-

Posts

1,298 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 201Steve

-

I am about to loose my mind over the insanity of the maintenance community. I caught the symptoms of a sticky exhaust valve on my IO-360 very early. Over the last year, I was seeing slightly elevating levels of Nickel in my oil analysis, with the last reading showing 10ppm. Fast forward to last week, I was having slight morning sickness over the duration of 3 starts. Roughness lasted approx 30 seconds. Shot a boroscope into all cylinders. Arrived at #4 and found it stuck open a little bit. PER LYCOMING SERVICE INSTRUCTION 1425A, they outline exactly the STANDARD procedure to first address this issue. Via the "rope trick" drop the valve into the cylinder, clean the valve guide with a hand reamer, and reinstall. A 45 minute job at best for someone who's experienced with it. Please... someone explain to me why the 4 mechanics I've talked to have never done this before? Want to immediately pull the cylinder? WHY! I explain to them that Lycoming addresses this in detail, as to what to do FIRST. Exhaust valve sticking may be the most common valve train item... yet they don't even know how to do the simplest of procedures. Mike Busch theory aside, it is a LYCOMING recommendation. It's not some back woods remedy. All of that said, I can't deal. I'm ordering the stuff to do it myself with supervision. I'm pretty sure the reamer needed is 0.4995-0.5005 (.5000) for my engine. Looking at https://www.mcfarlaneaviation.com/articles/valve-guide-cleaning-reamers-for-lycoming-engines/ Can anyone confirm this is correct size before I order? Also, any other suggestion on what tools to have handy in the process would be great! 77J Lycoming IO-360 A1B6D

-

Rope trick - valve guide reaming in Texas inquiry.

201Steve replied to cnoe's topic in General Mooney Talk

I am sending you a direct message -

Oil Change frequency for turbocharged Mooney

201Steve replied to Richard Knapp's topic in General Mooney Talk

io360 here. I whole heartedly believe the oil filter could easily go 100 hours. It holds 1/4 quart maybe when cold. I would put good money on zero difference in an otherwise identical lifetime comparison with one changing filter every swap, and one changing filter every 2 or 3 swaps. With a quick drain valve, it wouldn’t even need to be de-cowled and you could change just the oil in 5 minutes of labor. That said.... it’s my airplane and I enjoy treating it like a baby, so I change it with the oil. -

Mooney Fatality, Bartow, FL.

201Steve replied to mike_elliott's topic in Mooney Safety & Accident Discussion

Knowing nothing abt formation flight, it would seem the last guy in the line would have the least liability to the group. That’s why I asked. -

Mooney Fatality, Bartow, FL.

201Steve replied to mike_elliott's topic in Mooney Safety & Accident Discussion

Are you simply referring to the last minute addition or is there also some significance of the #4 position? -

Lol no. ATC asks me that pretty regular though. “I’m an ER grad, was that one of their Mooney’s!?” Nope.... Mooney just circled the corner on acquiring as many 201XX combinations they could get there hands on in 1977.

-

I am based at KSSI and commute to Cole in Dalton. 2 other Mooneys on our field, one also uses Cole, other uses a guy out of Jacksonville although I don’t have his info. Seems to work good having a neighbor, as we regularly use each other as chase planes to and fro.

-

I had an erroneous reading on my G5 a few months ago in VMC. It was a turbulent day, and it kinda cocked itself in a left bank even in straight/level. Apparently it was an “algorithm error” that was prone to error in turbulence. A software upgrade seems to have resolved it but I’m still skeptical.

-

He’s “A” 201er. I’m “THE” 201er. =)

-

Local AP thought it very minor. Of course, seems like you get everything from “do nothing” to “buy a new prop” with this kind of stuff. Here are the best pics I could capture. Thoughts @Cody Stallings ?

-

Best guess says “they” ask questions only after they do it.

-

Got a little prop nic needs to be filed down a bit. What kind of file should I use?

-

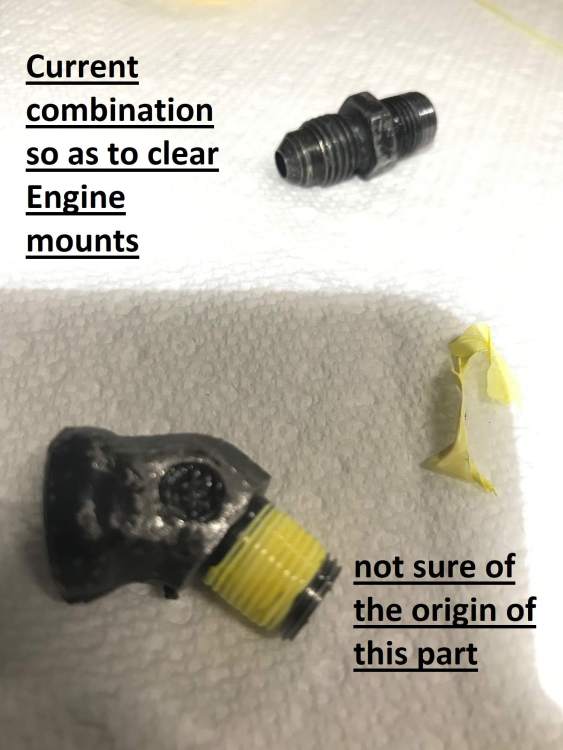

@jetdriven if I’m following correctly, you have a ‘77 with a B6D. So, the port should be in the same place, as that’s what I have as well. But I can’t grasp where your port is... the pic doesn’t appear to be in the same spot. Do you have another zoomed out picture so I can see where yours is? I wonder if there was more than one Acces case used? Or if there are more than one option to tap it, as carusoam mentioned. I was thinking of JPI 900 but would also have the same size problem I guess. I have tons of room on the right side of panel though... what are your thoughts on using the G3x engine monitor? Are you keeping the JPI or ditching it for the g3x engine mon? also great idea on the the timesert. Looks way more sealable than a helicoil.

