-

Posts

193 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 65MooneyPilot

-

-

I did install the steering Mod and it has been working great. I am leaving for Grandma’s house this morning but will be back Saturday night so I can go over to the hangar on Sunday if you still need the measurement.

-

I just helped do an annual on a J model that has the system and it is a disaster. The engine starts and runs but in cruise there is something horribly wrong. It was supposed to have been professionally installed but it requires 14.1 gallons an hour of fuel flow to keep the cylinder head temp below 475. The spark plugs get completely loaded up with lead. If your engine is running good with the magneto do not try to fix it. Checking the timing is a challenge. My neighbor had to check it on his airplane with a strobe light while the engine was running. On my neighbors plane the spark trigger that plugs in where the mag was had a manufacturing defect that they failed to detect during the three times he sent it in. It would be nice to hear Justin’s story to see how he got a good installation. They also want you to send in your mag or pay 1k. Why would an electronic ignition manufacturer need your old Mag? Obviously I am not a big fan. Good luck If you decide to install it.

-

CO2 detectors the "Good The Bad and The Ugly

65MooneyPilot replied to Jpravi8tor's topic in Vintage Mooneys (pre-J models)

Check the panels under the back seat. They need to have tape around them to seal them up. -

VOR Approaches Using GPS

65MooneyPilot replied to donkaye, MCFI's topic in Avionics/Panel Discussion

The EU rules should be our rules here in the states where you verify the points in the database with a current approach plate. Every 121 carrier I worked at, this is the procedure if caught out and the database goes out of date. I have flown to countries that were not in the loaded database and had to enter in all the Lat Longs of all the points on the arrival and departure. Just like the old days when we had 9 waypoints and had to keep loading them in as you went. We used to build are own approaches in the “Box” for VFR and low visibility. It is not acceptable to build an LPV approach so I would not do that, but verifying points for an approach that has not changed would be fine with me. Having a current database is no guarantee the points are correct either. Years ago United doing an approach into SFO almost had a major disaster because one of the points was wrong on the approach. So getting back to the original post, doing an approach with pink needles and monitoring with green needles for a non precision approach for me would be preferred and legal. -

Cracked main gear found during annual

65MooneyPilot replied to rbmaze's topic in Vintage Mooneys (pre-J models)

Well I am glad that you continued your investigation. Did the inspector strip off the paint to inspect the area? Now you can move forward. Excellent job! -

Cracked main gear found during annual

65MooneyPilot replied to rbmaze's topic in Vintage Mooneys (pre-J models)

They should have stripped the paint off before inspecting it. That way you know you are looking at the metal, not cracked paint. If it is really cracked you will be able to see it with the famous 10X magnifying glass. That is not cracked. -

Yoke compatibility

65MooneyPilot replied to Mister_Bevilaqua's topic in Vintage Mooneys (pre-J models)

Ok, thanks. That is what I was looking for. I am thinking to change it a little bit and put two switches on there. One for PTT and the other for the autopilot disconnect. -

Yoke compatibility

65MooneyPilot replied to Mister_Bevilaqua's topic in Vintage Mooneys (pre-J models)

Thanks, I would really appreciate a picture. You are awesome -

Yoke compatibility

65MooneyPilot replied to Mister_Bevilaqua's topic in Vintage Mooneys (pre-J models)

So the actual wires go thru a hole in the yoke behind the clock? -

Yoke compatibility

65MooneyPilot replied to Mister_Bevilaqua's topic in Vintage Mooneys (pre-J models)

Sorry I was not specific enough. I have this type of yoke without the modern switches inside or that add on switch. I am assuming the wires go behind the clock and thru the control wheel shaft. Thanks -

Yoke compatibility

65MooneyPilot replied to Mister_Bevilaqua's topic in Vintage Mooneys (pre-J models)

Just wondering how they run the wires in the back into the yoke. Do you have a picture of that? I am assuming they drill a hole or notch it. Thanks -

When I first setup my G5 I thought I would try knots. I did not take long for me to change it to MPH. When I flew large Boeings I was taught to cross check instruments. So it started to drive me crazy when the speeds were not the same. When I fly now the two instruments are very close which my cross check likes. Yes you could look at the inner knots to cross check but after flying the Mooney for over 30 years on the MPH scale I did not want to reinvent the wheel. If ATC assigns a speed to me then I can look at the inner scale. I don’t fly much IFR anymore to have to think about what speed I am flying. I keep below 250 knots under 10K. Not the greatest picture but the airspeed matches.

-

You never have to worry about runaway trim.

-

Take off trim moves based on CG and Flap setting. I realize in a short body Mooney the range is not large but it will change some. So note the CG and flap setting. Mooney recommends taking off with flaps. Some pilots do not. So keep this in mind when you are setting the configuration for takeoff.

