 8,000 feet. At 12 gph, it's roughly 165 kts true. I'm typically turning 2,300 rpm for these numbers. The fuel flow is the key number when LOP as that determines your HP using a multiplier of 14.9 for our 8.5:1 compression engines. You can take that HP calculation, convert to % power (make sure to use 280 max HP if you are referencing the POH) and then find your "book" speed expected. I've run the engine flat out at 8,000 feet (2,700 rpm) to see where it would top out at. It's around 185 kts true. Mooney claims 197 kts true for the 310 hp Ovation 3 (not in the POH). A touch of left or right rudder trim can affect my numbers, but I don't have enough data to be sure about that. I'm at least 10 knots slow to book. Most people here attribute this to TKS and Mooney's aggressive test protocols that remove antennas, the passenger step and who knows what else. I've put effort into rigging the gear and the control surfaces appear to be within spec. I find the speed of these machines is more than you need or even want when buzzing around with friends and family. I've never wanted more speed in the terminal area. As someone said, it breaks the sound barrier going down. I'm pulling inches off in the descent to keep it below the yellow arc and love the flexibility the speedbrakes provide. Where we all could appreciate more speed is in cross country cruise. The Acclaim guys have us beat there. I've put away the POH book speed values and have gotten good with seeing 170 kts true on the G1000. The delta against book amounts to only a few minutes on a typical cross country. And when the machine is running well, it's an enjoyable place to spend time. Something that will make you smile nonetheless is the fuel economy. My numbers suggest that the acclaim flying at our same speeds will burn 2 gph more (based on POH fuel burn figures). The catch of course is that the Acclaim can fly at altitudes and speeds that we can't match (albeit at higher fuel flows). Enjoy the new bird! Set your expectations about performance a little lower than book and you'll be happy with what you get. Best, Ed

-

I thought I'd add my recent experience to this thread. My 2008 Ovation is new to me as of 9 months ago and we missed oxygen leaks at the pre-buy. Reason is that the pre-buy shop focused on the expired tank and once it was back in did not have time to catch what turned out to be 2 leaks. A few months later, I suspected a leak based on periodic gage readings. I had the tank filled to 1,800 psi and started charting the pressure over time. It was down to 1,200 over 30 days. The shop did the easy part first which as to open the avionics access panel in the rear fuselage and spray bubble solution around. They found leak number one at a T fitting. They tightened that up and the leak stopped. They recharged the system and yet I continued to notice pressure loss. A month later when we had the interior out for CIES fuel senders install, the shop checked for leaks at the pressure gage fitting and found the second one. They tightened that one up. Pressure has held steady at 1,800 for two months now (up and down slightly for temperature changes). It feels good to clean up a squawk. Best, Ed

-

I'm happy to lend my voice to this thread extolling to virtues of this system. I ordered it in February a couple of months ago, received it quickly and presented it to my shop that had no prior experience with it (LHS system with gear warning option). The avionics-skilled A/P elected to wire it to the AUX circuit of the G1000's audio panel. We tested the audio messages from the LHS system against streaming ATIS to make sure it would not mute out (which it did not). He also wired the power to an unused breaker labeled "Radar Altimeter". We thought "close enough". The installation was relatively painless, given we had the interior out for CIES gages anyway. We mounted the laser in the rear access panel inside the left main gear. As you folks who have this already know, the big win here is the aural altitude callouts during the last 15 seconds of flying. I've flown with it for 15 hours so have not yet really focused on matching up my flair with a specific altitude callout. But what's immediately clear is I no longer bounce the plane on due to misjudged height. I'm rotating when I hear "five" and have arrested my descent when I hear "two". Now, 100% of the landings are at least good, whereas before, 50% were at least good. If you are coming down too fast or in gusty winds, the callouts tell you where you are relative to the pavement. Your hand on the yoke does the rest. My field (KPTK) is at 980 feet msl and so immediately upon touch down I get a "1,000" callout. The A/P riding along with me got a chuckle out of that. I'll be disabling the GPS altitude callout feature soon. Well done Microkit! Ed

-

Ovation 3 fuel flow jumps 1 gph back and forth

Ed de C. replied to Ed de C.'s topic in Modern Mooney Discussion

Looks like we have this on solved. The Savvy guys and John Paul at GAMI said they've never seen this before. We swapped in a new mixture control cable to no effect. Upon advice from Savvy and GAMI, in mid-February I had the shop pull the fuel pump, fuel metering unit at the throttle body, and the flow divider and send out for IRAN. I didn't want to sneak up on this one given the downtime. The fuel shop reported that they found a "bad spring" in the fuel metering unit. All parts went back in and the fuel system was adjusted. First thing I noticed on the test flight was that the "Check Gear" aural warning (and red light at the gear switch) came on at 16 inches of MAP. That's no good since we spend plenty of time at 13 inches with the gear up descending into the traffic pattern or slowing before FAF. I was pretty sure the A/P neglected to set the throttle cable switch for the gear warning correctly. The shop owner suggested I carry a sharpie next time I fly and mark the throttle control where I want the gear warning to activate. I set it for 10 inches MAP, the A/P made the adjustment and we're set. There's still more travel to go so the gear warning will sound as I pull power off to start the flair. Good news is that after 15 hours of flying, the fuel flow anomaly has not returned. Best, Ed -

Ovation G1000 PFD failed at Master On

Ed de C. replied to Ed de C.'s topic in Modern Mooney Discussion

Getting around to wrapping up this story on the dead PFD. I went with a Garmin overhaul of my unit. Probably a mistake, since it cost me about 6 weeks of downtime with the Christmas holidays between Garmin and my shop. They had to reload software anyway, so next time I'll pay the extra $500 for the Garmin exchange to save time. The shop installed the new unit in mid-January. As luck would have it, the PFD was stuck in reversionary mode due to a failed reversion switch on the Audio Panel (G1000 unit). The A/P found it by ringing out the wire harness and confirmed by test-swapping in a known good Audio panel from a nearby DA-40 rental. So, my audio panel went to Garmin, this time for factory exchange. Once that was back in the plane later in the month, all was well. I was observing at the shop as all this was going on. I'm realizing: Stuff just breaks. All we can do is treat the equipment well and hope the failure probability Gods look upon us with favor. Then carry extra cash in the wallet. Best, Ed -

If you want a turbo, get it. When I queried this group 9 months ago about what to get, there were basically two camps: 1) The Ovation should do the job, or 2) you want a turbo. I'm a flatlander in Michigan with no missions out west. But, even Mike Busch says he would not own a non-turbo. I was on the Acclaim bandwagon and called Jimmy Garrison to see what he had and advice. He said, "Look Ed, if you think you'll want to be flying a lot in the flight levels then get a turbo. But if that's not you, let me talk you into an Ovation. The market is 3x larger for Ovations than Acclaims, the cost of ownership is less, dispatch reliability is higher, and below 8,000 feet the Ovation is just as fast." My research indicated that at the same speed/altitude the Ovation will be 2 gph less than the Acclaim (the Bravo will be worse, but less expensive.) The catch is that the Acclaim (and to a lesser extent the Bravo) can fly speeds the Ovation cannot and altitudes the Ovation cannot. But as the turbo guys will point out, don't let my rationalizations dissuade you: if you want the turbo capability, and are OK with the debatable tradeoffs, get the turbo. 100% of the turbo guys say they have no regrets. There are some non-turbo guys that quietly say "sometimes I wish I had a turbo." For me, the jury is still out. Best, Ed

-

I'll bite: is the GFC500 functionally different from the GFC700? Other than the separate box and wheel (probably nice) I would have guessed both work the same. The more I fly the G1000/GFC700 the more impressed I am with it. Truly amazing capability.

