-

Posts

610 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Nukemzzz

-

It did look like the glass jewel would pry off. I wonder if the inside is smudged because over 54 years the fumes from grease on the tach cable adhered to it.

-

I started the surgery today... Does anyone have any hints about how to remove the haze from the glass of my Tach? I can’t tell if it’s internal or external

-

Limited right aileron travel with clunking

Nukemzzz replied to flyingchump's topic in Vintage Mooneys (pre-J models)

Also... pictures of the plane or it didn't happen. -

Limited right aileron travel with clunking

Nukemzzz replied to flyingchump's topic in Vintage Mooneys (pre-J models)

My first thought is a PC servo hanging up but I've not looked at the diagrams to see if this is likely. Don't get too excited, my experience with a new airplane has been months of working on it (also a 66' E). lol -

-

So selecting the best transponder value is complicated. I thought I wanted the Garmin, now I'm seeing it's not only the most expensive option, but I guess it also doesn't come with the GPS antenna? My IA is recommending Trig. My avionics guy seems to like Apperro Stratus. I'm concerned that I don't know enough about the inter-connectivity benefits between brands and models for one. Is there a benefit to the Garmin because the altitude encoder is separate and it can talk directly to my future GPS unit which makes adding it cheaper for example? If I get the Trig will adding a GPS cost me more later? I was thinking that I'd buy the transponder, mount it all, have the Avionics guy make the important connections after that and then bring it online. I had a notion that the remote encoder would make this easier but maybe not. What do I lose if I just go with the cheaper Trig or Appareo? (One way is to go with the tiny Trig one and the separate GPS Position box). https://www.aircraftspruce.com/pages/av/adsb/appareo11-16274.php https://www.aircraftspruce.com/pages/av/adsb/trigtt22.php Any advice on this for me?

