Texas Mooney

Verified Member-

Posts

62 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Texas Mooney

-

Sounds like they are just barely making payroll and paying utilities. And are in danger that any unexpected or annual bill will put them under. I wonder if the MSC's have to pay in advance to order parts from Mooney. Then they are the ones directly at cash risk of a Mooney default - in addition to not being able to support the brand.

-

I see comments about visiting the Factory. But nothing about anyone from Mooney giving any update on the current situation or outlook. Maybe I missed it. Were the “unobtanium” parts that only Mooney can get discussed? - the 40:1 Dukes gears topic which new member MathewP was asking the CEO to purchase, the usual No-back spring shortage..

-

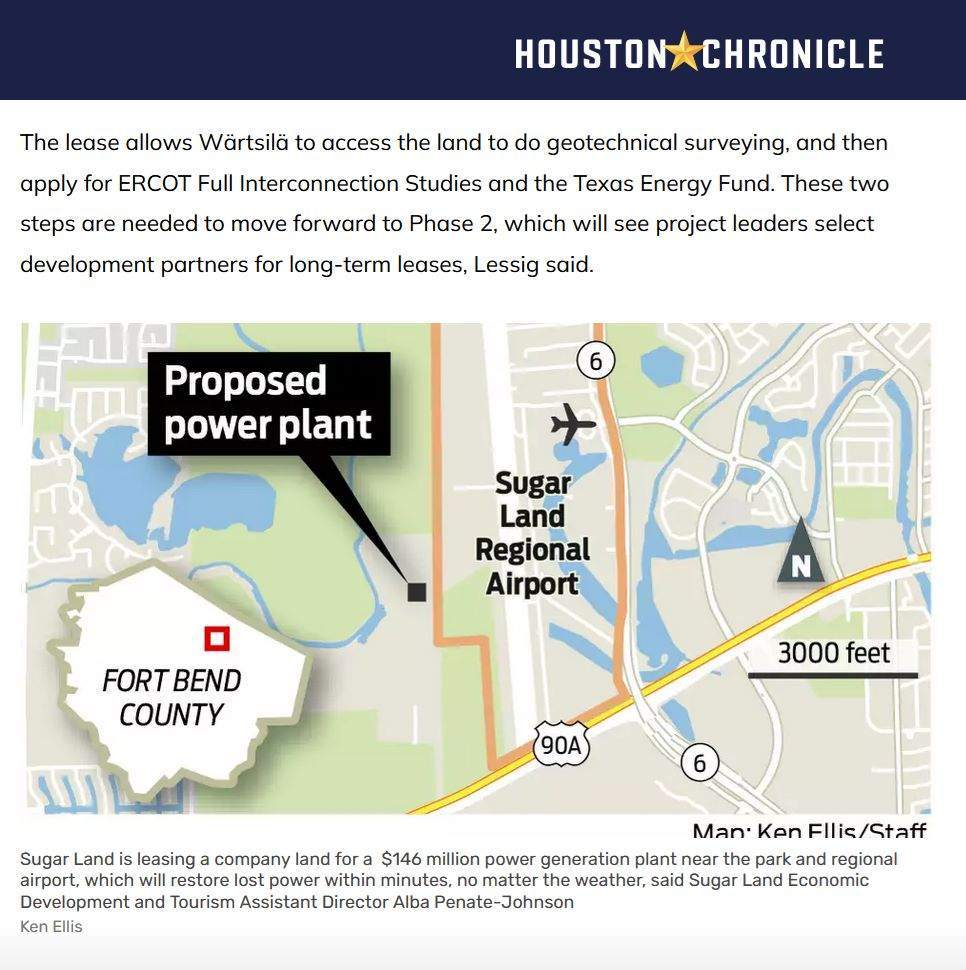

Yup - some of the highest property tax rates in the nation in "(fake) low tax" Texas, That is why the airports in Texas, both public and private, get sold and turned into housing and offices- Robert Mueller in Austin, Weiser, Andrau, and old Westheimer in Houston. The city and county make way, way, way more from property taxes than from hangar rent or fuel sales. The City of Sugar Land talks about developing some of KSGR into " retail, office or hospitality " in their long term plan. https://communityimpact.com/houston/sugar-land-missouri-city/business/2022/04/22/sugar-land-regional-airport-eyes-future-development/ And many may not be aware that the City of Sugar Land has signed a lease to allow a power plant on 9 acres next to KSGR. It used to be a State Prison Farm that paid no taxes....now it will pay $$$$ in taxes. Joy for pilots - lots of power lines and exhaust stacks even if it is "rapid start diesel engine generators". It looks like this: https://www.houstonchronicle.com/neighborhood/fort-bend/article/sugar-land-power-plant-extreme-weather-19474629.php https://communityimpact.com/houston/sugar-land-missouri-city/business/2024/05/31/146m-power-plant-in-sugar-land-aims-to-minimize-impact-of-weather-disasters/

-

Are you Instrument Rated?

