-

Posts

247 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by fuellevel

-

CiES Fuel Senders and Existing Resistive Gauges

fuellevel replied to Toothdok50's topic in Vintage Mooneys (pre-J models)

So a year ago the Cessna Cardinal group got ahold of us and asked if there was any way to support the existing analog gauges. Luck for them we had a Cardinal based on an airport 1/2 mile from our facility. We made this work to a level I was actually very happy with however it took quite a bit of effort to get there and a 337 approval. That solution and 337 now circulates in the Cardinal Club this could be done with Mooney C and Mooney F but it takes an organized contingent to get accomplished the result looks like the tachometer on a new Mustang where the gauge sweeps upon power application and settles on a value in the tank (this eliminated the going up vs going down hysteresis of the analog gauge. This method cured a lot of issues and was again far better than our earlier attempts. The process wasn't for the faint of heart. I will publish what they did to see if there are similarly committed people on Mooney space Scott -

Fuel Sender (Transmitter) Question - M20C

fuellevel replied to Toothdok50's topic in Vintage Mooneys (pre-J models)

Yes JPI converted the system over to be an installer software change so that the resistive or frequency can be handled by the installer rather than changing the configuration in the factory. So all new JPI 900 and 930 are compatible with the CiES Senders. Older units would still need to be returned to JPI to be converted but that cost has come down dramatically. Equally we still can supply analog output units so that the JPI can remain in place. If you have a JPI or want to get a JPI 9XX system - we have you covered Basically we solve a lot of issues with installs so JPI makes it easier to use CiES senders -

M20F Fuel Stick - I know I know

fuellevel replied to sdflysurf's topic in Vintage Mooneys (pre-J models)

It is a broad based response to posts and not specific but I am addressing arguements that refute my position. Given my situation - what would you do.. I grew up in aviation and around aircraft every single day of my life. And I was told that in regards to aircraft if you do something wrong or see something wrong it is to be brought up - without consequence. I have designed many systems used on Mooney aircraft factory and aftermarket - I will and wish to design many more aviation systems in aircraft of the future However I seem to be stuck here for a moment. Being stuck here requires me to interact with pilots all day and aircraft companies about a very specific and important aspect of powered flight., that being fuel indication Being here makes me review all accident and incident data related to fuel issues and GA Aircraft. Being here makes me search for and read aviation research that appears to have been forgotten or disgarded because it did not conform to standard thinking in regards to aviation fuel quantity. Being here makes me collate data to test theories on fuel accidents Being here makes me pick up the phone and ask a pilot about an accident that occured over a year ago. Being here requires me to consult on accident investigations regarding fuel. It is an understandably extremely unique position . If anybody wants in, hey the more the merrier I am sorry after all this I have come up with a WTF , wake up and smell the coffee admittedly brusque attitude - but see the first paragraph , I cant stand idley by. I just cant. I highly doubt I have barkered my product directly I am talking about safety in a field I am involved in from design, certification and application. I have seem and heard more about this subject than anyone i have yet encountered save some of the big boy system engineers . Because Parker Hannefin wrote the book on aircraft fuel systems, now is that also marketing - i dont really think so. They are sharing in my mind thier observations to make future systems well engineered and safe. That is the only textbook on the subject by the way They dont recommend a stick (tongue in cheek) I am here because Cirrus asked for a better and more accurate system and I wasnt doing anything of importance at that time. I did not ride into this on some marketing mission to change the world, far from it. I would rather work on a new aircraft system design asolving a new OEM issue and for the most part I am. For example 2 years ago I designed the Cirrus Conviencae controller - remote entry light up aircraft and cockpit. I dont tell anybody about the virtues of remote keyless aircraft entry, it isnt an item of safety. I highly doubt I would STC it even if you asked nicely. The FAA asked us directly to STC the fuel quantity product. Today i am working on two other projects, I dont talk about that and you will read about in future aviation magazines - you wont need those either. So yes I believe i have lifted the covers over an unsavory element of aviation, one that is an item of safety. An element that by every measure needed to change . Iam aware I have competitors and I may be driving some of you to them - I am definately OK with that -