-

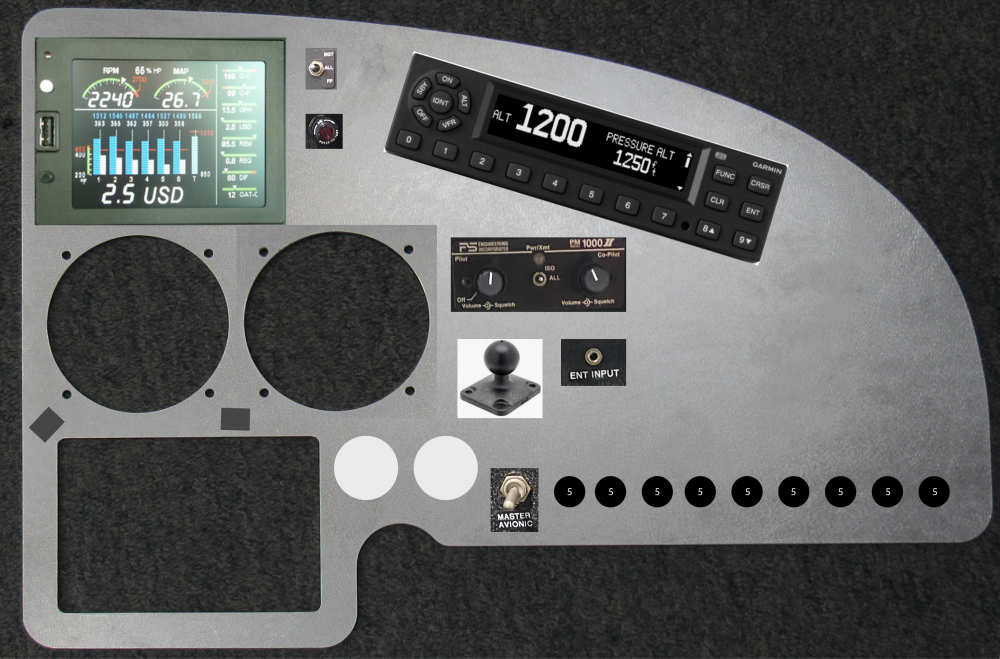

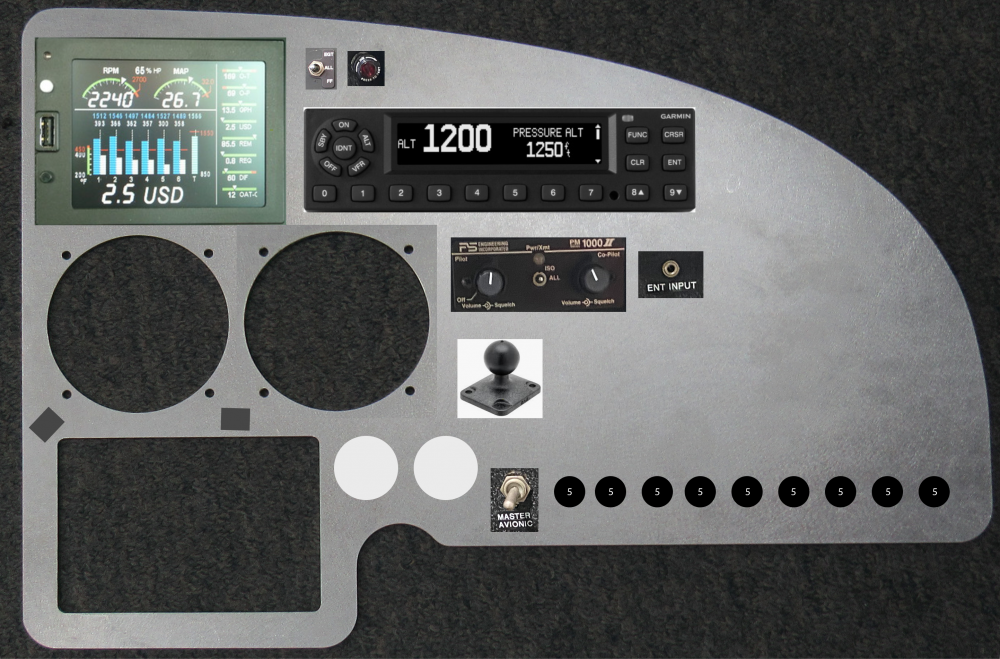

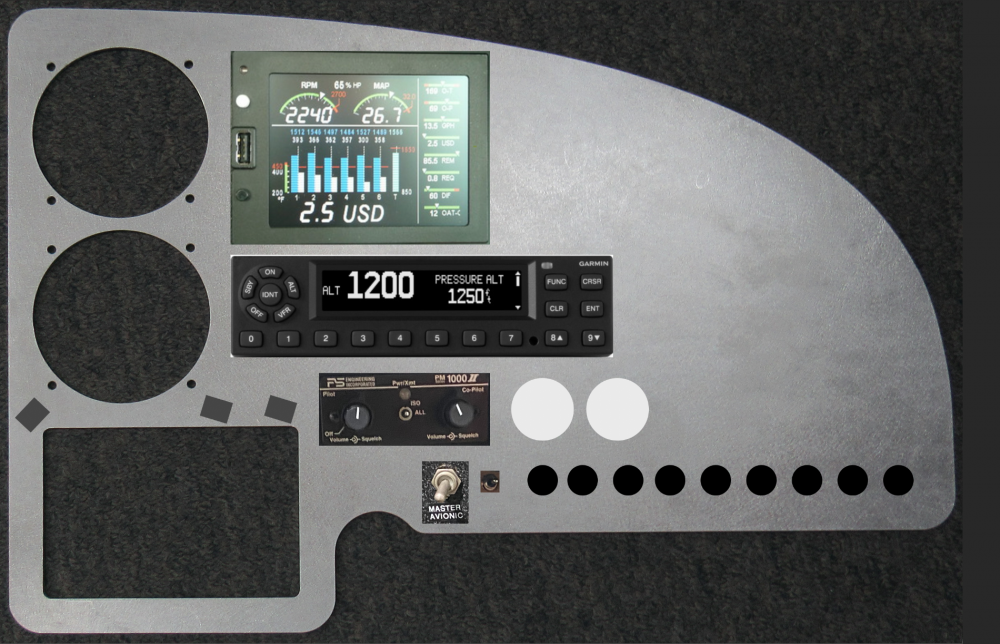

Revision #2. Thanks to Andy for the idea for moving EDM Closer. Note that I think I want a Ram mount under the intercom so I can place my full size iPad on that side tilted towards me. I'm not sure if I should put it above or below the audio panel. I'll likely port the audio into the "ENT Input". I've never tried that input, but I believe it is sound into the intercom...like music. If so, it seems useful to have Foreflight sound piped into the intercom here as well. of m

-

Good point. And especially true if I add Manf and RPM to the JPI.

