-

Posts

1,468 -

Joined

-

Last visited

-

Days Won

13

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Marc_B

-

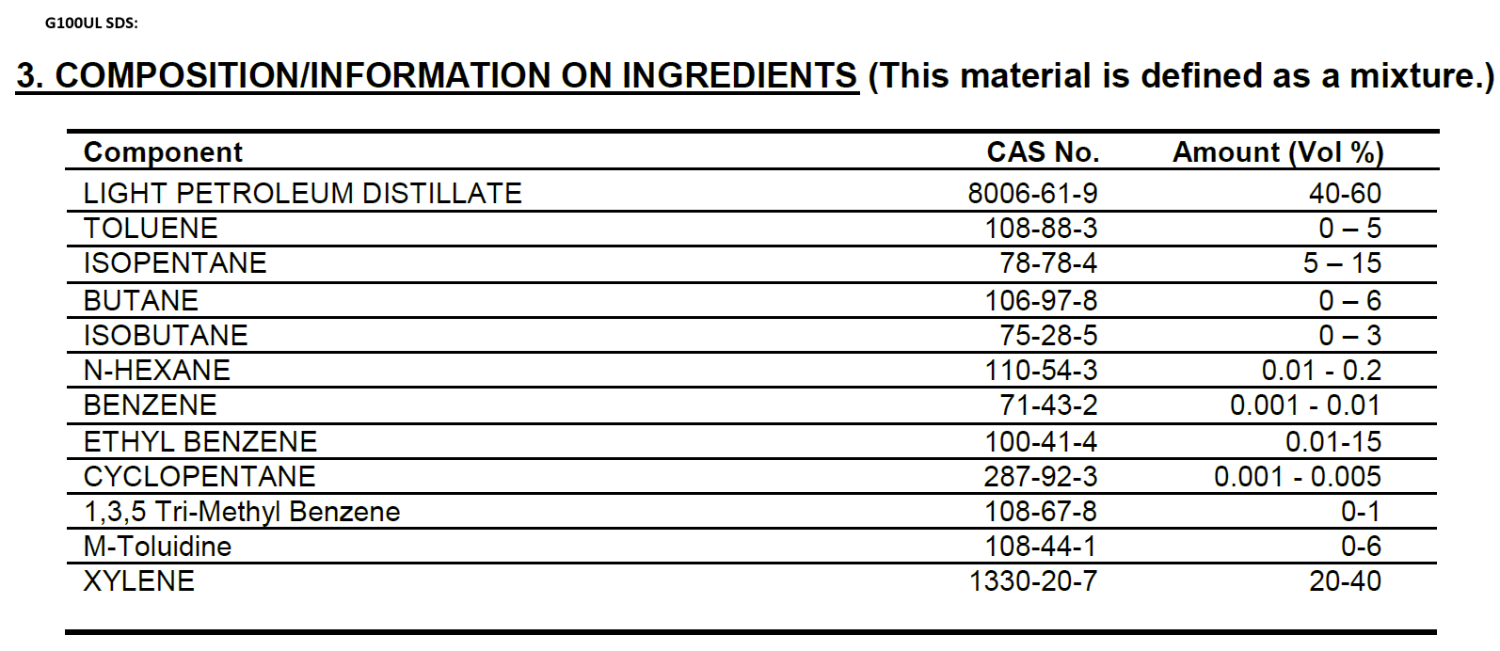

That's what was implied, but toluene isn't the only aromatic in aviation fuel. "Low boiling aromatics, which are common constituents of aviation gasolines, are known to affect elastomers to a greater extent than other components in aviation gasoline." In place of lead, G100UL uses increased amounts of aromatics (predominantly xylene, but also uses toluene, m-toluidine, and others) for octane. Unfortunately, for proprietary reasons, the composition of this fuel isn't shared openly or with it's users. Production Detail Hydrocarbon Analysis results are just listed as "Satisfactory" if it conforms to GAMI's standard and it doesn't appear these are shared with distributors, FBOs or end users. Mr. Braly's comment was also made with an example of 29% toluene from 2010, but my question is does this reflect current 100LL available at the pump? If overall aromatic concentration in G100UL is higher than 100LL, how does this affect seals/sealant/paint in the short term and over the life of an airframe? I think Mr. Braly is asking us to make a comparison that I don't feel we've been given enough detail to actually understand. GAMI performed limited testing in development. But there has not been extensive airframe testing across the fleet in vivo that covers the wide range of airframes and equipment, in the complete range of standard engine use in practice, and with older equipment with a variety of construction and maintenance over the years. We’ve also not seen any longitudinal tests over engine TBO or life. Perhaps for clarity instead of saying "Beta" testing, the more specific term is "end-user testing."

-

So if I understand this correctly: The four major distributors of aviation fuel in California are Avfuel, World Fuel, TITAN, and EPIC. GAMI is working with Vitol to mix ~1 million gallons of G100UL. California's use of 100LL annually is ...gallons per year (?) (edit: link from EIA ~60,000 gal per day??) Previous Consent Decree with 26 FBOs (9 out of business or sold) being used to say when an unleaded fuel is commercially available to distributors, that all distributors in California have to stop selling 100LL in California. Commercially Available definition being pushed is that an unleaded fuel "is commercially available" when an FBO can call Distributor (Vitol) and order Unleaded AvGas (G100UL) and have it delivered. https://www.avweb.com/aviation-news/g100ul-court-action/