M20F Fuel Stick - I know I know

fuellevel replied to sdflysurf's topic in Vintage Mooneys (pre-J models)

@andy95. There are many examples but I chose these as, personally i have held military trained pilots who taught and corrected me to a higher standard. That is a personal bias based on my experience. One was witnessed by many pilots who on forums railed against those that declared stupidity in this case as the cause. A group of pilots who gathered at this small airport for coffee and treats to discuss aircraft. The preflight and fueling according to their reports happened 20 yds in front of them. The pilot did as I was told by those military pilots who taught me for pre flight. - something on this aircraft will kill you son, it is your preservation of life to find it before it accomplishes its task. To say from reports that it was thorough preflight would be a gross understatement. The second case I can only rely on the pictorial image of the aircraft. To say it was well maintained is also an understatement and followed up my assessment of the pilots character in the interview I did. It is a Cherokee I would have been very proud to own myself. He did own and use a fuel hawk. To limit an aircraft to 1/2 its capability is an antithesis to any benchmarks we use to judge aircraft Range, useful load, speed. To limit the useful capability of an aircraft caused by an unknown directly due to inadequate instrumentation, instrumentation that is historically so bad it requires a stick in the tank on preflight for every flight as a standard work around, ...... is frankly madness. This is from the 1000 ft view. Qualifier. Preflight of aircraft requires a visual confirmation of fuel when it is practical and a slight thump on the lower surface when it is not visible but acceptable for the flight intended. If standard POH published numbers don’t matter the PA 28 is superior to the MOONEY M20C INTENTIONALLY INFLAMMATORY STATEMENT TO ILLUSTRATE A POINT. As obviously it isn’t, as we regularly use published numbers to illustrate to superiority of one aircraft over another, or justify our purchase or ownership including range. -

M20F Fuel Stick - I know I know

fuellevel replied to sdflysurf's topic in Vintage Mooneys (pre-J models)

So I have one statistic and two examples on the “stupidity” issue. I also realize I am swimming upstream to conventional aviation alphabet group pundit thought and FAA safety guidance. Statistically pilots with higher ratings CFII, Commercial, ATP are more susceptible to fuel accidents. Statistically, there is a histogram cloud of accidents at approx 3000 hrs of total time. Stupidity should show up as lower rated and lower time pilots if I believed that argument. 2 examples - both PA 28 First one the head of an aviation school in Ohio ex Air Force Colonel. A by the book preflight known as a pilots pilot and a strong role model for all aviators. This pilot plans a trip of nearly 4 hrs and in front of a group of colleagues (who regularly hang around the airport) preflight and fuels the club aircraft. He departs for a funeral of a friend in Kentucky or Tennessee. He tells 3 to 4 miles out he tells ATC he is short on fuel, 2 miles short of the destination runway he puts the aircraft into a row of trees above a small creek. He breaks his back and has a severe head trauma, he has no cognitive memory of the accident or events. He has flown an aircraft with a 5 hr maximum flight time that he departed with full fuel. The FAA handed down the rubber stamp “failure to plan.....”. As the investigation was cursory which is the rule of a fuel related accidents as the current thought is that they are caused by “stupidity”. His friends, wife and congressman appeal the NTSB ruling - this goes nowhere. INTERESTING they did take pictures of the fuel senders. They are crudely rebuilt from my eyes, nothing was said about the fuel qty system in the report. I did go to Wash DC to illustrate that there should be more comprehensive investigations of fuel accident aircraft using this as an example. This to, went no where Second a pilot and his future son in law take of in Texas for a planned flight near Corpus Christi for some fishing together time. The flight plan is for slightly under 4 hrs. Interesting is that this pilot is slightly deviating his flight to place his flight path over an airport at every cardinal hr in the flight plan and he is keeping tabs on fuel consumption utilizing his fuel gauges. ( I googled his aircraft it was 200% better than any PA 28 I ever flew in). This is strange that fuel gauges are mentioned. Everything is good at hr 3 and he presses on to his destination as 3 hrs was a go no go decision point in his plan. Any deviation and he would land at this cardinal airport. This is all in the pilots comprehensive flight notes. Everything going to plan. 3/4 of the way to his destination the aircraft hiccups despite showing fuel in the tank. He switches tanks and hits a little turbulence and the selected tank goes to zero. In fact both tanks now indicate zero. This and he notes is not to plan as there should be 13 or so gallons remaining, and mysteriously 5 just disappeared to the hesitation tank and now the drawn tank is showing no fuel which by plan should have an equivalent amount. At this point the destination airport is in visual sight and the closest airport so by switching tanks and applying a little rudder pressure he milks both tanks completely dry and he is aligned and straight in on approach. His sight line is a little low and to preserve his future son in law from a potential clipping of the airport perimeter fence with his gear he elects to turn slightly and land in a field. By gauges his fuel consumption goes from 10 gal/hr , 8, 8 to 30 at the end. The FAA shows up rubber stamps the “failure to plan....”. He protests that he has planned illustrating his fuel receipt and comprehensive notes. No aircraft investigation takes place, other than the cursory examination of the tanks, by the FAA yes both are bone dry. So this pilot talks to me, and I learn that he too is ex Air Force and retired as the lead flight instructor for all domestic and foreign C130 flight engineers. This is the reason for the comprehensive flight notes, strange noting of all gauge readings against a plan as this was ingrained. Even the cardinal go no go flight plan. The NTSB investigation blames him for paying attention to his fuel gauges which the FAA Handbook of Aeronautical Knowledge tells you, you should never trust. Yes you can blame stupidity, I don’t anymore., this is now two examples out of hundreds. You basically can’t find what you are not looking for. . Blaming stupidity and not actually looking for a root cause is one of many things the exercise of Lean Manufacturing has schooled my thinking. -