-

So I'm starting to lay things out to see how it looks. The attached mock up is to scale. Everything but the transponder and lights I already have and I'm just rearranging. White circles is the two cigarette lighter sockets. I just can't see paying $300 for USB sockets when this works fine. The grey little boxes are post lamps for primary engine gages, I'll drop Nulites under the RPM and Manf/Fuel gages. Can you think of any issues with this layout?

-

I’ll be making a trace of the blank part when it arrives in case I need another one day!

-

Would you recommend that I just install the non LED? Any idea how long the standard ones last? Seems to be the easiest way to go.

-

By works fine do you mean that the LED ones dim then as well?

-

That would be nice but it's out of my price range at the moment. I'm exhausting most of my rainy day funds with the engine out for repair, nose gear overhaul, flap pump repair, and the broken engine mount.... I might just put a slot for the Transponder now and hold on that purchase in fact.

-

I plan to fly in the dark quite a lot actually, and at some point I plan on getting my IFR rating. Until then no IMC will be planned, but stuff happens... I would like to use LED because of the longer life as well as the lower power consumption (I'm sticking with a generator during this engine overhaul). However, I don't want to mess with the core aircraft electrical system at this time. If the standard Nulite has a good track record of lasting as many hours as the engine, then I'll probably just use them...if I can trim them enough to get them to fit in this Co-Pilot side installation. That way i can just connect the existing panel cover wires directly to the new Nulights and carry on.

-

Ok, I'm very confused by Nulites. They need to do some major work on their product information. I've been researching them for an hour and several things are unclear. I see Nulite and Nulite LED. I see some Nulite LED Kits that include a PWM dimmer to allow dimming of the LED version in the kit. However, I also see in many LED version listings that they can be used with existing aircraft dimming systems. It doesn't say some, it doesn't say you may need to change out all the lights for LED., it says it works with existing dimmers. The version that doesn't say LED has no mention of what the light source is, nor how long it should last. If they last as long as regular incandescent bulbs then you all are crazy for using them if you have to take the panel apart to replace them for $54 each time one burns out(nowhere does it say if the internal bulb is replaceable or how it is even lit). Also, their website is terrible and not helpful, it has no mention of LED wiring. How in the world were you all able to pick what you need and what sold you on a product that is so poorly described? I'm also seeing that they are too big to fit the MP/Fuel and RPM gages in another post on this forum which is what I need them for. Its unclear if I can even make them fit if I trim them. Help! How long does the non-LED last in your experience? Is the bulb replaceable or just the whole unit If I put an LED version in two of my gages in the M20E and use the wiring from the existing panel post lights what will happen? Will they work or not? If they will work, then what the heck do I need the kit with the dimmer for? My guess is the answer is no because LED needs PWM to dim and these are too cheap for that circuit to be included in the light housing itself. I'm not doing the whole dash panel at once and so for a period of time, if I get the LED, I'll have a mix of old post lights and these LED Nulights. It seems that I'll need to run these on a different circuit with a separate dimmer in the dash if I'm right about them needing a PWM dimmer. It really seems like I should skip the LED version if you all report that the standard ones don't burn out. /Rant

-

So it turns out Lasar has a blank panel to get me started for about $150. This might be my easiest path to getting started.

-

Here you can see the middle stack. The Narco radio is quite large. In the bottom there was a DME...it was stolen before I bought the plane. I removed the tray last weekend to make it easier to get to the control cables. So I have wires ready to go for the transponder!