-

Everything looked basically normal until he was about halfway down the runway. Then he departed to the left. Unfortunately someone dropped the camera. On Beechtalk there is a lot of discussion about whether the tail wheel (spinning 360) should have been locked. https://imgur.com/gallery/gryder-electra-UVWwTk8

-

Does your insurance policy specifically require a CFI or does it have an “Open Pilot Clause” which allows any pilot with specified sufficient hours in retract gear, type and perhaps Instrument Rating? That might expand the pool for you.

-

What happened to owners maintaining their planes?

Texas Mooney replied to NewMoon's topic in General Mooney Talk

I agree with you. 90 day oil changes is not just dubious, it is ridiculous. Many owners nowadays struggle to fly once a month. I can’t wait for the availability of unleaded Avgas and the introduction of modern long life l aviation oils with corrosion inhibitors. -

If you need/want the OEM 40:1 Gear Set

Texas Mooney replied to Matthew P's topic in Vintage Mooneys (pre-J models)

Then what is your issue with the FAA? I applaud your effort to contact the so far unresponsive Mooney management and beg them to take cold hard cash in advance to place an order with their supplier for a part/product which Mooney controls the intellectual property (design specs). But there is nothing stopping your from making the gear per OPP guidelines and if approved, install it on your plane and report back here. What am I missing? -

If you need/want the OEM 40:1 Gear Set

Texas Mooney replied to Matthew P's topic in Vintage Mooneys (pre-J models)

I am not sure where you are coming from with the comment "and they want to chime in" or "share a viable solution". The FAA has created a viable solution. The FAA will respond to your request for approval (i.e. 'chime in" after you initiate). Go make your part. You may be able to get it approved and put it on your plane. If it fails that is between you and your insurance company (although they may not know that you are exposing them to the liability of an unproven part) The issue is that the FAA is not going to bless OPP made parts that are intended to be sold to others. But if you want to get a PMA and sell gears they will likely approve that. -

If you need/want the OEM 40:1 Gear Set

Texas Mooney replied to Matthew P's topic in Vintage Mooneys (pre-J models)

Stop blaming the FAA. The problem is Mooney. In October 2020 the CEO told Mooney Flyer magazine "Supporting the existing fleet remains the new owners’ top priority." Yet in 2024 they have time to manufacture parts for other aircraft companies and to talk about it. Duh. 2020-OctTMF.pdf (themooneyflyer.com) Page 4 -

If you need/want the OEM 40:1 Gear Set

Texas Mooney replied to Matthew P's topic in Vintage Mooneys (pre-J models)

You may have missed the 2020 announcement that Meijing Group sold 80% of Mooney International Corp to a Wyoming based investment group named U.S. Financial LLC. In any event, the legal entities that own the Production Certificates and the TCDS have always been US based even when Soaring America (sub of Meijing) owned the Delaware based Mooney Corp. MOONEY INTERNATIONAL CORP. :: Delaware (US) :: OpenCorporates Mooney International Corp. :: Texas (US) :: OpenCorporates -

He has time to talk to others about how Mooney is making good margins making parts for other aircraft companies.