M20F Fuel Stick - I know I know

fuellevel replied to sdflysurf's topic in Vintage Mooneys (pre-J models)

Well depending on location the 1/8 can translate to 2 to 3 gallons. Combine that with a slight occilation of the fuel surface and the error may increase. I can share some data to show that. The plastic pipette method controls that to a large extent. So is the stick perpendicular to level, and is it in the same location on the tank floor , and is the aircraft level. All of these add up to slight errors in observed level. So we plan for a reserve 1 hr is typical. It appears looking at starvation data that sometimes the errors both on the ground and in the air add up. I know this as the only scientific research performed on GA pilots showed a staggeringly high number of pilots preflight with an assisted visual inspection. Stick, tab or other mechanical method. The most obscure FAA funded aviation research nobody points to in my opinion. So using starting assumptions that are close to accurate, combined with in-flight hard/fast and published rules are again close to accurate but are not always. The idea of a starting fuel level being the be all end all method of evaluating fuel in flight is slightly flawed. As I also point out that fuel totalizers did not change the starvation exhaustion statistic In other words pilots with fuel totalizers run out of fuel. This is born out in reviewing accident data. So the systems we use, to historically “work-around” what is considered to be traditionally flawed in-flight cockpit indication, are not entirely effective. It seems very plain to me now, it was not always that way. And I know that some of you will believe this to be marketing or sales, but the fortunate or unfortunate situation of having my career go down this path has immersed me in this little niche with hourly conversations with pilots like yourselves and situations that came very close or resulted in an off field and never reported or categorized . I have talked to the father and son of the previous poster and have found the similarity of circumstance is not congenital personality traits, it is a system design issue. Long ago in the start of Lean Manufacturing/TOYOTA way I learned that it wasn’t bad personalities causing issues, it was placing people in situations where success was not assured. -

No problem. Because K factors are set for the aircraft as a single number. When in actuality there should be at least three and potentially 4. Let me explain when we correct the flow to the spinning wheel in the flow transducer the response is not exactly linear. So K factors should be different from taxi to take off to cruise to descent. While that may be needlessly or overtly accurate it is what we would do if we built fuel transducers. K factors set to average flight will converge to an accurate solution on getting to the end of the average flight. Keep me informed Sent from my iPhone using Tapatalk