-

I can't advise you on the bolt removal, but I can commiserate. I just went through a full gear rigging on my Ovation and it was 3 and a half days of hassle/frustration with my A/P. We found both inboard gear door control horns severely bent to the point where they were contacting the spar. Clearly some prior rigging episode jammed something to cause that level of deformation. 2 new horns on order for $1,500. The leadtime is 8 weeks, so in the meantime the tech straightened the existing brackets (horns) to function. We're OK with that since it's temporary and there's little load on that part of the horn actuating the inboard gear door. As a mechanical engineer, I nodded sagely at my mechanic's proposal. After rectifying that, we had a problem with the nose gear door (pilot side) that would not close completely. It seemed the nose wheel was retracted high enough, but the door link was too long and had no adjustability left to shorten. The tech found that by playing with the washers around the rod end bearings he was able to get the door to close fully. I don't like the fact that we are out of travel, but it seems to solve the problem for now. Other than these two problems, we found that by following the service manual to the letter we were able to get everything to work out. Had it not worked out and we needed, say, more nose wheel up travel, it would have been a miserable process of playing with the nose gear eccentrics and the main gear adjustable spring compressions. The manual is 90% but the missing 10% will tear your hair out. Someone who does gear rigging all the time should offer a supplement. My A/P said my gear was the most challenging he had experienced. Best, Ed

-

As others have said, it's not really a 3. But having recently gone through the purchase process of an Ovation 3 you might want to take a good look at this one. You've got almost all of the functional O3 features for $100k less. Modern glass, GFC500, TKS, 310hp, mid-time engine. Others might comment on how close to G1000 functionality the G3 touch/GTN 750 setup brings you. I'm skeptical of the 1,100 pound useful load with TKS (mine is 933 lbs) but I've got Oxygen and G1000. Based on my speed numbers, his advertised 175 knots on 13.2 gph is plausible (with TKS). Best, Ed

-

HELP - Seating and Interior ideas (desperately) needed.

Ed de C. replied to FlyingScot's topic in Modern Mooney Discussion

Red knob in center is fuel. White ring on right side is the gascolator pull ring. -

HELP - Seating and Interior ideas (desperately) needed.

Ed de C. replied to FlyingScot's topic in Modern Mooney Discussion

I had Hector do a couple of front seat bottom cushion replacements and floor mats. He fit this small project in over a couple of months. The cushions are flawless but it's the floor mats that deserve note (picture). I elected to go with a chocolate brown, and we pulled rearward the Mooney logos. Couldn't be more pleased with the experience and result. Best, Ed -

Thanks Lance - Regarding the orientation, vertical fits nicely while horizontal has a piece of the light housing protruding in front of the Nav light. Either way, my question remains how to attach the light housing to the wing tip shelf. The light housing has no obvious attaching mechanism (no screw holes, no clips or latches, etc.). I assume my 2008 Ovation wing tip geometry is the same as all other Ovations and Bravos that had factory recognition lights. What did you guys do to retrofit?

-

Good afternoon folks - I received two of these replacement recognition lights yesterday for my Ovation and am wondering how to install them. The old lights attached to the wing tip structure with two screws (pictures show this clearly). The replacement lights have no screw mounts but otherwise will fit fine. Do we just put a dab of adhesive to fix the light to the wingtip? Some other method? The light should be removable down the road. Whelen says it's a minor alteration requiring logbook entry. I'm allowed to do that myself, right? Thanks for your comments. Ed

-

5 years? I think we have you covered. There will be lots of well-cared-for airplanes ready for you. We will do our part. Best, Ed

-

Good evening, folks - Bad luck this morning. When I turned on the master for the pre-flight of my 2008 Ovation (G1000), the PFD did not turn on, the MFD did normally and in reversionary mode. Circuit breakers all in. I turned off the master, preflighted the plane for a short reposition across the field to the maintenance shop for scheduled work. I climbed in, turned on the master and same thing (no boot up of the PFD, MFD in reversionary mode). About two minutes later I noticed an odd smell of something electrical. I pulled the PFD breaker, and the smell went away. I called Ground (yep, you lose Com 1 and Nav 1 when the PFD goes out) and taxied to the shop. And I made a mental note to order a hand-held radio for my flight bag. Temp at time of taxi was 20 F, which was my first time starting up this cold (Reiff preheater did its job), but this plane has spent much time in Canadian cold before. At the shop we did several things: After looking under the panel for anything obvious, we pushed in the PFD breaker and turned on the master. No PFD boot and no key lighting (MFD booted and keys were lit as before.) 2 minutes in, we noticed the same electrical burnt smell. Master off, and the tech pulled the PFD screen out. Burnt smell was noticeable at the PFD-side connector and the harness-side connector. All pins on both sides of the connector looked normal. The tech opened up the harness-side connector and saw no evidence of a problem. With the phone advice of another tech, we pulled the MFD display and plugged it into the PFD harness connector and turned on the master. The MFD fired up to the initialization screen and we shut it off quickly, not being sure what software confusion would occur with this experiment. This result meant that the harness was supplying power, and that the dead PFD screen was the fault of the PFD display itself. The MFD went back into its normal spot and fired up normally as before. So, it looks like I have a dead PFD display. There was some shop talk by the avionics guy of opening the unit up and looking at the power leads inside for an easy fix, but others were not sure that was legal. My contribution was to say that whatever we do has to be OK from a paperwork standpoint. Is this a simple bad luck case of me needing to pony up for a refurbished PFD display (Garmin exchange presumably) or is there some other option? Until the shop calls Garmin for options, I have no clue what I'm looking at. Anybody else encounter a dead PFD display like this? Obviously glad this did not happen when starting a trip (or worse). Ed