-

So while the engine, motor mount, nose gear, control cables, and flap actuator are all out, I decided that since I've already dug a massive hole...why not keep digging? I'd like to start work on two more things: 1. Replace the co-pilot panel 2. Install an ADSB equipped Transponder See the current state of the panel below. Note the EDM-730 in the top right. I put it there to quickly get me back in the air with plans to clean things up later...well...the engine is out for at least another month so I might as well do it now. There is also a TB instrument in the glove box...useless there. I also need a transponder and so I might as well go with ADSB. I'm leaning towards getting a GARMIN GTX 335 ADS-B TRANSPONDER WITH GPS + GAE 12 ENCODER / MULTI CHARGER PROMO KIT FOR CERTIFIED AIRCRAFT. I don't know much about Avionics... would you agree this is a good one for me? My overall plan: Keep the RPM and Manf/fuel gages in their current location. I like the steam gages and they work fine. Shift the 730 over to the left top so it is closer. Remove the engine monitor warning light for now and move it to Pilot side later. Put the transponder right below it to save space in the middle stack for a GPS at a later date. Put the Audio Panel to the right of the EDM Put USB plugs somewhere or keep cigarette lighters. (the latter is easier since both are already wired and ready to go. Maybe put an i-Pad mount in the open space that this has created. Or put a really cool Mooney Logo and drop the needed placards (I think many are missing) over here. Put all the add on breakers above the factor breaker location (You can see several in the glove box area, what you maybe did notice is a couple of rouge ones on the right side in random locations.) Some day I'll re-do the pilot panel, move the TB over to the pilot side at that time, replace the Narco radio with another KX so it's smaller, and insert a GPS unit in the stack to move back towards IFR capabiltiy. My plan is to have a local shop cut the co-pilot panel for me, however, I don't have good resources for making my own engineering drawings (Even though I'm an engineer)... My day job company uses Creo (Pro-E) and I no longer need the software in my current role so I don't have it any longer. My main home PC is a MacBook, but I do have an older laptop that can maybe run Solidworks. I think the easiest route for me is to use the EAA provided Solidworks. Does anyone have the SolidWorks cad file to get me started? Much of it I could measure, however, the upper right portion of the panel isn't easy to define since is a sweeping curve. Hopefully one of you have already plotted this out. Or... maybe I can contract one of you to make the CAD file for me? Lastly... I'm not sure what I would need to do to mount the Transponder case. I think it needs to screw in from the sides at the panel so I'd need provisions for this behind the panel but I'm not sure. Thoughts on this? I figure if I start with this it will be a trial run for doing the pilot side later. Thanks for your help and guidance!

-

A modern ~15 liter Diesel engine is expected to run 20-25k hours before overhaul (1 million miles). 100k miles between oil changes in some fleets. They are a bit less sensitive to the power/weight ratio in my market than an airplane however. Lol

-

We use DLC coatings a lot in our designs at my day job. DLC is an extremely hard coating so it wears slower. Beyond the anti-corrosion benefits, it also lowers friction between the two parts and friction plays a big part in spalling. It does this by causing the two parts in contact to no longer be metalugically similar. Steel on steel under high contact loads has an adhesive component to the Friction because the two parts want to fuse together. This is how galling occurs. DLC on steel breaks this tendency. DLC coating isn’t cheap, and it’s tricky to only coat specific regions of a part. A camshaft lobe is only under high load on the outer base circle so this is the only region that would benefit. It would be nearly impossible to only coat those regions and so the tappets are coated instead. It would be a waste of money to coat the whole cam and coating both part provides no benefit. It would probably make things less robust. This isn’t a trouble free solution. It’s very tricky to get the coating to adhere and then to survive high temps. But, if done right it’s hard to beat. I’m about to put these DLC lifters in my A1A.

-

So Lasar called, the nose gear truss is on its way. While on the phone they told me that they are only authorized to fix an engine mount tube that cracks right at the mount so they can re-weld it. And they can’t replace tubes. I think maybe they didn’t want to repair mine since I said it was full of water in that tube and likely rusted AWI hasn’t returned multiple calls, emails, and I always get voicemail at the engine mount shop. So I tried Loree Air. They answered, was really helpful on the phone, and called back in 15min with a quote to strip the mount, fix the tube, add the missing SB at that tube, measure in a jig and check for cracks, and repaint it. They quoted a range of $1300-1700 and 4-6 weeks. Does anyone have experience with Lorre Air?

-

I'm not up to speed on aviation lingo yet. In my day job industry (I'm an engineering leader at a diesel engine company) we say "engine swing" to indicate any time an engine is pulled from a chassis. I see now that the engine can be the most value part of this vehicle so maybe I should use the term "air frame removal"? lol

-

I do 99% of all my work on cars, motorcycles, my yard my house, etc. After painting a some cars, a tractor, and a motorcycle years ago I learned that unless you paint regularly it’s hard to save money on DIY painting because of the equipment needed and the left over chemicals. If they can paint it for a reasonable price I’ll likely let them do it. I’m running around 75% doing my own work on the plane so far and that’s sometimes a tough pill to swallow. But it’s ok, because sometimes things I fixed didn’t work and that’s not a good deal in aviation. Lol Waiting in a quote from AWi.

-

I'm in Columbus Indiana. I believe my IA is wanting the frame inspected as well since it was broken there may be other areas that have been over stressed. He seemed to be specifically against sending it to a nearby welder.

-

Lasar now tells me that they don't have authorization to repair broken engine mounts and they recommend AWI. I'm confused.