-

But this raises an interesting distinction. Development of a usable fuel substitute is much different than the large scale refining, mixing, distribution and testing/quality control of said alternative fuel. So the wrinkle is that G100UL forgoes the standard certification process that's inherent in much of the refining, processing and distribution of typical fuel sources. If you unplug from the "system", it's apparently difficult to develop your own distribution process or else G100UL would already be widespread. (and especially if your product is likely more expensive than the local alternatives) EDIT: G100UL does spell out several ASTM testing criteria for their fuel and has a fuel spec linked below that appears very similar in content and form to the ASTM standards. "In general, each producer of each production batch of Grade G100UL avgas and each entity involved in the transfer, distribution and ultimate retail sale of Grade G100UL avgas shall, unless otherwise contra-indicated, conform to industry standard practices consistent with the historic production, distribution and quality assurance practices applicable to the production, distribution, and retail sale of ASTM D910 100LL." https://www.g100ul.com/dl/06-9690000 Rev 12C9.pdf "Evaluation of results of detailed hydrocarbon analysis (DHA) for full compliance with this specification is reserved for Production Approval Holder. See Appendix X1.8 for additional information" "Evaluation of the DHA is conducted by the PAH (GAMI). Results will be provided to the producer. If satisfactory, the results for Table I, line 25 will be reported as “Satisfactory.""

-

The Type Certificate for my aircraft says: "100LL or 100/130 octane minimum grade aviation gasoline". 100LL is actually a 100/130 fuel. The ASTM D910.(year) just is a fuel specification so that when a distributor receives a batch of fuel it has been certified and tested to conform to a standard. This standard does allow variations in content and so some fuel may have different amounts of components...but it conforms to the ASTM D910 standard for leaded aviation fuel. ASTM in the way we use it is a quality assurance standard. They have specs and testing procedures that insure that the fuel conforms to a standard anywhere you purchase it. The FAA sets the standard...ASTM just insures that the standard is met. I don't care where or how my fuel is certified, but I very much care that the fuel I purchase meets a standard. I wouldn't want hot rod joe mixing up my 100UL and my FBO passing it off as AVGAS.