-

Reading through this - did Kris get his aircraft to read correctly. I’d hate to think he is still off 6 gallons. So if you set K factor from the fuel replaced at the same ramp attitude as the example - you are likely to get the same result. Sent from my iPad using Tapatalk

-

I will look to see if I have calibration data for that specific model and configuration. Yes you can be quite a bit off if you don’t level and brace the aircraft properly. Our advantage is that we can measure very small vertical changes in fuel level, it can also be a curse. Privately let me know who did the install and when I am in the area I can demonstrate why being careful and accurate is important. We have suffered through the idea that fuel level is crap in GA and it will remain so. Unfortunately if you don’t take care with any system, original resistive, ours or any others it will perpetuate the myth. I will check the database when I get to the office Sent from my iPad using Tapatalk

-

JPI 900 Installation Costs for 76 M20F

fuellevel replied to jerrodmonaghan's topic in Avionics/Panel Discussion

It is interesting, we send thousands of senders to OEMs and we never hear another word. The aftermarket is a different story. On our way down to the AEA convention in Palm Springs from Bend OR, we stopped along the way to address some installs that needed help. Fuel senders new or old get the blame as that is the legacy of their operation in aircraft. You can’t measure fuel in aircraft so senders of any type won’t work even ours. So frustration sets in. Problems with CiES sender installs fall into two camps. One they are not getting between 8 and 32 volts. So here we have found bad solder connections (cold joints), bad grounds, wires crimped over insulation, connections to voltage sources other than aircraft bus. Installers will scream we sent them defective parts (our OEM MTTF is in excess of 90,000 hrs) Rarely if ever is it a bad sender, most likely the sender has insufficient voltage to operate. And yes I have seen bad installs on both sides of the same aircraft. Two The sender arm is physically restrained. The senders once they have power, are absolute position senders straight up and no joke. Straight out horizontal they produce 127 HZ. all of them, every single one.. If they are not changing values as fuel is added, the sender float or arm is against something in the tank. So we want to maximize the measurement range so CiES senders have more physical travel than resistive. If an installer first places the sender in place and bolts it home the sender arm may get wedged against something hard or soft ( Sealant) in the tank. The action of tightening bolts down can exert a pretty high force. I get this with top mounted senders on Beech where the float is now forced against the bladder and lower wing skin with the added force of tightened screws. This can be avoided by first making electrical connection so that we all know they are working (un restrained by the tank) and then carefully physically installing the senders. We encourage installers to bend the arms to keep the sender arm free through the range of motion. So why do we have issues - well first the FAA wants us to pattern arm length and float position to a legacy sender assuming the factory had a clue at that time. Some OEM senders appears to have used what was available vs what was optimal. As we find these less than ideal situations, we document and revise supplying this information to the FAA. For example we just revised legacy 172, 175 arms. There were many reasons fuel quantity systems have the reputation they do. Careless indifference on the part of the manufacturer was one. Carelessly bolting in a sender that needs to move to operate is another. Installers that pay attention to these two points swear by our senders, Those that don’t and refuse to use basic diagnostic tools, swear at them, and tell us fuel senders will never work in GA aircraft. Because we are the choice of most OEM aircraft, glacially the former attitude will change over time. If your avionics shop swears at them, I know several only a few miles away that will welcome the work. By the way we fixed the 3 problem aircraft all in less than an hour, just using a Digital multimeter and we have new installer advocates now that their is better understanding of the system and how it interfaces to the aircraft. Knowing intimately the situation you describe, it might make sense to take a multiple stop trip through Florida. -