-

Ovation 3 fuel flow jumps 1 gph back and forth

Ed de C. replied to Ed de C.'s topic in Modern Mooney Discussion

I see the images did not load in order. Hopefully you can tell that #1 and #3 go together and #2 and #4 go together. Ed -

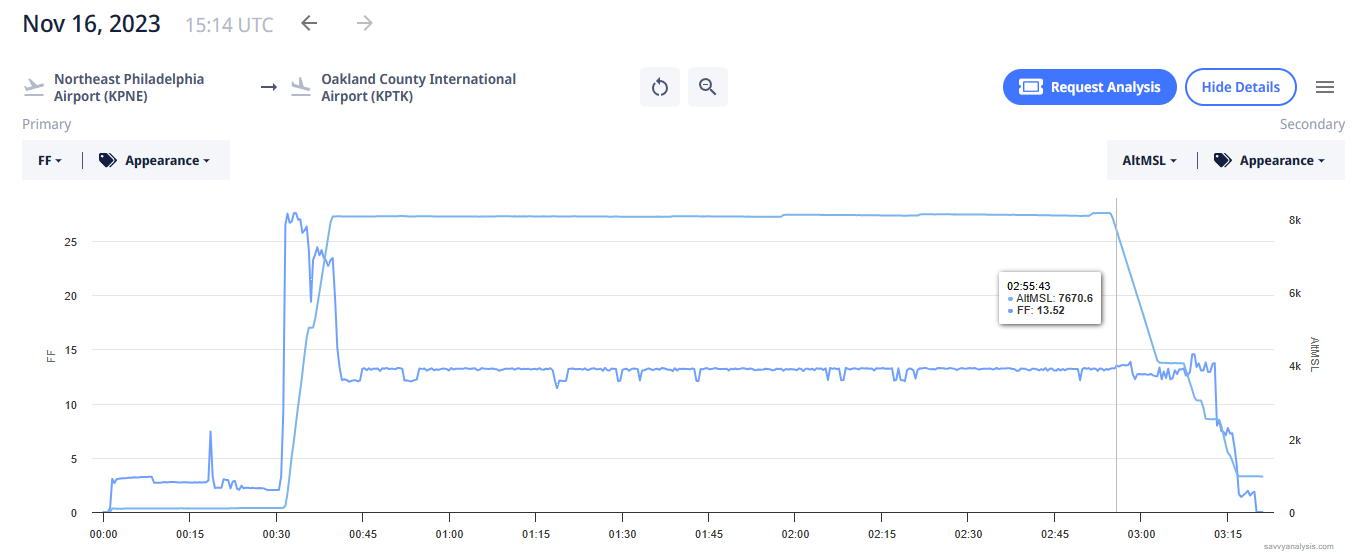

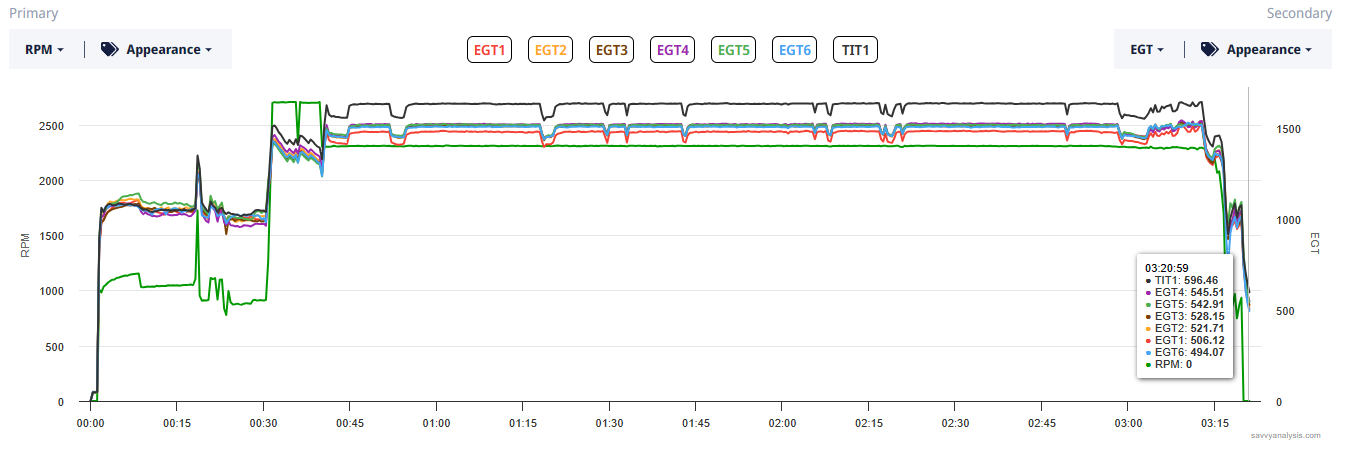

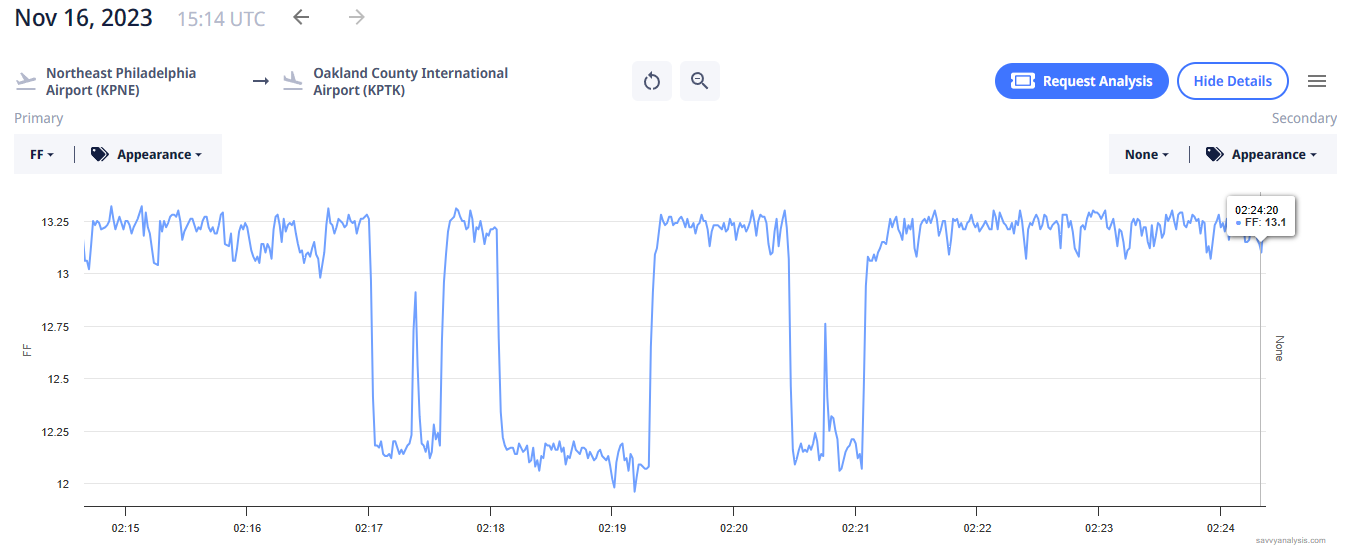

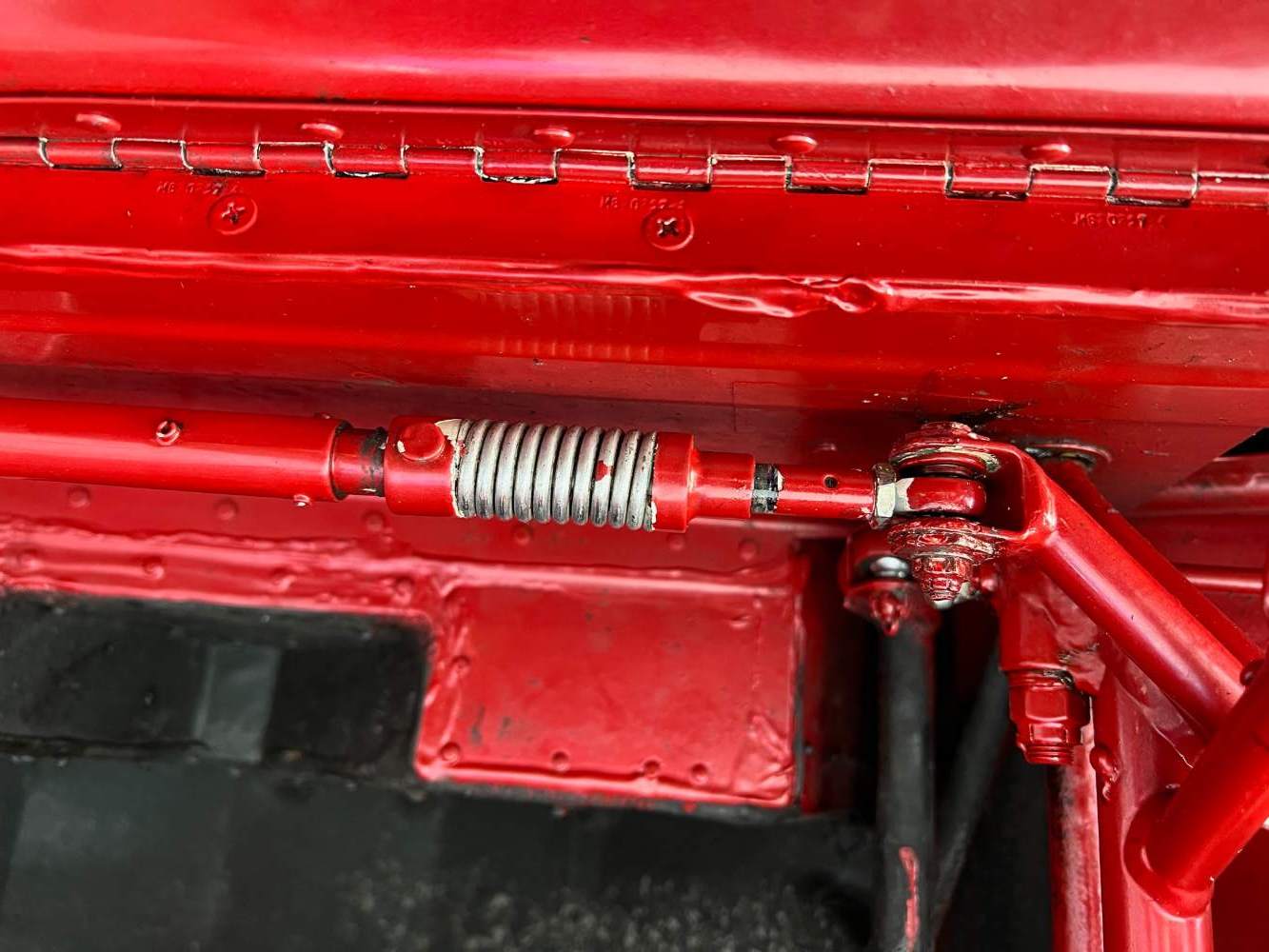

Good evening, folks, I thought I would run this odd fuel flow situation by the group in case anyone has seen this before. It seems to be different than what others have reported in fuel flow fluctuation posts in the past. After leveling off for cruise and setting LOP mixture, I'm getting significant fuel flow fluctuations of up to 1gph. When I first noticed it on one of the first flights since I owned the airplane in September, the fluctuations tended to by "spiky" downward of varying amounts up to 1 gph. Now, the traces are not spiky but step changes upwards and downwards by 1gph. The dwell after the step change is variable. (pictures of engine data are attached). It's definitely not instrumentation since I can feel it and the EGTs and RPMs react in each case. The step changes have gone from one or two in a 2-hour flight a month ago to quite frequent 2 weeks ago (seems to be getting more frequent). Disconcerting. There was some shop work done between the "spiky" excursions and the now step function excursions: Adjusted max rpm up to 2,700, adjusted idle low speed down to 650 rpm, installed set of GAMI injectors, lubricated all control cable ends. It's a 2008 Ovation 3 (G1000) with IO-550-G with 310 hp STC and 150 hours on the overhauled engine. 