-

Looking for a Gear Motor PN# LA11C2114

65MooneyPilot replied to Paulie's topic in Vintage Mooneys (pre-J models)

No you can not post this on the forum because aircraft parts require FAA oversight when they are repaired. So if the shop is not certified by the FAA they are taking a risk with their business. Many alternator repair places have gone through this. -

Looking to see if I fit in a m20c

65MooneyPilot replied to Quantum Blueberry's topic in Vintage Mooneys (pre-J models)

Thanks for the update. The Cherokee is a great learning airplane. You can also move up in the Piper aircraft. I have flown a lot of them over the years. The Cherokee 235 is a nice aircraft and the Cherokee 6-300 is a great plane. Multi engine Seminole is another good training plane. All ATP schools use them and I got my Multi engine commercial instrument in it and my ATP. So good luck and fly safe. -

I just had both my eyes done and it has been a good experience. Before the surgery my left eye was the better eye and now after surgery my right eye is super clear. With the new lenses everything is brighter. It’s like having a car that you have to replace or buff out the headlight lens on. I had astigmatism and upgraded to have that removed. Now no glasses needed except reading glasses. Four weeks of eyedrops three time a day, no heavy lifting for a week and no swimming for a month to keep bacteria out until fully healed. No restrictions on flying.

-

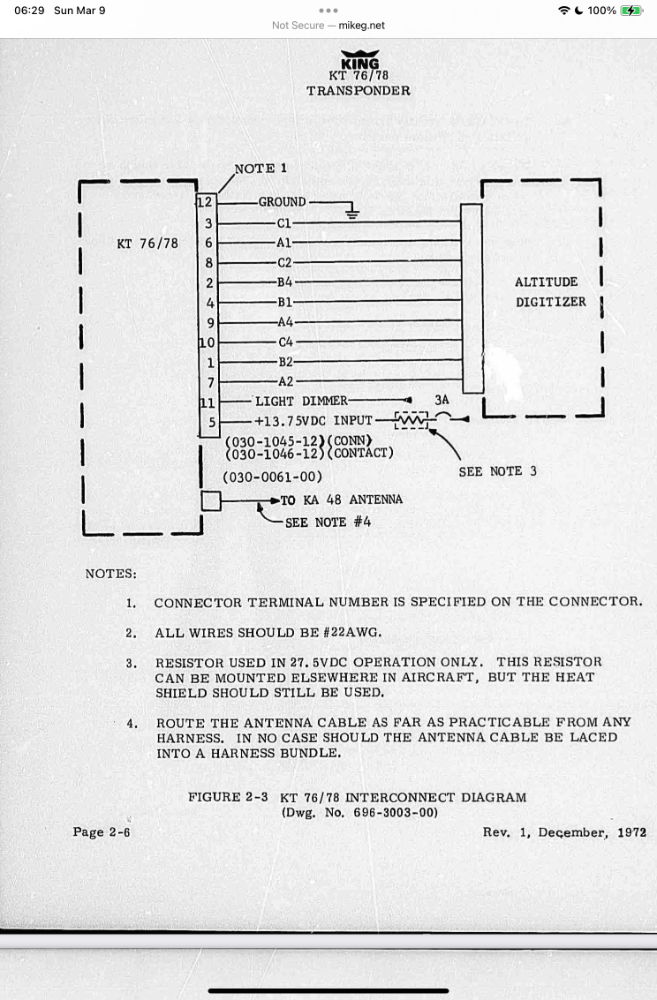

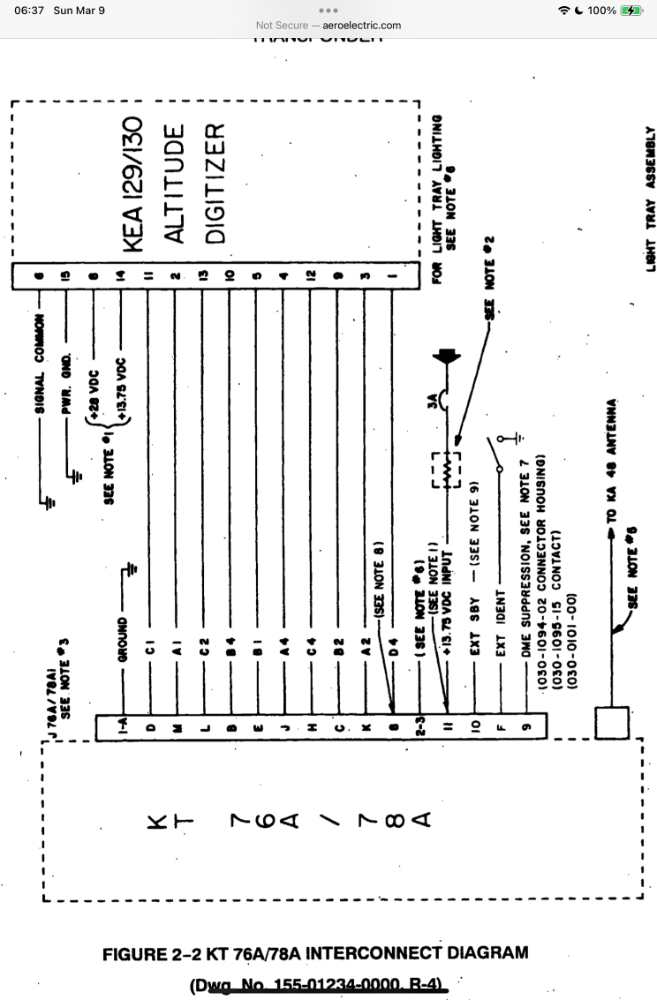

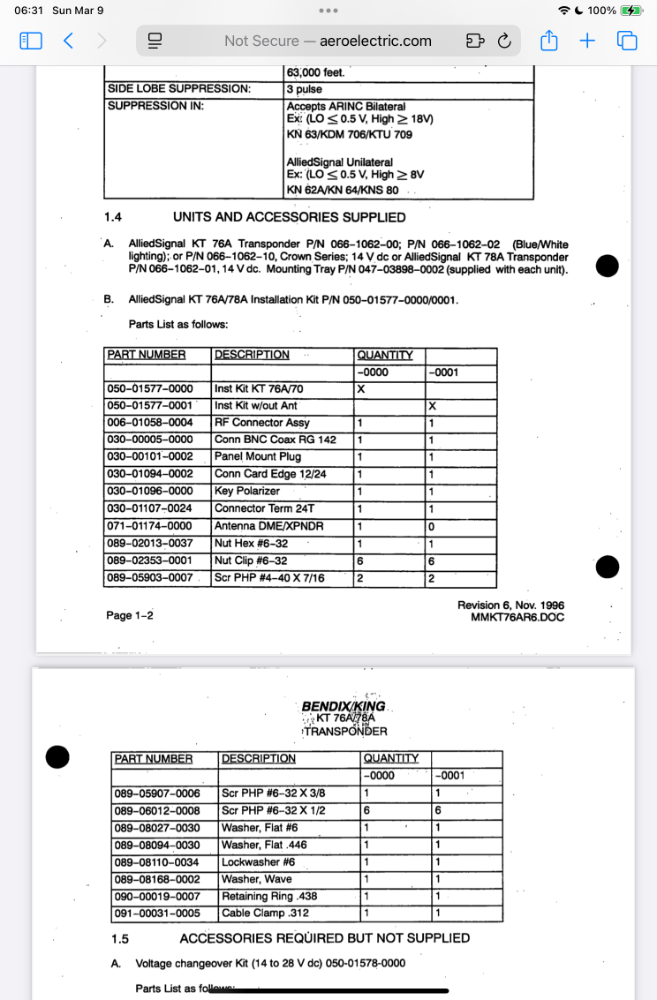

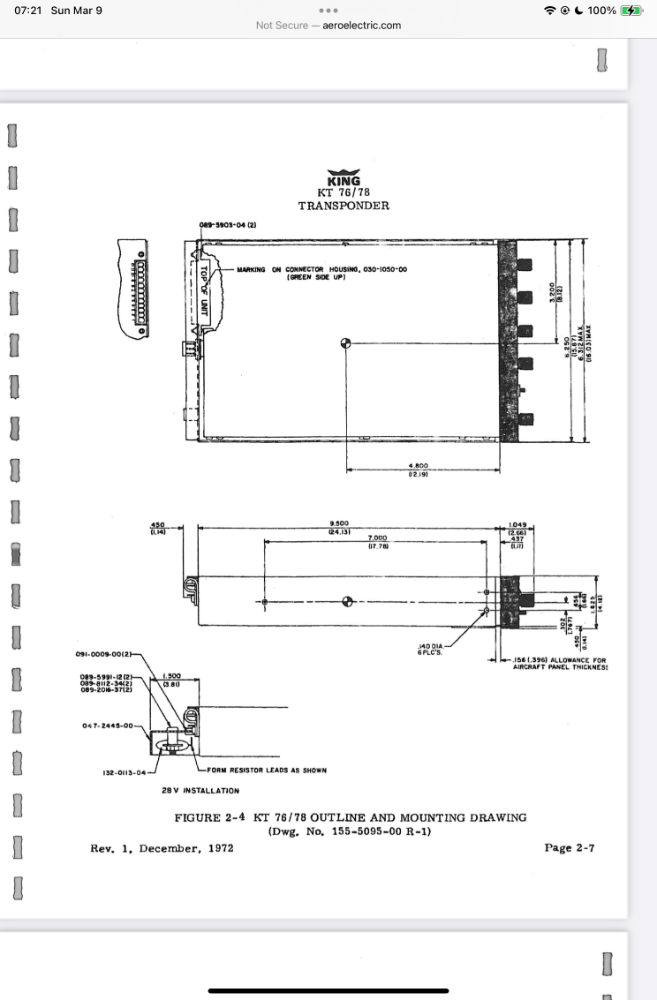

I just looked at the IM manuals and it looks like the connector on the KT76A has more connections and is different. The trays have different p/n’s. KT76 only has 12 connections and the KT76A has 15 connections. The connectors are labeled differently with letters and the KT76 are numbers.