JPI 900 Installation Costs for 76 M20F

fuellevel replied to jerrodmonaghan's topic in Avionics/Panel Discussion

The JPI pricing has changed - I have heard $100 to convert and all new JPI appear to have frequency as a software option. Please check with JPI to be sure but this appears to be the case lately. So the economics have changed slightly. So the no moving parts is interesting marketing from Edward Simmonds (Simmonds Electroprecision and the ESNA lock nut company ES is Edward Simmonds the NA is North America) when the Capacitive probe came around in 1948 for aircraft - Kind of like "it takes a licking but keeps on ticking" though we have long transitioned from Timexs Fuel is in motion in the tank - the capacitive while it doesn't move is subject to a variety of wetted and unwanted surfaces to maintain a steady output in 1970 this was accomplished with discrete electronics - the Signal Conditioner and this was far simpler than the Selsyn system adopted for fuel level measurement for commercial aircraft float fuel systems . In modern sense for this same function everybody uses some form of micro-controller (interesting history, the Selsyn was take from the aiming system for Naval Gunnery). The biggest issue in capacitive is adjusting for the dielectric - not so bad with Jet A but more difficult with avgas and the fact that you have wires in the tank of the aircraft. Yes it doesn't move but yes it is connected to the aircraft electrical system - this is a hold up and bad ju ju with certification lately - for instance Garmin in their EIS TXI only allowed resistive senders - and because we are isolated, we have separate FAA approval for interface with that system and Garmins blessing . This interestingly, has not been a direct safety issue - no accidents in GA despite some spectacular lightning event incidents that traveled through the fuel quantity system. As far as the FAA was concerned there were suspicions in the TWA 800 accident, so new capacitive systems have various intrinsic barriers employed to keep lightning or arcs out of the tank and this adds precipitously to cost. Strangely they applied this to resistive senders and these in newer aircraft had to add resistors in series or magnetic coupling in the case of Cirrus - which made a bad system untenable. If you take a close look at the late and very un-lamented Cessna Pennycap - this system required twice as many probes as you can't get the probe close to the wing surface due to lightning attachment this was true even in 1969. We are now replacing Cessna 400 twin pennycap systems at an astonishing, to me, rate. We don't have those wiring or lightning issues - so true to the original mission can we make a better fuel sender accuracy and reliability, make it cheaper than modern capacitive- less probes more accuracy more total fuel measurement and quadruple the reliability. So the proof is in the pudding and moving parts in and of themselves has no impact on the measurement quality or accuracy as we have demonstrated. I am fascinated that Edward Simmonds marketing - No Moving Parts is still an active part of the aviation lexicon - I only wish I had 1/4 of that skill -