2,000 hours on the airframe and control cables. The mixture knob has some play in it, meaning I can push/pull on it maybe 1/16" to 1/8" (throttle and prop controls have zero play). I tried that in flight and the gph change per engine data was minor, maybe 0.4 gph). There's also some lash at the fuel control unit at the other end (unfortunately, I cannot attach the video of the movement). We also notice the bracket holding the mixture cable end at the fuel control unit is surprisingly flexible (much more flexible than the setup in the Cirrus models in the shop.) It's a 2-piece bracket assembly and it's the piece attached to the accessory case (not holding the cable) that flexes. That flex appears to cause movement at the fuel control unit lever arm, and when combined with the cable lash, the lever arm can move quite a bit (maybe 1/8" or more) with no movement in the cockpit. Savvy looked the data over and said they've never seen this sort of trace before on a Continental. It's as if something is bouncing from one limit to another. Our combined best thinking is to replace the mixture control cable and go from there. We'll look at the attaching bracket carefully for any cracks that might explain its flexibility. If that doesn't fix it, maybe IRAN the fuel control unit next. Have any of you seen something like this? Ed Pictures 1 and 2 are of the complete 3-hour flight, the step changes are apparent and uncommanded. Pictures 3 and 4 blow up one portion to show the moves in more detail. RPM overshoot is evident along with EGT reactions. All uncommanded.