-

@Vance Harral sounds like when I got back into flying after 10 years off...I flew with a CFI probably 5-6 sessions (in air, not counting ground time and I also requested a night flight) before he signed me off on a BFR and I was upfront with my intention for training to get me back where I was and not just a signature. So maybe an Instrument Proficiency Check turns into Instrument Proficiency Training which finishes as an IPC...not necessarily on the same flight or maybe even the same day. By "minimum," I mean the basic requirements for completion, not the size of the list.

-

One other thought...A checkride vs an IPC are two entirely different things. Given that the FAA doesn't require a DPE to conduct an IPC, it is my opinion that the intent is different. Flight check as well as instruction; same idea as BFR. Meaning when I fly with a CFII for an IPC, as a customer I'm expecting to demonstrate elements of proficiency, but I'm also expecting to learn things and brush up on things as well.

-

That's a very important point. This is an interesting point. I've completed a couple IPCs with a CFII even though I was IFR current, not primarily for the checkoff, but rather as training and maintenance of proficiency and to reset the clock so to speak. I certainly understand the difference of basic components and requirements of an IPC to reset currency after a lapse as a minimum requirement of entry into the IFR system. But I don't think there's any reason why Instrument Proficiency Training can't also meet the minimum criteria set forth for an IPC and get a sign off by a CFII in the process. This is exactly what the MAPA PPP training does with both BFR and IPC after course completion. vs. a pilot who is proficient and capable but not Instrument current so needs a CFII check off in the form of a basic IPC. I guess what I mean is that just because there is a minimum list of criteria for an IPC, doesn't mean that it has to cover only basic minimum items.

-

It’s a Service Letter from 2017. https://www.lycoming.com/sites/default/files/attachments/SL270%20Extended%20Maintenance%20Intervals%20for%20%20Engines%20Operated%20on%20Unleaded%20Fuels_0.pdf

-

MODERATOR: What about a forum for Alternative Fuel Discussion and move all threads about alternative fuels there? It'd be nice to see real world data for changes in fuel consumption, changes in engine monitor data, problems seen, pictures of before/after borescope/fuel leaks/etc.

-

Most threads discussing unleaded fuel seem polar. Either you are a fan of all things unleaded, or you're against change. The problem is that currently there isn't an organization that has taken ownership for responsible transition to unleaded fuel, monitoring adverse events and collecting data for implementation and outcome. This is where I've always hoped that a partnership with AOPA and the FAA would step in. Blanket praise isn't any more helpful than blanket condemnation. I'd rather discuss what issues have been seen and how to mitigate them in a rational way. You're not going to hear much detrimental information from GAMI and no one should expect to. They're selling a product that has to reach an inflection point to make it to the transition to be the only 100UL fuel out there when 100LL is removed legislatively. Unfortunately in current state, most FBOs are unlikely to carry a variety of fuels...perhaps phase "2" after transition will be to explore options for multiple fuel availability? After all, we see diesel, E85, 85/87/91 and sometimes even ethanol free fuels all regularly at the pump. We need to openly and rationally discuss issues that are being seen with any new fuel so that we can better understand how to mitigate risk and continue to fly safely. Sounds like G100UL uses increased amounts of xylene instead of lead for octane. My guess is that the overall aromatic content of G100UL is higher than 100LL. There's also other compounds that may result in paint staining if not promptly removed and cleaned. Also due to the higher xylene content it produces more black soot as the aromatics produce soot when burned, moreso when flown rich. G100UL has been tested to mix with 100LL, but no other mix testing has been publicly released. It is interesting that when the G100UL STC was applied universally, this was more directed at the engines than the airframes. I'm sure that extensive testing was done on an engine stand in product development, but that doesn't equate to the beta testing that will result with the early adopters in a wide range of aircraft. We'll start to see more real world data that (by the nature of live testing) has plenty of confounders (i.e. no one has perfect paint, and very few will have perfect sealant, etc.). But that doesn't mean we just blankly magnify or minimize the issues seen. The problem is that it's turned into being "up to us" to read and understand this, and with the limited data each of us have, that puts us more in a position of speculation than fact. So we all make our own decision to what appears to be the "best" option. Many times this becomes more of an emotional decision than a rational one. At the end of the day, lots of aircraft have old paint, old engines, old sealant, old components, because new piston aircraft production/purchase is low. So what do we need to do with our aircraft in preparation for use of alternative fuel? If we have aircraft without hardened valve seats, are there fuels that won't work? Are there certain components, seals, hoses, sealant, etc that aren't compatible with alternative fuels? Should this escalate our need to reseal a minor leaking wet wing? Yes, the aviation industry is moving away from lead. Yes, there is a large political and fear based aspect to this (you're poisoning our children). Yes, there are changes that will have to be made and challenges for all involved from producer to consumer. But this is the way aviation fuel is moving regardless of whether we move with it and even despite efforts to move against it. But at the end of the day, the most important part is that we keep the fleet, the public and ourselves safe. So lets discuss the details so that we all can be better educated, more knowledgeable pilots. MODERATOR: What about a forum for Alternative Fuel Discussion and move all threads about alternative fuels there? It'd be nice to see real world data for changes in fuel consumption, changes in engine monitor data, problems seen, pictures of before/after borescope/fuel leaks/etc.