So in the interest of education and sharing what we know. We extensively tested resistive senders alongside ours when we were going through development and certification. Actually the performance of the float, led us back to using this device to find the fuel surface as it isn't easy to mess that up. Yes you can pull the senders and ultrasonically clean them and they will perform better for a while. Or you can get the resistance wire rewound, but there are issues . Trouble is that most new senders are printed ink resistance grids and they simply wear out. Avgas is an especially good solvent and what is designed for autogas is not exactly compatible with avgas, in regards to printed ink composition. Here is the critical issue and - Mooneys will perform better in this regard due to sender placement. Unlike the heavy equipment the senders are normally applied to - fuel movement in aircraft is particularly aggressive due to the length of the tank this motion takes the float out of plane with the normal arc movement. Pretty good if the motion is up and down with the rising of fuel in the tank - bad if it is fore and aft like on on climb, descend and taxi. Always filling to full mitigates this effect as the floats can't move. This motion tends to wear the pivot on a resistance sender - Resistance senders rely on a precise contact pressure on the grid to minimize wear of the grid or wire and provide a good electrical connection. The longer the arm on the float - the greater the issue. I doubt that this issue is addressed in a rebuilt sender - I have a few that have been donated Basically clean repair or replace the printed grid or wire test and return. Uniform contact pressure is the key to accurate readings - anything less or more causes issues. The float sender reads fuel by slowly, very slowly dropping to be in contact with the fuel surface - too much friction will hold the sender suspended in air until vibration brings it back into contact with the fuel surface (corrosion and corruption assist or in better words don't assist here). To little friction allows free motion with interrupts in contact with the grid (the windshield wiper fuel gauge). Aircraft have quite a bit of vibration so the floats will get shaken down eventually. Electronic instruments are susceptible to this loss of signal - far greater than the analog gauge they replace - we have lots of AOG requests on new installs of JPI, EI, And Garmin systems as what the owner thought were working fuel senders now become exposed. So with how we measure and how we build - this above is taken into account - we actually have a relatively free pivot connection however side to side motion does not affect accuracy or interrupt output - only loss of power to the sender Why do we know this is good - well we have 26,000 senders in the field - On Cirrus Aircraft now getting to be 8 yrs old we have zero in service replacements - our MTBF is now over 80,000 hrs - the senders are airframe life rated. There is no discernible wear and if wear occurs it does not affect accuracy or output Why are they relatively expensive - well unlike components in the cockpit these devices live in a far harsher environment. They are relatively complex circuit devices. The FAA Certification guys considers these items to be "CRITICAL" to flight So the environmental testing we are subject to would quickly ruin your new radio or GPS. This forces us to use higher graded components throughout. And to achieve longevity we have some pretty complex and detailed coating requirements on the billet machined parts we use. In a relative sense - we should be three to four times more expensive vs an analog sender. Because of our non-contact measurement nature we meet a new FAA/EASA fuel and lightning safety requirement and we have a lot of OEM business around the world. Quantity and consistent production allows us to offer competitive pricing. The flexible nature of our sender allows for the unique customization we can do without charging substantially more - For example in the mix this week are senders for a Ford Tri motor, Grumman Mallard and a PBY Catalina how's that for obscure. We are dedicated to making fuel indication for all aircraft - airworthy. No other complex component on the aircraft is warranted for the life of the purchaser - I like to think that says it all

-

Opinion on topping off tanks! Before Flight or After?

fuellevel replied to wcb's topic in General Mooney Talk

@carusoam Well the ground filling component is a function of the smartphone APP I showed - tongue in cheek - for fuel level on the ground to replace a stick. With an accelerometer onboard the integral phone modem - aircraft attitude and ramp angle can be considered. This APP is being developed for several of our commercial customers where this is a critical issue. Equally hauling out a stick - does not inspire customer confidence. Kenmore - DeHavilland Beaver - Floats or Gear Cape Air - Tecnam P2012 - Commercial Application We are quite popular in Alaska for the reasons you stated in your post - weight performance is critical for several missions and commercial operators are utilizing the combined fuel information & GPS allow operators to put customers safely in places, that a lack of precise aircraft loading knowledge would have carried too much risk and liability. As the season is over we have this month, approx. 90 orders for Cessna 180, 185 headed in that direction. Our acceptance rate in Alaska is staggering. So the intention of this APP takes care of Tundra Tires, Floats or Conventional Gear without cluttering up the cockpit with unnecessary flight information. Once this portal is in place there are a lot of things that could be added in the future - tire pressure, oil level, De-ice fluid, oleo pressure, strain gauges for critical structure (not a Mooney Issue) - the list goes on ...... So yes - I think we are on to something. -

CiES Fuel Senders Resource Thread

fuellevel replied to Marauder's topic in Avionics/Panel Discussion

Could have been - but not likely - most of those parts were Airbus helicopter where they are not quite gold plated but should be -

CiES Fuel Senders Resource Thread

fuellevel replied to Marauder's topic in Avionics/Panel Discussion

just a nice little video in the machine shop Video -

M20F Fuel Stick - I know I know

fuellevel replied to sdflysurf's topic in Vintage Mooneys (pre-J models)