-

I thought I'd put a wrap on this thread and tell you all where I landed. After talking to Jimmy Garrison back in June, I selected an Ovation over an Acclaim. I think he had wise advice: "Ed, if you plan to fly in the flight levels a lot, then get an Acclaim. But if that's not you, let me tell you about the advantages of an Ovation." I took a good look at my Michigan-based missions and decided that an Ovation with TKS would probably be the best fit. (More than one of you hinted at that answer.) I settled there knowing there would be times when I wished I had a turbo. After that, it was a matter of deciding on the must-haves and nice-to-haves and searching. I put TKS and the Garmin GFC-700/500 high on the list. There was a good-looking Canadian 2008 Ovation 3 out there, but I hesitated to wade into the import unknowns since this was my first purchase. The advertisement for that airplane changed to say that the seller would procure a U.S. N-number. At that point, I figured a bunch of unknowns/risk would be eliminated, so I drove to Oshawa Ontario (the east side of Toronto) to have a look. That was mid-June of this year. I was a bit surprised that the selling broker did not clean the airplane either outside or inside. Any car I've ever sold was detailed to put the best face forward. Much oil on the belly, grimy interior, lots of chipped paint... I almost walked away. Fortunately, I realized I needed to look past the cosmetics that a small amount of money and/or elbow grease would solve. The good bones were all there, including all the options I could want: WAAS, G1000 w/GFC 700, Oxygen, SVT, TKS, 310 Hp STC. It had 1,900 hours on it and the engine and prop had been replaced 100 hours ago due to an unfortunate encounter with a taxi way sign. I quickly learned that the plane had been maintained by our colleague here M20doc during its 6 years in Canada. I visited his shop near Toronto and had a great conversation about the plane and his business. He was sad at the prospect of seeing it go back to the States. I offered the broker a hair less than his asking price and sharpened the text of what the seller was going to do for the import process. This is a good place to say that I was very glad I was dealing with a broker, for several reasons. One is that there is no seller's emotion about parting with the airplane. The other is that this Canadian broker was experienced in exporting planes to the U.S. and knew the steps. Somewhere along here, my accountant and attorney both advised me on how to setup a company structure to own the airplane. It's pretty clear that most liability cannot be escaped if the owner is the pilot, and he/she screws up. The tax advantages are another matter. Most of my flying will be for business and charity. My accountant, an airplane owner himself, explained the dry-lease concept, SIFL rates, and accelerated depreciation. Some detailed spreadsheet work on my part was compelling. The record keeping is a hassle, but the savings is going to be worth it in my particular circumstance. Forming the company structure with the help of my attorney (and accountant) was a learning experience but went smoothly. There are pieces with the Feds and my state. Back to the airplane, where to do the pre-buy was an early question. The broker had recent good experience with a New York shop about 45 minutes across the border. I had contracted with Savvy Aviation to help me with the pre-buy and they green-lighted the broker's preferred choice. In mid-July, I rode along on the ferry flight from Oshawa, Canada to Jamestown NY to run a couple of Savvy engine checks and confirm the autopilot worked and all other advertised options and systems were OK. I caught a ride back with the ferry pilot and his chase plane comrade so that I could pick up my car in Oshawa and get back to Detroit. The experience of trying to get customs clearance back into Canada was miserable and I wouldn't wish that on anyone. By contrast the ride into the U.S. via entry at Buffalo was simple and efficient. It took a month to get from first view of the airplane, through offer, acceptance and negotiations, including where to do the pre-buy, getting on the shop's schedule and getting the plane to the shop. The NY shop was great, but shorthanded and so the pre-buy was slow to get going. Both the broker and I pushed. Being a 5-hour drive from Detroit, I made the trip 3 times to poke around and keep some gentle pressure on. The pre-buy punch list was 50 items long. I was surprised at what was considered an airworthiness item (a leaking baggage door seal?) but was counseled to go with what the mechanic says. Airworthiness items were to go to the seller, and I would handle the rest, many of which were cosmetic. The seller balked at replacing the expired oxygen tank (we settled at splitting it 50/50) and pushed back on some fuel seepages and TKS panel wet out failures. Minor items I could live with (at least I figured that at the time). Once the pre-buy was complete and the seller and I agreed on who would pay for what, we moved into the second phase which was the import process. That revolves around getting a fresh airworthiness certificate from the FAA. Which means the DAR. This NY shop had lots of experience with importing airplanes and had a good relationship with a DAR to do that. Basically, they do an annual. There was little risk of something new coming up after the thorough pre-buy, but if it did, it would be on me. Most of the costs of the import process (customs, annual inspection, DAR fees, N-number application, etc.) I negotiated that the seller would pay for. But fixing annual discrepancies was a grey area. The seller and I split the cost of the escrow with the Oklahoma company, that the broker had experience with, and the escrow process proved painless. The escrow company knew all about imports and handled the FAA interactions flawlessly. While the shop was scheduling in the DAR, I was scheduling flight training with Mike Elliott's team. My insurance through AOPA only required I get a checkout in make/model with a properly credentialed flight instructor (because I had 200 hours in an M20J previously). Scheduling pressure meant that we started to run out of time to chase down all the items on the pre-buy that were deemed to be optional. There were a few items flagged that I failed to take seriously enough and now I'll pay for: the nose gear would not retract fully and an erratic right fuel gage reading. These were not items that prevented getting the new Airworthiness Certificate we needed from the DAR. Back to these in a minute. We got the DAR signoff in early-September. The rest of the punch list was finished up and the shop owner (a long-time Mooney pilot) flew the plane just before I and Mike Elliott's guy were scheduled to fly it away for training in North Carolina. He caught a glitch or two (setting up the transponder for the new N-number). I flew the plane away in mid-September, 3 months after seeing if for the first time in Canada. The flight training with Sam (Mike Elliott's guy) was money well spent. He and I met up in NY to pick up the plane and he quickly spotted a frozen static system drain. Seems the prior owner never actuated it. I had the NY shop order a new one after the shop was unable to unfreeze it. When you are looking at the cost of this kind of training, you get creative and Mike helped me realize that it might be most efficient to fly to Sam's home base in North Carolina and train there. That happened to be in the beautiful western North Carolina mountains, mountains being something I had no experience with. As you folks already know, it's all about the approaches and landings in a long-body Mooney. Sam had me target initially 80 knots on final and run full up trim in the flair with power reduction to idle. It took 8 or 10 practice landings to get it down. The other work of instrument approaches was routine since I had recent time in a G1000 setup in DA-40s. Now I target 72-75 on short final and continue to get the landing distances down below 3,000 feet. Now, having the plane in Pontiac, Michigan since mid-September, it's been about sorting out remaining squawks and working up to actual IMC flying. The night lighting is exceptional compared to other small planes I've flown (the DA-40 was terrible). While I found the DA-40 at night was more difficult to judge the flair and land smoothly, I've found the Ovation to be just as easy to land at night as during the day. The GFC-700 is fabulous, meaning it is intuitive and competent with approaches. I continue to learn the G1000 capabilities, especially with flight planning. Once I figure out Vertical Nav, I figure I'll qualify for some sort of prize. My next step is to fly actual approaches in IMC and then put night and IMC together. We are beginning icing season in Michigan, so these risks (night, IMC, Ice) need to be handled carefully. The remaining squawks are significant but I think manageable. The first is to clean up the gear rigging. Back at the pre-buy the shop mechanic said he could not quickly sort out the nose gear retraction due to fighting the down preload. As we were running out of time, I agreed to table it for a future time. I'll need to pay for a complete re-rigging. That erratic right fuel gage turned out to be interesting. The pre-buy mechanic couldn't replicate the problem he had originally spotted, so naturally I pretended it didn't exist and agreed to move on (time was short after all). Well, on the early flights I made the gage acted up. I mentioned it to my local mechanic in Michigan and he had a look with a borescope. Turns out the right-side inner fuel sender is weeping slightly with fuel staining at the bulkhead and contacts. A set a nifty CIES digital senders and labor to install will run around $6k. But, hey, it's an improvement, so it's in New Math territory... I was having trouble running much LOP so I popped for GAMI injectors. Funny, the injectors they ship out appear to be identical. Regardless, the results were notable: I could run much leaner, and the engine was smoother. We think two should be tweaked and GAMI is sending them out. A new head-scratcher is a weird fuel flow fluctuation I'm seeing in cruise. The FF will jump up 1 gph un-commanded. Then often jump back down the same 1 gph. It looks digital, bounces between 12.2 gph (my initial setting at level off LOP) and 13.2. Nothing in between or beyond. The variable is how long it parks before it moves again. I feel it and the EGTs move commensurately, so it's not instrumentation. Savvy is scratching their heads over this one. There's some play in the mixture linkage both at the fuel control unit and in the cockpit. We suspect the red knob is allowing excessive lash and will start there. We had a curious wing walk delamination on the ferry flight down to New York. The wing walk had been patched (the forward 2 feet or so). After the flight, 30% of the patch had peeled back. I had the whole thing removed and replace with a single piece. Looked beautiful at first. Then after filling the tanks and departing for North Carolina, I noticed a bubble under the forward section. I thought, "C'mon guys, didn't you get the air bubbles out when you glued it down?" Well the bubble got bigger until at some point it oozed out under the door. Damn! Fuel smell. There's a fuel leak that ate away at the prior patch causing it to peel away. I cut away pieces until I found the offending screw that was leaking. Should be a quick fix. I've made plenty of rookie mistakes in my first 30 hours of flying the Ovation. Not putting the mixture in all the way on takeoff (luckily the baffing is good and the CHTs normally run possibly too cool), botched ATC instructions, climbing past 3,000 AGL with the gear and flaps still down on a miss approach, and one time not latching the baggage door. Sure enough, it popped open on takeoff and the signal was the cold breeze on my neck. I kept speed low in the return pattern, landed and did the walk of shame to jump out and latch the thing at the runup area. Now I know why the door didn't fit very well from the beginning: seems I'm not the first guy to do this. That slipstream load bends the hinge slightly. Each goof causes a new entry on my checklist. I watch that gear down indicator like a hawk and triple check I haven't left the sidewinder tug attached to the nose gear. I recently ran a couple of interesting test flights: the service ceiling and altitude lost turning back to the airport after a simulated engine failure. For the service ceiling I strapped on the oxygen and took off with throttle and RPM full forward (2,700). The results at each 1,000 feet of altitude is shown below. I was fairly light (2,900 lbs) and the day was a little colder than ISA. My climb performance at 120 knots was substantially better than 280hp book (Ovation GX2), to be expected with the 310 hp upgrade. When I pulled back to 105 knots at the higher altitudes, the climb was only a little better than 280 hp book. I leveled out at 22,000 feet. The MP on descent was a bit higher than on climb indicating some ram effect (around 0.5 inches). For the engine out simulation, I setup the configuration at a 120-knot climb (gear and flaps up) and chopped the power to idle at a specified altitude. I allowed the plane to continue climbing (and turning back) until the indicated airspeed hit 85 knots, then held 85 knots. A road below was my simulated runway so that I knew the series of turns that would be necessary. By the time I got re-aligned with the road in the opposite direction I had lost around 800 feet from when the power was chopped. That tells me I really need 1,000 feet of altitude to be confident of making it back to the airport. I can only imagine what goes through your mind if an engine failure on takeoff happens for real. Also, I now know about the built-in gear down aural warning and wonder how any of us are landing gear up (if we are). My hope is that some of you will find this informative and/or entertaining. Consider it small payment for all that I’ve gleaned from the group over the past year. Best, Ed Service Ceiling test data.pdf