-

And just to be clear, not all seeps and leaks are an airworthiness issue or flight hazard. Some are very slight and not an issues other than leaving a blue "fingerprint" when it dries.

-

Wet wings are an accepted and widely used practice of using the inside of the wing structure as a fuel cell. The issue is that the sealant has a life span that can last up to 30-40+ years if hangared and kept wet with fuel. Over time the sealant contracts and becomes brittle and eventually begins to pull away or break down allowing leaks. Often these leaks may track along ribs and exit the wing at a location distant from the source of the leak. Some leaks can be uncovered and "patched" but often the material applied for the patch (especially if just applied over old sealant) will also contract on curing and just put more tension on the old sealant. So depending on the overall age and condition of your sealant, sometimes it just makes more sense to have the entire wing resealed. I've used WeepNoMore, and Paul Beck is one of the well known tank resealers that has developed his techniques for removing and resealing to an art and stands behind his work. You'll also find good reviews from others about Wet Wingologists. There are a few shops (i.e. Don Maxwell) who have had good experience with patching, but sometimes this is ultimately just kicking the can down the road a bit; but that also depends on the overall condition of your sealant in general. For cost comparison, having two tanks resealed in 2022 cost just under 9k and was billed at about 100 hrs (aka it's a handful of chemicals and a crap ton of work!). I could have waited longer for reseal but I wanted to get this done before repaint.

-

FAA IPC Guidance Advisory Circular 61-98D Two good resources pertaining to IPC's. But I typically just make sure that I've gone over the things that I do regularly, the things that give me issues, and hand flying while task saturated to work on drift and good scan. If you can find some "good" aka wicked approaches in your area that's always a good idea. i.e. we have a few VOR approaches that I'd never fly in real life, but they have quirks that DEMAND that you're ahead of the aircraft. For example, KAKO VOR Rwy 29. it has a short final approach segment that's steep and it looks like it's lined up with the runway but it isn't exactly. So it's easy to look at it quickly and think it's the same as every approach, but it's definitely not.

-

I’ve usually reserved things for big ticket items, a job well done, or worked in quickly. After my avionics were done, I brought my shop a brisket I smoked overnight for lunch as a thank you. I’ve brought doughnuts and pizza before. The intent wasn’t payment or a “tip” but a sincere thank you for their service In my mind the best tip is an invoice paid quickly in cash and vocal positive referrals.

-

Out of curiosity, can anyone say what the aromatic content amounts are in the California G100UL?