Data I have - it isn't very interesting to most. But you are more than welcome to come on in and look through it. We will even provide coffee. All of it is tied to published data either ours filed with the FAA or that filed with the US government by some other organization. I have to do this, as we would reasonably expect that this would have to be proven to the FAA / NTSB or further in a court of law. This adds just a touch of voracity A stick you create for this use will never be mentioned or photographed in an incident or accident - don't believe me - the NTSB Accident files are open to anyone, Advisory Circular 23.17 the FAA specifically calls out that a totalizer can not be an approved fuel gauge Digital fuel flowmeters are not a required powerplant instrument except for turbine engine airplanes with an Amendment 23-43 certification basis. They are optional equipment and should not be considered replacements for fuel quantity or fuel pressure indicators What I am saying is - the methodology of getting a starting observed fuel value - Stick, observation, full tanks et all and then relying on a Totalizer or Time to determine in flight fuel level is not the intention of what should be used in a certified aircraft to determine actual in flight fuel level. Why - the FAA says so - or at least it says so in this location. An FAA stated design goal or recommendation is relavent regardless of how effective or accurate an alternative method is to a user in practice - this is the religious or rote component I mentioned. Because it is common or that everyone is doing it doesn't mean we should not reflect on it and ask why - or question the underlying reasons (Potentially that Fuel qty instrumentation in GA has been substandard or has not met or been maintained to the FAA design goal) The Standard for GA Fuel qty instrumentation is 3% of fuel tank value or 0.75 of a gallon on a 25 gallon tank - I know I am writing the ASTM spec and this relies on specifications for GA that have been written and published since the 1930's - so it has to be better than 1 gallon Bottom line - despite the advent and increasing usage of fuel totalizers the GA, fuel accident rate has remained unchanged. That fact is distressing, as this component is perceived as a safety item people rely on and tout the accuracy of. I hear your statement repeated countless times - my totalizer is accurate to less than a gallon. What I believe is that a totalizer or time in tanks has the potential to mislead or provide bad pilot information especially when it is critical information for continued flight. I believe, as do most of the people who have accurate fuel indication (Not vendor specific and a few Mooney owners) in that having the ability for a comparative in flight fuel quantity data from two different sources is a an item of safety - that I hope will be a proven better solution. i.e one that shifts the accident statistic southward, Doing something by rote for safety that has been proven by data to offer no change to the accident statistic is the classic definition of lack of careful thought or reflection. -

M20F Fuel Stick - I know I know

fuellevel replied to sdflysurf's topic in Vintage Mooneys (pre-J models)

I simply post a picture of an app illustrating a different method with a comment of - "You still use a stick" There was no sales pitch or offer of any product just my logo, which is over on the left as well Can't we just get along. -

M20F Fuel Stick - I know I know

fuellevel replied to sdflysurf's topic in Vintage Mooneys (pre-J models)

Cyril. I trust what we are doing in supplying accurate fuel level from a fixed location, is a very significant improvement on sticking a tank . Yes this is heresy to some, as this has been the time honored method that has kept some but not all safe. Aviation is like a religion - you trust what you were told at an early age and believe it throughout your life. It is a basic fact that what we can do relative to fuel level is better than you can do with a procedure with a stick. I will put up $1,000 for someone who believes they can be more accurate with a stick full stop. Name the place and location. We have 5,000 aircraft with our system, so I have users who back up my voracity. What is better is that our system travels with you when you fly, You can get a better than a stick reading in flight. - Level flight no turbulence. Initiating your flight with a basic stick level understanding of starting fuel level - has proven to be an issue. -

M20F Fuel Stick - I know I know

fuellevel replied to sdflysurf's topic in Vintage Mooneys (pre-J models)

The app and aircraft interface are in final development, Mooney’s and Malibu’s have been shown it first. Some of you will be offered the app and the aircraft interface to beta test and provide feedback. There has to be benefits to being early adopters. -

M20F Fuel Stick - I know I know

fuellevel replied to sdflysurf's topic in Vintage Mooneys (pre-J models)