-

How to Mute Avidyne TAS system on G1000?

Ed de C. replied to Ed de C.'s topic in Modern Mooney Discussion

The answer to the annoying traffic alerts on the ground turned out to be simple. After some recent maintenance, I noticed that the mechanic had pulled the traffic alert breaker. Bingo. I'm now taxiing to the runway with the breaker pulled and push it in just before taking the runway. I pull it after landing. I put one of those colored rings on the breaker to spot it easily. The yoke mounted mute switch deals with the short final alerts. Ed -

How to Mute Avidyne TAS system on G1000?

Ed de C. replied to Ed de C.'s topic in Modern Mooney Discussion

Hello M201MKTurbo - I cannot find this setup menu in the G1000. Can you please give me some direction there? I tried the Aux pages but there's nothing there about alert volumes. Neither is there any softkey action on Map/traffic page. Much appreciated, Ed -

How to Mute Avidyne TAS system on G1000?

Ed de C. replied to Ed de C.'s topic in Modern Mooney Discussion

Sure enough, the TAS button on the yoke mutes the Avidyne traffic alert (hurray!). Now if I can turn down the alert volume I'll be set. As I take a microfiber rag with interior cleaner, I'm discovering all sorts of easter eggs, like how to fold down the rear seats, an obscure music in jack... Good input guys, like adding USB outlet on the pilot's side, not just the cigarette outlet on the passenger side. First world problems. Best, Ed -

How to Mute Avidyne TAS system on G1000?