-

That wasn't what I'm implying. Rather, does this sample from 2010 reflect the 100LL we're currently using and does it reflect the averages that the 100LL fleet used? I'm not a chemist. Just trying to learn more about the products we use. From ASTM D910: X1.8.1 Aromatics Content—Low boiling aromatics, which are common constituents of aviation gasolines, are known to affect elastomers to a greater extent than other components in aviation gasoline. Although Specification D910 does not include an explicit maximum aromatic limit, other specification limits effectively restrict the aromatic content of aviation gasolines. Benzene is virtually excluded by the maximum freezing point of −58°C, while other aromatics are limited by the minimum heating value and the maximum distillation end point. Thus, the heating value limits toluene to about 24 %. Xylenes have a slightly higher heating value and, therefore, would permit somewhat higher aromatic concentrations; however, their boiling points (above 138°C) limit their inclusion at levels not higher than 10 %. Total aromatic levels above 25 % in aviation gasoline are, therefore, extremely unlikely.

-

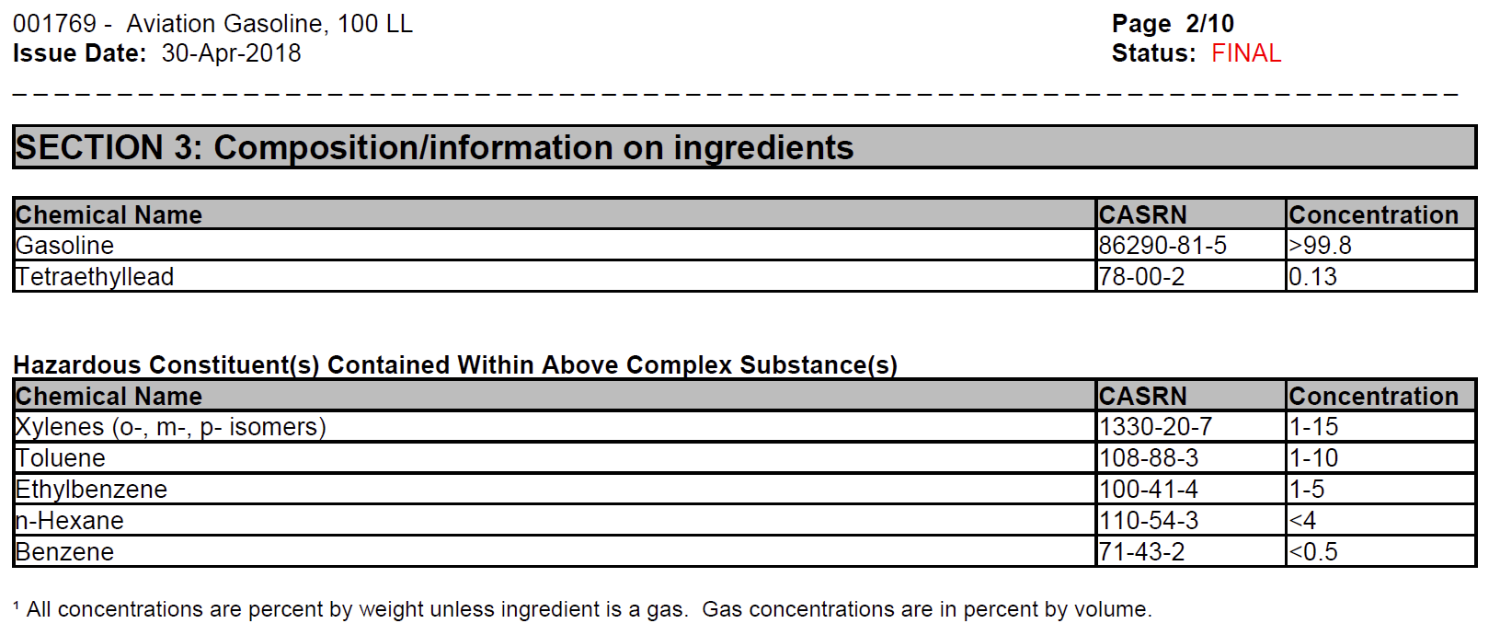

Mr. Braly, I'm sure that many of us (and probably more than 6) would love to learn more and see the shop in Ada! I always had the Advanced Pilot Seminar on my bucket list and I think it used to be held in Ada? My comments shouldn't be seen as inflammatory and certainly didn't have that intent. The SDS sheets I saw mentioned <10% toluene; @Fly Boomer you found one with <15% and <20% and the sample Braly shows from 2010 has 29%. That's still is a decent difference. I'm aware that there are variations from manufacturers and even from batches. G100UL SDS shows up to 40% xylene and up to 5% toluene. But how accurate are SDS and do they reflect product at the pump?? A single fuel sample from 2010 doesn't really help understand a comparison for composition of G100UL and 100LL; especially if current fuels aren't reflective of that sample. And certainly doesn't help to understand what happened to the tank in this thread and if it has anything to do with G100UL.

-

Outlier compared to (google search for "100LL SDS") of the SDS for 100LL from a variety of manufacturers... EDIT FOR CLARITY: I didn't find one that had 29% toluene. Most showed <10-15%. This was the SDS source I showed the picture from (Phillips 66 SDS): https://www.aviation-fuel.com/pdfs/MSDS_for_AvGas_100LL_from_P66_dated_3-04-13.pdf

-

This sample from 2010 seems like an outlier. Do you have a current sample of 100LL compared with a current sample of G100UL? Thanks for helping to understand this!

-

@Ibra I'm not exactly sure what to make of Mr. Braly's comments regarding Toluene vs Xylene. His comment seems to imply that 100LL is more of a solvent than G100UL and infers that 100LL is more likely to damage sealant or paint rather than G100UL. It's hard to say what is exactly in a mix of fuel without testing that sample and there no precise consistency from mix to mix. One can easily pull the SDS for both 100LL and G100UL, but this may not truly reflect the average batch. But the 29% Mr. Braly quoted may not be reflective of the typical fuel you see at the pump and it's hard to say what the spec for the California batches of G100UL were...has anyone tested this fuel for comparison? Might be helpful...Mr. Braly has this information. 100LL SDS: G100UL SDS: At least from the SDS, it appears overall 100LL has much less Xylene+Toluene than G100UL. I'm not suggesting that this is causal to anything, but just trying to reconcile and understand Mr. Braly's comments regarding Borger Phillips 66 100LL sample and extrapolating that to the 100LL fuel in general and somehow saying G100UL has less = safer for equipment? As an aside, is it even established that it's (edit: ONLY) Toulene that's causing damage to sealant/paint?