Actually - I like the reaction. A fixed position (i.e. mounted in the tank) accurate reporting device should if designed correctly outperform A methodology that involves human interface, that coordinates a predictable repeatable action in a nearly impossible still volume of fuel with a porous and human marked stick. The ability to project that accuracy on the ubiquitous smartphone that everyone caries os just a succinct way of illustrating this disparity The last cars to come equipped with a stick are Early 1950's Volkwagon Beetles and MC TD's for a point of reference I am not driving in the illustration and I hardly qualify as a teenager. The fact that this former methodology (Stick) has no impact on fuel starvation and exhaustion statistic in aviation. An Actual Scientific Study was performed that indicated that this methodology for long distance flights is nearly universal or near 100% in the pilot population and slightly less so for a short distance flights. If you look at the current Nall Report - the Fuel Statistic remains stubborn while overall accidents in aviation are falling Funny - in speaking to people much older than me, it was equally unsuccessful in Volkswagen Beetles and MG TDs If I told you 10 years ago that you would take strangers into your house and rent them a spare room or get into a car with a total stranger to be taken somewhere - your arguments to those concepts may have had equal vitriol - yet here we are with Airbnb, Uber and Lyft The world does change -

M20F Fuel Stick - I know I know

fuellevel replied to sdflysurf's topic in Vintage Mooneys (pre-J models)

-

Erratic idle... SOLVED!!

fuellevel replied to Guitarmaster's topic in Vintage Mooneys (pre-J models)

Muuhh. Ha ha ha. Picture me setting down my morning coffee and wringing my hands in contemplation of my evilness. OK - evil test period over., now back to adding Cessna Twins to the AML -

m20k fuel senders and engine monitor install

fuellevel replied to FloridaMan's topic in Modern Mooney Discussion

Yes JPI has come around. Nobody in Aviation likes the new guy, that is a rule and probably in the CFRs I wasn’t so popular here as well. In later Mooneys there is a conversion box to take the analog resistive input and convert it. I don’t have one, but I suspect a voltage divider so that sensors from potential other manufacturers like Rochester could be used without changes to the instrument panel. Resistive to Frequency wasn’t a big item back then as fuel totalizers using frequency were new. This method was also applied to Bonanzas and Barons as another example. In most cases with a new Engine monitor or engine information system this box goes away. Garmin EIS would be the only potential exclusion as it accepts resistance, voltage and frequency, So the conversion box could stay, but the active question for the install shop is why. -

Need help with CGR-30P choices

fuellevel replied to jbs007's topic in Vintage Mooneys (pre-J models)

To be specific EI senders are variable voltage and Hall effect sensor based. CiES are Frequency or analog & frequency and are based on Anisotropic Magneto Resistive or AMR technology. Yes I dug into a EI sender to investigate potential patent infringement. a Google search on AMR vs Hall Effect will tell you more. Yes similar concept, but different in detail. CiES senders are TSO’d and that is a difficult accomplishment one you won’t see at this price point by any other manufacturer. -

CiES Fuel Senders Resource Thread

fuellevel replied to Marauder's topic in Avionics/Panel Discussion

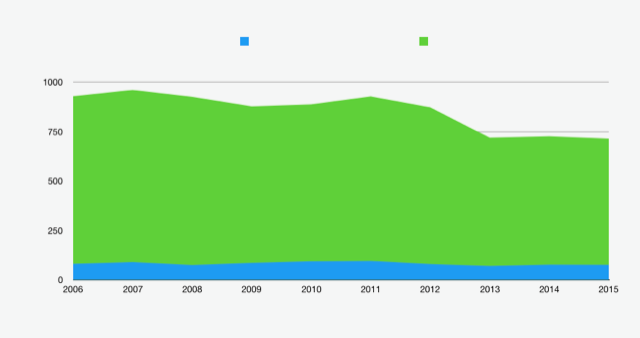

Spending time in Willmar MN after OSH18. Thanks for stopping by . We are getting lots and lots of Mooney data and finishing up with a G1000 install. The Mooney G1000 fuel quantity interface which is similar to the Beech G36 and G58 leaves something to be desired, but it is working and calibrating. Pictures are not of the G1000 but of clean Mooney tanks. The charting and pdf are reference notes and a graph. The Senders individually supply data to the Garmin . And yes I know what the TCDS says for fuel qty owner wanted more....... The travel appears to be limited by a nutplate ot stop of which the Mooney has many. Mooney.pdf