Tim-37419

Verified Member-

Posts

184 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Tim-37419

-

Very nice. This should be a quick sale.

-

Lightspeed headset special offer

Tim-37419 replied to NotarPilot's topic in Miscellaneous Aviation Talk

I think Vance is on to something, in my plane, if I have the side window open while taxing I get the popping. Close the little window and it goes away. -

New orings 100% solved the issue.

-

They are but I can't tell if they were o-rings that were crushed in to that shape over the last 40 years or if they are supposed to be xxxxxx - someone help me with the proper geometric term. Certainly a cheap thing to try though, I'll source some orings and give it a try. I typed the above yet never clicked submit. I'll try both orings and an alternate material like felt or leather. Either of those makes a lot of sense now that I think about it. I will report back with what I learn.

-

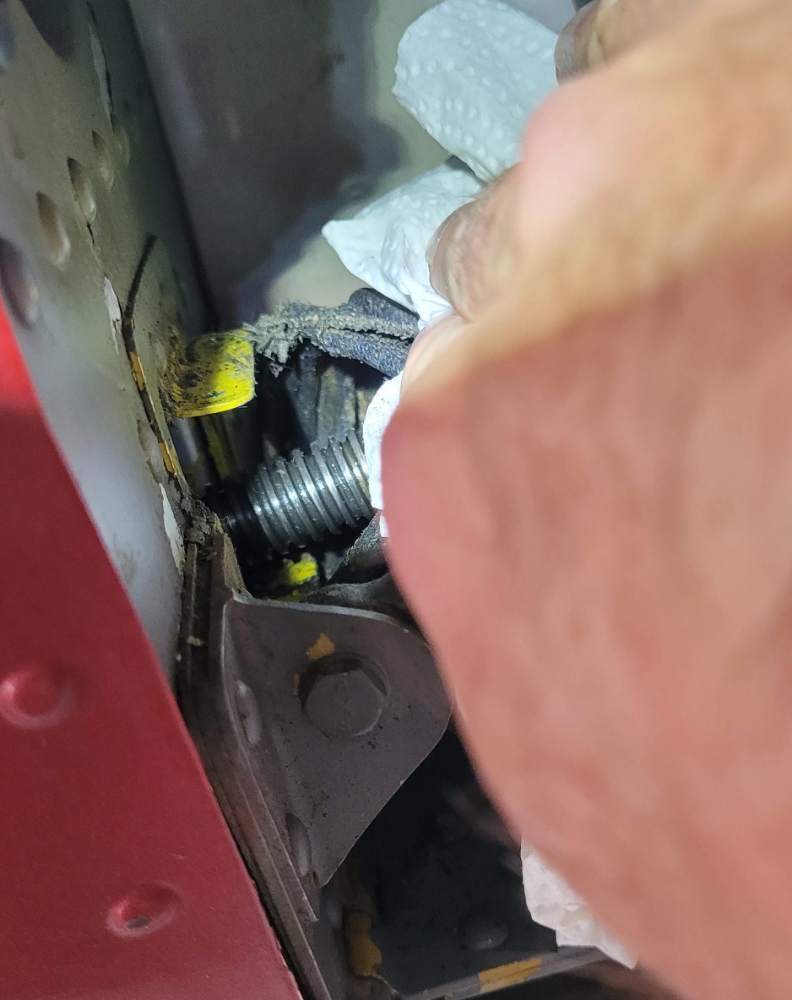

Found a similar thread in the pre J section but the description doesn’t match the parts on my J. My throttle doesn’t lock anymore and I only found the entire assembly in the IPC. MacFarlene said they don’t have a rebuilt kit. Certainly I’m not the only one who has a worn out throttle. Is my only option to buy a new one? photo attached.

-

I just noticed that my last annual, the airframe logbook references an annual, but the engine and the prop logbooks reference a 100 hour inspection. Does that sound right to everyone?

-

Yes, there is a thread barrel connector! I'll definitely do that, thank you.

-

Yes except when cold, then a little higher.

-

My JPI oil pressure indicator has been jumping around the last couple months. The analog gauge (also in the video) is where it usually sits when the engine is warm, it is approx 10psi higher when cold. I don't remember what phase of flight I was in but my oil temp is normally 10 degrees higher than what you see in the video and holds steady (unless in a long climb). I head in to annual in a couple weeks, interested your opinions. I have 1600 hours on the engine in case that's relevant. https://photos.app.goo.gl/vHWxTJziByg1M8s58 Tim

-

This was all I needed to know - This AC is not mandatory and does not constitute a regulation.

-

-

-

-

-

I do have a bit of play in the trim wheel now that I know it’s not supposed to be there it will annoy me until I fix it :-).

-

Success! Removed the rectangular access panel took out the top two cloth sleeve screws, I couldn’t get to the bottom two. Jack screw looked dry but not 30 years neglected dry. greased it up and sprayed the bearing or maybe it was some sort of sleeve that goes through the bulkhead with tri flow. run the trim full up and full down twice reapplied grease ran the trim again reinstalled cloth sleeve. Definite anxiety over dropping the tiny screws but didn’t happen. Helps to have slightly magnetized screwdriver. reinstall panel clean up treat myself to fast food lunch thats a great day. I took a few photos for Rob that I will post later. Thank you to all who chimed in.

-

Will do @rturbett I found the answer to my cloth sleeve question in a thread titled “68 M20C trim jack screw cover” In a nutshell, yes it’s removable but no, I should not expect to find an OTS replacement.

-

Not making much progress other than emptying my can of trilube. I have not yet removed the belly plate but everything I’ve inspected has the appearance of being maintained (ie greased). I am not washing away grease with trilube btw. I did notice the chain on the trim wheel as a bit of slack (which I would expect) but the chain on the electric trim motor in the tailcone is very tight. I checked the service manual, I can’t find anything more specific than “re-tension drive chain” Does anyone know if the chain should be tight or have a bit of slack like pretty much any other chain drive I’ve ever seen? Also, is the aft jackscrew inside a cloth sleeve at a rearward bulkhead behind an access panel? Not sure how to get in the sleeve and I do not want to tear a 30 yr old sleeve that I probably can’t replace.

-

At which point you will get very hungry

-

-

@larryb - could you help me find that in the IPC? I searched section 27 but came up dry. I'm 180lbs, can I lay in the tailcone? I'm assuming the bearing is way back there somewhere.

-

Lightspeed headset special offer

Tim-37419 replied to NotarPilot's topic in Miscellaneous Aviation Talk

@NotarPilot room for another? -

Yep, I do have a BK AP. Thank you all for the tips. I have my marching orders.

-

The cost of annual maintenance thread triggered a thought for me. During the cold snap, my trim was so stiff that I immediately landed. To adjust the trim I needed to hit the switch and turn the wheel. It seems cold soaked below freezing is when it gets bad. Non freezing cold to include entering below freezing temps at altitude is fine. I found some old threads that implied it's not uncommon and something to keep in mind of you live up north. Should I give the squawk to my A&P during annual? The shop is not a MSC and I want to avoid them fixing something that isn't fixable (and then me paying for it) Thx!

-

ASPEN MAX page select missing

Tim-37419 replied to anthonydesmet's topic in Avionics/Panel Discussion

@anthonydesmet page 2 is traffic and weather, page 3 is SVT, I think you are right - you have lost your unlocks.