Ed de C. replied to Ed de C.'s topic in Modern Mooney Discussion

Hmmm. I was thinking of posting a question about what this odd button on the yoke labeled TAS might be. Sneeking suspicion that is my mute button right there. I'll test it out shortly and see if that answers my question. -

Good evening folks - I'm slowly getting to know my new Ovation and one annoying feature is the frequent alerts I get from the Avidyne TAS 600 system for traffic on the ground or close by when I'm on short final to a busy tower-controlled airport. Is there a way to mute these alerts? Not only are they frequent, they come through painfully loud unless I dial back the headset volume control. I have a 2008 Ovation 3 with this system onboard and G1000. Evidently this plane was built without ADS-B in (it has the GTX-33ES transponder), and the Avidyne is how traffic comes in. I've scoured the Avidyne manual. It makes reference to a mute button (if equipped). The manual pictures show such a mute button on an optional dedicated Avidyne display but says nothing about a G1000 setup. There is a mute softkey on the G1000 MFD traffic page but it does not mute the Avidyne alert. Does anyone know if there is a way to temporarily mute the audio alert? Thanks, Ed

-

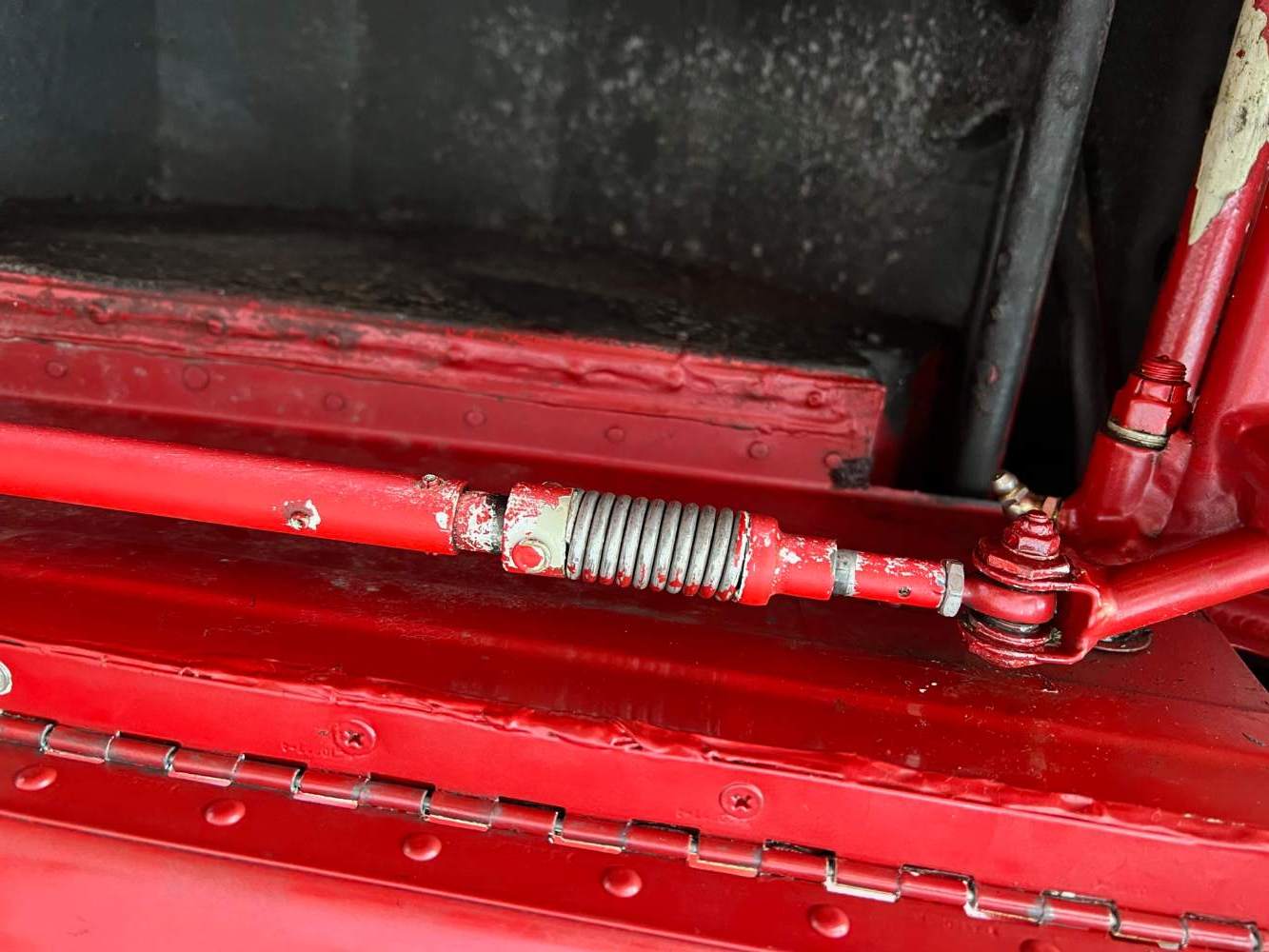

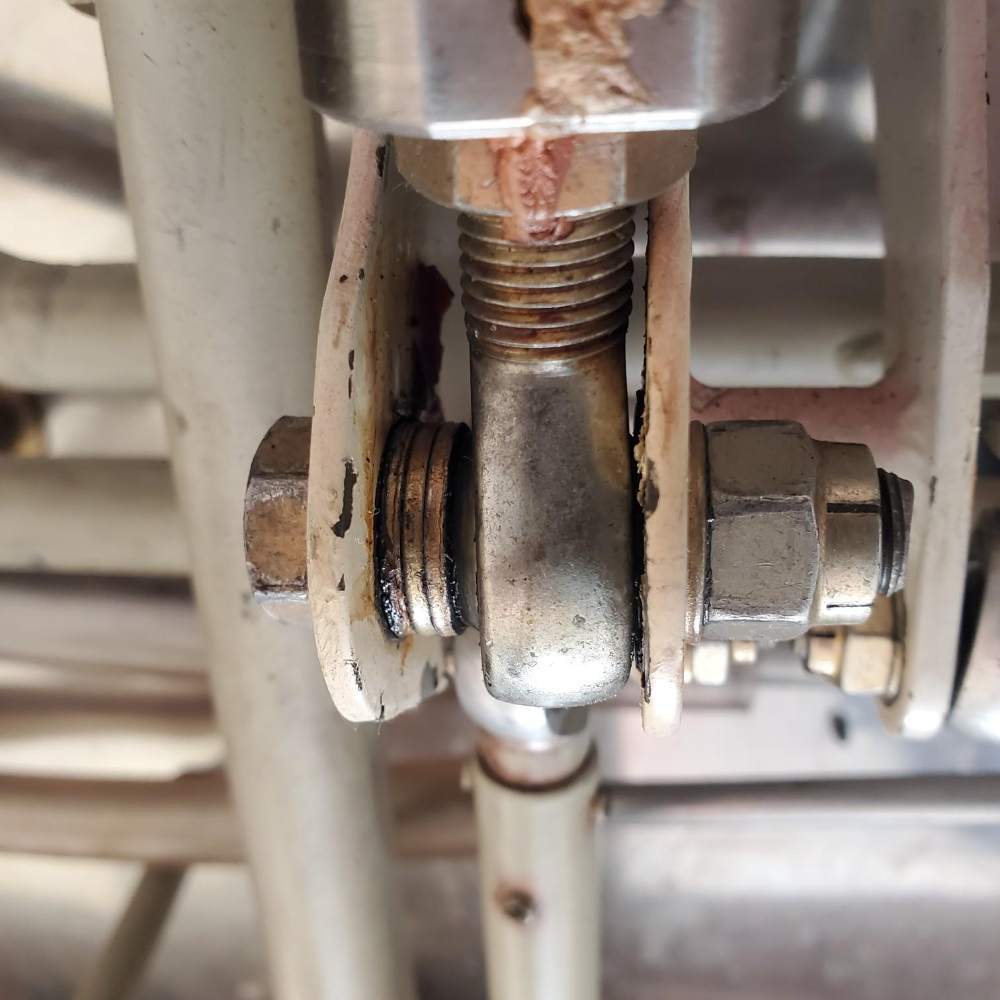

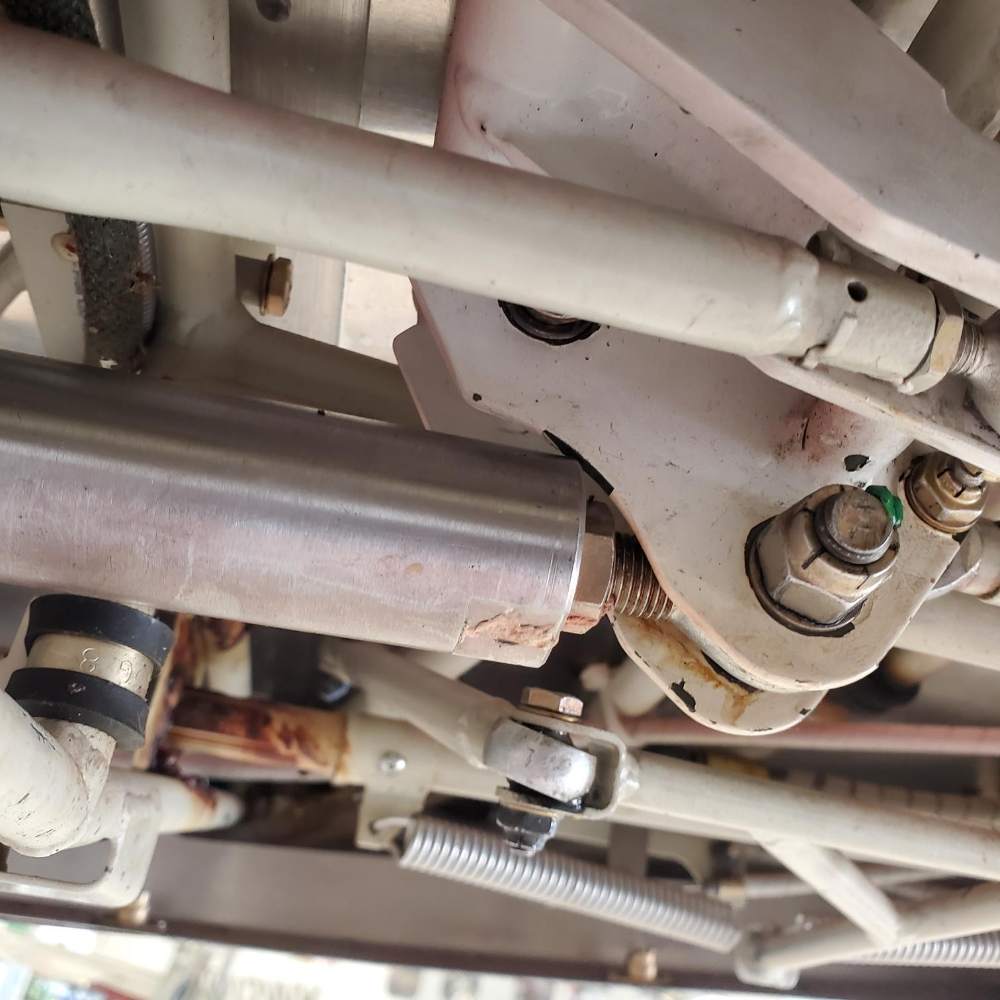

Good evening folks - I just got my new-to-me Ovation home to Michigan yesterday There are a couple of remaining squawks from the import and annual inspection process done at a NY shop that has Mooney experience but not a ton of it. The main thing being that the nose gear does not retract fully into the well leaving the doors partially open. This might explain a part of the 7 - 10 knot speed deficit against book I reported last month. I'd like to tighten this up. The nose wheel is not going all the way up on retraction (which is keeping the nose gear doors slightly open). Photo’s attached. The