-

Found this "Investment Reports - provided by Newsweek" article online dated May 28, 2024. It is an interview with Jonny Pollack and seems to be current because Pollack says in the interview that he has been CEO of Mooney for four (4) years without taking a salary. https://www.investmentreports.co/interview/jonny-pollack-1180 Key Points: "We currently enjoy good margins manufacturing parts for several other aircraft companies: our main challenge is scaling up." 35 employees "I believe the future lies in composite technology, which allows for rapid production in molds" "Our plan includes refining existing models to build more efficiently and increase their useful load." Interestingly blames the Trump Administration trade wars for the inability of Soaring America (subsidiary of Meijing Group) to continue funding the business resulting in shut down of aircraft manufacturing. That means that Mooney remained a negative cashflow sinkhole with every Ultra that they built. Content Provider for Interviews Jonny Pollack Jonny Pollack CEO Mooney International 28 May 2024 You are an avid aviation enthusiast and have likened flying a Mooney aircraft to flying a Ferrari in the sky. What exactly makes the Mooney aircraft so unique? Mooney aircraft stand out due to their engineering excellence. Each Mooney is handcrafted, ensuring meticulous attention to detail and quality. In general aviation, trainer aircrafts use cables and pulleys, which delays response time, whereas we use pushrods, allowing immediate feedback to any control input. It's also extremely fast, holding general aviation speed records at 240 knots true airspeed at 25,000 feet in ideal conditions - the closest competitor is 8 or 9 knots slower. We use a turbocharged Continental IO550 engine and a laminar flow wing featuring a sturdy aluminium spar extending from tip to tip, which enhances its efficiency and safety. This design has been a staple in Mooney aircraft for over 70 years. You joined Mooney as CEO in 2020 following a turbulent few decades consisting of financial troubles and multiple changes of ownership. Why did you join what many people considered a company on the brink of collapse? I joined Mooney partly due to a personal connection to the brand and partly due to a vested interest given that I had previously purchased my own Mooney aircraft. For context, the previous owners - investment firm Soaring America - were impacted by trade wars under the Trump administration, could no longer fund operations, and had to cease production. Initially, I evaluated the company’s status and prospects, but driven by a sense of responsibility to our clients and the broader community relying on our aircraft, I ended up accepting the CEO position without a salary for four years. Mooney faces operational challenges, mainly supply chain issues that affect our parts availability. It’s my responsibility to stabilize our financials and preserve the company sufficiently so that eventually, new leadership can turn things around and Mooney can return to manufacturing aircraft in full. I consider my tenure as managing the company through crisis effectively, aiming to set a foundation for future success so we can transition away from being a parts manufacturer to resuming full aircraft manufacturing under the Mooney brand. As you focus on building a more solid foundation for Mooney, what economic uncertainties are keeping you awake at night? The aviation business presents challenges in building aircraft efficiently. The complexity arises from managing thousands of parts and adhering to stringent Part 23 certifications. Such certifications demand a rigorous quality control system where every component must meet precise standards. This requirement not only enhances safety but also significantly raises costs. Moreover, the dependency on a reliable supply chain has been a critical issue, especially post-Covid. The necessity for a robust infrastructure of engineers and quality assurance teams to comply with FAA regulations adds another layer of complexity. These factors combine to make aircraft manufacturing costly, with the net margin severely impacted by substantial overhead costs associated with maintaining the necessary quality controls. Tell us about Mooney’s portfolio and geographical spread of customers across the US and the world? We operate 7,000 aircraft worldwide, exclusively manufactured in the United States. Many are certified for international flights, such as in Australia and South Africa. We don't sell aircraft outside the U.S., yet interest has risen in our all-metal aircraft due to global warming concerns and structural integrity in extreme heat. Mooney aircraft, primarily aluminum, are known for efficiency and reduced fossil fuel consumption. In the U.S., our main clients are individual pilots. While our competitors focus on family-oriented marketing with safety features such as parachutes, our planes have a slightly lower useful load like the SR-22. Due to our aircraft’s payload limitations and narrower cockpits, we cater to that specific demographic. You have mentioned that Mooney operates like a startup but also uses 1970s technology. How do you plan to modernize the design and accelerate automation to keep Mooney competitive in 2024? We will be modernizing both our manufacturing methods and the products themselves. Currently, we produce metal aircraft using traditional methods such as stamping and forming but I believe the future lies in composite technology, which allows for rapid production in molds—however, this method involves significant certification costs and time. All planes fundamentally use technology developed from the early days of aviation, with recent changes focusing on propulsion methods like VTOL and hybrid engines. Our plan includes refining existing models to build more efficiently and increase their useful load. Do you have a projected timeline for when Mooney might become revenue-neutral or cash-positive and begin a transition? We currently enjoy good margins manufacturing parts for several other aircraft companies; our main challenge is scaling up. Unlike Cessna, which services thousands of trainers, our fleet consists of only 7,000 aircraft. Once we have acquired the necessary capital, I anticipate we could be revenue-neutral within a year. At that point, I'd likely step aside to let new leadership drive further growth. Given the intense competition, why have you opted to keep Mooney in Texas and not outsource for cheaper manufacturing labor? Mooney's identity is deeply ingrained in Texas; it's part of our legacy. Our commitment remains strong due to significant incentives to retain manufacturing operations locally. Although our team size is smaller than ideal—35 instead of 235—our team embodies the spirit and dedication Mooney stands for. Licensing production overseas would involve complex and costly certification processes in those countries. We prefer to build kits in Texas and ship them abroad for assembly under strict regulations, maintaining our quality standards and supporting our local community. JoeBen Bevirt Joby Aviation 28 May 2024 Thomas Olivier Omnos 28 May 2024 71-75 Shelton Street, Covent Garden, London WC2H 9JQ, UK info@investmentreports.co +40 740 631 208 Investment Reports © 2024 All rights Reserved

-

The account he used in the past still exists, but he has not signed in under that name since December 2022. His last post was July 2022. Has he become a Zombie CEO or is he lurking around incognito under another name?...