-

$180! Dang! Good info. Thank you

-

-

This pic looks like a different location than mine

-

Looking for some feedback on this. I have to think it's not the first time this has been an issue for someone, but I can't seem to find much of anything on it. Maybe I'm using the wrong search terms. I have a 77J. There is an Oil pressure port on top of the Oil filter assembly/accessory case. From there, a pipe threaded fitting goes into the port, where a hose leading to the oil pressure guage follows. From what I *think* I've surmised, the correct fitting (a one piece 45 degree angled pipe fitting with an oil flow-restrictor hole) must be installed on the accessory case BEFORE the engine is hung. The problem is the engine mount/frame. If you attempt to install this fitting after the engine is hung, you don't have clearance to screw the fitting into the port (bumps the eng frame due to the angled fitting). That said, I believe a compromise was made on mine, and the fitting was essentially constructed with two fittings, that in connection with each other, is quite similar to the appropriate fitting, but installed separately, you can make the clearance. I believe the fitting used (where it installs to the accessory case) is perhaps not 100% sympatico with the threading of the accessory case... because it started leaking. It blew about 3/4 quart of oil through the fitting over the course of a 3 hour flight. I took the whole thing apart to inspect, and there is thread damage in the accessory case port. In a jam on the road, I wrapped the fitting with Yellow Teflon and it made the seal leak free. Understanding that it's not really a great fix, I'm trying to weigh my options. If I could find a straight fitting (no angle) that married better to the port threads, maybe problem solved and there is sufficient threading left deeper into the pipe thread. The flex hose is long enough where I believe the angled fitting may not be necessary at all. A straight fitting would also allow precise torque where your not worried about where the fitting is pointing, so as not to bump either the Vac pump of engine frame. I can't find anything along those lines, that also has the oil flow restrictor built into it made by Lycoming. It seems like it would be a really common type fitting but I can't find anything other than the angled fitting on Aircraft Spruce. They Lycoming Parts guide lists a Plug for that port, so maybe it was a Mooney part. If a better-mating fitting, that I could actually get on there isn't an option and/or the threads are damaged enough, I'm left with another decision. how to repair the tapered threads in the accessory case. I've gotten answers of all varieties ranging from replacing the accessory case, to helicoil, to plugging it and tapping oil pressure somewhere else. It's such a stupid little problem, but it's the second time on the road it's presented a problem (the first time, i just removed, reinstalled and no problem for six months. This last time, I wrapped with yellow teflon. Duration still TBD. Surely someone is going to pop in here and know exactly this problem and what to do to resolve it!?! I've attached a couple of pictures -the port with fitting removed -the fittings currently affixed in tandem -the fitting that i THINK is the correct part -the current setup of the install There are a few angles here, so if you have any experience with this, I am open to any and all feedback. Thanks

-

You can never really get out... lol. "kinda retired"

-

Cool! I just checked it out. I am part of the Crossfit cult, so it def fits the bill. Do you guys work with any CF affiliates?

-

Has anyone tried the Element Fire or at least made the purchase? I read in the Vans forum that someone pointed out that it only ships via ground. I'm wondering if anyone has taken it up to altitude. No idea if there is a correlation there, but if you've taken it up and it hasn't popped or anything, I guess it's reasonably safe? I've had a heck of a time selecting a suitable fire extinguisher with the poor reviews (leaking) on the very small PRT (Spruce), high cost of the "good" halon, and the burden of a big bottle somewhere. Really like the Element Fire idea. From all that I've gathered, the biggest issue thus far is the inability to shut it off. As mentioned somewhere above, I guess you could either vent it out the pilot window or either just throw it out.

-

I saw this on another forum. If not allowed, so be it. I’m always interested in doing business with people that have similar interests. It’s all about relationships and I’m typically closer with customers/vendors that like the same things as me. Topping that list, Mooney! In an effort to potentially connect with other Mooney flyers in a professional capacity, post below what you do for work! ************************************** I am in the trucking business. We operate in 48 states and Canada, specializing in oversized/overweight cargo. We typically haul industrial machinery, heavy equipment, silos, transformers, generators, asphalt plant equipment, as well as your typical flatbed freight.

-

Roger that, I just came out of the hangar. Update is done. Easy peezy. From here on, I won't wait 9 versions later to keep it up to date.... Thanks for the help!

-

@bradp I’m going to pull up the info tonight, but is a recalibration required when updating software?

-

@bradp thank you for the helpful info. I believe the software is v2.4 if I recall correctly so there ya go... I’ll have to look into the install calibration. it came with plane, now have 150 hours with it and this is the first time I’ve suspected an error. thanks again, great feedback