-

I think what most people realize is that most industries are somewhat self serving and some companies downright flaunt the lines of criminal. Remove GAMI from the situation and just say Product X and that they brought a product to market with extensive self directed tests that were loosely overseen or reviewed by the FAA for a focused population and then made broadly applicable to a much larger population unilaterally. It's not conspiracy theory, its a distrust for the corporate workflow and not blankly wanting to accept "trust me, I'm one of you" to end up costing not just $100, but potentially more ($70K engine, $30K paint, $10K reseal). In my mind, the manufacturers SHOULD be performing their own tests, and then the FAA/PAFI/EAGLE should be independently cross checking these with standard performance tests. Instead you have a fuel industry that is likely intentionally interfering with testing and approval as the current product has a great profit margin and given that it's the de facto"Gold Standard", it has less liability. (despite the fact that current fuel has many maintenance downsides that we've all just gotten used to). The best way forward currently is for those who have access to, and want to use, alternative fuels to have a registry where they can report certain key maintenance events, keep pictures, and factually show presence or absence of issues with the available fuels. Instead we have speculation and fear, and cases like UND that have some data but it's not really public. The problem with just attributing ANY and every issues to GAMI isn't exactly scientific either. "That leak was known but small" and now it's worse has tons of confounders. Not a scientific test with n=1, but certainly something that can help highlight future testing and real world data needed. My first thought was when was it resealed or factory sealant, who did the work, have there been any patching done, what products were used for patching, what was the worst amount of leaking already seen? What paint was used, was there any existing filiform corrosion or poor adhesion under the paint, what was the overall condition of the paint and how was this progressing over the past year(s)? One of the access panels looks like the paint was chipped off all around it, what was done there and why? Speculation loves the anecdote, and you can point a story in any direction with limited information. For those who use an alternative fuel, it would be nice to have a registry with details such as: year of manufacturer of aircraft, year and type of paint, year and type of tank sealant/bladder, year and type of engine, and then have details for things such as overhaul and specs, factory new/reman engine, tank reseals or patching, and a gauge for overall condition of these items to begin with. The FDA has FAERS "Adverse Event Reporting System" that comes to mind. You can't know all the data, exhaustively, before you release a product. You just can't. But that doesn't mean that it shouldn't be tracked and checked by the FAA to determine what issues might pop up.