-

Did he in fact sell his Acclaim (N705SE) or did he just transfer it to an LLC? N705SE is now registered to TXNY LLC which suspiciously sounds like someone that lives in NY that travels to TX.....

-

If you need/want the OEM 40:1 Gear Set

Texas Mooney replied to Matthew P's topic in Vintage Mooneys (pre-J models)

This would be so, so much easier if Mooney Corp would just order the proprietary parts from their third party supplier. This is just like the No back spring, the wing fuel gauge dials, the F air intake boot, etc, etc, etc. Back in 2020 the entrance of new owners was proclaimed "new management is made up “entirely of pilots and Mooney owners giving the company a unique and valuable perspective going forward.” Pollack said to Flying “Mooney has to become a parts company first,”. Pollack's 2020 Letter to Owners is still on the Mooney Corp site : " It’s my firm belief that Mooney owners and pilots have remained true to the Mooney brand despite a factory that hasn’t always reciprocated. Well, it’s time that Mooney return the favor ..." However, owners have offered to prepay group orders, MSC's like Top Gun have offered to prepay group orders but Mooney does nothing. The start of this topic offer to prepay a group order "but he (CEO) needs to consider". What is there to consider? How long is this ridiculous debate going to go on? MS routinely states that Pollack or other Mooney management attend MooneyMax. What the heck is discussed there with Mooney Corp ownership (US Financial LLC), Board members or Mooney Management? Who are the owners beyond Pollack and what is their intention? I know the usual comment will be "Mooney doesn't owe us answers". True - just like past owners - but the propaganda in 2020 is just BS. If Mooney lacks the resources and/or desire to order proprietary parts, then they should just release drawing/specs and release their vendors to sell direct. -

Your plane used to have the vacuum gauge mounted there before the vacuum system was removed. Go look at the old Aircraft.com pictures. Also from the detail in your picture it looks like that large Philips head screw, center-top, is holding that plastic panel in place. N252VM | 1986 MOONEY M20K 252TSE on Aircraft.com

-

Mod Squad 261 Thunderbird conversion 198902-1989 Mooney M20K 231 to 252 Conversion.pdf (aeroresourcesinc.com) Mod Works Trophy 262 conversion . (The owner of Mod Works, Bob Meier, also owned the STC. Coy Jacobs Mooney Mart did it and called it the Award 262. Lake Aero Styling LASAR also did some conversion. ) 199707-1997 Mooney M20 Modifications.pdf (aeroresourcesinc.com) Also see p. 90 Flying Magazine - Google Books "From memory, there were actually two "Trophy" conversions: the Trophy 261, and the later 262. I had the 261 conversion done to my 231 in the early 1990s when Coy Jacobs was at Punta Gorda, and the firm was called Mod Works. When Tim took over the Mod Works, Coy left and established the Mod Squad, and the Trophy 262 conversion was created. I believe they were essentially built to the same goal: to build a 252 clone, but leaving it a 12 volt system. The later 231 and 252 airframes were the same (I'm sure there might have been some minor differences such as rounded window corners) with the 252 having a one piece belly pan, and an improved Continental engine with a better wastegate system, an intercooler, some more engine tweaks. and a different propeller. The 261/262 STC conversions replaced everything firewall forward with the same engine propeller combination as the factory 252, and added a one piece belly pan, as well as a new cowl with a different variable vent system (the 252 cowl). The 261/262 POH was a reprint of the 252 POH, and I regularly flew her at FL270 (with Prist in the fuel tanks). The conversion, at that time, was generally less expensive than selling a perfectly good 231, and buying a new factory 252. In my case, while the 261 conversion was supposed to use a remanufactured engine, I actually got a brand new engine since at that point there were no remanufactured engines for the 252. It was a great airplane, and I owned her for about 16 years. I would not think that converting a 231 would make much sense now, since there are good existing conversions for sale, and 252 prices are reasonable at this point. If you really want to pursue the STC, you might want contact Coy Jacobs at his company: Mooney Mart. Before a whole bunch of negative postings come in about Coy, I want to say that all of my dealings with him, including selling my 261 though him, were honest, without gile, and met my expectations. I think that he, and Paul Lowen at LASAR know more about Mooneys than anyone else I have ever met. I am not endorsing Coy, as I know some Mooneyspace members have had "difficulties" with his work. I can only tell you about my experiences."