eccentrics at the rod-end bearing on both “F” tubes are adjusted full up. 2 photos attached. Both left and right gear tubes F rod end bearings are turned fully in (short) to get downlock tension within limits. As a mechanical engineer, this is a red flag to me. The mechanic tried lengthening the tubes (turning out the rod end bearings): one turn brings the nose gear up sufficiently to close the doors but the downlock tension falls out on the low side of limits by a significant amount. At the other end of the tubes inside the belly the mechanic reports: “I did find that when the MLG actuator was reinstalled that they didn’t properly shim the rod end to the bell crank attachment allowing for interference/contact see attached pictures for details. I have corrected this shimming issue so that the shaft housing is no longer contacting the bell crank housing when gear is fully retracted.” 2 pictures attached. Our sense is that something is adjusted wrong deeper in the system, causing the nose gear rod end bearing to have to be fully turned in to work. The mechanic advises we find a Mooney expert that does gear rigging frequently (he doesn’t) and would know where to look for the problem. We know that at one time the fit was tight based on paint wear on the doors and some wear on the bearing threads. I've been given a couple of names in Minnesota (Benson at KBBB and Wilmar at KBDH) and of course Don Maxwell. Unfortunately, Savvy tells me that Don does not work with Savvy and I'd like to keep Savvy in the mix. I'm in Michigan and would certainly welcome advice as to where to turn to for expert handling of the gear. I hesitate to throw this at my local shop who sees a few Mooneys now and then. Your advice is certainly appreciated. Best, Ed

-

Good evening folks - I'm sure this has been posted before but nothing comes up searching on "maps". How are you all creating those cool maps showing where you've landed? It's not a feature in Mooneyspace directly. Thanks! Ed