-

@Jetter2 Don’t think you’ll find your Cardinal faster than most well trimmed Mooneys and certainly not compared to turbo Mooneys. The M20K 252 & Encore strikes the sweet spot with fuel efficiency and speed per HP. The long bodies have larger engines and are faster but with higher fuel flow and weight. If a Cardinal RG is your jam, just go with it. No need to justify a decision that has big personal and some emotional aspects. Owning any aircraft is WAY better than owning none!! But don’t come to a Mooney fan website expecting to validate the conclusion you had when you first joined. We love our Mooneys here!

-

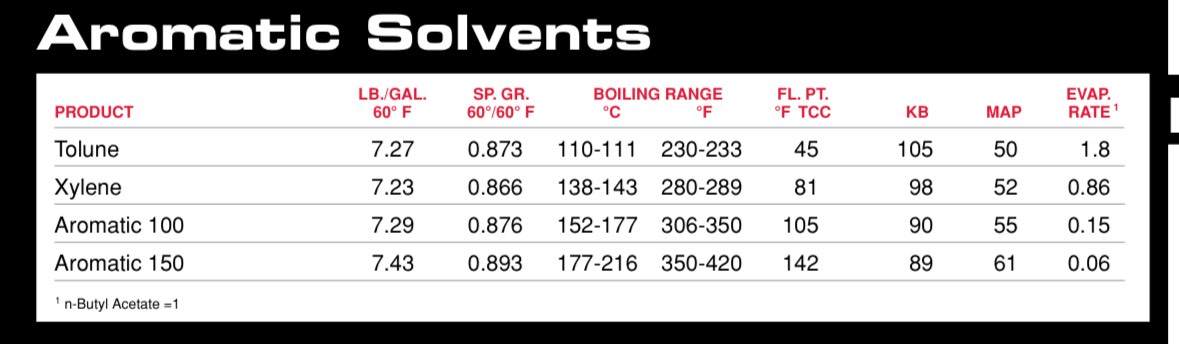

@George Braly out of curiosity, what is the standard percentage of xylene and toluene in G100UL? Kb value (solvent "aggressiveness") for xylene is lower (98 vs 105) compared to toluene, but the evaporation time is over three times longer. Also, according to G100UL SDS there’s up to 40% xylene. Curious if this makes a difference in paint staining or issues…..dwell time vs solvent "strength" vs concentration? You seem to feel that 29% toluene from Borger Phillips is high? Certainly understand fuel containing solvents, but many use 100LL to clean painted areas (i.e. soot/lead/oil on belly). Trying to understand the refueling hygiene required with G100UL vs typical practice with 100LL; especially wrt not wiping or smearing spilled G100UL.

-

For what’s its worth, G3X is older than G500TXi and still no G4X or G3Xi…so I say the G500TXi is a great piece of equipment and for me WAY more user friendly and capable than the legacy. For me no regrets or disappointment