-

Useless Chatbot/AI Joins Mooneyspace

Texas Mooney replied to Texas Mooney's topic in General Mooney Talk

This is really strange. "Amaramani" joined MS on Saturday. Yesterday morning "it" made single posts in each of three (3) General Mooney Talk topics. All three posts were in the same format with rather simplistic sounding advice tagged to some technical detail that it "scraped" up. All three had exactly the same ending paragraph. I remember the one post on the topic looking for a Shaw 531-001 fuel cap because it said "Shaw sells products directly so order it from Shaw". That is total crap - that AI Bot seems to have missed that Shaw Aerospace was sold to Parker Hannifin in 2008 and these are no longer made or sold. There was another on "The Best Way to Remove a Fuel Sender" topic. I don't remember the third one. However all three post are gone now. If you go to the "Amaramani" profile it states that three (3) posts were made but none show up now on the profile page. BTW - "Amaramani" means "the mythological gem, or the celestial wish-yielding gem." translated from Kannada which is a Dravidian language mainly spoken in the southwestern region of India. Coincidence? -

I was referring to "hybrid" composites as structural load bearing members. The composite shell on the Ultra is not structural load bearing. It is wrapped over the 1950's era steel frame which is load bearing.

-

In GA single engine piston, yes there are still examples of current metal aircraft designs that compete with composites. But those are legacy designs with sunk cost. Eyeballing the GAMA numbers, about 950 of the 1,508 SEP (and electric) delivered in 2023 were composite or "plastic" as many label them. Some have gone "hybrid" like TECNAM which has retained metal wings and empennage but converted the fuselage to composite in their 244 deliveries. The direction of new models or entrants seems to be clear.

-

Peerless? Every airplane is a balancing act of compromises. Shine/excel in one area but not in all - maybe ever weak in some. It's like beauty or art - in the eye of the beholder. Useful load is important to many. There is a reason that Beechcraft sold over 18,000 Bonanza's. I fail to see how training in a composite M10T trainer with a Continental CD-135 diesel engine would spur a new pilot to seek out an old steel and aluminum Mooney with a Lycoming (or maybe Cont 6) avgas motor. The notion that Mooney Ultra's sold at a discount or bargain to Cirrus is rubbish. The touted "$795,000" price for an Ultra Acclaim announced in 2016 was for a plane without AC or FIKI. AC was a $29,000 option and FIKI was $65,000. Add those options and that takes the price to $889,000. The price list for a loaded GTS SR22T with FIKI and AC in 2017 was $877,00. And useful load was still over 1,200 lbs. with a chute and full options. 2017-SR22T-International-Pricelist - CIRRUS Aircraft - PDF Catalogs | Technical Documentation | Brochure (aeroexpo.online) The bigger problem was that on the Mooney, FIKI and AC cut into the marginal 980 lbs UL without options. Even Flying Magazine claimed that they were happy to not have AC on the Ultra due to the 66 lbs. weight penalty. FIKI weighs another 95 lbs. Fully loaded an Ultra Acclaim UL drops to about 820 lbs. Imagine telling your spouse that you are going to pay $800,000 for a new plane WITHOUT AC. Actually the biggest problem is that Mooney was selling every Ultra at a loss..... The Mooney M20U Ovation Ultra is a Product of Big Investment - FLYING Magazine Mooney Acclaim Ultra: Tops in Raw Speed - Aviation Consumer

-

Only one continuing problem for Mooney - no spare cash to invest in inventory - and when they do pay a third party to set-up a manufacturing run, they don't have the cash to order in a large economic order quantity that would drive price down. This is the same story with the "No Back Spring" in the landing gear actuators, the air intake boot on the F, the dial faces in the wing fuel gauges, etc., etc..... They live "hand to mouth".

-

Invaded 3 General topics already.

-

If you need/want the OEM 40:1 Gear Set

Texas Mooney replied to Matthew P's topic in Vintage Mooneys (pre-J models)

Mooney does not produce them. They buy them from a third party vendor based upon proprietary Mooney drawings and/or specifications. The only problem is that Mooney does not have the cash to place a prepaid order in an economically large quantity like any normal going concern would.